Running Belt Adjustment

Warning: ALWAYS UNPLUG THE TREADMILL FROM THE ELECTRICAL OUTLET BEFORE

CLEANING OR SERVICING THE UNIT.

Clean: General cleaning the unit will greatly prolong the treadmill.

Keep treadmill clean by dusting regularly. Be sure to clean the exposed part of the deck on either

side of the walking belt and also the side rails. This reduces the build up of foreign material

underneath the walking belt by wearing the clean running shoes.

Warning: Always unplug the treadmill from the electrical outlet before removing the motor

cover. At least once a year remove the motor cover and vacuum under the motor cover.

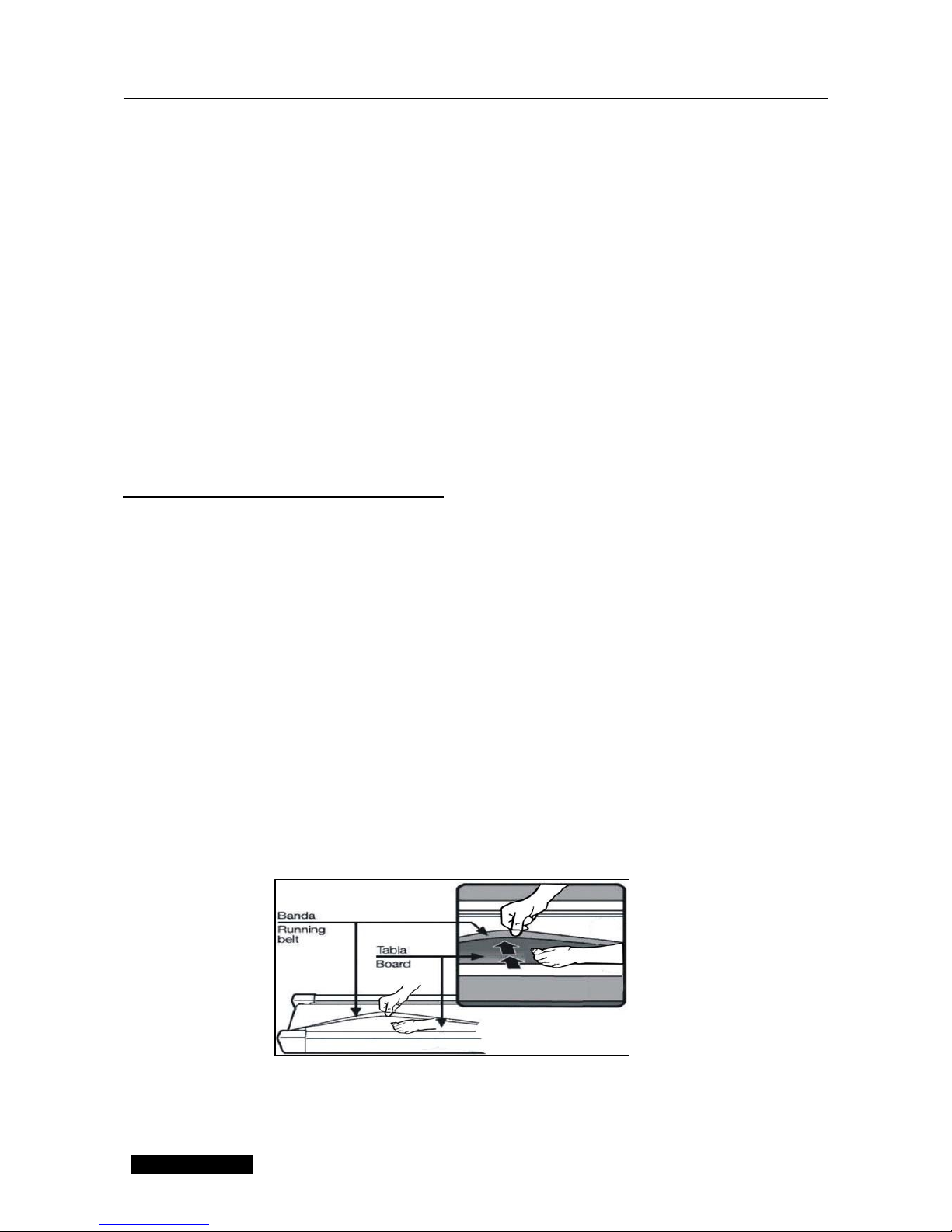

RUNNING BELT AND DECK LUBRICATION

This treadmill is equipped with a pre-lubricated, low maintenance deck system. The belt/ deck

friction may play a major role in the function and life of your treadmill, thus requiring periodic

lubrication. We recommend a periodic inspection of the deck. You need contact with our service

center if you find the damage of the deck.

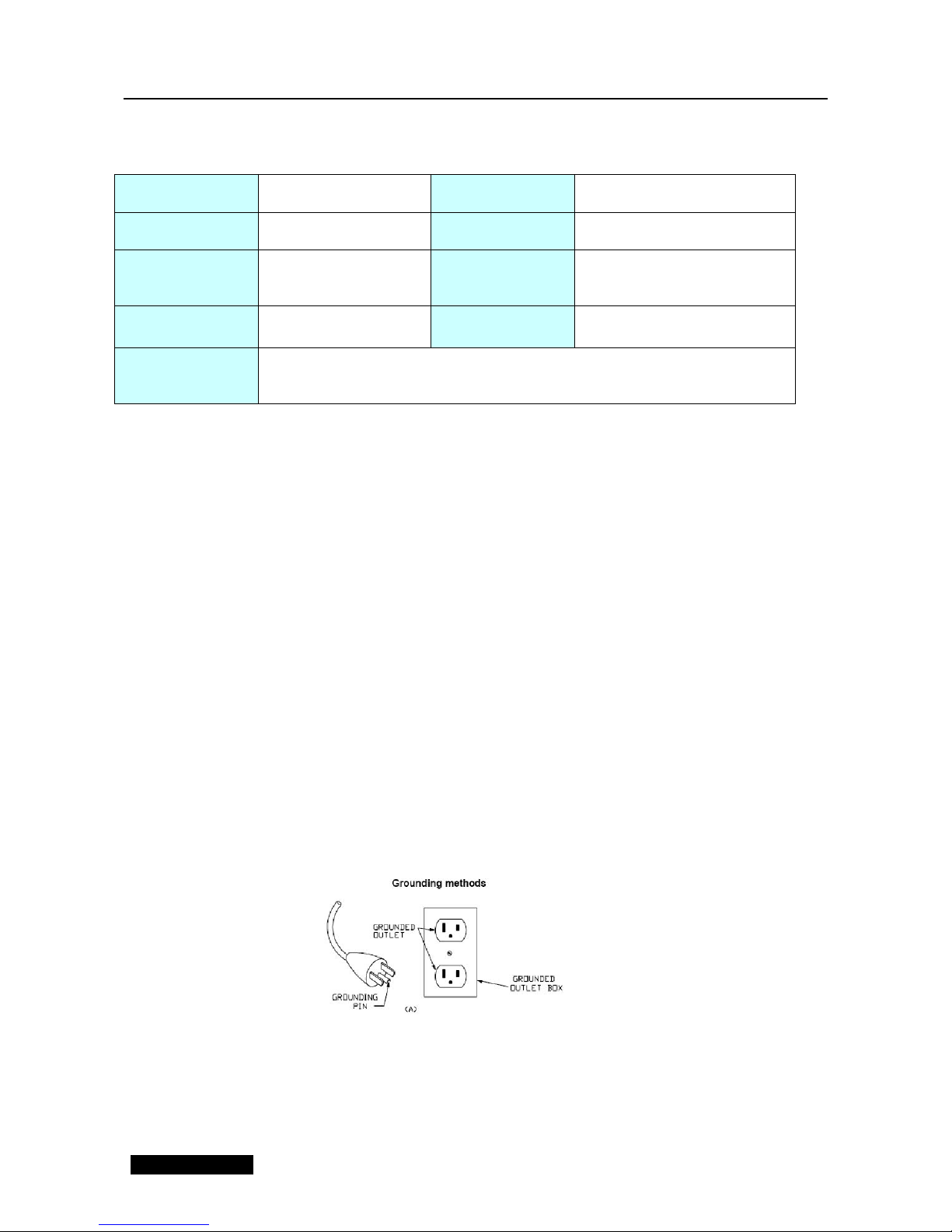

We recommend lubrication of the deck according to the following timetable:

Light user (less than 3 hours/ week) annually

Medium user (3-5 hours/ week) every six months

Heavy user (more than 5 hours/ week) every three months

We recommend that you buy the lubrication from our distributor or directly to our company.

Attention: Any repair need the professional technician.

14