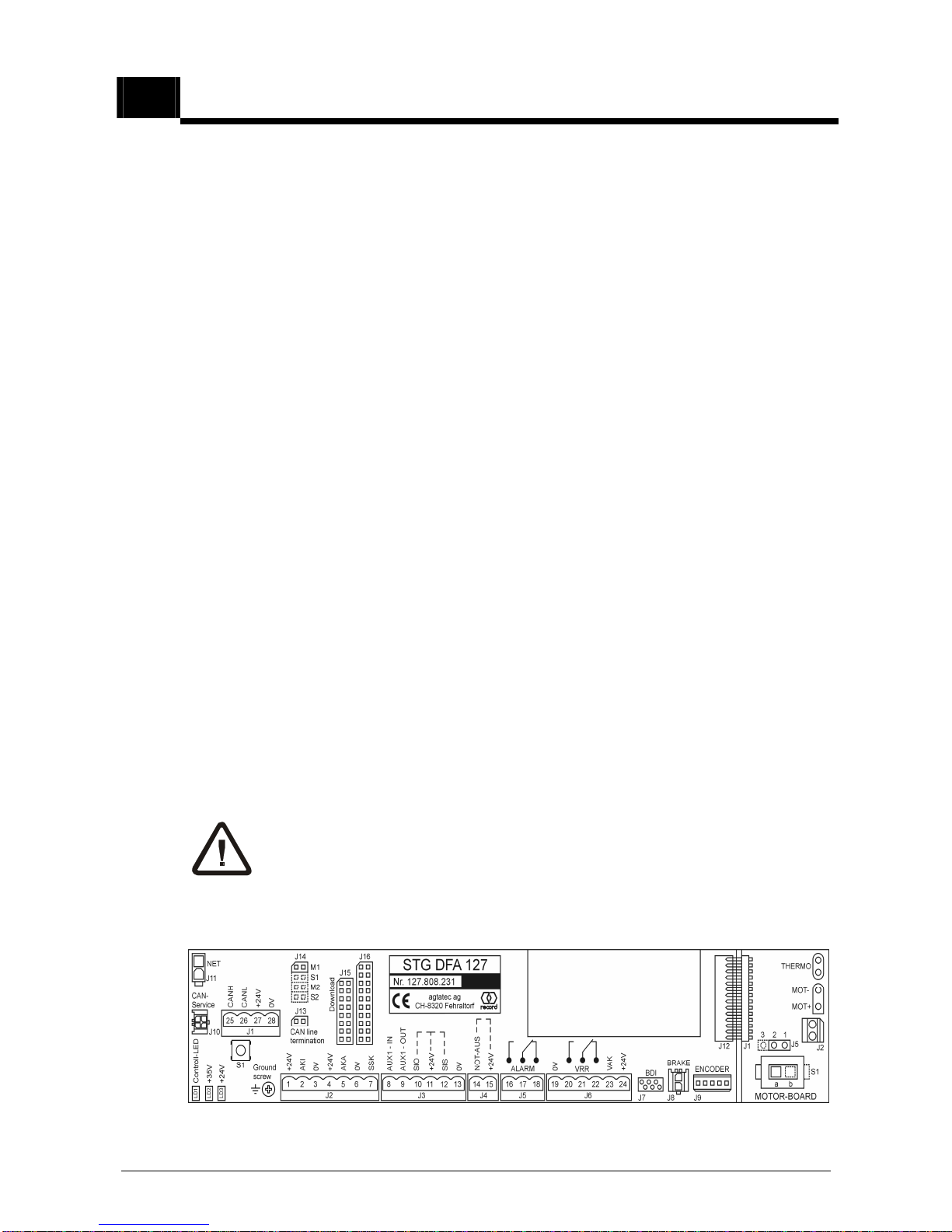

Operating instructionsDFA127 Full PowerRev. B11/2006 Page 3 of20

2 Safetyinstructions

The recordDFA 127 swingdooroperatorhasbeen constructed inaccordancewith

the latest stateofthe art and the recognised technicalsafetyregulations, including

limitingofforcesand speeds. Nevertheless, dangercan ariseforthe userifnot

used asintended.

Installation, maintenanceand repairstothe recordDFA 127 must only

be performed byqualified and authorized personnel(technicians).

2.1 Use as intended

The DFA 127 swingdooroperatorisconstructed exclusivelyfornormalservice

withswingdoorsindryroomsand must be installed withinorinside buildings.

A different application oruseextendingbeyond thispurposeisnot considered use

forthe intended purpose. The manufacturerdeclinesall responsibilityforresulting

damage; the operatoralone shall bearthe associated risk.

Useforthe intended purposealsoincludesobservation ofthe operatingconditions

specified bythe manufacturer, includinguseand adjustment ofthe correct type of

arms, inaddition toregularmaintenanceand repair.

Unauthorised modificationstothe automaticdooroperatorexclude anyliabilityof

the manufacturerforresultingdamage.

2.2 General safetyand accident prevention regulations

Ingeneralno safetydevices(sensors)maybe dismantled orputoutof

service.

Duringthe learningcycle(whichmustonlybe performed bytrained per-

sonnel) the safetydevices(sensors)areswitched off!It mustbe en-

sured,therefore,beforeinitiatingthe learningcyclethatno personsor

objectsaresituated inthe dangerzone ofthe movingdoorleavesdur-

ingthe operation inordertoavoidinjuryordamage!

Noobjectsmust be placed inthe openingzone / pathofthe swingdoor

toavoidcrushingand shearingpoints!

The safeguardforcrushingand shearingstrainsat the side edgemust

be provided bythe manufacturer..