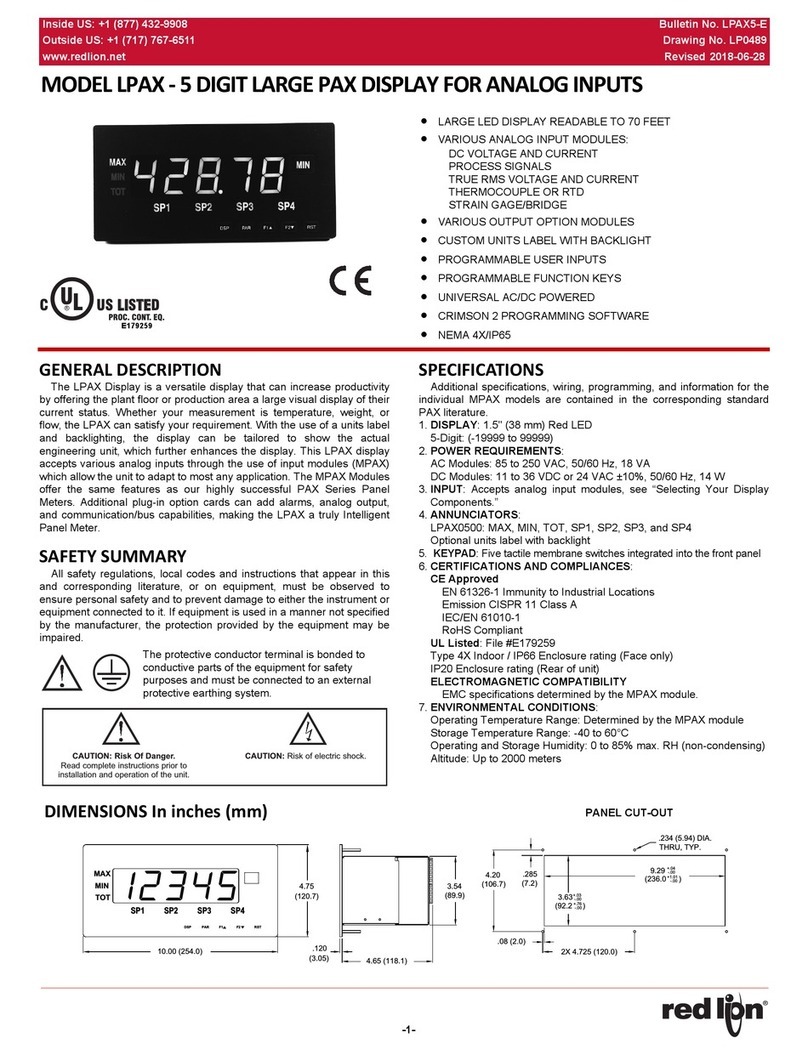

5

Although most of the expected applications for the BFD use a single BFD and

a G3, the design allows some flexibility for those applications where more than

one BFD is required.

Up to 7 BFDs maybe connected to a single serial port, each one identified by

a unique address in the range 0..6. The address is set by DIP switch positions 1,

2 & 3, eg, to set BFD address to 6, set 1 and 2 ON, and 3 OFF. Note that each

of the 32 display boards in the BFD will have to have these DIP switches set for

the same unit address. Power must be cycled OFF, then ON so that the new DIP

switch values will take effect.

The remote display primitive describes a region of the current Display page

to be rendered on a BFD. The configuration of each “remote display primitive”

includes the logical serial port that the BFD is connected to, and the unit address

of the BFD as set by it's DIP switches. By placing more than one “remote

display primitive” on the G3’s Display Page, each BFD can be made to display

different information.

A BFD may show the same information as another BFD on the same serial

port by simply setting the unit addresses the same on both units. To show the

same information on BFDs on different serial ports, simply overlay the remote

display primitives on the current Display page and configure the logical port and

BFD address as appropriate.

The display information from the G3 must be passed to each BFD. The

easiest way to do this is to wire to the unused RS485 connector in the first BFD

(See Figure 3a) and connect it to the second unit (daisy chain wiring). Power for

each unit can be wired as normal.

USING MULTIPLE BFDS WITH A SINGLE G3

MULTIPLE BFDs DISPLAY THE SAME INFORMATION

REPLACING A DISPLAY BOARD

The display boards are held in place by a display frame assembly, which is

built from nine aluminum display rail extrusions. The extrusions have a slot on

each side to receive the PC board edge of the display boards. The boards simply

slide into place. A male right angle connector on the top side of the board mates

with a female connector of the board above it, thus, passing the power and signal

from the top board to the bottom board. In normal operation, the display frame

is fastened to the enclosure using 4 nuts (Figure 8a). However, these nuts can be

removed to service the display, if required. The display frame has a pivot point

along the bottom edge, which allows the top edge of the frame to tilt outside the

enclosure, providing access to the top display boards. Display boards are easily

removed by disconnecting the appropriate wiring connection from the top board

(Figure 7b), separating the boards and sliding them out the top of the frame

assembly (Figure 8).

Each display board has a 8 circuit dip switch which is used to set its location

address. This address is determined by the board’s physical location within the

BFD display (Figure 7a).

1. Turn off AC mains power to the BFD at the circuit breaker.

2. Remove the rear cover of the BFD. Do Not Remove The Front Window To

Attempt To Gain Access To The Inside Of The BFD.

3. Remove the AC mains 3 position removable terminal block (Figure 3c).

Disconnect the main wiring harness connector (Figure 10a) from the power

supply. Disconnect the fan cable assembly (Figure 5a) or the NEMA 4 cooler

cable assembly (Figure 6b). Disconnect the RS485 cable to the G3 (Figure

3a).

4. Remove the 6 #8 kep nuts which fasten the power supply subassembly to the

enclosure. Remove the power supply subassembly (Figure 8b).

5. Remove the NEMA 4 Cooling kit (if applicable - See “Instructions for

installing the optional NEMA 4 cooling kit”).

6. Remove the 4 #8 kep nuts which fasten the display frame assembly to the

front of the enclosure (See Figure 8a). The display frame assembly will now

tilt back to allow access to the display boards.

7. Lift off the display frame top stop bracket (See Figure 8).

8. Locate the column of display boards with the faulty display board and remove

the two wiring cables (which connect the main wiring harness to the top

display board, Figure 7b).

9. Remove the appropriate board (See Figure 8). Note the DIP switch setting

(Figure 7a) on the old board.

10. Change the DIP switch setting on the replacement board and install the new

board in the same position as the old board. Make sure that the board-to-board

pins are properly aligned.

11. Re-connect the two wiring bundles observing the proper orientation of the

connectors (Figure 7b).

12. Repeat steps 1 through 7 in reverse order.

13. Note that if the DIP switch setting on a board must be changed (due to

incorrect setting), the power to the unit must be cycled in order for the change

to take effect.

TROUBLESHOOTING

FIGURE 7