[company logo]

Contact: [company contact info]

[company address]

[company email]

FOR IMMEDIATE RELEASE:

New Programmable Large Digital Display for Analog Inputs Offers

High Visibility for Challenging Industrial Applications

[Location]—[Date]—Presenting important process data to the plant production floor is now easily

accomplished with the introduction of a new line of large digital displays. [Company] announces

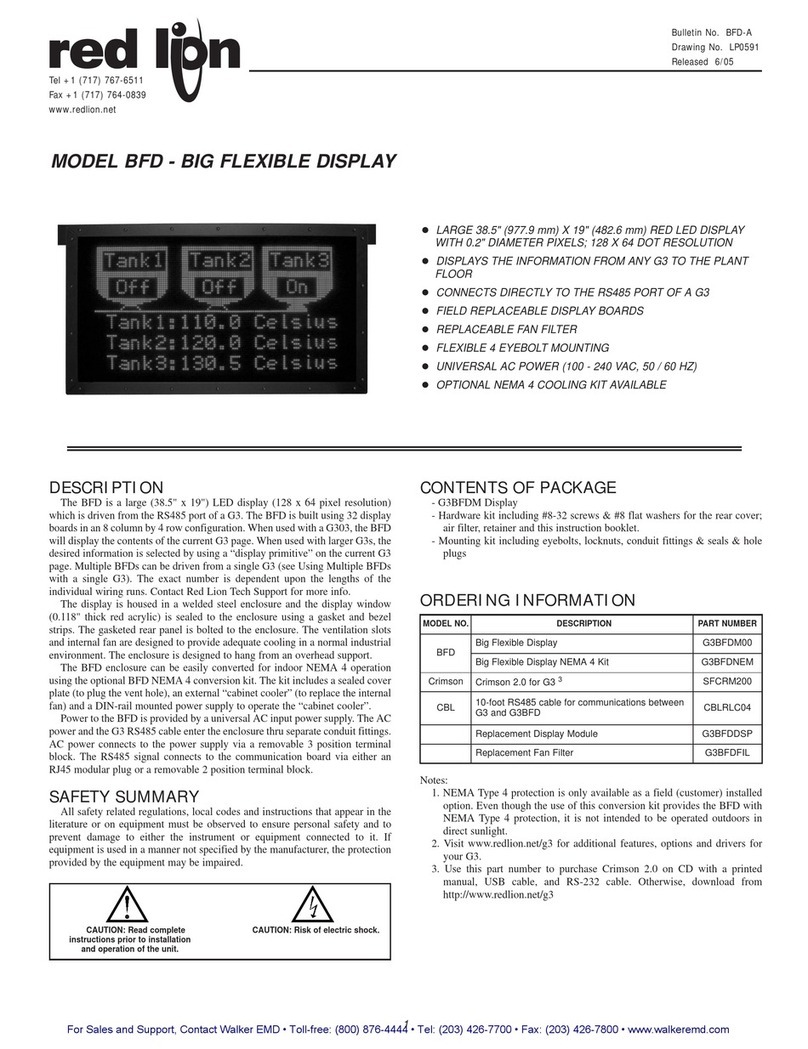

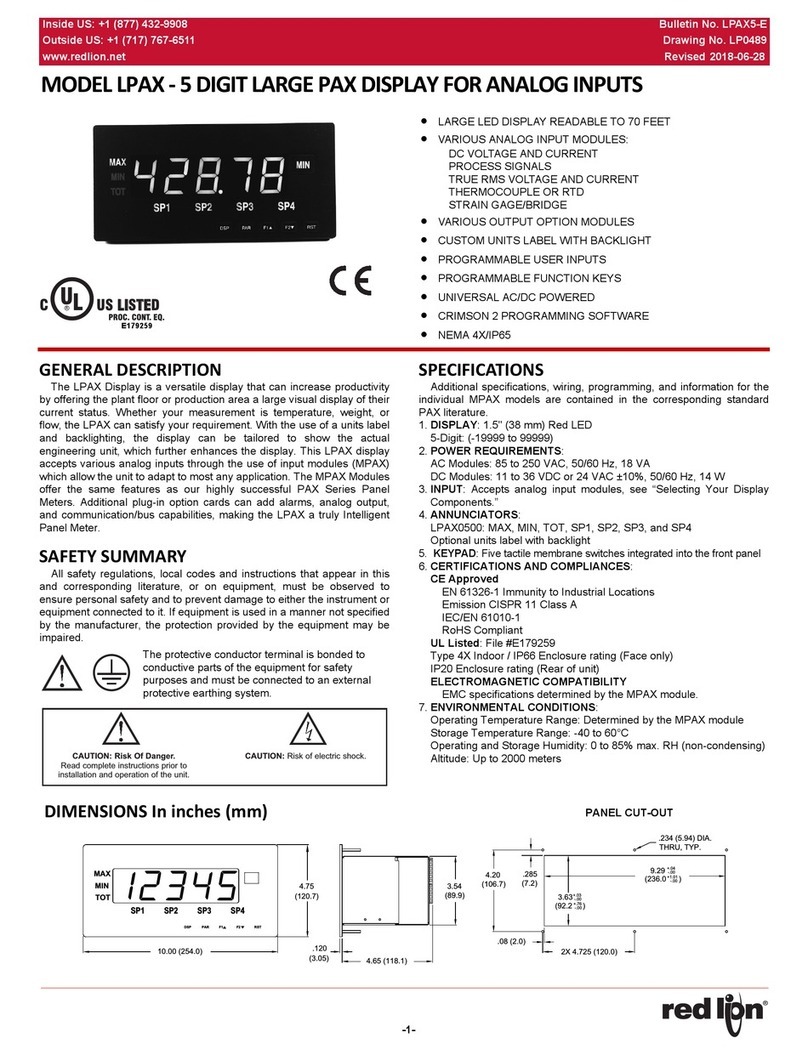

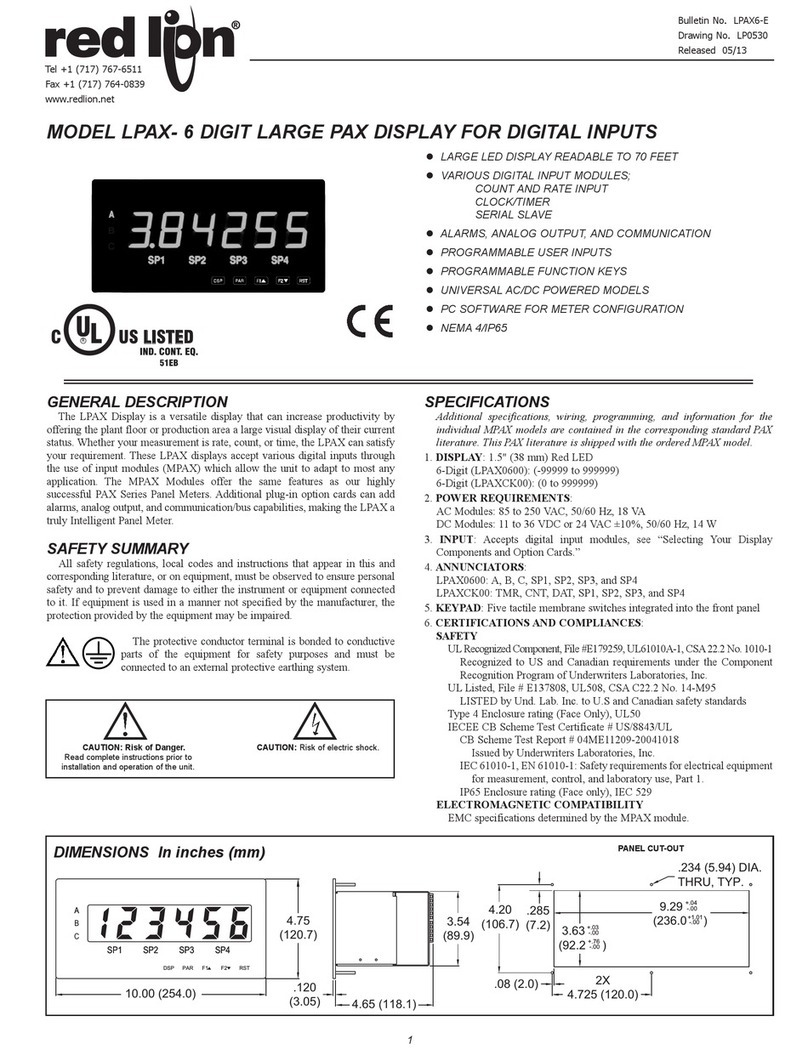

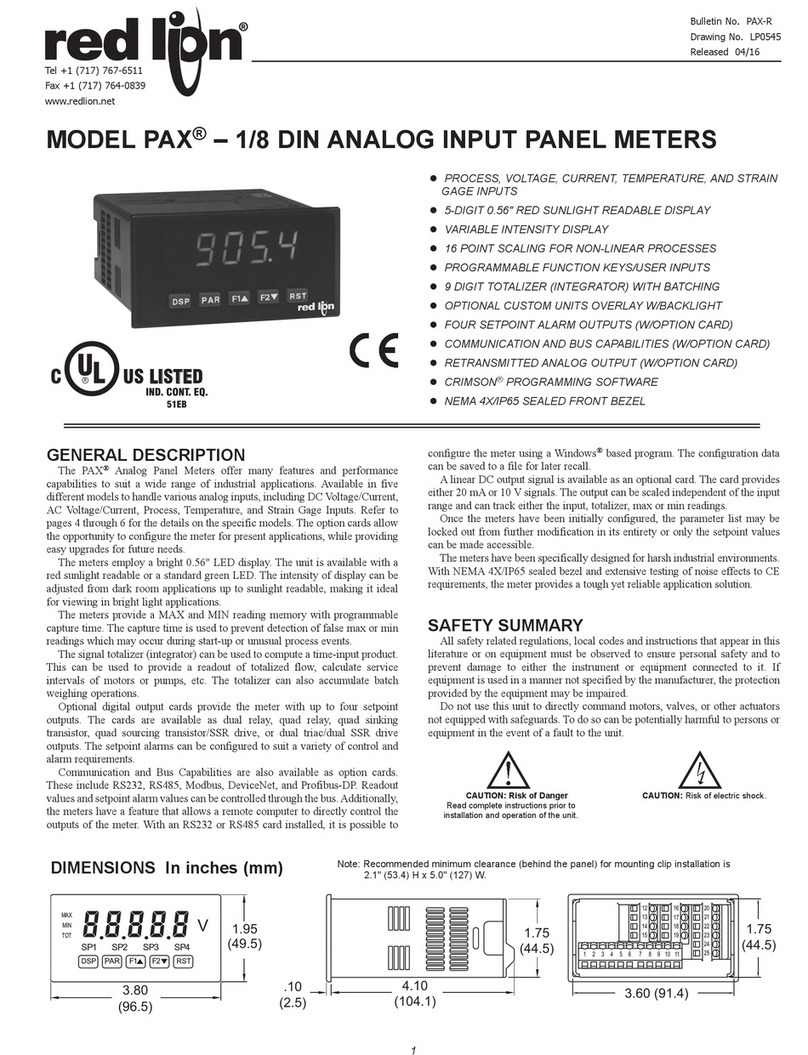

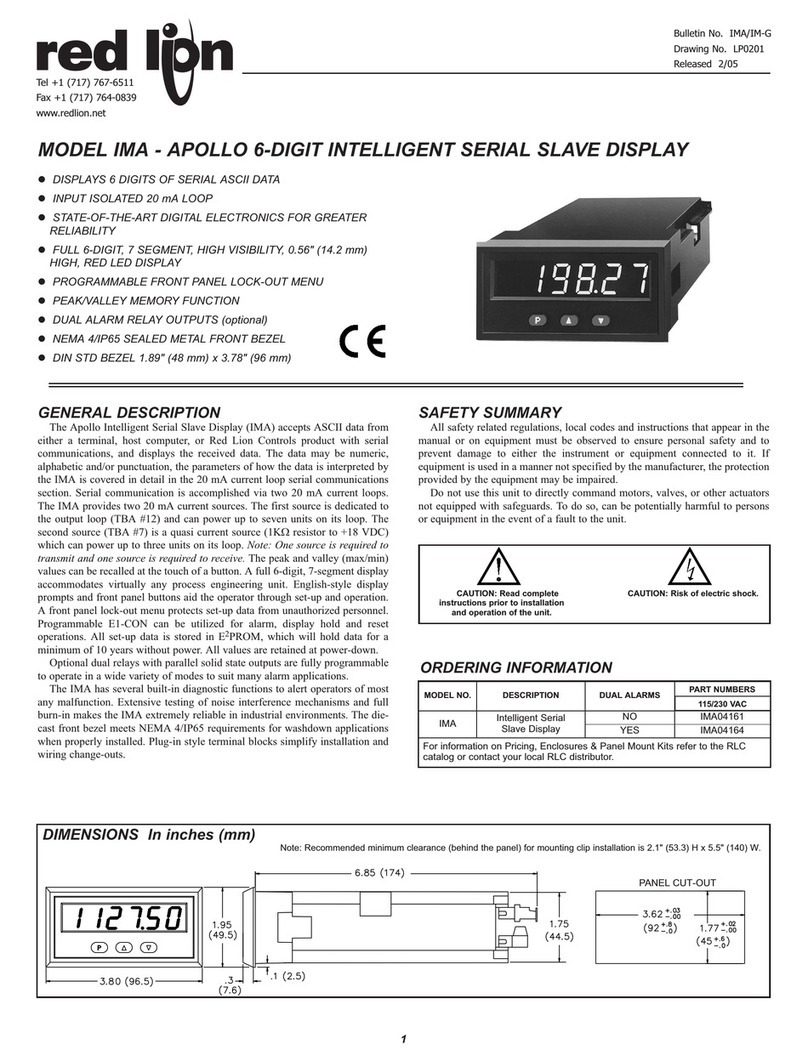

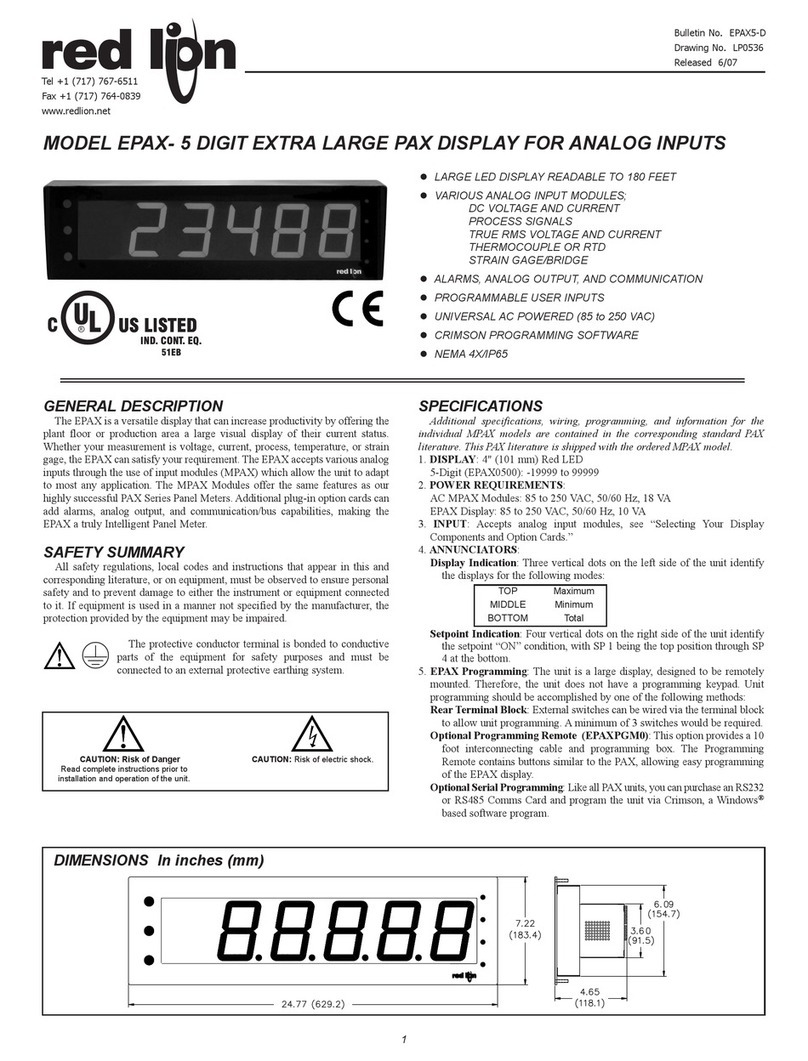

the new programmable LDA, Large Digital Display for Analog Inputs from Red Lion. The LDA is

a versatile 5 digit display available in 2.25 inch and 4 inch high red LED digits, with readability

up to 130 feet and 180 feet, respectively. The LDA is available as a volt, current, or process

meter with scaling, RS232/RS485 serial communications, and dual Form C relay outputs. The

LDA also offers lightweight aluminum NEMA 4X case construction and adjustable display

intensities.

“The LDA offers a reliable, highly visible 5 digit display, making it an ideal solution for reading

flow rates, pressure or temperature measurements, or other challenging production floor

applications,” said Jeff Thornton, product manager, Red Lion panel meters and displays.

“Programming the LDA is made simple with our easy-to-follow push-button menu or by using

Red Lion’s robust Crimson Programming Software. Also, the LDA is capable of accepting

current, process, or voltage signal, scaling them to the desired readout and transmitting the

results on the large, easy-to-read display.”

The LDA offers dual 5 Amp relays for control capability and two serial communication methods

to relay the displayed information to a management system. RS232 communication allows the

LDA to communicate with a control console up to 50 feet away, while RS485 communication

allows the connection of up to 32 devices on a single pair of wires over distances of up to 4,000

feet. Once connected, the LDA adjusts to a wide variety of industrial applications by allowing

users to set numerous scaling parameters through various programming options. The LDA

Programming Menu is organized into six separate modules, grouped together by parameters

related in function. Also, the LDA’s nonvolatile E

2

PROM memory retains all programming

parameters and count values once power is removed, securing information in case of an

electrical outage.

For additional information on the LDA or other digital display solutions, please contact [contact

name] at [phone] or by e-mail at [email].

[company description]

News Release News Release News Release News Release News Release