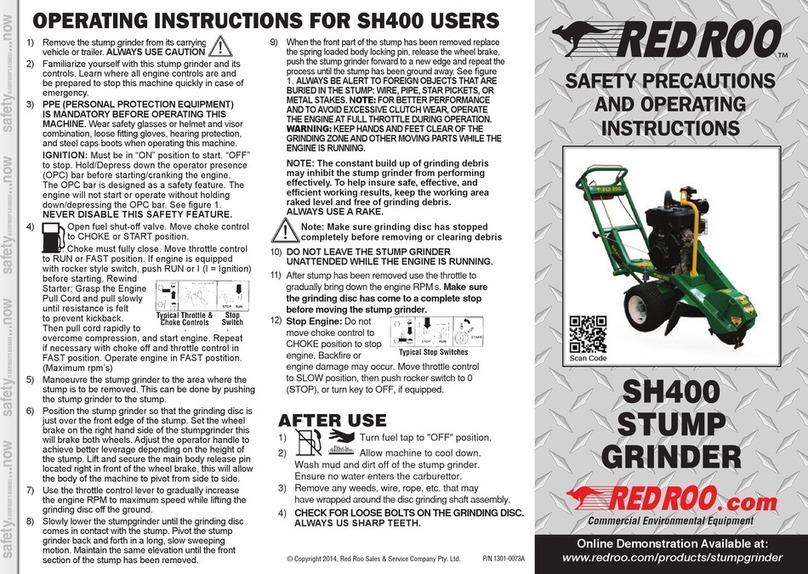

OPERATING INSTRUCTIONS

FOR SH400 USERS

OPERATOR MUST BE TRAINED

1) DO NOT allow any person to operate the

stump grinder without rst reading and

understanding the safety and operating

instructions. KNOW THE CONTROLS AND

HOW TO STOP THE STUMPGRINDER QUICKLY IN

CASE OF AN EMERGENCY.

2) NEVER allow CHILDREN or UNTRAINED ADULTS to

operate the stump grinder.

3) PPE (PERSONAL

PROTECTION

EQUIPMENT)

IS

MANDATORY before

operating this machine. ALWAYS wear

protective clothing when operating the stump

grinder This includes, but not limited to; safety

glasses, loose tting gloves, steel capped boots and

hearing protection. Never wear loose tting clothing

or jewelry when operating the stump grinder. Keep

all clothing away from moving parts. Clothing could

become caught in the machine resulting in injury.

4) ALWAYS operate the stump grinder in a

well-lighted area.

5)

NEVER operate the stump grinder on an

angle that exceeds 15º degrees. Keep

your work area clear and free of debris.

6)

NEVER operate the stump grinder when fatigued.

AWAYS BE ALERT! If you get tired while operating

the stump grinder take a break. If you have any type of

physical or mental condition that may be aggravated

by strenuous work, consult with your physician before

operating this piece of equipment. NEVER operate

the stump grinder under the inuence of medication,

alcohol or drugs.

7)

SAFETY INSTRUCTIONS FOR RH918 USERS

OPERATING

INSTRUCTIONS

USE COMMON SENSE

AND PLENTY OF IT

TRANSPORT

BEFORE USE

1) DO NOT allow any person operate the

rotary hoe without first reading and

understanding the safety instructions and

operating instructions.

2) NEVER allow children to operate the rotary hoe.

8) ALWAYS make certain the Tyne Control Lever is

set at neutral while loading and unloading the

rotary hoe, or moving to and away from working area.

9) NEVER run the machine in reverse while the tynes

are rotating. Always move the tyne control lever to

“OFF” before reversing the wheels.

11) DO NOT leave the machine unattended while the

engine is running.

12) DO NOT overspeed the engine or alter the governor

settings. Excessive speed is dangerous and will

shorten engine life.

13) NEVER operate the rotary hoe in an

enclosed area. Engine exhaust contains

carbon monoxide, an odourless and

tasteless poison.

14) STOP the engine and disconnect the

spark plug lead(s) and allow engine to

cool before inspecting or performing

maintenance on the rotary hoe.

15)

1)

REFUELLING

* Shut off the engine. DO NOT REFUEL

AN ENGINE WHILE OPERATING!

* Allow engine to cool. Minimum 5 minutes

* USE UNLEADED FUEL ONLY.

Use clean, fresh unleaded fuel.

* Do not mix oil with unleaded fuel.

* Do not over-fill fuel tank. Allow space

for fuel expansion.

10) NEVER operate the unit without the safety

guards in place and in working order. Keep

the unit well maintained and in good

working order.

4) ALWAYS use the rotary

hoe in a well lighted area.

7) NEVER operate the rotary hoe when fatigued.

ALWAYS BE ALERT! If you get tired while

operating the rotary hoe, take a break. If you have

any type of physical or mental condition that may

be aggravated by strenuous work, consult with

your physician before you operate this equipment.

NEVER operate the rotary hoe under the influence

of medication, alcohol or drugs.

6) DO NOT allow other persons near the

rotary hoe. It is up to the operator to keep

bystanders and animals a minimum of 6

5) ALWAYS operate the rotary

hoe on level ground only.

Police the area before rotary

hoeing. Remove any foreign objects in the digging

area - bricks, rocks, wire and sticks. Locate and mark

any sprinkler heads, water pipes, gas lines,

electrical and telephone cables or any other hazard

either below or above ground.

3) ALWAYS wear protective clothing when operating

the rotary hoe. This includes, but is not limited to;

safety glasses, loose fitting gloves, steel capped

boots and hearing protection. NEVER wear loose

fitting clothing or jewellery when operating the

rotary hoe. Keep all clothing away from moving

parts. Items could become caught in the machine,

resulting in injury.

KNOW THE CONTROLS AND HOW TO STOP

THE ROTARY HOE QUICKLY IN AN EMERGENCY.

metres (20’) away from the machine while in

operation.

ALWAYS KEEP YOUR HANDS,

FEET AND BODY AWAY FROM

THE DIGGING ZONE WHILE

ENGINE IS RUNNING.

* Do not smoke.

* Allow no naked flame or hot material in refuelling area.

* Use only approved fuel containers and funnels.

Remember, fuel is a potential hazard .

Be sure Tyne Control Lever is set to “Neutral”

while loading and unloading the rotary hoe

and when moving to or from jobsite.

Ensure that all grass and weeds have been cut

as low as possible.

2) If the rotary hoe is to be used in clay or hard

ground conditions, it is recommended to water

the area thoroughly and allow sufficient time

for earth to soften.

3) Police the area. Remove any

foreign objects from the area.

4) Identify and mark the location of sprinkler heads,

gas pipes, telephone cables etc.

“The Right Way to Rent”

You alone know the operational demands and

special conditions affecting the equipment in

your situation and therefore assume the

responsibility for developing, carrying out, and

enforcing the safety concepts which apply to your

own operation to effect the greatest safety for

yourself andthe people around you.

DO NOT allow other adults, children or

animals near the chipper mulcher shredder.

IT IS THE RESPONSIBILITY OF THE

OPERATOR to keep bystanders and animals a

minimum of 6 metres (18ft) away from the stump

grinder while in operation.

8)

ALWAYS KEEP YOUR

HANDS, FEET AND

BODY AWAY FROM

THE GRINDING AREA

WHILE THE ENGINE IS RUNNING.

SAFETY PRECAUTIONS FOR SH400 USERS

USE COMMON SENSE AND

PLENTY OF IT

OPERATOR MUST BE TRAINED

safety

IS EVERYBODY’S BUSINESS

...nowsafety

IS EVERYBODY’S BUSINESS

...nowsafety

IS EVERYBODY’S BUSINESS

...nowsafety

IS EVERYBODY’S BUSINESS

...now

SAFETY INSTRUCTIONS FOR RH918 USERS

OPERATING

INSTRUCTIONS

USE COMMON SENSE

AND PLENTY OF IT

TRANSPORT

BEFORE USE

1) DO NOT allow any person operate the

rotary hoe without first reading and

understanding the safety instructions and

operating instructions.

2) NEVER allow children to operate the rotary hoe.

8) ALWAYS make certain the Tyne Control Lever is

set at neutral while loading and unloading the

rotary hoe, or moving to and away from working area.

9) NEVER run the machine in reverse while the tynes

are rotating. Always move the tyne control lever to

“OFF” before reversing the wheels.

11) DO NOT leave the machine unattended while the

engine is running.

12) DO NOT overspeed the engine or alter the governor

settings. Excessive speed is dangerous and will

shorten engine life.

13) NEVER operate the rotary hoe in an

enclosed area. Engine exhaust contains

carbon monoxide, an odourless and

tasteless poison.

14) STOP the engine and disconnect the

spark plug lead(s) and allow engine to

cool before inspecting or performing

maintenance on the rotary hoe.

15)

1)

REFUELLING

* Shut off the engine. DO NOT REFUEL

AN ENGINE WHILE OPERATING!

* Allow engine to cool. Minimum 5 minutes

* USE UNLEADED FUEL ONLY.

Use clean, fresh unleaded fuel.

* Do not mix oil with unleaded fuel.

* Do not over-fill fuel tank. Allow space

for fuel expansion.

10) NEVER operate the unit without the safety

guards in place and in working order. Keep

the unit well maintained and in good

working order.

4) ALWAYS use the rotary

hoe in a well lighted area.

7) NEVER operate the rotary hoe when fatigued.

ALWAYS BE ALERT! If you get tired while

operating the rotary hoe, take a break. If you have

any type of physical or mental condition that may

be aggravated by strenuous work, consult with

your physician before you operate this equipment.

NEVER operate the rotary hoe under the influence

of medication, alcohol or drugs.

6) DO NOT allow other persons near the

rotary hoe. It is up to the operator to keep

bystanders and animals a minimum of 6

5) ALWAYS operate the rotary

hoe on level ground only.

Police the area before rotary

hoeing. Remove any foreign objects in the digging

area - bricks, rocks, wire and sticks. Locate and mark

any sprinkler heads, water pipes, gas lines,

electrical and telephone cables or any other hazard

either below or above ground.

3) ALWAYS wear protective clothing when operating

the rotary hoe. This includes, but is not limited to;

safety glasses, loose fitting gloves, steel capped

boots and hearing protection. NEVER wear loose

fitting clothing or jewellery when operating the

rotary hoe. Keep all clothing away from moving

parts. Items could become caught in the machine,

resulting in injury.

KNOW THE CONTROLS AND HOW TO STOP

THE ROTARY HOE QUICKLY IN AN EMERGENCY.

metres (20’) away from the machine while in

operation.

ALWAYS KEEP YOUR HANDS,

FEET AND BODY AWAY FROM

THE DIGGING ZONE WHILE

ENGINE IS RUNNING.

* Do not smoke.

* Allow no naked flame or hot material in refuelling area.

* Use only approved fuel containers and funnels.

Remember, fuel is a potential hazard .

Be sure Tyne Control Lever is set to “Neutral”

while loading and unloading the rotary hoe

and when moving to or from jobsite.

Ensure that all grass and weeds have been cut

as low as possible.

2) If the rotary hoe is to be used in clay or hard

ground conditions, it is recommended to water

the area thoroughly and allow sufficient time

for earth to soften.

3) Police the area. Remove any

foreign objects from the area.

4) Identify and mark the location of sprinkler heads,

gas pipes, telephone cables etc.

“The Right Way to Rent”

You alone know the operational demands and

special conditions affecting the equipment in

your situation and therefore assume the

responsibility for developing, carrying out, and

enforcing the safety concepts which apply to your

own operation to effect the greatest safety for

yourself andthe people around you.

MAXIMUM ANGLE

OF OPERATION

DO NOT EXCEED

15º ANGLE

USE COMMON SENSE

AND PLENTY OF IT

SAFETY INSTRUCTIONS FOR HT912USERS

INSTRUCTIONS

DO NOT allow any person to operate the

hydraulic trencher without first reading and

understanding the safety instructions and

NEVER allow children to operate the hydraulic trencher.

ALWAYS use hydraulic trencher in a well lighted area.

ALWAYS make certain that all control clutches are in

the “disengaged” position prior to starting the engine.

The safety clutch lever/Operator Presence Control on

the left handlebar is for operator protection. DO NOT

tape down or otherwise bypass this Safety Device.

NEVER wear loose fitting clothing or jewellery when

operating the hydraulic trencher. Keep all clothing

away from moving parts. Item could become

caught in the machine, resulting in injury.

ALWAYS wear protective

clothing when operating

the hydraulic trencher.

This includes, but is not limited to, safety glasses, hard hat

loose fitting gloves, steel capped boots and hearing protection.

operating instructions. KNOW THE CONTROLS AND

HOW TO STOP THE HYDRAULIC TRENCHER QUICKLY

IN AN EMERGENCY.

1)

2)

3)

4)

Police the area before trenching. Remove any foreign

objects in the digging area eg bricks, rocks, wire and

sticks. Locate and mark any sprinkler heads, water

pipes, gas lines, electrical and telephone cables or any

other hazard either below or above ground.

5)

DO NOT leave the machine unattended while the engine

is running. DO NOT park on incline or park

perpendicular to slope. DO NOT freewheel down incline.

7)

DO NOT overspeed the engine or alter the governor

settings. Excessive speed is dangerous and will

shorten engine life

8)

NEVER operate the hydraulic trencher when fatigued.

ALWAYS BE ALERT! If you get tired while operating

the hydraulic trencher, take a break. If you have any

type of physical or mental condition that may be

aggravated by strenuous work, consult with your

physician before you operate this equipment. NEVER

operate the hydraulic trencher under the influence of

medication, alcohol or drugs.

9)

NEVER operate the unit without the safety

guards in place and in working order. Keep

the unit well maintained and in good working order

Remove the hydraulic trencher from its

trailer. Use caution.

Police the area. Remove any

foreign objects from the area.

Identify and mark the location of sprinkler heads,

gas pipes, telephone cables, etc.

IGNITION: Must be in “ON” position to start. “OFF”

to stop.

ENGINE: Throttle cable controls engine speed.

Operate at full throttle (all the way forward).

WHEEL DRIVE CONTROL LEVER: Controls wheel

speed forward or reverse after clutch lever is engaged.

DIGGING BOOM CONTROL LEVER: Raises and lowers

the digging boom.

DIGGING CHAIN CONTROL LEVER: must be in “ON”

position BEFORE clutch lever is depressed in order

to start chain in motion. Chain moves in a forward

direction after clutch lever is engaged.

SAFETY CLUTCH LEVER/OPERATOR PRESENCE

CONTROL: (At left handle grip) Activates WHEEL

DRIVE and DIGGING CHAIN controls when depressed.

Stops all motion when released.

FORWARD/REVERSE DIGGING CHAIN CONTROL

LEVER: Allows manual operation of chain in forward

or reverse rotation to dislodge objects or dig difficult

terrain. (This control can be used with the clutch lever

released.) To reverse chain, DIGGING CHAIN control

must be in “OFF” position.

Familiarize yourself with the hydraulic

trencher and its controls.

10)

1)

1)

2)

1)

Free Wheel Hub Feature - Operation:

Pull one free wheeling pin slightly, using the split

ring. Rotate the pin until the 3mm (1/8”) diameter roll

pin aligns with the slot in the mounting plate. Allow

the pin to slide through the slot. Repeat for the other

wheel. Roll the trencher until each pin drops into a

hole in the hub. The wheel hubs are now locked.

Reverse the procedure to unlock the wheels.

2)

DO NOT allow other persons near the hydraulic

trencher. It is up to the operator to keep

bystanders and animals a minimum of 6 metres

(20ft) away from the machine while in operation.

12)

NEVER operate the hydraulic trencher in an

enclosed area. Engine exhaust contains carbon

monoxide, an odourless and tasteless poison.

13)

WARNING: Hydraulic oil is under extreme

pressure and can get under skin and burn

or poison. Check for leaks with cardboard.

14)

STOP the engine and disconnect the spark

plug lead(s) and allow engine to cool before

inspecting or performing maintenance on

the hydraulic trencher.

15)

REFUELLING

* Shut off engine. DO NOT REFUEL AN ENGINE

WHILE OPERATING!

* Allow engine to cool. Minimum 5 minutes

* Do not smoke. *Allow no naked flame

or hot material in refuelling area.

* Use only approved fuel containers and funnels.

Remember, fuel is a potential hazard.

* Do not over-fill fuel tank. Allow space for

fuel expansion.

* USE UNLEADED FUEL ONLY. Use clean,

fresh unleaded fuel.

* Do not mix oil with unleaded fuel.

16)

ALWAYS KEEP YOUR HANDS, FEET AND BODY

AWAY FROM THE DIGGING CHAIN AND OTHER

MOVING PARTS WHILE ENGINE IS RUNNING.

11)

ALWAYS operate

hydraulic trencher

on level ground only.

6) MAXIMUM

ANGLE OF

OPERATION

DO NOT EXCEED 15ºANGLE

BEFORE USE

OPERATION

TRANSPORT

SAFETYPRECAUTIONS

AND OPERATING

INSTRUCTIONS

™

GT5

GARDEN

TILLER

OPERATION OF GT622

1) Remove the garden tiller

from its trailer/carrier/ute. Use caution.

2) Familiarize yourself with the machine and its

controls.

5) Ensure the tyne engagement control lever is in

the neutral position. The tyne engagement

control lever is located

machine below handle bar. The neutral position

on the left hand side of the

of the lever is achieved by simply releasing the

tyne engagement control lever.

4)

3) Adjust wheels if required, using the handle wheel

adjustment lever.

Adjust depth shoe if required, using the depth

control adjustment lever.

6) Open fuel shut-off valve. Set choke

control to Choke or Start position.

Set throttle control to Run or Fast

position. Set engine

stop switch to On or

Run position. Pull

starter cord rapidly.

Repeat (if necessary)

with choke off.

pull up on the tyne engagement control lever.

The tynes will begin to turn. Release the tyne

7) When in position to begingardentilling,

engagement control lever to stop the tynes turning.

Tyne speed is governed by engine throttle setting.

WARNING! –KEEPHANDSAND

FEET CLEAR OF TYNES AT ALL

TIMES!

8) Do not hurry the job. Proceed slowly and allow

the machine time to do the job. When ground

is extremely hard, consider reducing the engine

speed. Consider watering the surface and reducing

engine speed. Adjust wheels and depth shoe

accordingly while tilling.

WARNING! –IN CASE OF DIFFICULTY,

RELEASE THE TYNE ENGAGEMENT

CONTROL LEVER. ALL TILLING ACTION

STOPS.Turn the engine "STOP" switch

to off located on the engine or on handle.

9) Stop Engine: Release the tyne engagement

control lever. Move throttle to Slow position.

Set engine stop switch to Stop or Off position.

DO NOT move choke

position to stop engine.

Backfire or engine

damage may occur.

AFTER USE

1) Turnfuelshut off valve to the "OFF"

position.

2) Allow machine to cool down.

3) Wash mud and dirt off of the garden tiller.

Ensure no water enters the carburettor.

4) Removeanyweeds,wire,rope or other

materialthatmayhavewrappedaround the

tynes and rotor assembly.

5) Returnwheels and depth control handle to

transport position.

© Copyright 2014, Red Roo Sales & Service Company Pty. Ltd. 1301-0069-A

Commer

“The Right Way to Rent” cial Outdoor Power Equipment

control to Choke or Start

You alone know the operational demands and

special conditions affecting the equipment in

your situation and therefore assume the

responsibility for developing, carrying out, and

enforcing the safety concepts which apply to your

own operation to effect the greatest safety for

yourself andthe people around you.

SAFETY INSTRUCTIONS FOR RH918 USERS

OPERATING

INSTRUCTIONS

USE COMMON SENSE

AND PLENTY OF IT

TRANSPORT

BEFORE USE

1) DO NOT allow any person operate the

rotary hoe without first reading and

understanding the safety instructions and

operating instructions.

2) NEVER allow children to operate the rotary hoe.

8) ALWAYS make certain the Tyne Control Lever is

set at neutral while loading and unloading the

rotary hoe, or moving to and away from working area.

9) NEVER run the machine in reverse while the tynes

are rotating. Always move the tyne control lever to

“OFF” before reversing the wheels.

11) DO NOT leave the machine unattended while the

engine is running.

12) DO NOT overspeed the engine or alter the governor

settings. Excessive speed is dangerous and will

shorten engine life.

13) NEVER operate the rotary hoe in an

enclosed area. Engine exhaust contains

carbon monoxide, an odourless and

tasteless poison.

14) STOP the engine and disconnect the

spark plug lead(s) and allow engine to

cool before inspecting or performing

maintenance on the rotary hoe.

15)

1)

REFUELLING

* Shut off the engine. DO NOT REFUEL

AN ENGINE WHILE OPERATING!

* Allow engine to cool. Minimum 5 minutes

* USE UNLEADED FUEL ONLY.

Use clean, fresh unleaded fuel.

* Do not mix oil with unleaded fuel.

* Do not over-fill fuel tank. Allow space

for fuel expansion.

10) NEVER operate the unit without the safety

guards in place and in working order. Keep

the unit well maintained and in good

working order.

4) ALWAYS use the rotary

hoe in a well lighted area.

7) NEVER operate the rotary hoe when fatigued.

ALWAYS BE ALERT! If you get tired while

operating the rotary hoe, take a break. If you have

any type of physical or mental condition that may

be aggravated by strenuous work, consult with

your physician before you operate this equipment.

NEVER operate the rotary hoe under the influence

of medication, alcohol or drugs.

6) DO NOT allow other persons near the

rotary hoe. It is up to the operator to keep

bystanders and animals a minimum of 6

5) ALWAYS operate the rotary

hoe on level ground only.

Police the area before rotary

hoeing. Remove any foreign objects in the digging

area - bricks, rocks, wire and sticks. Locate and mark

any sprinkler heads, water pipes, gas lines,

electrical and telephone cables or any other hazard

either below or above ground.

3) ALWAYS wear protective clothing when operating

the rotary hoe. This includes, but is not limited to;

safety glasses, loose fitting gloves, steel capped

boots and hearing protection. NEVER wear loose

fitting clothing or jewellery when operating the

rotary hoe. Keep all clothing away from moving

parts. Items could become caught in the machine,

resulting in injury.

KNOW THE CONTROLS AND HOW TO STOP

THE ROTARY HOE QUICKLY IN AN EMERGENCY.

metres (20’) away from the machine while in

operation.

ALWAYS KEEP YOUR HANDS,

FEET AND BODY AWAY FROM

THE DIGGING ZONE WHILE

ENGINE IS RUNNING.

* Do not smoke.

* Allow no naked flame or hot material in refuelling area.

* Use only approved fuel containers and funnels.

Remember, fuel is a potential hazard .

Be sure Tyne Control Lever is set to “Neutral”

while loading and unloading the rotary hoe

and when moving to or from jobsite.

Ensure that all grass and weeds have been cut

as low as possible.

2) If the rotary hoe is to be used in clay or hard

ground conditions, it is recommended to water

the area thoroughly and allow sufficient time

for earth to soften.

3) Police the area. Remove any

foreign objects from the area.

4) Identify and mark the location of sprinkler heads,

gas pipes, telephone cables etc.

“The Right Way to Rent”

You alone know the operational demands and

special conditions affecting the equipment in

your situation and therefore assume the

responsibility for developing, carrying out, and

enforcing the safety concepts which apply to your

own operation to effect the greatest safety for

yourself andthe people around you.

3)

a. Move the fuel valve

lever to ON

position. a. Put Wheel Drive Lever in neutral.

c. Have engine at full throttle (forward).

d. Hold Digging Chain Control Lever in On position.

e. Squeeze the safety Clutch Lever/Operator Presence Control.

f. Slowly lower the digging boom until the desired trench

depth is achieved using the Digging Boom Control Lever.

g. Put Wheel Drive Control Lever in reverse. Start at low speed.

h.

a.

Adjust the wheel speed until a workable speed is reached

Use a very slow speed for trenching and adjust for soil

conditions as necessary. If objects such as rocks or roots

jam in the chain, release the Safety Clutch Lever/Operator

Presence Control, then reverse the chain to dislodge the

debris. If necessary move the trencher forward a few

inches and trench the area again.

Shut off switch on

console should be

used, not shut off

switch on engine.

b. Turn the engine switch

to the OFF position.

c. Turn the fuel

valve lever to the

OFF position

1) Allow machine to cool down. Wash mud and dirt off of

the hydraulic trencher. Ensure no water enters the

carburettor

2) Remove any objects that may have wrapped around

the trencher chain or assembly.

b. Be sure both hubs are engaged (turn hub lock handle

clockwise). (See Free Wheel Hub Feature)

b. To start a cold

engine, move the

choke lever or choke

rod (applicable

types) to the

CLOSED

position.

To restart a

warm engine,

leave the choke lever or choke rod in the OPEN position.

c. Move the

throttle lever

away from the

MIN position,

about 1/3 of the

way toward the

MAX position.

d. Turning the engine switch

to the ON position.

RECOIL STARTER

Pull the starter grip lightly

until you feel resistance,

then pull briskly.

Return the starter

grip gently.

STARTING THE ENGINE: 5) TRENCHING PROCEDURE:

6) STOPPING THE ENGINE:

WARNING - KEEP HANDS AND FEET CLEAR

OF TRENCHING CHAIN AND OTHER MOVING

PARTS AT ALL TIMES!

WARNING! - In case of difficulty, release the

Safety Clutch Lever/Operator Presence Control

All trenching action stops. Turn the Engine

Stop button to STOP located either side on the

main control console or the engine.

4)

a. Start and warm up engine.

b. Put Wheel Drive Control Lever in neutral.

c. One wheel hub may be disengaged (free wheeling)

for easier steering before driving machine to work

loccation. (See Wheel Hub Feature)

d. Squeeze the safety Clutch Lever/Operator Presence

Control and change the Wheel Direction Control to

desired speed and direction.

e. Adjust the wheel speed and navigate the trencher to the

starting position. The trencher is designed to dig toward

the operator (with the Wheel drive Control Lever in

reverse). With this in mind, position the machine to

start the trench. Note: When initially engagaing the

rotating chain into the ground, be aware that in the hard or

rocky ground the rotating trencher chain may

aggressively dig in and lurch forward. For this reason

make sure that theres is sufficient clearance from

structures, objects or people in front of the machine.

AFTER USE

Make sure that there is sufficient clearance from

structures, objects or people in front of the machine

© Copyright 2013

, Red Roo Sales & Service Company Pty. Ltd. 1301-0066-A

Move the throttle lever

to the MIN position.

Some engine applications use a

remote-mounted throttle control

rather than the engine-

mounted lever shown here

MAXIMUM ANGLE

OF OPERATION

DO NOT EXCEED

15º ANGLE

USE COMMON SENSE

AND PLENTY OF IT

SAFETY INSTRUCTIONS FOR HT912USERS

INSTRUCTIONS

DO NOT allow any person to operate the

hydraulic trencher without first reading and

understanding the safety instructions and

NEVER allow children to operate the hydraulic trencher.

ALWAYS use hydraulic trencher in a well lighted area.

ALWAYS make certain that all control clutches are in

the “disengaged” position prior to starting the engine.

The safety clutch lever/Operator Presence Control on

the left handlebar is for operator protection. DO NOT

tape down or otherwise bypass this Safety Device.

NEVER wear loose fitting clothing or jewellery when

operating the hydraulic trencher. Keep all clothing

away from moving parts. Item could become

caught in the machine, resulting in injury.

ALWAYS wear protective

clothing when operating

the hydraulic trencher.

This includes, but is not limited to, safety glasses, hard hat

loose fitting gloves, steel capped boots and hearing protection.

operating instructions. KNOW THE CONTROLS AND

HOW TO STOP THE HYDRAULIC TRENCHER QUICKLY

IN AN EMERGENCY.

1)

2)

3)

4)

Police the area before trenching. Remove any foreign

objects in the digging area eg bricks, rocks, wire and

sticks. Locate and mark any sprinkler heads, water

pipes, gas lines, electrical and telephone cables or any

other hazard either below or above ground.

5)

DO NOT leave the machine unattended while the engine

is running. DO NOT park on incline or park

perpendicular to slope. DO NOT freewheel down incline.

7)

DO NOT overspeed the engine or alter the governor

settings. Excessive speed is dangerous and will

shorten engine life

8)

NEVER operate the hydraulic trencher when fatigued.

ALWAYS BE ALERT! If you get tired while operating

the hydraulic trencher, take a break. If you have any

type of physical or mental condition that may be

aggravated by strenuous work, consult with your

physician before you operate this equipment. NEVER

operate the hydraulic trencher under the influence of

medication, alcohol or drugs.

9)

NEVER operate the unit without the safety

guards in place and in working order. Keep

the unit well maintained and in good working order

Remove the hydraulic trencher from its

trailer. Use caution.

Police the area. Remove any

foreign objects from the area.

Identify and mark the location of sprinkler heads,

gas pipes, telephone cables, etc.

IGNITION: Must be in “ON” position to start. “OFF”

to stop.

ENGINE: Throttle cable controls engine speed.

Operate at full throttle (all the way forward).

WHEEL DRIVE CONTROL LEVER: Controls wheel

speed forward or reverse after clutch lever is engaged.

DIGGING BOOM CONTROL LEVER: Raises and lowers

the digging boom.

DIGGING CHAIN CONTROL LEVER: must be in “ON”

position BEFORE clutch lever is depressed in order

to start chain in motion. Chain moves in a forward

direction after clutch lever is engaged.

SAFETY CLUTCH LEVER/OPERATOR PRESENCE

CONTROL: (At left handle grip) Activates WHEEL

DRIVE and DIGGING CHAIN controls when depressed.

Stops all motion when released.

FORWARD/REVERSE DIGGING CHAIN CONTROL

LEVER: Allows manual operation of chain in forward

or reverse rotation to dislodge objects or dig difficult

terrain. (This control can be used with the clutch lever

released.) To reverse chain, DIGGING CHAIN control

must be in “OFF” position.

Familiarize yourself with the hydraulic

trencher and its controls.

10)

1)

1)

2)

1)

Free Wheel Hub Feature - Operation:

Pull one free wheeling pin slightly, using the split

ring. Rotate the pin until the 3mm (1/8”) diameter roll

pin aligns with the slot in the mounting plate. Allow

the pin to slide through the slot. Repeat for the other

wheel. Roll the trencher until each pin drops into a

hole in the hub. The wheel hubs are now locked.

Reverse the procedure to unlock the wheels.

2)

DO NOT allow other persons near the hydraulic

trencher. It is up to the operator to keep

bystanders and animals a minimum of 6 metres

(20ft) away from the machine while in operation.

12)

NEVER operate the hydraulic trencher in an

enclosed area. Engine exhaust contains carbon

monoxide, an odourless and tasteless poison.

13)

WARNING: Hydraulic oil is under extreme

pressure and can get under skin and burn

or poison. Check for leaks with cardboard.

14)

STOP the engine and disconnect the spark

plug lead(s) and allow engine to cool before

inspecting or performing maintenance on

the hydraulic trencher.

15)

REFUELLING

* Shut off engine. DO NOT REFUEL AN ENGINE

WHILE OPERATING!

* Allow engine to cool. Minimum 5 minutes

* Do not smoke. *Allow no naked flame

or hot material in refuelling area.

* Use only approved fuel containers and funnels.

Remember, fuel is a potential hazard.

* Do not over-fill fuel tank. Allow space for

fuel expansion.

* USE UNLEADED FUEL ONLY. Use clean,

fresh unleaded fuel.

* Do not mix oil with unleaded fuel.

16)

ALWAYS KEEP YOUR HANDS, FEET AND BODY

AWAY FROM THE DIGGING CHAIN AND OTHER

MOVING PARTS WHILE ENGINE IS RUNNING.

11)

ALWAYS operate

hydraulic trencher

on level ground only.

6) MAXIMUM

ANGLE OF

OPERATION

DO NOT EXCEED 15ºANGLE

BEFORE USE

OPERATION

TRANSPORT

BEFORE USE

1) Inspect the immediate area and

remove any foreign objects from the

area.

2) Identify and mark the location of sprinkler heads, gas

pipes, telephone cables, electrical cables, etc.

3) Check the fuel level, oil level, and air lter before starting

the this machine.

4)

ANGLE OF OPERATION. Do not exceed

an operation angle greater than 15 degrees.

Make sure that the oil in the crankcase is at

the top level before starting.

USE EXTREME CARE IF OPERATING THIS MACHINE

ON AN ANGLE.

SAFETY INSTRUCTIONS FOR RH918 USERS

OPERATING

INSTRUCTIONS

USE COMMON SENSE

AND PLENTY OF IT

TRANSPORT

BEFORE USE

1) DO NOT allow any person operate the

rotary hoe without first reading and

understanding the safety instructions and

operating instructions.

2) NEVER allow children to operate the rotary hoe.

8) ALWAYS make certain the Tyne Control Lever is

set at neutral while loading and unloading the

rotary hoe, or moving to and away from working area.

9) NEVER run the machine in reverse while the tynes

are rotating. Always move the tyne control lever to

“OFF” before reversing the wheels.

11) DO NOT leave the machine unattended while the

engine is running.

12) DO NOT overspeed the engine or alter the governor

settings. Excessive speed is dangerous and will

shorten engine life.

13) NEVER operate the rotary hoe in an

enclosed area. Engine exhaust contains

carbon monoxide, an odourless and

tasteless poison.

14) STOP the engine and disconnect the

spark plug lead(s) and allow engine to

cool before inspecting or performing

maintenance on the rotary hoe.

15)

1)

REFUELLING

* Shut off the engine. DO NOT REFUEL

AN ENGINE WHILE OPERATING!

* Allow engine to cool. Minimum 5 minutes

* USE UNLEADED FUEL ONLY.

Use clean, fresh unleaded fuel.

* Do not mix oil with unleaded fuel.

* Do not over-fill fuel tank. Allow space

for fuel expansion.

10) NEVER operate the unit without the safety

guards in place and in working order. Keep

the unit well maintained and in good

working order.

4) ALWAYS use the rotary

hoe in a well lighted area.

7) NEVER operate the rotary hoe when fatigued.

ALWAYS BE ALERT! If you get tired while

operating the rotary hoe, take a break. If you have

any type of physical or mental condition that may

be aggravated by strenuous work, consult with

your physician before you operate this equipment.

NEVER operate the rotary hoe under the influence

of medication, alcohol or drugs.

6) DO NOT allow other persons near the

rotary hoe. It is up to the operator to keep

bystanders and animals a minimum of 6

5) ALWAYS operate the rotary

hoe on level ground only.

Police the area before rotary

hoeing. Remove any foreign objects in the digging

area - bricks, rocks, wire and sticks. Locate and mark

any sprinkler heads, water pipes, gas lines,

electrical and telephone cables or any other hazard

either below or above ground.

3) ALWAYS wear protective clothing when operating

the rotary hoe. This includes, but is not limited to;

safety glasses, loose fitting gloves, steel capped

boots and hearing protection. NEVER wear loose

fitting clothing or jewellery when operating the

rotary hoe. Keep all clothing away from moving

parts. Items could become caught in the machine,

resulting in injury.

KNOW THE CONTROLS AND HOW TO STOP

THE ROTARY HOE QUICKLY IN AN EMERGENCY.

metres (20’) away from the machine while in

operation.

ALWAYS KEEP YOUR HANDS,

FEET AND BODY AWAY FROM

THE DIGGING ZONE WHILE

ENGINE IS RUNNING.

* Do not smoke.

* Allow no naked flame or hot material in refuelling area.

* Use only approved fuel containers and funnels.

Remember, fuel is a potential hazard .

Be sure Tyne Control Lever is set to “Neutral”

while loading and unloading the rotary hoe

and when moving to or from jobsite.

Ensure that all grass and weeds have been cut

as low as possible.

2) If the rotary hoe is to be used in clay or hard

ground conditions, it is recommended to water

the area thoroughly and allow sufficient time

for earth to soften.

3) Police the area. Remove any

foreign objects from the area.

4) Identify and mark the location of sprinkler heads,

gas pipes, telephone cables etc.

“The Right Way to Rent”

You alone know the operational demands and

special conditions affecting the equipment in

your situation and therefore assume the

responsibility for developing, carrying out, and

enforcing the safety concepts which apply to your

own operation to effect the greatest safety for

yourself andthe people around you.

P/N 1301-0073A

SAFETY FIRST – Stay Alert, Do Not Get Hurt

Read this section before use!

The HT912 Hydraulic Trencher is designed to dig trenches and therefore is potentially

dangerous. Careless or improper use may cause serious or even fatal injury.

It is important that you read and understand the contents of this manual and that you allow only

mature,adultindividuals to operate yourHT912 Hydraulic Trencher. It is yourresponsibility to

ensure that any individual who operates your Trencher have read and understood this manual.

Never use the Hydraulic Trencher for any other purpose than digging trenches. The machine is

designed for this purpose only. Any other use may cause serious or even fatal injury and/or damage

to the machine.

ABOUT THIS MANUAL

The information contained in this manual has been prepared to assist you in the safe operation, the routine

maintenanceandgeneralcare of yourRedRooproduct. By following theseguidelines,youmaylook

forward to years of reliableservice fromyourRedRoo. Information is categorisedanddenoted by the

following symbols and phrases:

SAFETY Identifies general safety practices.

FIRST

DANGER! An instruction which, if not followed, could result in serious or fatal injury.

WARNING! An instruction which, if not followed, could result in personal injury.

CAUTION! An instruction which, if not followed, could damage machine components.

4

HAZARD SYMBOLS & MEANINGS

Before operatingthisMachine read

andobserve all Warnings, Cautions

andInstructions on theMachineand

in theOperatorsManual. Although the

reading of information contained in

thismanualdoesnoteliminatethe

risk involved in operatingthis

machine,yourunderstanding of this

information will promotethe correct

andsafeuse of yourmachine.Failure

to followInstructionsandSafety

Informationcould result in serious

injury or death.

Read Hearing

Protection

Eye

Protection

Wear

Gloves

Cut Hand

No

Bystanders

High Pressure

Fluid

Moving

Parts

Hot

Surfaces

Don’t Refuel

Hot Engine

Check Before

Digging

Explosion

Electrical

Shock

Toxic

Fumes

Remove Spark

Plug Leads

Identifies general safety practices.

An instruction which, if not followed, could result in serious or fatal injury.

An instruction which, if not followed, could result in personal injury.

An instruction which, if not followed, could damage machine components.

SAFETY FIRST – Stay Alert, Do Not Get Hurt

Read this section before use!

The HT912 Hydraulic Trencher is designed to dig trenches and therefore is potentially

dangerous. Careless or improper use may cause serious or even fatal injury.

It is important that you read and understand the contents of this manual and that you allow only

mature,adultindividuals to operate yourHT912 Hydraulic Trencher. It is yourresponsibility to

ensure that any individual who operates your Trencher have read and understood this manual.

Never use the Hydraulic Trencher for any other purpose than digging trenches. The machine is

designed for this purpose only. Any other use may cause serious or even fatal injury and/or damage

to the machine.

ABOUT THIS MANUAL

The information contained in this manual has been prepared to assist you in the safe operation, the routine

maintenanceandgeneralcare of yourRedRooproduct. By following theseguidelines,youmaylook

forward to years of reliableservice fromyourRedRoo. Information is categorisedanddenoted by the

following symbols and phrases:

SAFETY Identifies general safety practices.

FIRST

DANGER! An instruction which, if not followed, could result in serious or fatal injury.

WARNING! An instruction which, if not followed, could result in personal injury.

CAUTION! An instruction which, if not followed, could damage machine components.

4

HAZARD SYMBOLS & MEANINGS

Before operatingthisMachine read

andobserve all Warnings, Cautions

andInstructions on theMachineand

in theOperatorsManual. Although the

reading of information contained in

thismanualdoesnoteliminatethe

risk involved in operatingthis

machine,yourunderstanding of this

information will promotethe correct

andsafeuse of yourmachine.Failure

to followInstructionsandSafety

Informationcould result in serious

injury or death.

Read Hearing

Protection

Eye

Protection

Wear

Gloves

Cut Hand

No

Bystanders

High Pressure

Fluid

Moving

Parts

Hot

Surfaces

Don’t Refuel

Hot Engine

Check Before

Digging

Explosion

Electrical

Shock

Toxic

Fumes

Remove Spark

Plug Leads

9) NEVER operate the stump grinder without the

safety guards in place and in good working

order. Always keep the stump grinder well

maintained and in good working order.

10)

11) DO NOT LEAVE THE STUMP GRINDER

UNATTENDED WHILE THE ENGINE IS RUNNING.

12)

DO NOT over speed the engine or alter the governor

settings. Excessive speed is dangerous and will shorten

engine life.

13)

NEVER OPERATE THE STUMP GRINDER

IN AN ENCLOSED AREA. Engine exhaust

contains carbon monoxide, an odourless and

tasteless poison that can kill.

14) STOP the engine, disconnect the spark

plug leads and allow engine to cool before

inspecting or performing maintenance.

15) REFUELIING

* Shut off engine. DO NOT REFUEL AN

ENGINE WHILE OPERATING MACHINE!

* ALLOW engine to cool down.

Minimum 5 minutes.

* USE UNLEADED FUEL ONLY.

* USE CLEAN FRESH UNLEADED FUEL.

* Do not mix oil with unleaded fuel.

* Do not over-ll fuel tank. Allow space for

fuel expansion.

* Do not smoke.

* Allow no naked ame or hot material in

refuelling area.

* Use only approved fuel containers and

funnels.

REMEMBER FUEL IS A POTIENTIAL

FIRE HAZARD/HANDLE WITH CAUTION

USE COMMON SENSE

AND PLENTY OF IT

SAFETY INSTRUCTIONS FOR HT912USERS

INSTRUCTIONS

DO NOT allow any person to operate the

hydraulic trencher without first reading and

understanding the safety instructions and

NEVER allow children to operate the hydraulic trencher.

ALWAYS use hydraulic trencher in a well lighted area.

ALWAYS make certain that all control clutches are in

the “disengaged” position prior to starting the engine.

The safety clutch lever/Operator Presence Control on

the left handlebar is for operator protection. DO NOT

tape down or otherwise bypass this Safety Device.

NEVER wear loose fitting clothing or jewellery when

operating the hydraulic trencher. Keep all clothing

away from moving parts. Item could become

caught in the machine, resulting in injury.

ALWAYS wear protective

clothing when operating

the hydraulic trencher.

This includes, but is not limited to, safety glasses, hard hat

loose fitting gloves, steel capped boots and hearing protection.

operating instructions. KNOW THE CONTROLS AND

HOW TO STOP THE HYDRAULIC TRENCHER QUICKLY

IN AN EMERGENCY.

1)

2)

3)

4)

Police the area before trenching. Remove any foreign

objects in the digging area eg bricks, rocks, wire and

sticks. Locate and mark any sprinkler heads, water

pipes, gas lines, electrical and telephone cables or any

other hazard either below or above ground.

5)

DO NOT leave the machine unattended while the engine

is running. DO NOT park on incline or park

perpendicular to slope. DO NOT freewheel down incline.

7)

DO NOT overspeed the engine or alter the governor

settings. Excessive speed is dangerous and will

shorten engine life

8)

NEVER operate the hydraulic trencher when fatigued.

ALWAYS BE ALERT! If you get tired while operating

the hydraulic trencher, take a break. If you have any

type of physical or mental condition that may be

aggravated by strenuous work, consult with your

physician before you operate this equipment. NEVER

operate the hydraulic trencher under the influence of

medication, alcohol or drugs.

9)

NEVER operate the unit without the safety

guards in place and in working order. Keep

the unit well maintained and in good working order

Remove the hydraulic trencher from its

trailer. Use caution.

Police the area. Remove any

foreign objects from the area.

Identify and mark the location of sprinkler heads,

gas pipes, telephone cables, etc.

IGNITION: Must be in “ON” position to start. “OFF”

to stop.

ENGINE: Throttle cable controls engine speed.

Operate at full throttle (all the way forward).

WHEEL DRIVE CONTROL LEVER: Controls wheel

speed forward or reverse after clutch lever is engaged.

DIGGING BOOM CONTROL LEVER: Raises and lowers

the digging boom.

DIGGING CHAIN CONTROL LEVER: must be in “ON”

position BEFORE clutch lever is depressed in order

to start chain in motion. Chain moves in a forward

direction after clutch lever is engaged.

SAFETY CLUTCH LEVER/OPERATOR PRESENCE

CONTROL: (At left handle grip) Activates WHEEL

DRIVE and DIGGING CHAIN controls when depressed.

Stops all motion when released.

FORWARD/REVERSE DIGGING CHAIN CONTROL

LEVER: Allows manual operation of chain in forward

or reverse rotation to dislodge objects or dig difficult

terrain. (This control can be used with the clutch lever

released.) To reverse chain, DIGGING CHAIN control

must be in “OFF” position.

Familiarize yourself with the hydraulic

trencher and its controls.

10)

1)

1)

2)

1)

Free Wheel Hub Feature - Operation:

Pull one free wheeling pin slightly, using the split

ring. Rotate the pin until the 3mm (1/8”) diameter roll

pin aligns with the slot in the mounting plate. Allow

the pin to slide through the slot. Repeat for the other

wheel. Roll the trencher until each pin drops into a

hole in the hub. The wheel hubs are now locked.

Reverse the procedure to unlock the wheels.

2)

DO NOT allow other persons near the hydraulic

trencher. It is up to the operator to keep

bystanders and animals a minimum of 6 metres

(20ft) away from the machine while in operation.

12)

NEVER operate the hydraulic trencher in an

enclosed area. Engine exhaust contains carbon

monoxide, an odourless and tasteless poison.

13)

WARNING: Hydraulic oil is under extreme

pressure and can get under skin and burn

or poison. Check for leaks with cardboard.

14)

STOP the engine and disconnect the spark

plug lead(s) and allow engine to cool before

inspecting or performing maintenance on

the hydraulic trencher.

15)

REFUELLING

* Shut off engine. DO NOT REFUEL AN ENGINE

WHILE OPERATING!

* Allow engine to cool. Minimum 5 minutes

* Do not smoke. *Allow no naked flame

or hot material in refuelling area.

* Use only approved fuel containers and funnels.

Remember, fuel is a potential hazard.

* Do not over-fill fuel tank. Allow space for

fuel expansion.

* USE UNLEADED FUEL ONLY. Use clean,

fresh unleaded fuel.

* Do not mix oil with unleaded fuel.

16)

ALWAYS KEEP YOUR HANDS, FEET AND BODY

AWAY FROM THE DIGGING CHAIN AND OTHER

MOVING PARTS WHILE ENGINE IS RUNNING.

11)

ALWAYS operate

hydraulic trencher

on level ground only.

6) MAXIMUM

ANGLE OF

OPERATION

DO NOT EXCEED 15ºANGLE

BEFORE USE

OPERATION

TRANSPORT

USE COMMON SENSE

AND PLENTY OF IT

SAFETY INSTRUCTIONS FOR HT912USERS

INSTRUCTIONS

DO NOT allow any person to operate the

hydraulic trencher without first reading and

understanding the safety instructions and

NEVER allow children to operate the hydraulic trencher.

ALWAYS use hydraulic trencher in a well lighted area.

ALWAYS make certain that all control clutches are in

the “disengaged” position prior to starting the engine.

The safety clutch lever/Operator Presence Control on

the left handlebar is for operator protection. DO NOT

tape down or otherwise bypass this Safety Device.

NEVER wear loose fitting clothing or jewellery when

operating the hydraulic trencher. Keep all clothing

away from moving parts. Item could become

caught in the machine, resulting in injury.

ALWAYS wear protective

clothing when operating

the hydraulic trencher.

This includes, but is not limited to, safety glasses, hard hat

loose fitting gloves, steel capped boots and hearing protection.

operating instructions. KNOW THE CONTROLS AND

HOW TO STOP THE HYDRAULIC TRENCHER QUICKLY

IN AN EMERGENCY.

1)

2)

3)

4)

Police the area before trenching. Remove any foreign

objects in the digging area eg bricks, rocks, wire and

sticks. Locate and mark any sprinkler heads, water

pipes, gas lines, electrical and telephone cables or any

other hazard either below or above ground.

5)

DO NOT leave the machine unattended while the engine

is running. DO NOT park on incline or park

perpendicular to slope. DO NOT freewheel down incline.

7)

DO NOT overspeed the engine or alter the governor

settings. Excessive speed is dangerous and will

shorten engine life

8)

NEVER operate the hydraulic trencher when fatigued.

ALWAYS BE ALERT! If you get tired while operating

the hydraulic trencher, take a break. If you have any

type of physical or mental condition that may be

aggravated by strenuous work, consult with your

physician before you operate this equipment. NEVER

operate the hydraulic trencher under the influence of

medication, alcohol or drugs.

9)

NEVER operate the unit without the safety

guards in place and in working order. Keep

the unit well maintained and in good working order

Remove the hydraulic trencher from its

trailer. Use caution.

Police the area. Remove any

foreign objects from the area.

Identify and mark the location of sprinkler heads,

gas pipes, telephone cables, etc.

IGNITION: Must be in “ON” position to start. “OFF”

to stop.

ENGINE: Throttle cable controls engine speed.

Operate at full throttle (all the way forward).

WHEEL DRIVE CONTROL LEVER: Controls wheel

speed forward or reverse after clutch lever is engaged.

DIGGING BOOM CONTROL LEVER: Raises and lowers

the digging boom.

DIGGING CHAIN CONTROL LEVER: must be in “ON”

position BEFORE clutch lever is depressed in order

to start chain in motion. Chain moves in a forward

direction after clutch lever is engaged.

SAFETY CLUTCH LEVER/OPERATOR PRESENCE

CONTROL: (At left handle grip) Activates WHEEL

DRIVE and DIGGING CHAIN controls when depressed.

Stops all motion when released.

FORWARD/REVERSE DIGGING CHAIN CONTROL

LEVER: Allows manual operation of chain in forward

or reverse rotation to dislodge objects or dig difficult

terrain. (This control can be used with the clutch lever

released.) To reverse chain, DIGGING CHAIN control

must be in “OFF” position.

Familiarize yourself with the hydraulic

trencher and its controls.

10)

1)

1)

2)

1)

Free Wheel Hub Feature - Operation:

Pull one free wheeling pin slightly, using the split

ring. Rotate the pin until the 3mm (1/8”) diameter roll

pin aligns with the slot in the mounting plate. Allow

the pin to slide through the slot. Repeat for the other

wheel. Roll the trencher until each pin drops into a

hole in the hub. The wheel hubs are now locked.

Reverse the procedure to unlock the wheels.

2)

DO NOT allow other persons near the hydraulic

trencher. It is up to the operator to keep

bystanders and animals a minimum of 6 metres

(20ft) away from the machine while in operation.

12)

NEVER operate the hydraulic trencher in an

enclosed area. Engine exhaust contains carbon

monoxide, an odourless and tasteless poison.

13)

WARNING: Hydraulic oil is under extreme

pressure and can get under skin and burn

or poison. Check for leaks with cardboard.

14)

STOP the engine and disconnect the spark

plug lead(s) and allow engine to cool before

inspecting or performing maintenance on

the hydraulic trencher.

15)

REFUELLING

* Shut off engine. DO NOT REFUEL AN ENGINE

WHILE OPERATING!

* Allow engine to cool. Minimum 5 minutes

* Do not smoke. *Allow no naked flame

or hot material in refuelling area.

* Use only approved fuel containers and funnels.

Remember, fuel is a potential hazard.

* Do not over-fill fuel tank. Allow space for

fuel expansion.

* USE UNLEADED FUEL ONLY. Use clean,

fresh unleaded fuel.

* Do not mix oil with unleaded fuel.

16)

ALWAYS KEEP YOUR HANDS, FEET AND BODY

AWAY FROM THE DIGGING CHAIN AND OTHER

MOVING PARTS WHILE ENGINE IS RUNNING.

11)

ALWAYS operate

hydraulic trencher

on level ground only.

6) MAXIMUM

ANGLE OF

OPERATION

DO NOT EXCEED 15ºANGLE

BEFORE USE

OPERATION

TRANSPORT

SAFETYPRECAUTIONS

AND OPERATING

INSTRUCTIONS

™

SG350

STUMP

GRINDER

4) IGNITION: Must be in “ON” position to start.

“OFF” to stop.

5) Open fuel shut-off valve. Move choke

control to CHOKE or START position.

Note: Choke must fully close. Move throttle

controlto RUN or FAST position. If engine is

equipped with rocker style stop switch, push

RUN or I (I = Ignition) before starting. Rewind

Starter: Grasp rope

handle and pull slowly

until resistance is felt

to prevent kickback.

Then pull cord rapidly

to overcome compression, and start engine.

Repeat if necessary with choke off and

throttle control in FAST position. Operate

engine in FAST position.

NOTE: The operator presence control bar is

designed as a safety feature. The engine will

not start or operate without depressing the

control bar. See Figure 1 (next page).

6) Push the stump grinder to the stump,

position the grinding disc over the front edge

of the stump.

7) Set the wheel brake on the right hand side of

the stump grinder and adjust the handle

position to achieve better leverage

depending on the height of the stump.

8) Use the throttle to gradually bring the engine

RPM s up tofull whilelifting thegrinding

disc off theground.

9) Slowly lower the stump grinder until the

grinding disc comes in contact with the

stump. Move the stump grinder back and

forth in a slow sweeping motion.

Maintain the same elevation until a section

has been removed, then lower the stump

grinder to take out the next section.

NOTE: Constant build up of grinding debris

may inhibit the stump grinder from

performing effectively. To help assure safe,

effective and efficient working results, keep

theworking area raked level and free of

grinding debris. ALWAYS USE A RAKE.

© Copyright 2014, Red Roo Sales & Service Company Pty. Ltd. 1301-0024-A

NOTE: Make sure grinding disc has

stopped completely before clearing debris

10) When the front part of the stump has been

removed, release the brake and push the stump

grinder forward to a new edge.

NOTE: For better performance and to avoid

excessive clutch wear, run the engine at full

throttle during operation.

WARNING!–Keep hands and feet

clear of the Grinding Disc and grinding

zone and other moving parts while

engine is running.

WARNING!

–In case of difficulty, release

the Operator Presence Control Bar. This

action will stop the engine. See figure 1.

11) After stump has been removed use the throttle to

gradually bring down the engine RPM s. Make sure

thegrinding disc has come to a complete stop

before moving the stump grinder.

12) Stop Engine: Do not

move choke control to

CHOKE position tostop

engine. Backfire or

engine damage may occur. Move throttle control

to SLOW position, then push rocker switchto 0

(STOP), or turn key toOFF, if equipped.

AFTER USE

1) Turn fuel tap to "OFF" position.

2) Allow machine to cool down.

Wash mud and dirt off of the stump grinder.

Ensure no water enters the carburettor.

3) Remove any weeds, wire, rope, etc. that may

have wrapped around the disc grinding shaft assembly.

4) CHECK FOR LOOSE BOLTS ON THE GRINDING DISC.

Commercial Outdoor Power Equipment

OPERATING INSTRUCTIONS FOR SG350

You alone know the operational demands and

special conditions affecting the equipment in

your situation and therefore assume the

responsibility for developing, carrying out, and

enforcing the safety concepts which apply to your

own operation to effect the greatest safety for

yourself andthe people around you.

“The Right Way to Rent”

USE COMMON SENSE

AND PLENTY OF IT

1) DO NOT allow any person to operate

the stump grinder without first reading

and understanding the safety

precautions and operating instructions. KNOW

THE CONTROLS AND HOW TO STOP

THE STUMP GRINDER QUICKLY IN AN

EMERGENCY.

2) NEVER allow children or untrained adults to

operate the stump grinder.

3) ALWAYS wear

protective clothing

when operating the

stump grinder. This includes, but is not limited

to; safety glasses, loose fitting gloves, steel

capped boots and hearing protection. NEVER

wear loose fitting clothing or jewellery when

operating the stump grinder. Keep all clothing

away from moving parts. Items could become

caught in the machine, resulting in injury.

4) ALWAYS operate the stump grinder in a well

lit area.

5) ALWAYS operate stump

grinder on level ground only.

Inspect the immediate area

before grinding. Remove any foreign objects in

the grinding area eg bricks, rocks, wire and

sticks. Locate and mark any sprinkler heads,

water pipes, gas lines, electrical and telephone

cables or any other hazard either below or

above ground.

6) DO NOT allow other persons near the

stump grinder. It is up tothe operator

to keep bystanders and animals a

minimum of 6 metres (18ft) away from the

machine while in operation.

7) NEVER operate the stump grinder when

fatigued. ALWAYS BE ALERT! If you get tired

while operating the stump grinder, take a

break. If you have any type of physical or

mental condition that may be aggravated by

strenuous work, check with your physician

before you operate this equipment. NEVER

operate the stump grinder under the influence

of medication, alcohol or drugs.

8) ALWAYS KEEP YOUR HANDS,

FEET AND BODY AWAY FROM

THE CUTTING AREA WHILE

ENGINE IS RUNNING.

9) NEVER operate the stump grinder

without the safety guards in place and

in working order. Keep the unit well

maintained and in good working order

10) DO NOT leave the machine unattended while

the engine is running.

11) DO NOT overspeed the engine or alter the

governor settings. Excessive speed is

dangerous and will shorten engine life.

12)

13) STOP the engine and disconnect the

spark plug lead(s) and allow engine

to cool before inspecting or

performing maintenance on the stump grinder.

14) REFUELLING

* Shut off engine. DO NOT REFUEL

AN ENGINE WHILE OPERATING!

* Allow engine to cool; minimum 5

minutes.

*USE UNLEADED FUEL ONLY.

Use clean, fresh unleaded fuel.

*DO NOT mix oil with unleaded fuel.

*DO NOT over-fill fuel tank. Allow

space for fuel expansion.

*DO NOT smoke.

* Allow no naked flame or hot material

in refuelling area.

* Use only approved fuel containers

and funnels. Remember, fuel is a

potential hazard.

SAFETY PRECAUTIONS FOR SG350 USERS

OPERATING

INSTRUCTIONS

FOR SG350

BEFORE USE

1) Inspect the immediate area.

Remove any foreign objects

from the area.

2) Identify and mark the location of sprinkler

heads, gas pipes, telephone cables, etc.

3) Check the fuel and oil level of engine

OPERATION

1) Remove the stump grinder from its

carrying vehicle, trailer or ute. Use caution.

2) Familiarize yourself with the machine and its

controls.

3) Manoeuvre the stump grinder to area near

the stump to be removed.

Operator Presence Control Bar

Wheel Brake

Engine

Lifting

Hook

Throttle Adjustment

Cutting

Height

Adjustment

Lever

Grinding Zone

“STAY ALERT – DON’T GET HURT”

NEVER operate the stump grinder

in an enclosed area. Engine exhaust

contains carbon monoxide, an

odourless and tasteless poison.

DISCHARGE

ZONE

DISCHARGE

ZONE

OPERATOR

ZONE

On/Off Switch Operator Presence Control Bar

Throttle Control

Remote Air Filtration

Engine Exhaust

Centrifugal Clutch

Lifting Hook

Belt Guard

Height

Control Lever

Main Body

Release Pin

Wheel

Brake Lever

Engine Pull

Cord

Engine

FIGURE 1

G

R

I

N

D

I

N

G

Z

O

N

E

G

R

I

N

D

I

N

G

Z

O

N

E