8

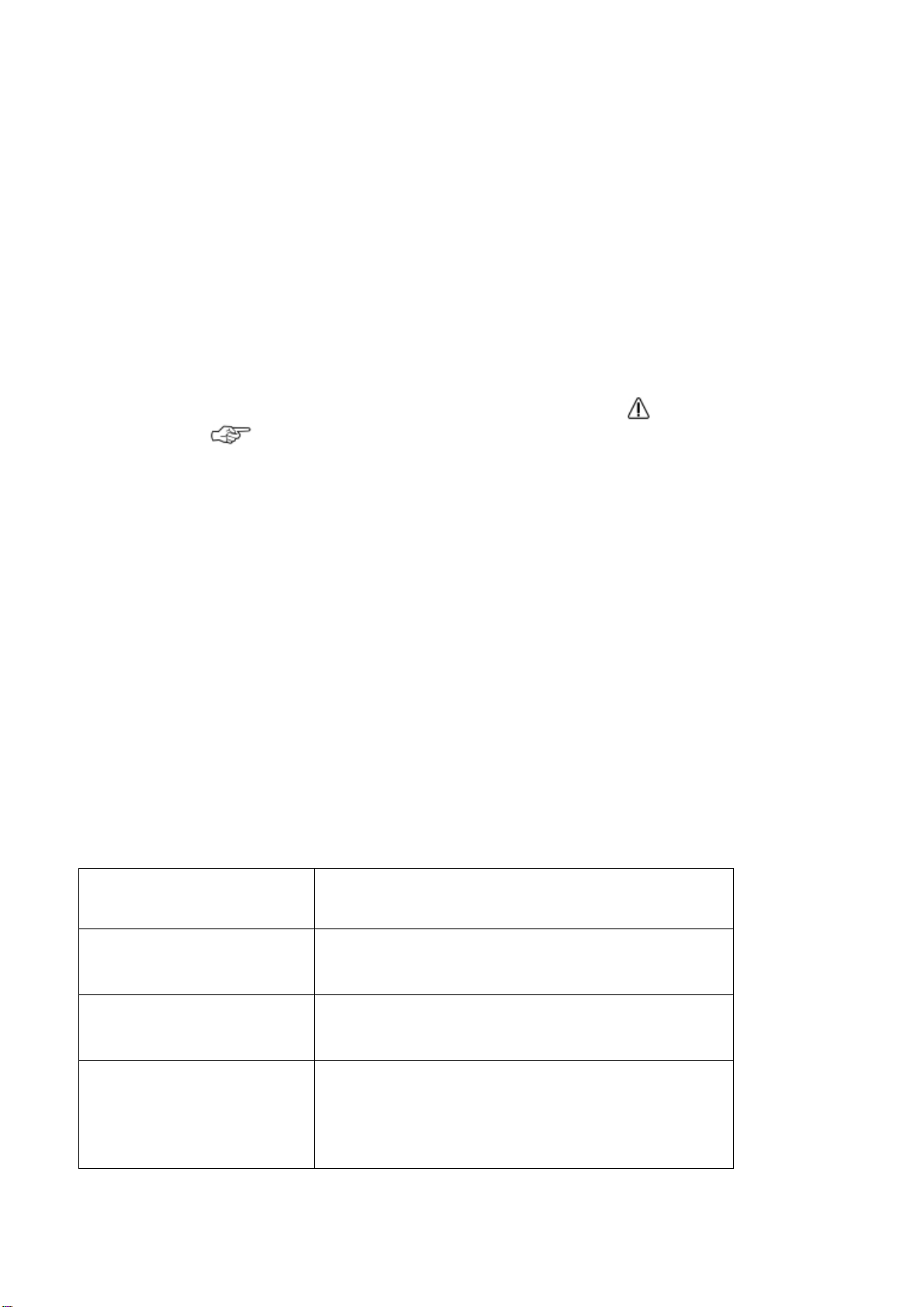

TABLE OF CONTENTS

PREFACE..........................................................................................................................2

WARRANTY CONDITIONS...........................................................................................................2

REGISTRATION CARD.................................................................................................................2

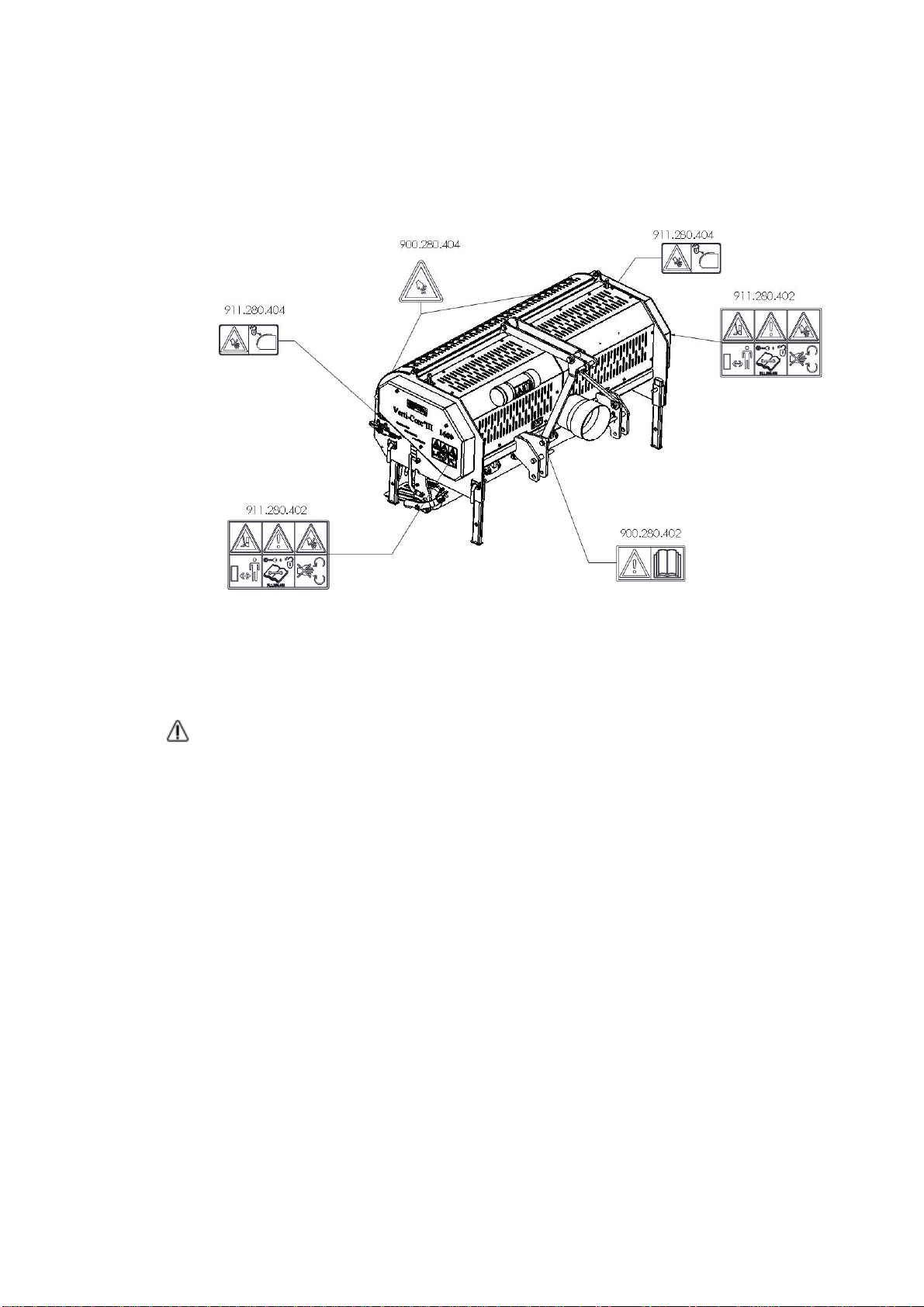

! SAFETY INSTRUCTIONS !...............................................................................................3

EU DECLARATION .......................................................................................................................7

1.0TECHNICAL DATA.............................................................................................................9

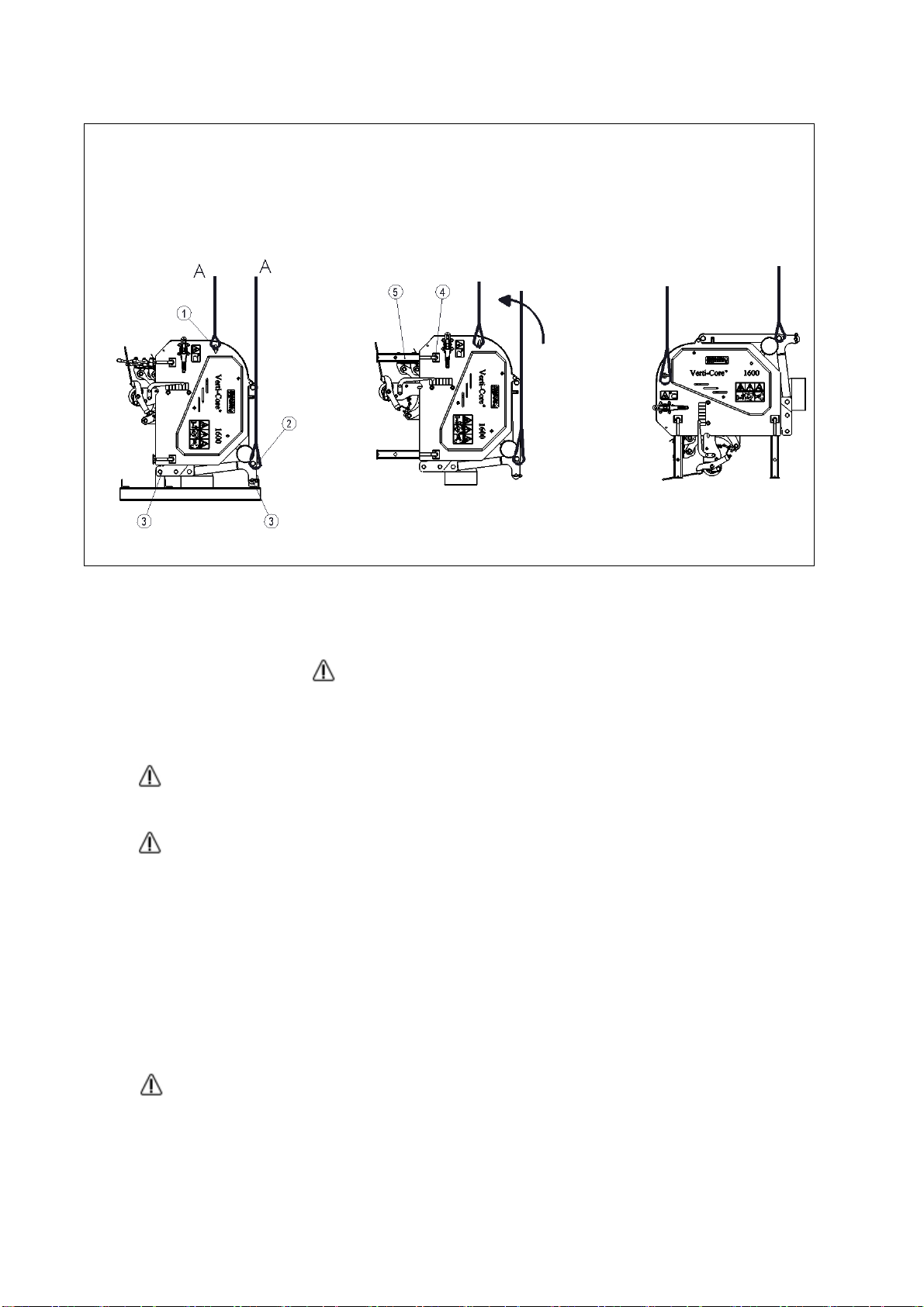

2.0TAKING THE MACHINE OFF THE PALLET....................................................................10

3.0THE PTO...........................................................................................................................11

3.1PTO LENGTH...................................................................................................................11

3.2PTO USE ..........................................................................................................................12

3.3PTO INFORMATION AND MAINTENANCE.....................................................................12

4.0CONNECTING TO THE TRACTOR .................................................................................14

5.0SETTING THE WORKING DEPTH...................................................................................15

6.0DRIVING SPEED..............................................................................................................16

7.0STARTING PROCEDURE...............................................................................................16

8.0USING THE VERTI-CORE III ...........................................................................................17

9.0TRANSPORTING THE VERTI-CORE III..........................................................................18

10.0DISCONNECTING THE VERTI-CORE III.........................................................................19

11.0TROUBLESHOOTING......................................................................................................20

12.0MAINTENANCE................................................................................................................21

13.0LUBRICATION PIONTS....................................................................................................22

14.0V-BELT TENSIONING......................................................................................................23

15.0TECHNICAL INFORMATION............................................................................................24

15.1REPLACING A CRANK/CONNECTING ROD BEARING.................................................24

15.2RELEASING CRANKSHAFT TENSION...........................................................................25

15.3TIMING AND TORQUES..................................................................................................25

16.0OPTIONS..........................................................................................................................27

16.1HOLLOW TINES...............................................................................................................27

16.2TURF HOLD DOWN FINGERS........................................................................................28

16.3WINDROW KIT.................................................................................................................28