3

RG26 Series Roll Groover Operator’s Manual

809-50356

IMPORTANT:

Read and fully understand this operating manual before

operating or performing maintenance on the RG26 Roll

Groover. It is essential to properly train and review with

operating personnel to become familiar with the tool’s op-

erations, applications, and limitations to prevent possible

bodily injury and property damage. All personnel should be

aware of the tool’s specific hazards.

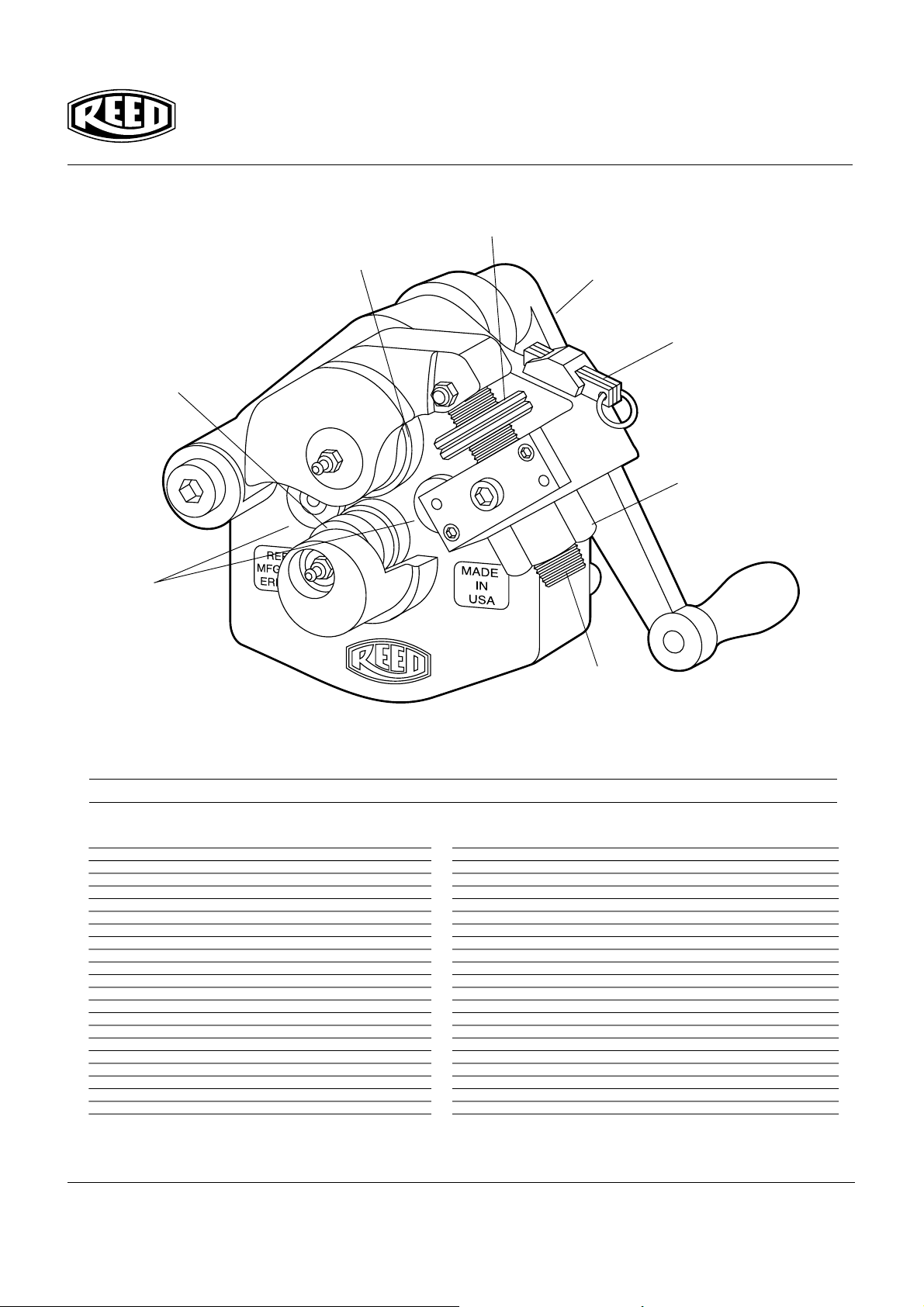

Reed RG26 Series Roll Groover

Description and Specifications

Description

The Reed RG26S Roll Groover is designed to form stan-

dard rolled grooves in steel, stainless steel, PVC, and alu-

minum pipe in 2-6" schedule 10, and 2-3" schedule 40.

The Reed RG26CU Roll Groover is designed to form stan-

dard rolled grooves in 2” to 6” copper tubing. The groove is

formed by a groove roll which is fed into the pipe wall. The

pipe is supported by a drive roll, which is relieved to permit

pipe wall deformation. The formed grooves comply with the

specifications required for mechanical coupling systems.

The only adjustment required is for the depth of the groove.

Designed for ease of use and portability, the RG26 Series

Roll Groover provides a practical solution for manual on-

site and in-place roll grooving.

Specifications

Capacity RG26S.................................2” - 6” Schedule 10

2” - 3” Schedule 40

Capacity RG26CU............2” - 6” K,L,M, and DWV Copper

Depth Adjustment ...........................Adjusting Nut, Depth

Gauges (included), and Jam Nuts

Actuation .................................Crank Nut and Ratcheting

Crank Handle (included)

Weight ........................................................21 lbs (9.55 kg)

Recommended Accessories

• Reed R450+ TriStand, Field Pipe Vise, CV6 bench

mounted chain vise, or #64 yoke style vise (when not us-

ing in-place)

• Reed JHV Pipe Jack (for long pipe lengths)

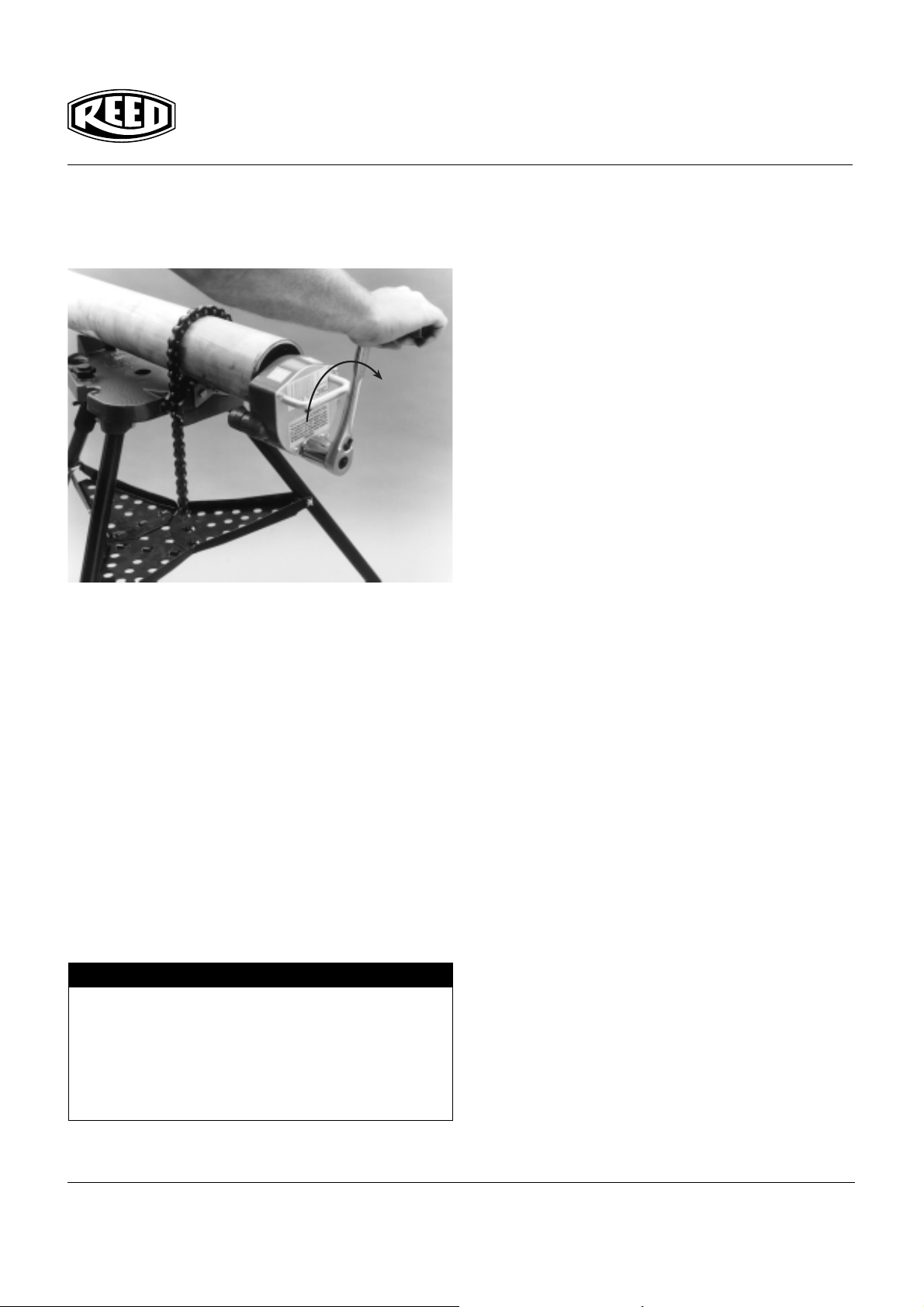

Important - Before Operating

Before operating the RG26 Roll Groover, read and

follow all safety information in the Operator’s Manual.

Safety Information

WARNING !

Serious injury can occur if all safety information and

operating instructions are not followed. These injuries

could include:

Loss of fingers, hands, arms or other

body parts if clothing or gloves get

caught in moving parts.

Impact injuries, including broken bones

if roll groover or workpiece falls.

Wear eye protection to prevent eye

injuries by thrown workpiece or

workpiece chips.

General Safety

Read and follow the safety information and instructions in

the operator’s manual.Store the operator’s manual in a clean

area and always at a readily available location. Additional

copies at no charge can be obtained by requests to Reed

Manufacturing Company.

Personal Safety

1. Wear snug-fitting clothes, safety shoes, hard hat and

safety glasses. Cover up or tie up long hair. Do not wear

loose clothing, gloves, unbuttoned jackets, loose sleeve

clothes, neckties, rings, watches or other jewelry.

2. Keep good footing and balance. Do not overreach. Keep

hands and tools away from moving parts of the roll

groover.

Work Area Safety

1. Keep children and visitors out of the work area. If visitors

must be in the area, keep them far away from the ma-

chine. Keep working environment clear at all times. When

using this tool at elevated locations or for overhead groov-

ing, keep area below clear of other personnel.

2. Keep work area clean, uncluttered and well lighted.

3. Keep floors dry and free of slippery materials.