95226-01 1 REEVES EMS, LLC

This document contains information proprietary to REEVES EMS, LLC and is intended solely for use by its customers. No portion of this document may

be reproduced for release to a third party without written consent from REEVES EMS, LLC.

1 GENERAL

1.1 Scope

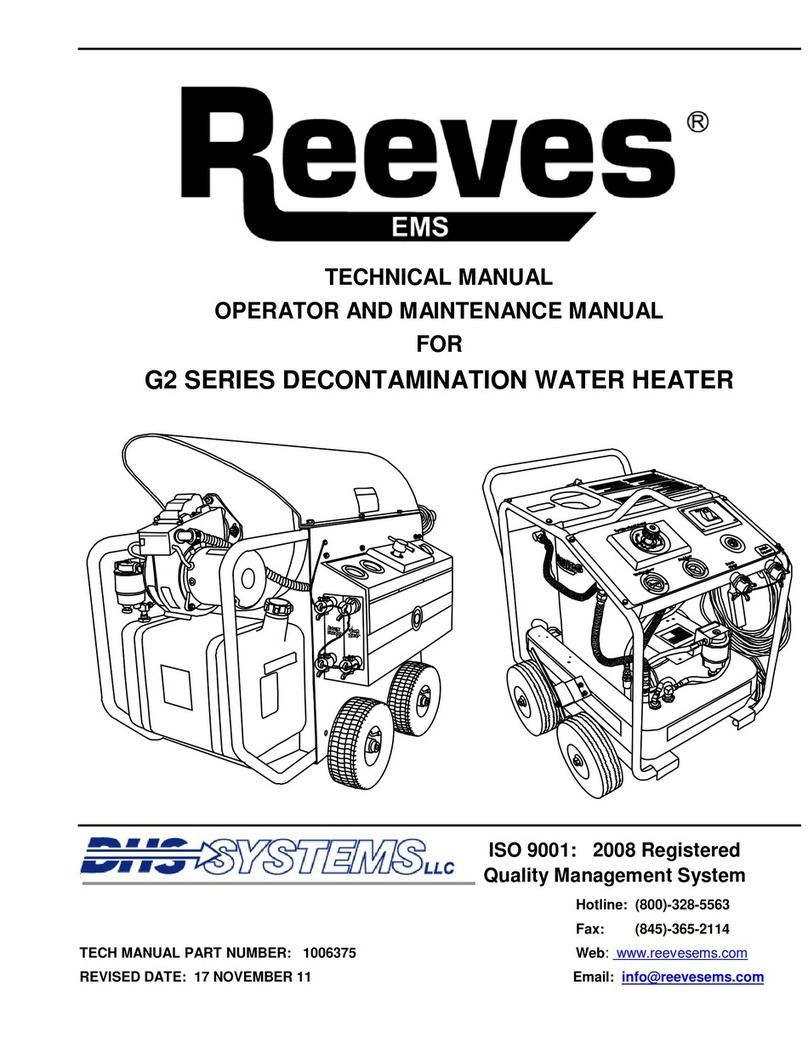

This Operator’s Manual describes the safe operation and field maintenance of the G2 / G2S Decontamination Water

Heater. You can be assured your hot water heater was constructed and designed with quality and performance in mind.

Each component has been rigorously tested to ensure the highest level of acceptance.

This operator’s manual was complied for your benefit. By reading and following the safety, installation, operation,

maintenance, and troubleshooting steps described in this manual, you will receive years of trouble free operation from

your new hot water heater.

1.2 Receipt of G2 / G2S Decontamination Water Heater

Once the unit has been uncrated, immediately write the model and serial number in the space provided below.

Model Number__________________ Serial Number_____________________

Inspect for signs of obvious or concealed freight damage. If damage does exist, file a claim with the transportation

company immediately. Be sure that all damaged parts are replaced and that the mechanical and electrical problems are

corrected prior to operation of the unit. If you require service, contact REEVES EMS, Customer Service. Please have the

model number and serial number available for all service calls.

1.3 Equipment Descriptions

The G2 Decontamination Water Heater is a man portable, easy to maneuver, four outlet system, with a heating output of

425,000 BTU. It also has a 6.6 gallon polyethylene decontamination solution holding tank and has the capability of

supplying hot water for one or two decontamination shelters. The G2S Decontamination Water Heater is a smaller

version of the G2 with similar features except it is a two outlet system and it doesn’t have the 6.6 gallon decontamination

solution holding tank. The G2S is capable of supplying hot water for a single shelter with a heating output of 168,000

BTU.

The G2 and G2S Water Heaters both have an enclosed fan-cooled electric motor with manual thermal overload

protection, and are capable of using No.1 or No. 2 Diesel / Kerosene for the burner. Both units have a built in Anti-Scald

Protection device and Pressure Relief Valve to protect the coils and components.

1.3.1 Solution Injector System

For best possible performance from the injector, please read this manual carefully and keep it in a safe place for further

reference. Your injector is made with high quality materials and includes the following features:

•Unit includes a non-electric, volumetric proportional injector system.

•Injector system designed to operate upon water flow.

•Built-in mixing chamber.

•Manual bypass OFF switch.

•In-line 100 micron filtration system.

•Automatic air relief valve

•Flow range: 2.6 to 660 gallons per hour (GPH).

•Injection rate: 1% (1:100) to 10% (1:10).

•Operating pressure: 6 – 100 PSI.