6

navigaTion using The basiC (remoTe) Display

Basic (Remote) Display User Interface

Most Guardian+ controllers ship with the Basic Display. The

display allows service technicians to change the major setpoints.

Setpoints can also be accessed using the Guardian+ Combo

Display or the controller’s web pages.

Controller Setup

Upon initially applying power to the controller, the controller

will initialize, then automatically enter Introduction Mode. The

Introduction Mode consists of four Types of Control options:

Ed - Electric Defrost with Mechanical TEV

EdE - Electric Defrost with Electric Expansion Valve

Ad - Air Defrost with Mechanical TEV

AdE - Air Defrost with Electric Expansion Valve

Step 1 - Using the and arrows, moves the user through

the available Types of Control options. Once the preferred

option is displayed press and hold the ENTER button for 3

seconds.

Note: For mechanical valve control, Ed and Ad options,

continue to Step 4. For Ede and AdE control options

continue to Steps 2, 3, &4.

Step 2 - Next, the controller prompts for the Expansion Valve

Type, and displays rS (RSV). If this is the correct selection,

press and hold the ENTER button for 3 seconds.

If not, use the or arrow to move to the correct valve.

With correct electric valve displayed, press and hold ENTER for

three seconds.

Note: Custom valve setup is not available from the Basic

Display.

Step 3 - The controller now prompts for Refrigerant Type

and displays 404 (R-404a) as the default. Change this value by

pressing the or arrow. Once you have the correct value,

press and hold ENTER for three seconds.

Step 4 - The fourth prompt is whether SMART ACCESS is

ENABLED or DISABLED. SMART ACCESS allows you to

easily view your controller online. Make your selection by using

the or arrow, and then press and hold ENTER for three

seconds. THESE ARE THE ONLY SETPOINTS REQUIRED

TO BEGIN CONTROLLING THE SYSTEM.

Additional Setpoints

For the majority of users, the Basic Display will provide the

necessary parameters to setup the controller.

From the default display, pressing the and arrows will cycle

through the Variables menu. The ENTER button will toggle

between the variable name and value.

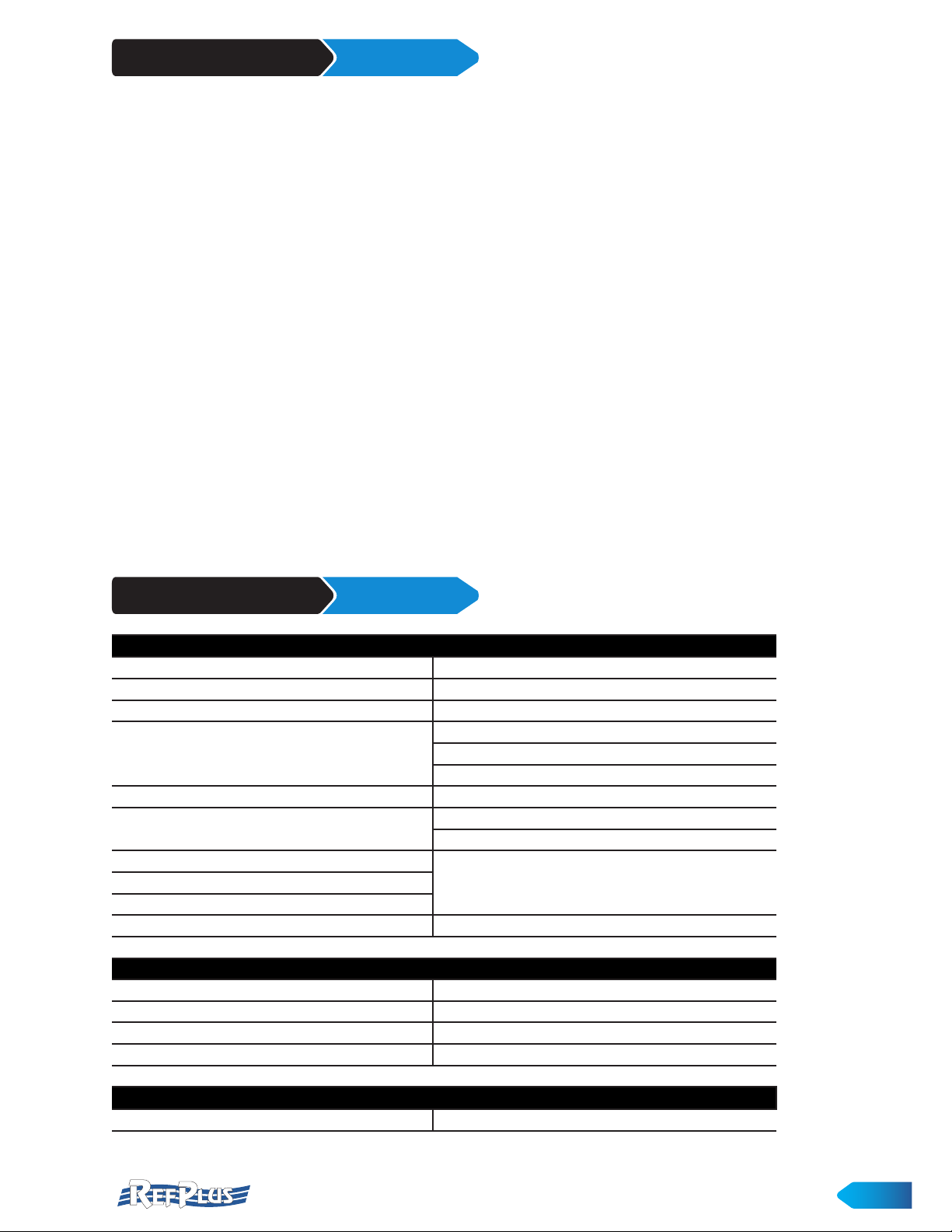

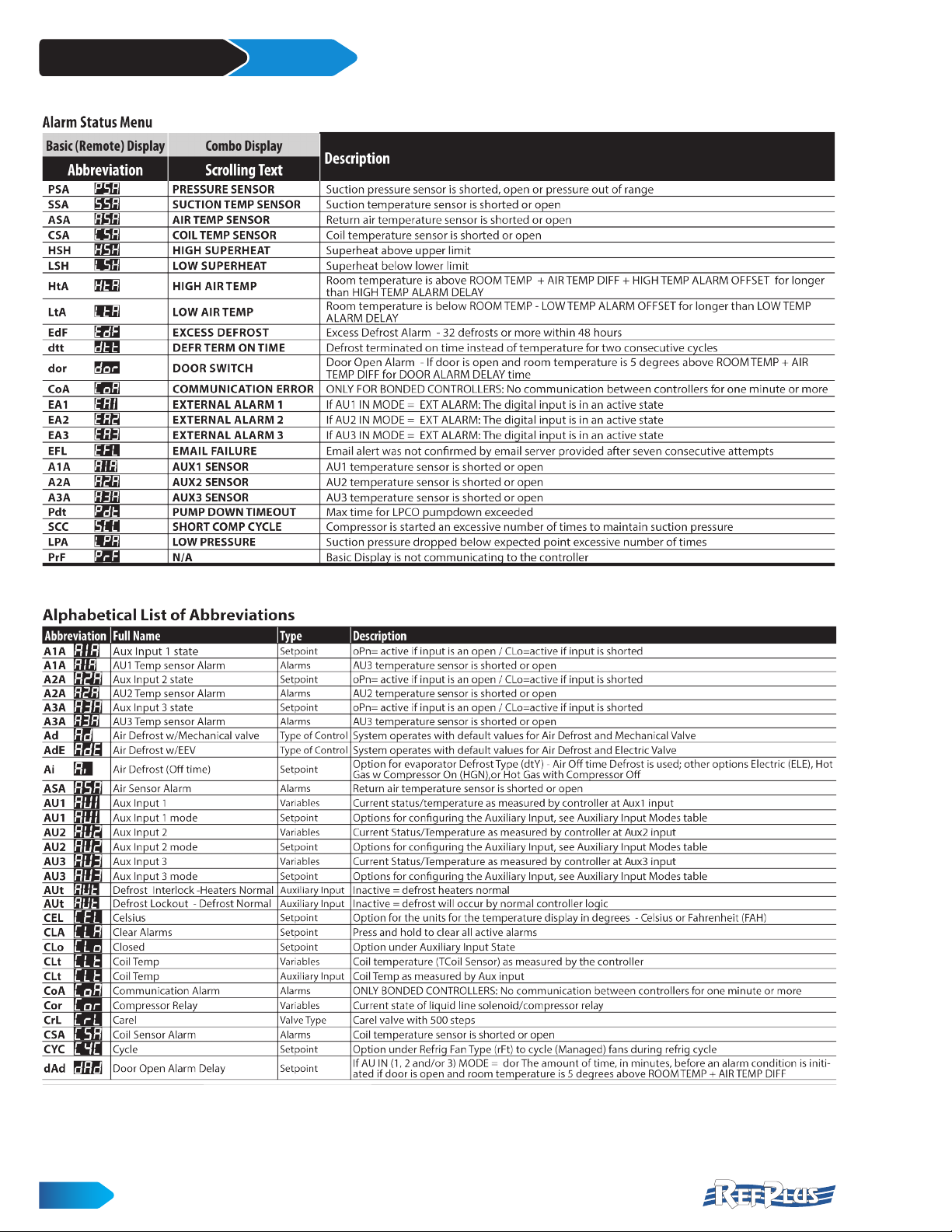

Changing Setpoints

Pressing and holding the ENTER button will enter the Basic

Setpoints menu. Press ENTER button to toggle between set

point and value.

Pressing and holding the BACK button will enter the Advanced

Setpoints menu. Press ENTER button to toggle between

setpoint and value.

When the parameter value is displayed it may be changed by

using and arrows, and ENTER buttons. The and

arrows will increase or decrease numerical values, and will scroll

through the available options, on the non-numerical setpoints.

Press and hold the ENTER button for 3 seconds to save the

displayed value.

To abort changes, press BACK to return to the parameter

abbreviation.

Manual Valve Control

Press and hold the BACK button & arrow to put the EEV

in Manual Control mode. and arrows will control the valve

opening. ENTER will advance to the next digit, and BACK will

exit this mode.

Manual Defrost

Press and hold

ENTER

and to put the controller into Defrost

(next mode).

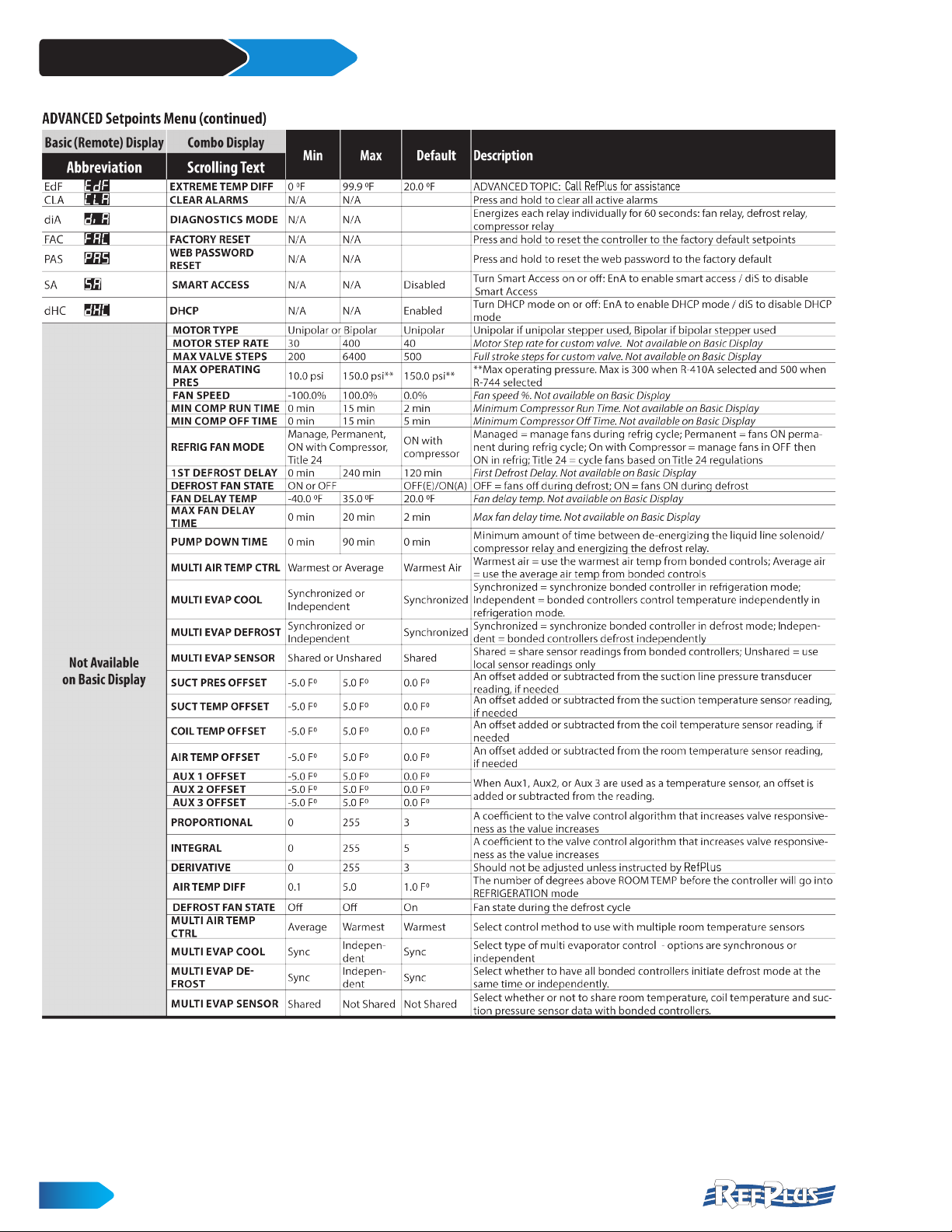

Diagnostics Mode

The Guardian+ has been programmed with a diagnostics mode.

When activated, the controller energizes each relay for 60

seconds. When the compressor relay is on the EEV will regulate

to the Superheat setpoint.

Display Firmware

Pressing and holding all 4 buttons ( BACK and ENTER )

will show the display’s rmware revision (dir – Display Revision)

Display Options

Simultaneously pressing and holding the and arrows will

show the address of the display (reserved for future versions).

Web Login

The User Name and Password are required when accessing the

controller using the web page.

The defaults are: User Name: ke2admin Password: ke2admin

IMPORTANT: For security purposes, the User Name and

Password should be changed from the default.