1

F O R M

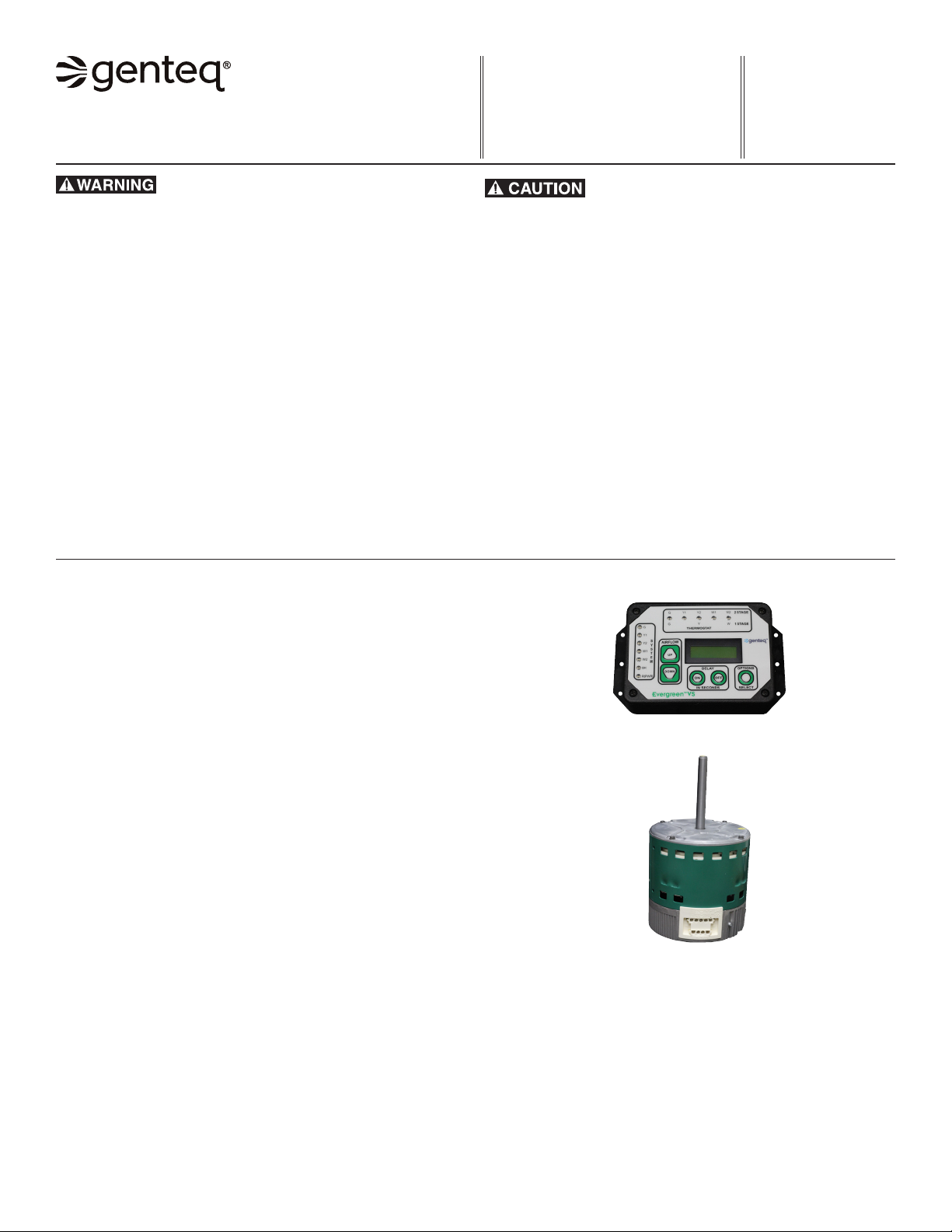

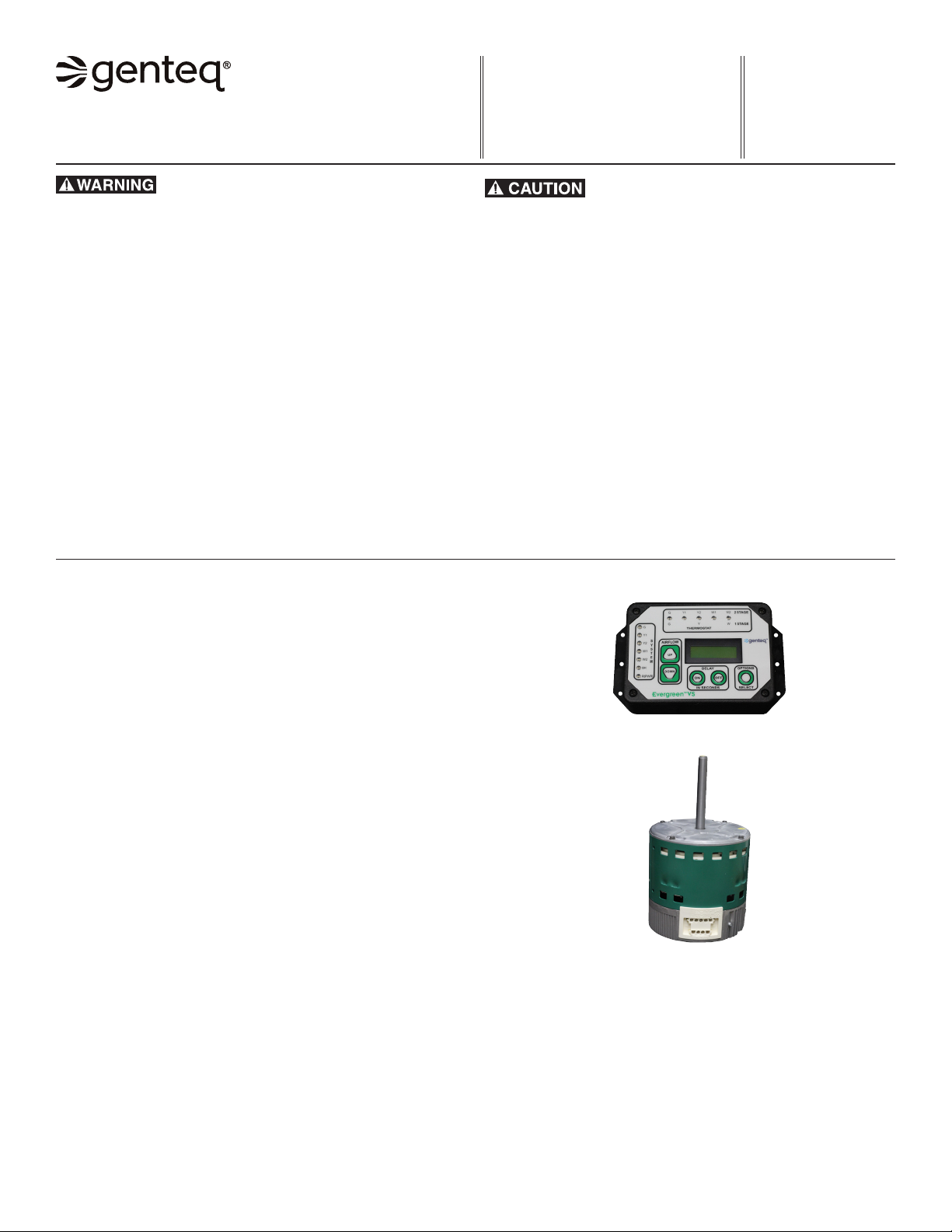

Evergreen®VS User Interface

Evergreen VS Motor

Installation Guide

G0075E

Revised

January 2020

Regal Beloit America, Inc.

1325 Heil Quaker Blvd.

LaVergne, TN 37086

Customer Service: 800 672 6495

thedealertoolbox.com

www.regalbeloit.com

CAUTION indicates a hazardous situation that, if not avoided,

could result in minor or moderate injury.

• Periodic inspections should be performed. Failure to perform

proper maintenance could result in premature product failure, in

addition to minor or moderate injury.

• Installation and service of this Evergreen VS user interface and

motor should be performed only by trained service technicians

familiar with these products.

• This Evergreen VS user interface and motor should be

installed in accordance with accepted practices and installation

instructions, and in compliance with all national and local codes.

WARNING indicates a hazardous situation that, if not avoided, could

result in death or serious injury.

• Read and follow all instructions carefully.

• Disconnect and lock out the main power from the unit being

serviced before installing the Evergreen VS user interface and

motor. It is also a good practice to confirm that the power is

disconnected with a voltmeter.

• Do not operate equipment without guards in place.

• Improper installation, adjustment, alteration, service,

maintenance, or use could cause explosion, fire, electrical shock,

or other conditions. Consult a qualified installer, service agency,

or your distributor or branch for information or assistance.

The qualified installer or agency must use the supplied or

recommended parts when installing or servicing this product.

• After installing the Evergreen VS user interface and motor, it is

the responsibility of the installing technician to verify the HVAC

system matches the manufacturer’s requirements for proper

operation, capacity, efficiency and safety. This includes but is not

limited to measuring the airflow and adjusting the Evergreen

VS user interface airflow and delay setting in each mode of

operation.

Evergreen®VS Motor

Table of Contents

1. Introduction

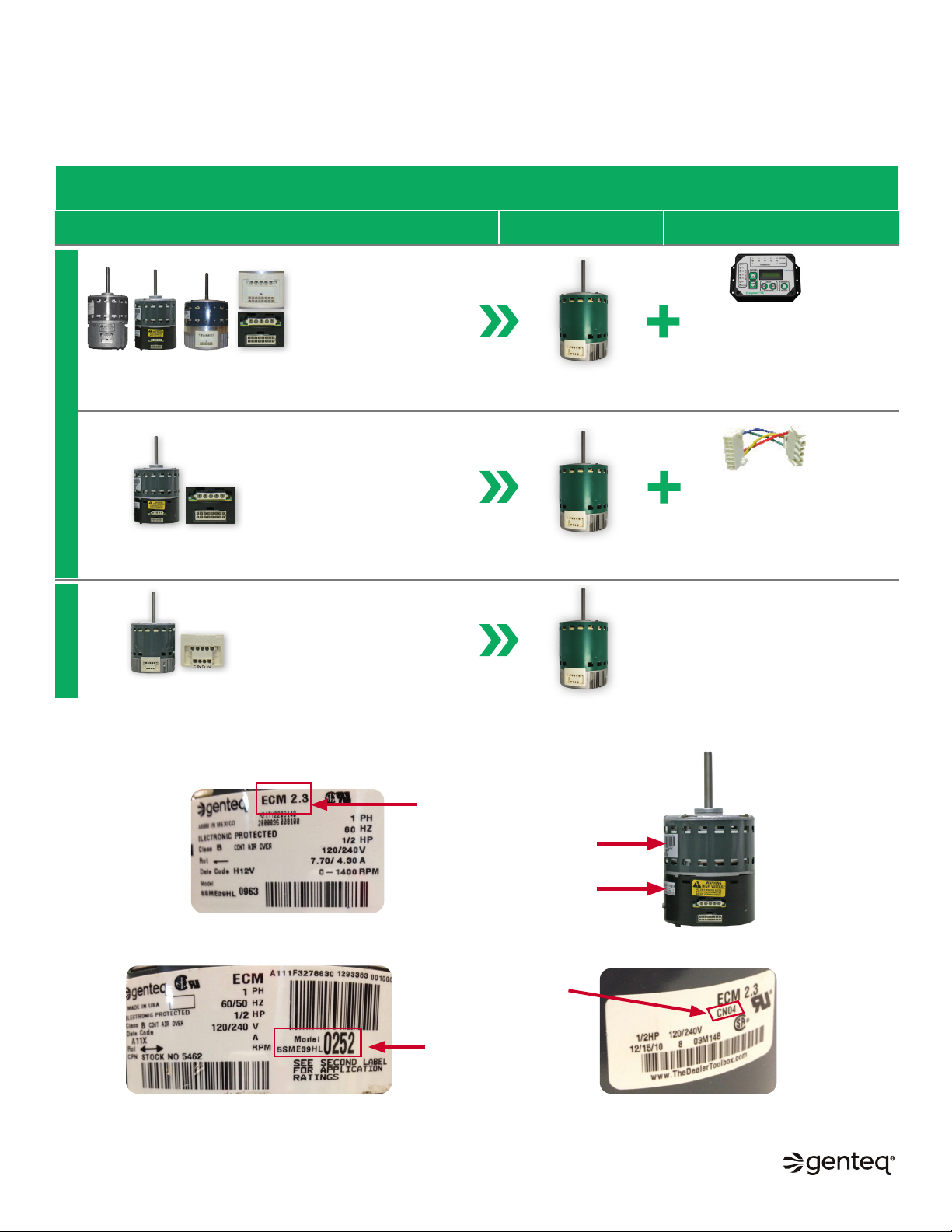

2. Evergreen VS Product Line Applications

and How to ID Genteq ECM Motors

3. Model 2.0, Genteq Models 2.3 and Eon®Applications

and Removal and Installation of the Motor

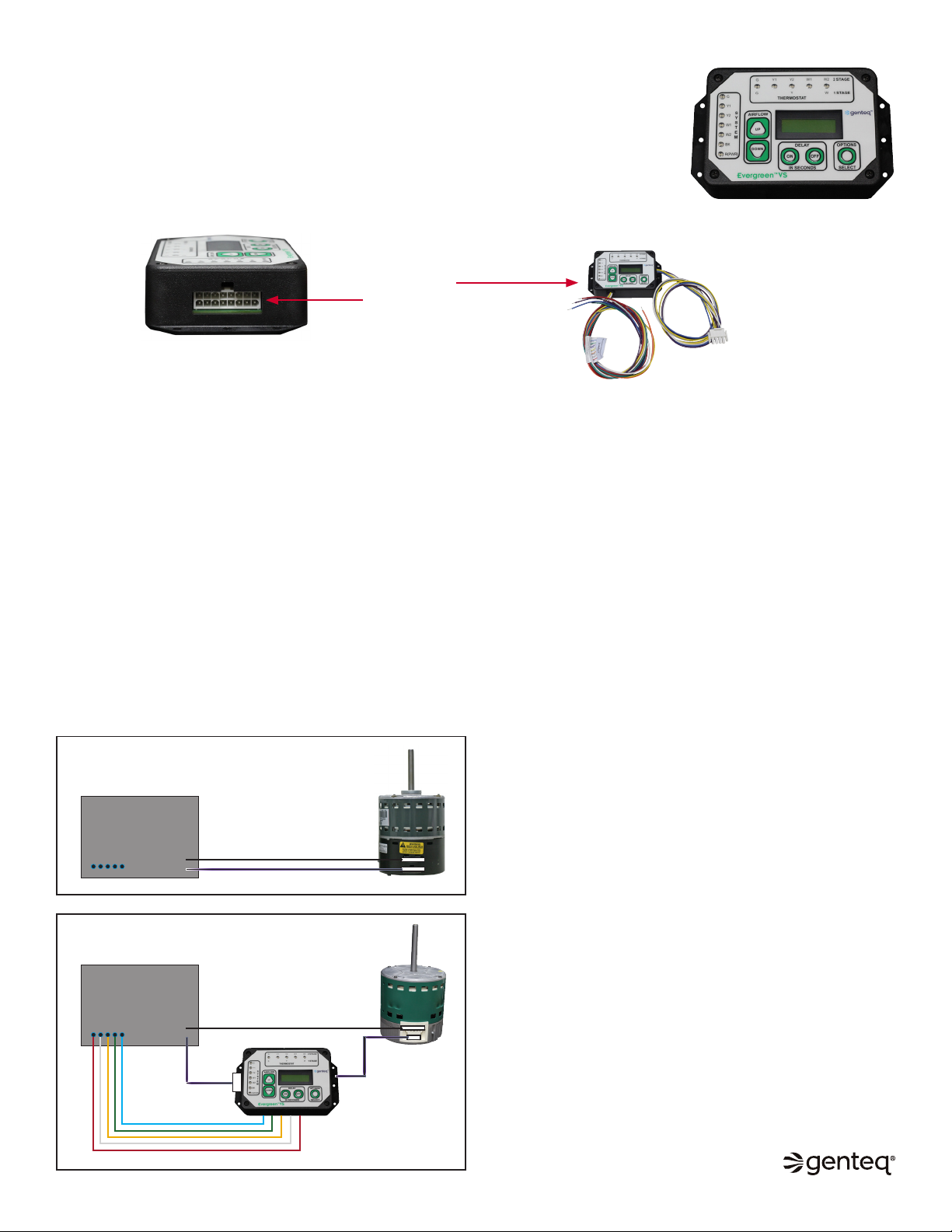

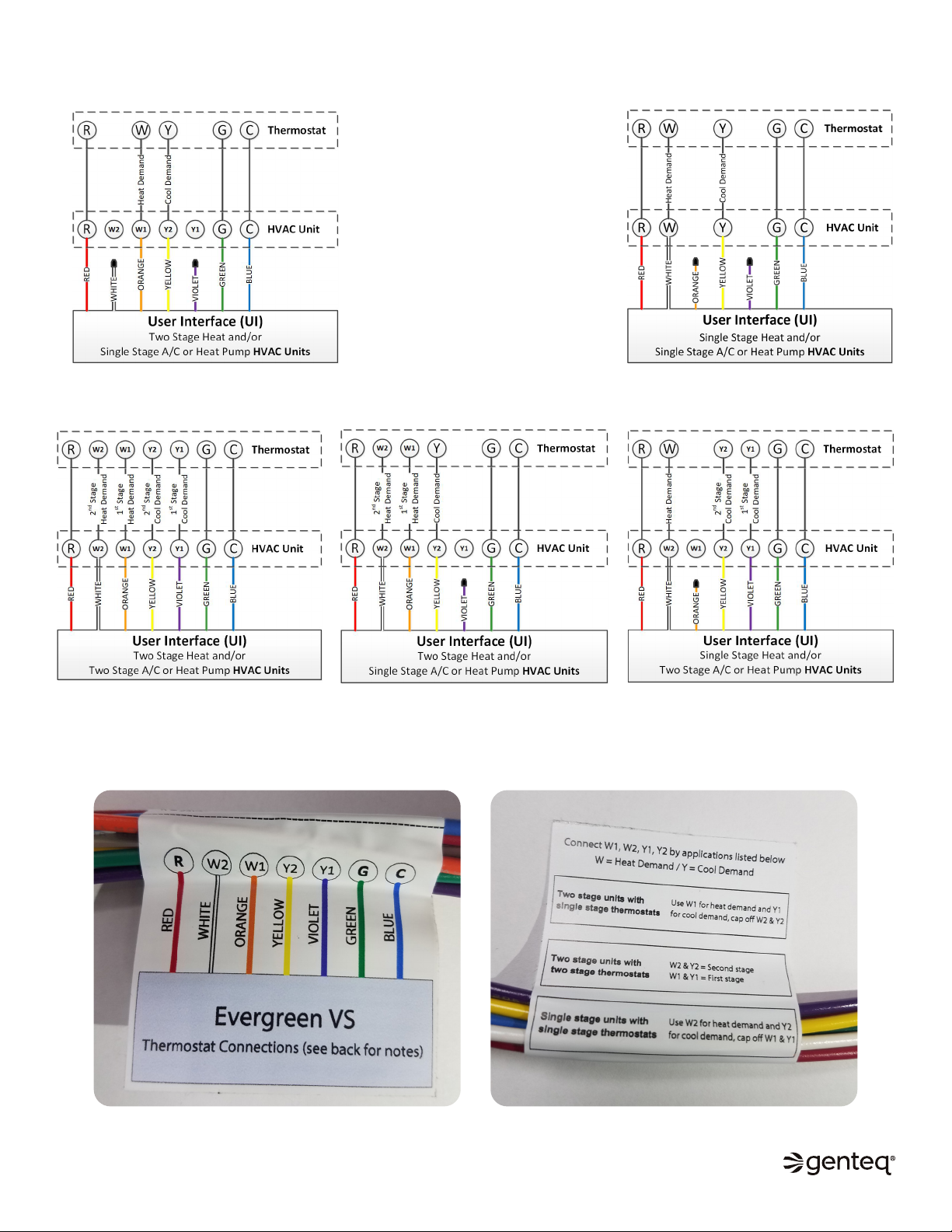

4-5. Installation of the Evergreen VS User Interface (UI)

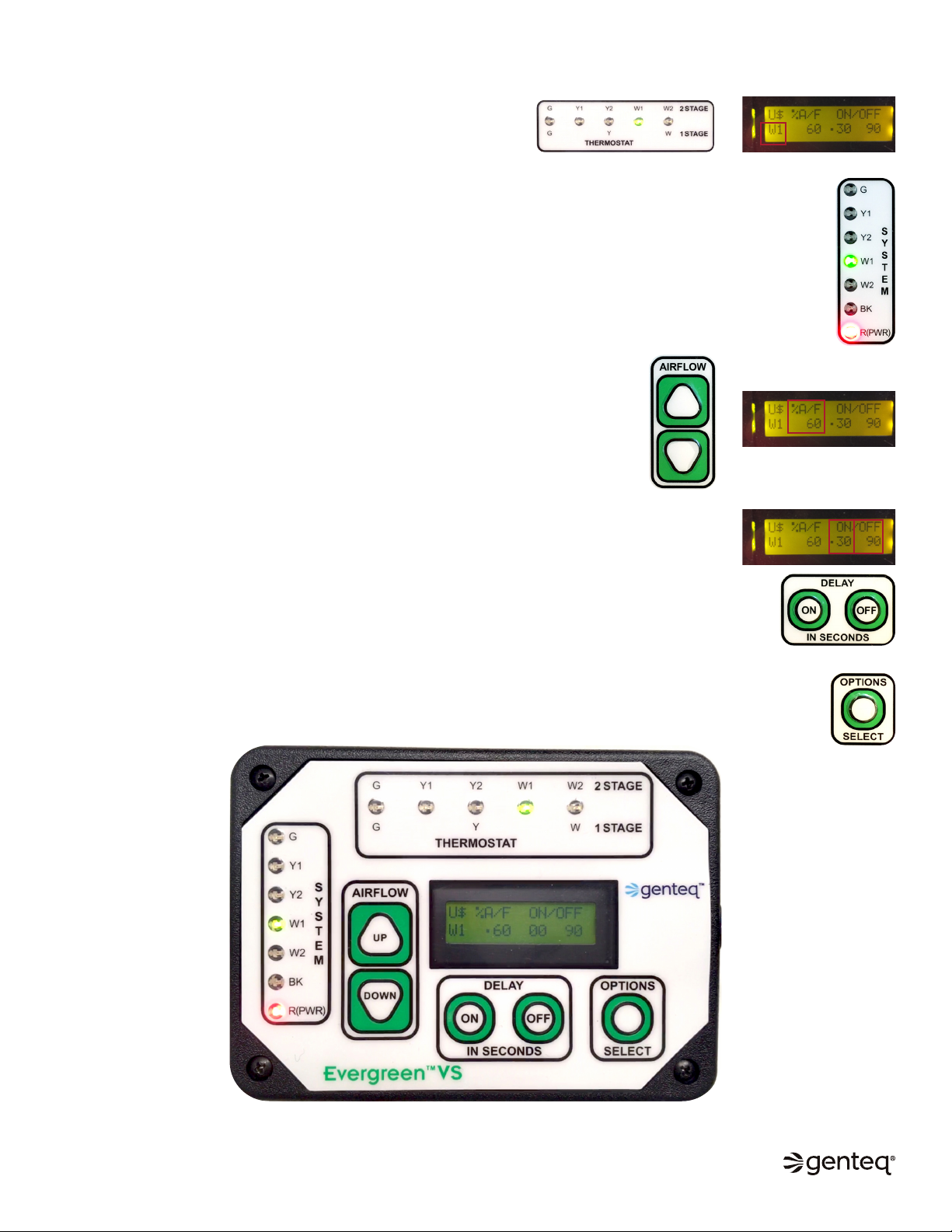

6. Evergreen VS User Interface (UI) Overview

7. Sequence of Operation

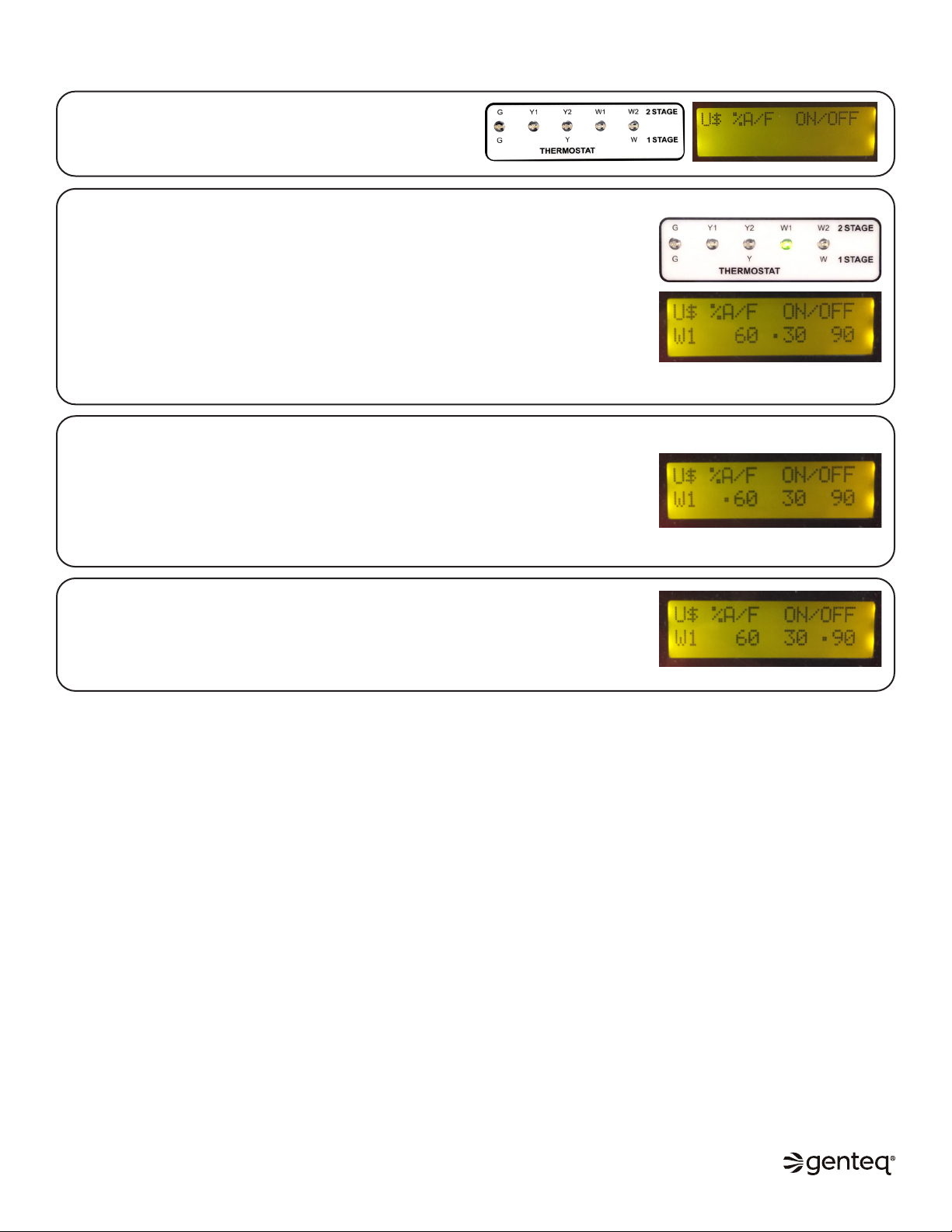

8. Commissioning

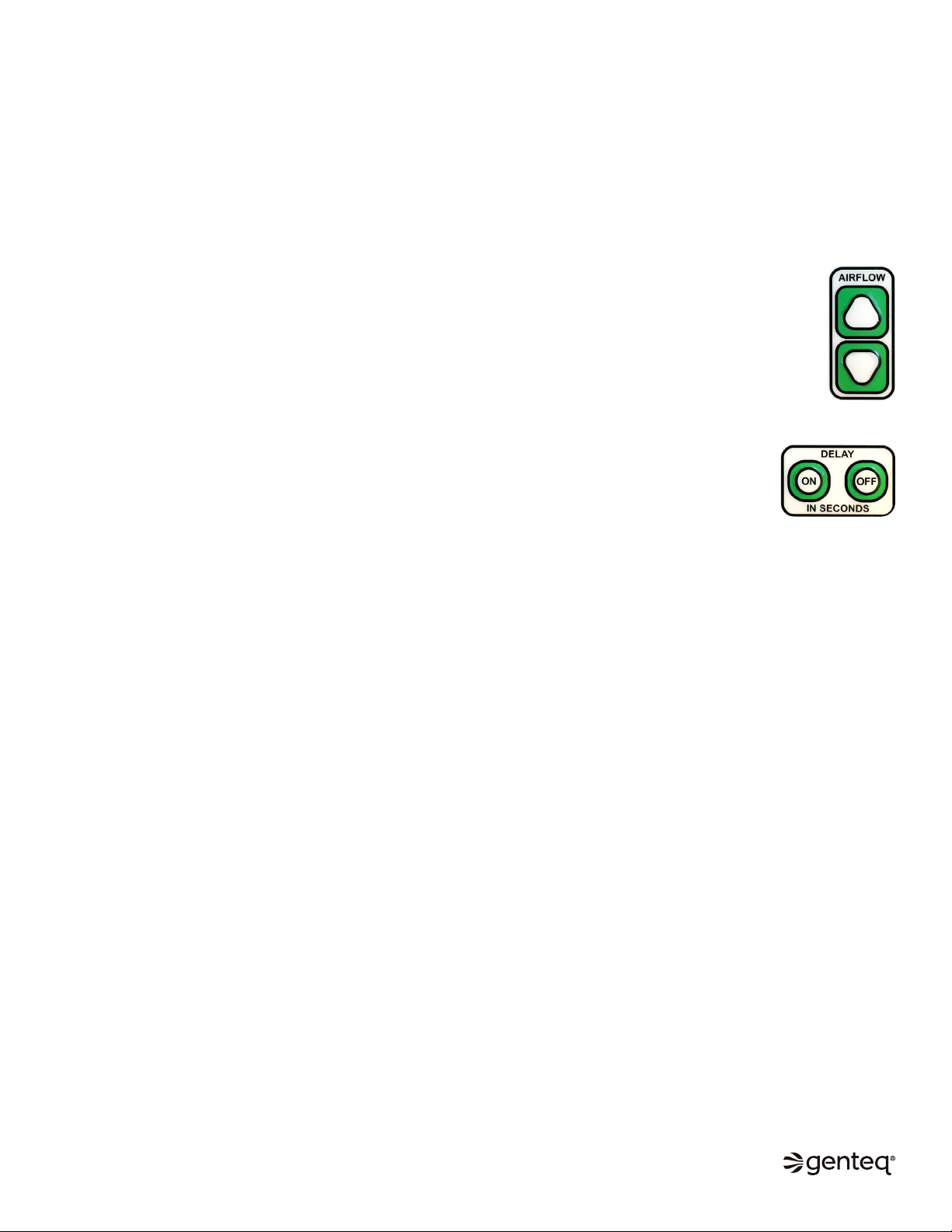

9. Airflow and Delay Adjustments

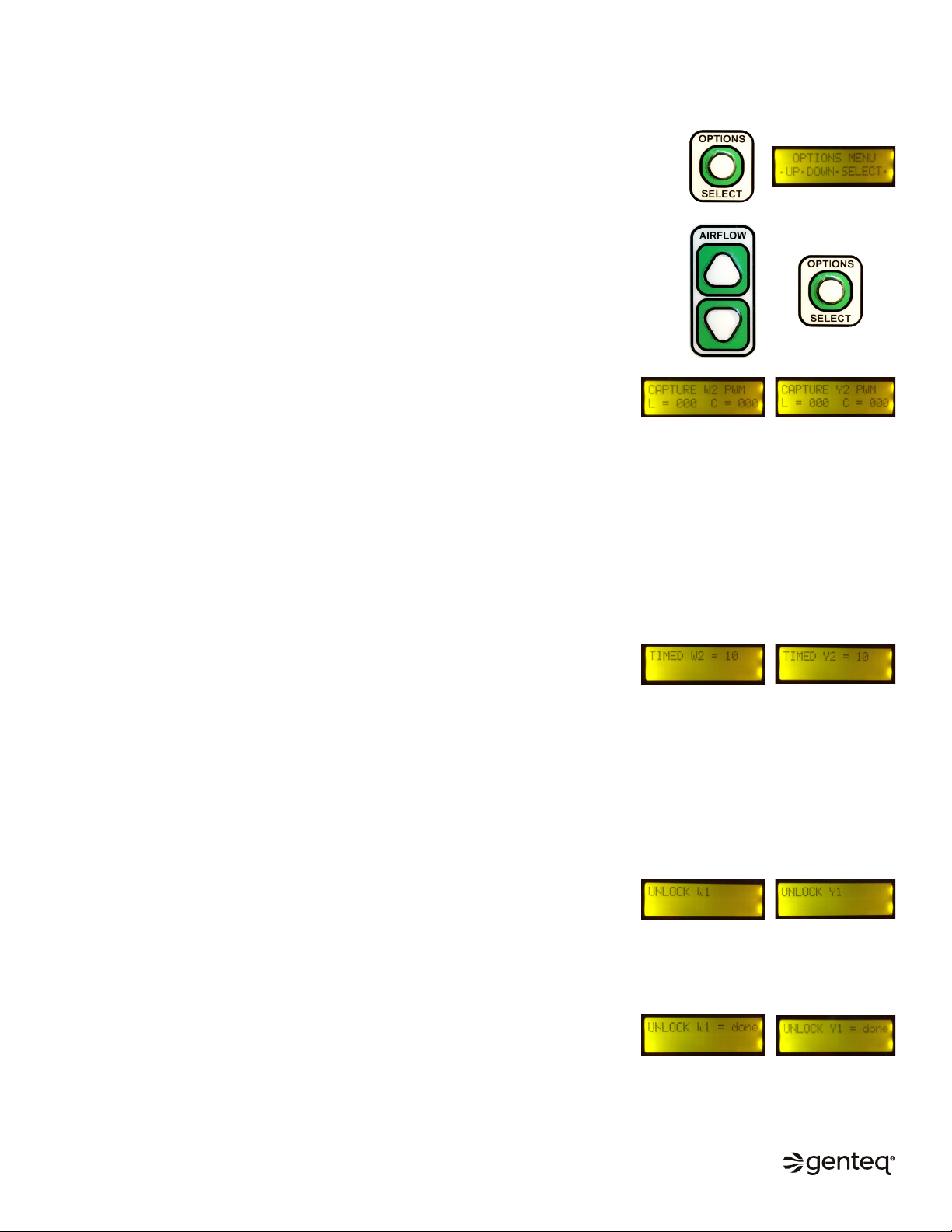

10-11. Options Menu

12. Evergreen VS User Interface (UI) Specifications

and Evergreen VS Motor Specifications

and Technical Support and Warranty

Page

Evergreen®VS User Interface

©2019, 2020 Regal Beloit Corporation, All Rights Reserved. MCIM20008E • Form# G0075E

INTRODUCTION

The Evergreen VS motor is designed to replace Genteq constant airflow (variable speed) ECM motors. This includes ECM indoor

blower motors made by Regal and its predecessor manufacturer and sold under other Regal and predecessor manufacturer brands.

The Evergreen VS motor is a constant airflow (variable speed) motor. It will operate in constant airflow mode when it is receiving digital

serial interface (DSI) and constant torque mode when it is receiving pulse width modulation (PWM) communication.