│4

Installation and Operation Manual RTC 12i - www.regulus.eu

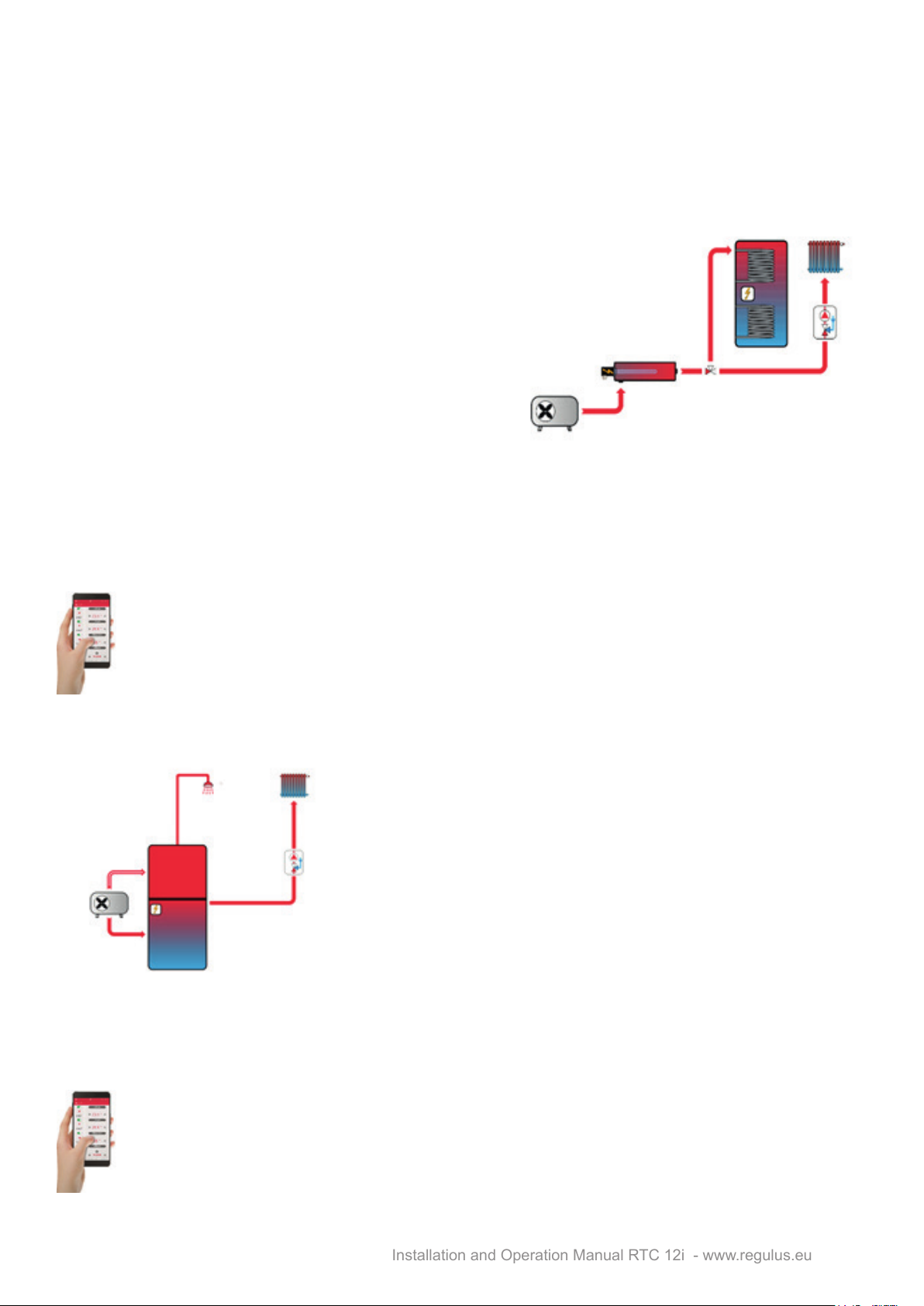

2. CONECTION VARIANTS

The heat pump is part of the energy system of the house. The correct design of a heat pump

depends on the energy needs of the building and should be carried out by a specialist. These

methods of connection are the most commonly used and serve as a basis for the project. If project

documentation exists, follow it.

2.1. Direct connection to a heating system, DHW heating in a hot water storage tank

The accessory is represented by an additional heat

source in the form of an in line heater (code 16166)

equipped with an electric heating element of up to 7.5

kW output and an optional indirect heated hot water

storage tank with a heat exchanger surface of min. 1.5

m2(e.g. Regulus RDC 300 – code 12759). The larger

the heat exchange area of the HW storage tank, the

faster the DHW heating will be and the heat pump will

be able to prepare hot water more economically, or it will

be able to heat DHW to a higher temperature.

Inthisdirectconnectiontotheheatingsystem,itisnecessarytokeeptheminimumowthrough

the heat pump at the level of min. 1335 l/h (0.37 l/s)withsucientheatsupplyfordefrosting,i.e.it

isnecessarytohaveapartoftheheatingsystemwithoutshut-ovalvesinstalled,e.g.thermostatic

valves. Approximately it is at least 5 radiators of normal size (e.g. 0.6 x 0.9 m), or at least 30 m2of

underoorheatingwithoutthepossibilitytobeshuto.

For system control, it is necessary to use an IR 14 RTC smart controller which controls the

entire heating and hot water system. It is equipped with an integrated web server permitting

control through a web browser, or via a smartphone or tablet with the IR Client application

(for Android and iOS).

2.2. Connection with a thermal store (combination with other renewable heat sources)

The accessories consist of a thermal store for heating only

(Regulus PS series), or a combination thermal store with

immersed DHW tank (Regulus DUO series), or a thermal store

with stainless steel tube DHW exchanger (Regulus HSK series).

TThis connection is suitable for combining a heat pump with

otherheatsources,suchasbiomassboilers,replaceinserts

and stoves with a hydronic heat exchanger, solar thermal

systems, solar photovoltaic systems, etc. The thermal store

shall be sized depending on the selected type and output of the

combined heat source, e.g. for combination with PV panels, the

total volume of the thermal store can be calculated using the

relationship 180 l / 1 kWp PV output. For example, for an array

of PV panels with a peak output of 5 kWp, the tank volume shall be 900 litres. Always have the size

and type of the thermal store determined by a specialist!

For system control, it is necessary to use an IR 14 RTC smart controller which controls the

entire heating and hot water system. It is equipped with an integrated web server permitting

control through a web browser, or via a smartphone or tablet with the IR Client application

(for Android and iOS).