3 │

GENERAL OPERATING INSTRUCTIONS

Readthismanualcarefullybeforeoperatingandkeepitataneasilyaccessibleplaceforfuture

reference.Ifneeded,themanualcanbedownloadedinpdfformatfromhttp://www.regulus.eu/,or

obtainedfromthecompanyandprinted.Ifyouhaveanydoubtsoruncertainties,pleasecontactyour

equipmentsupplierortechnicalsupportofRegulus.

SAFETY INSTRUCTIONS

- Thedesign,location,hydraulicandelectricalconnectionsmustbedesignedbyaspecialistin

accordancewiththeapplicableregulations.

- Theequipmenthasbeendesignedforheatingorcoolingofheatingwater.Otheruses,unless

specicallyauthorisedbythemanufacturer,isnotpermitted.Heatingwateroramixtureof

waterwithglycolorglycerinebasedantifreezemaybeusedasaheattransfermedium.

- Theheatpumpshallbesecurelyearthed.

- Respecttheoperatinglimitsoftheequipment.

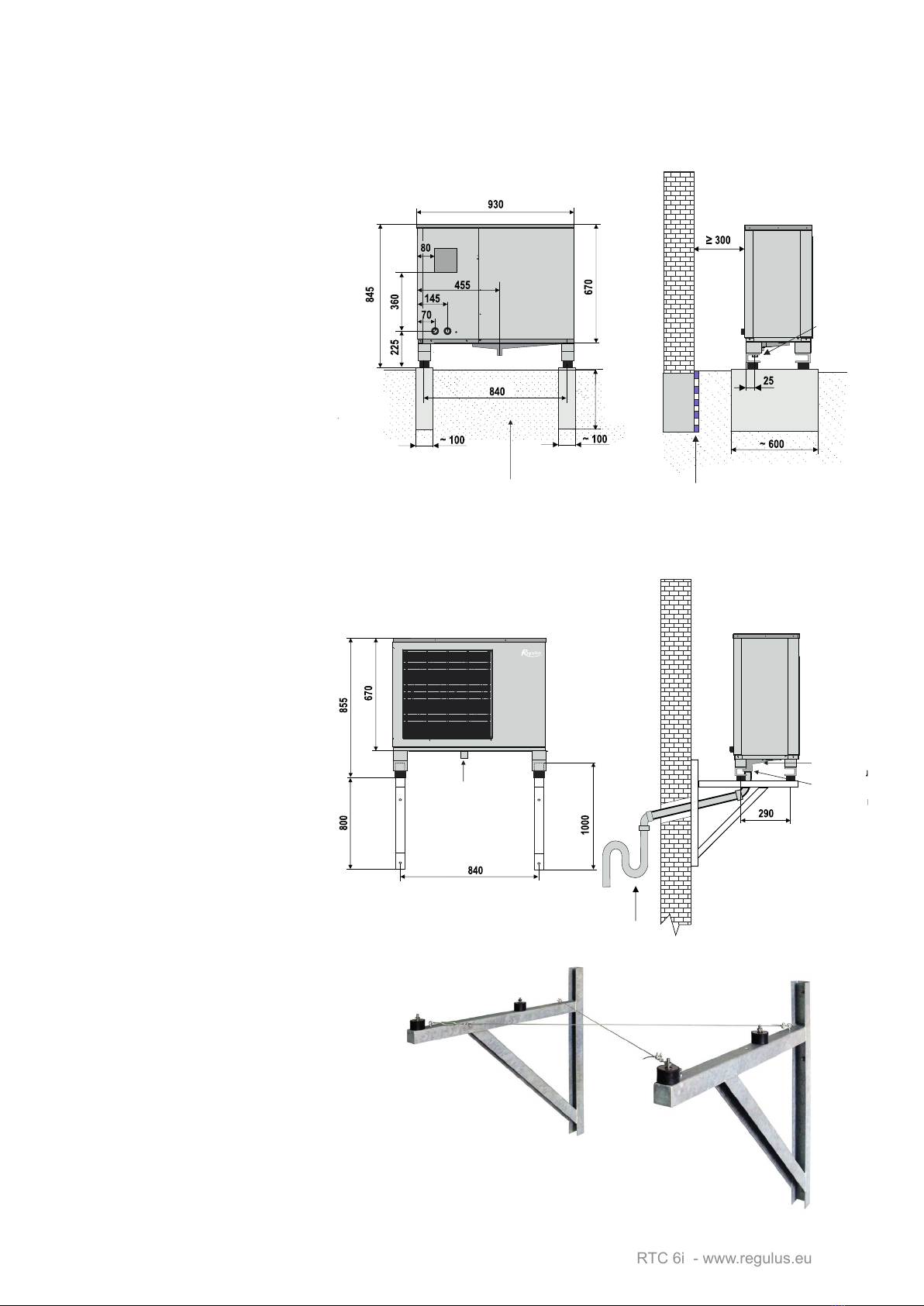

- The device is designed for outdoor installation. However, avoid installation in areas with

excessivedustorhumidity-suchasnearthehoodoutlet,etc.

- Theappliancemustbelocatedinanopenareawherethereisnoobstructiontotheowof

intakeorexhaustair.

- Theappliancemustnotbelocatednearopenamesorsourcesofignition.

- The equipment shall not be operated in an environment with explosive or chemically

aggressivegasesandsubstances.

- Allworkmustbecarriedoutbyprofessionalandqualiedsta.

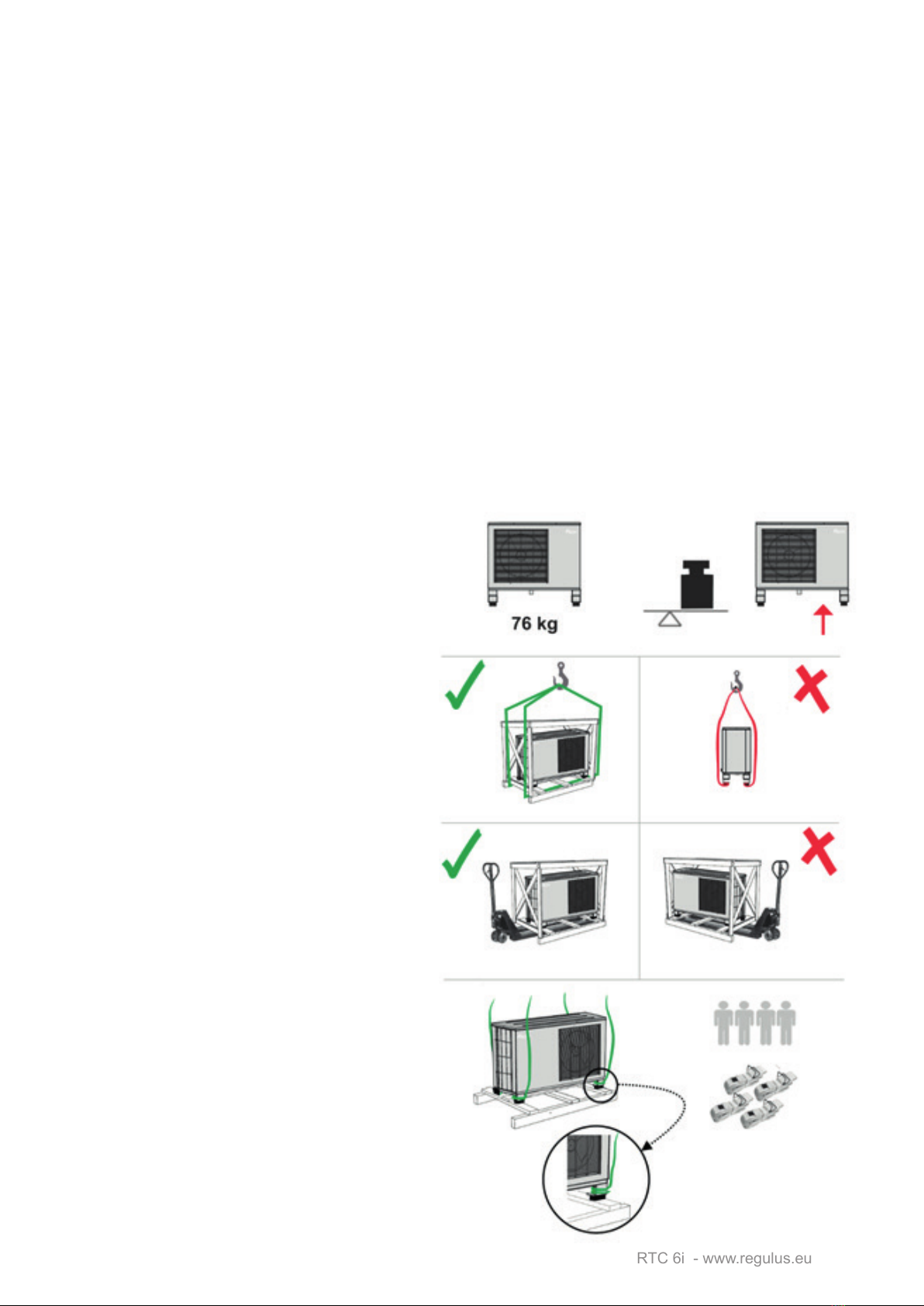

- Whenhandlingtheheatpumpwithacraneorotherliftingequipment,makesurethatthe

liftingdevices,lugs,etc.arenotdamaged.Neverstepundertheliftedload.

- Wearpersonalprotectiveequipment(goggles,gloves,etc.)

- Theequipmentcannotbeusedbychildrenandpersonswithreducedphysical,sensoryor

mentalabilities,orbyuntrainedpersonswholackthenecessaryknowledge.

- Ensurethattheheatpumpisswitchedobeforeanyintervention.

- Itisforbiddentocarryoutmaintenanceorcleaningwhentheequipmentislive.

- Itisforbiddentotouchtheequipmentbarefootorwithwetbodyparts.

- Donotspraywaterorotherliquidsontheequipment.

- Theequipmentcontainsrapidlyrotatingparts.Therefore,donotpushanyobjectsintothe

device.

- Theheatexchangerlamellasaresharpandcancauseinjury.

- Somepartsoftheequipment(e.g.thecompressoranditsoutletpipes)maybeveryhoteven

afterstoppingoperation.

- Itisforbiddentostandonthedevice,sitonitorplaceobjectsonit.

- Itisforbiddentopull,twistordisconnecttheelectricalcablesconnectedtotheequipment.

- Neverdisassemblecasing,covers,etc.thatareboltedtogether.

- Neverdisablesafetyfeaturesoftheequipment.

- Donotinterferewiththerefrigerantcircuitorelectricalwiring.Serviceworkmustonlybe

carriedoutbyanauthorisedserviceorganisation.

- Adamagedpowercablemayonlybereplacedbyanauthorizedserviceorganization.

- Itisforbiddentoleavethepackagingmaterialwithinreachofchildren,asthismayposea

dangertothem.

- It is forbidden to tamper with or replace any parts of the equipment without the express

permissionofthemanufacturer.

- Iftheseinstructionsarenotfollowedduringinstallation,operationandmaintenanceofthe

system,themanufacturerdoesnotfeelboundbythetermsofthewarranty.