PAGE 9

Reimers Electra Steam, Inc. 05/23/2022 RB‐30 Manual REV 7

working pressure is reached. The working pressure should

have been factory set to your specification. However, if you

wish to change the working pressure setting, proceed as

follows.

All pressure controls are factory preset and require no

adjustment. However, if a change of the operating steam

pressure is required, then proceed as

follows:

• Disconnect all power supplies from the boiler.

• Close the steam outlet valve

• Remove the cover from the pressure control enclosure.

• Turn the black knob of the operating pressure switch

clockwise to increase the pressure and counterclockwise

to decrease the pressure.

• Connect all power supplies to the boiler, open the

steam outlet valve, and install the pressure control

enclosure cover.

h.)

To shut off the boiler, turn the POWER switch on the boiler

control OFF

See Boiler Control Manual for detailed instructions.

The control provides four basic functions and two optional

functions. The following overview describes the functions.

Low water cutoff

Boiler high pressure cutoff

High water level feed shutoff

Automatic boiler refill

Automatic boiler blowoff (Optional)

Remote controlled boiler ON/OFF and boiler status

(Optional)

The low water cutoff function of the boiler control de

energizes the heating elements when the water level in the

boiler pressure vessel falls below the minimum acceptable

operating level. The control senses the water level in the

boiler pressure vessel through a probe, E3. When the tip of

the probe is in contact with water in the boiler, the boiler

operates normally. When the water level in the boiler falls

below the tip of the probe the control senses that water

level is low. The control will not deenergize the heating

elements when the probe loses contact with the boiler

water for short periods of time. But, when the probe loses

contact with the probe for a set time, the control de

energizes the heating elements and turns on the “LOW

WATER” boiler alarm light. Boiler operation can only be

resumed after determining why water level is low, restoring

normal water level in the boiler and pressing the “LOW

WATER” reset button [R]. After presseing the “LOW

WATER” reset button the alarm light “LOW WATER” turns

off, the lockout is reset and the heating elements are

energized.

The Low Water CutOff function short cycling timer can be

adjusted. See the Boiler Control Manual (Doc. #9101)

If the operating pressure control fails, the steam pressure in

the boiler can reach the value set on the high limit pressure

control. In that case, the high limit pressure control de

energizes the heating elements and locks them out. The

boiler alarm light “HIGH PRESSURE” comes on. After the

pressure control is replaced the HIGH PRESSURE alarm

light turns off.

When the high water level cutoff probe (E2) comes in

contact with boiler water, the boiler control turns off the

automatic refilling device, feed pump and/or solonoid valve.

At the same time the boiler controller deenergizes the

heating elements, closes the steam outletline through the

solenoid valve (SOL2) and displays a flashing “2” on the

LED display. As soon as the probe E2 looses contact with

the boiler water the boiler controller resumes normal boiler

operation automatically. (The boiler controller can be set to

require that the “EKey be pressed to resume boiler

operation. See the Boiler Control Manual for instructions.)

When the POWER switch is turned on and the water level

probe (E1) is in contact with the boiler water, the boiler

control keeps the boiler water feed pump and/or solenoid

valve deenergized. When the water level probe (E1) loses

contact with the boiler water, the boiler control energizes

the boiler feed pump and/or the solenoid valve after a set

ON delay time. When the water level probe makes contact

with the boiler water, the boiler controller deenergizes the

boiler water feed pump and/or solenoid valve after a set re

fill OFF delay time.

The ON and OFF delay time can be adjusted. See the

boiler control manual for instructions.

If the feedwater pump and/or solenoid valve remains on for

longer than the ON delay time the boiler control de

energizes the feed water pump and/or solenoid valve and

displays a flashing “0” on the control LED display. The “E”

key must be pressed to start a new refilling attempt.

See Boiler Control Manual for instructions.

See Boiler Control Manual for instrucitons.

The following are definitions for all boiler monitor

indications. See the control manual for details including

adjusting all parameters.

Flashing “0”: Boiler feed pump and/or solenoid remained

energized longer than the set time. Boiler feed pump and/

or solenoid are deenergized. Press “E” key to reset alarm

and start a new refilling cycle.

Flashing “1”: Following a blowdown cycle, the automatic

refill device did not stay on for the set time. Press”E” key to

reset the alarm.

Flashing “2”: The high water level probe (E2) has come in

to contact with boiler water. The feed pump and or solenoid

is deenergized and the heating elements are de

energized. As soon as the probe (E2) loses contact with

WARNING

Stand clear of scalding water or steam. Disconnect the

boiler from all power supplies.

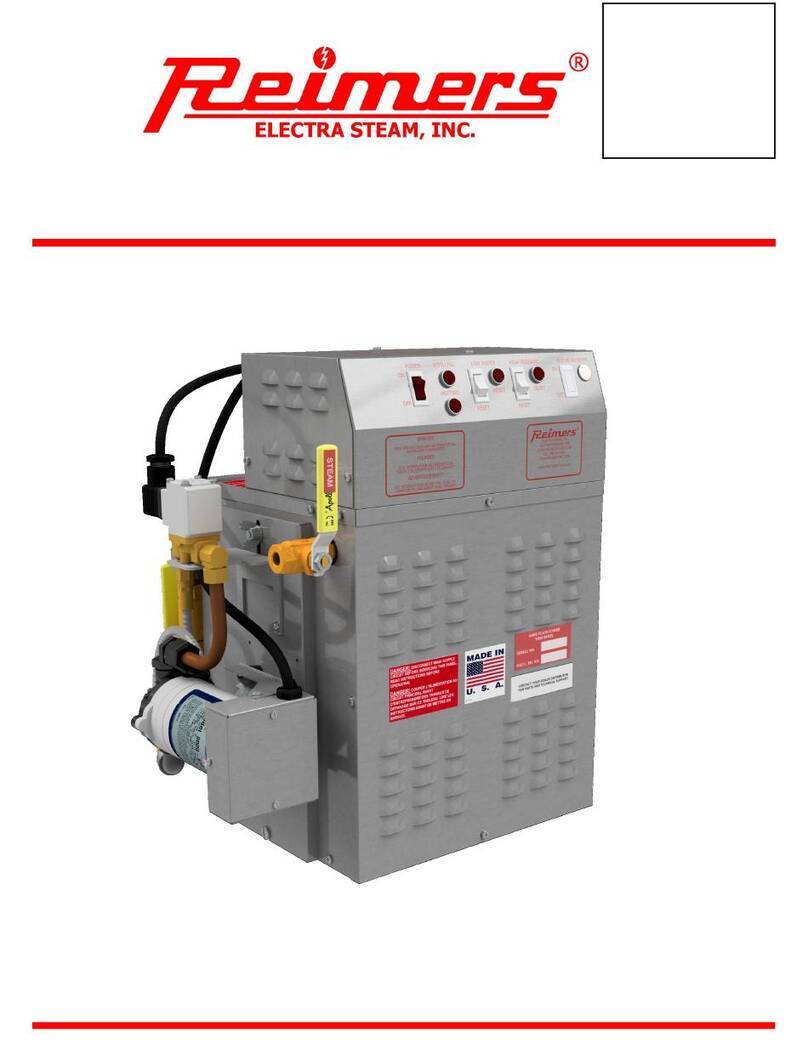

High Pressure Safety

Limit Pressure Switch:

DO NOT ADJUST!

Operating Pressure

Switch

Pressure Triggered Boiler

Blowoff Pressure Switch

when OPT1016 is

installed

2.2 Control Functions

2.2.1 Low Water Cutoff Function

2.2.2 High Pressure Cutoff Function

2.2.3 High Water Level Feed Shutoff

2.2.4 Automatic Boiler Refill

2.2.5 Automatic Boiler Blowoff (Optional)

2.2.6 Remote Controlled Boiler ON/OFF and Boiler

Status (Optional)

2.3 Boiler Monitor Definitions

Figure 09