Table of contents

0.1

1. Safety

1.1 General ..........................................................................................................1.1

1.2 Description of symbols and pictograms .........................................................1.2

1.3 Start-up ..........................................................................................................1.2

1.4 Servicing ........................................................................................................1.3

1.5 Cleaning.........................................................................................................1.3

1.6 Electrical safety..............................................................................................1.4

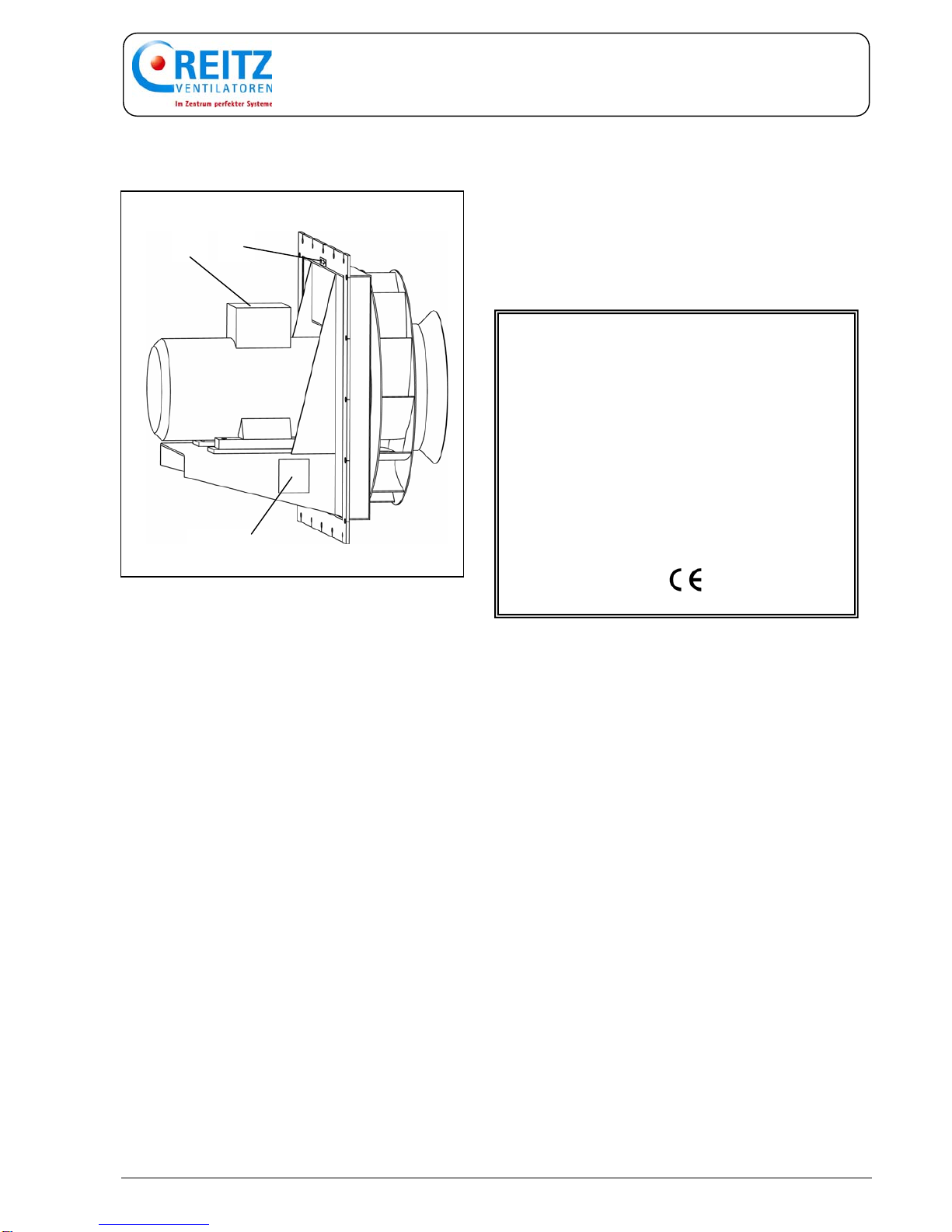

1.7 Description of labels and plates.....................................................................1.5

2. Application

2.1 Design conditions...........................................................................................2.1

2.2 Warranty.........................................................................................................2.1

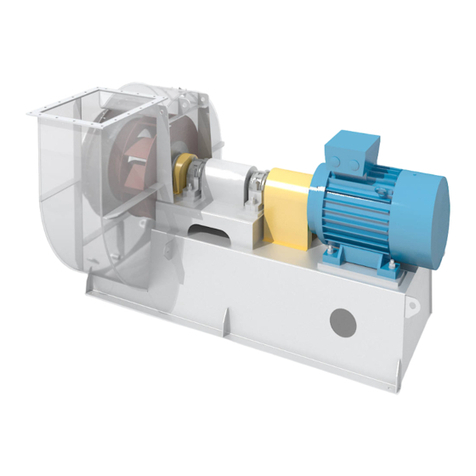

3. Description

3.1 Design............................................................................................................3.1

3.2 Options...........................................................................................................3.1

4. Assembly and installation

4.1 Scope of supplies...........................................................................................4.1

4.2 Transport........................................................................................................4.1

4.3.1 Storage...........................................................................................................4.2

4.3.2 Stand-by operation.........................................................................................4.2

4.4 Installation site ...............................................................................................4.2

4.5 Electrical connection......................................................................................4.3

4.6 Inspection.......................................................................................................4.4

4.6.1 Mechanical testing .........................................................................................4.4

4.6.2 Electrical testing.............................................................................................4.4

5. Start-up

5.1 Putting the fan into operation.........................................................................5.1

5.2 Putting the fan out of operation......................................................................5.1

5.3 Transient behaviour .......................................................................................5.2

5.3.1 General ..........................................................................................................5.2

5.3.2 Direct starting.................................................................................................5.2

5.3.3 Star-delta starting...........................................................................................5.2

6. Care and maintenance

6.1 Lubrication......................................................................................................6.1

6.1.1 Drive motor.....................................................................................................6.1

6.1.2 Shaft seal.......................................................................................................6.1

6.2 Troubleshooting .............................................................................................6.2

6.3 Queries/Sending-out of fitter ..........................................................................6.4

Technical data see data sheet!