If an empty cartridge is replaced by a full one containing

a different type of glue, nozzle and adapter must be

cleaned. For this, please read „Cleaning the

Nozzle/Nozzle Adapter after working with PUR Hot-Melt

Glue Cartridges“ in chapter „Cleaning and Maintenance“.

(Page 8).

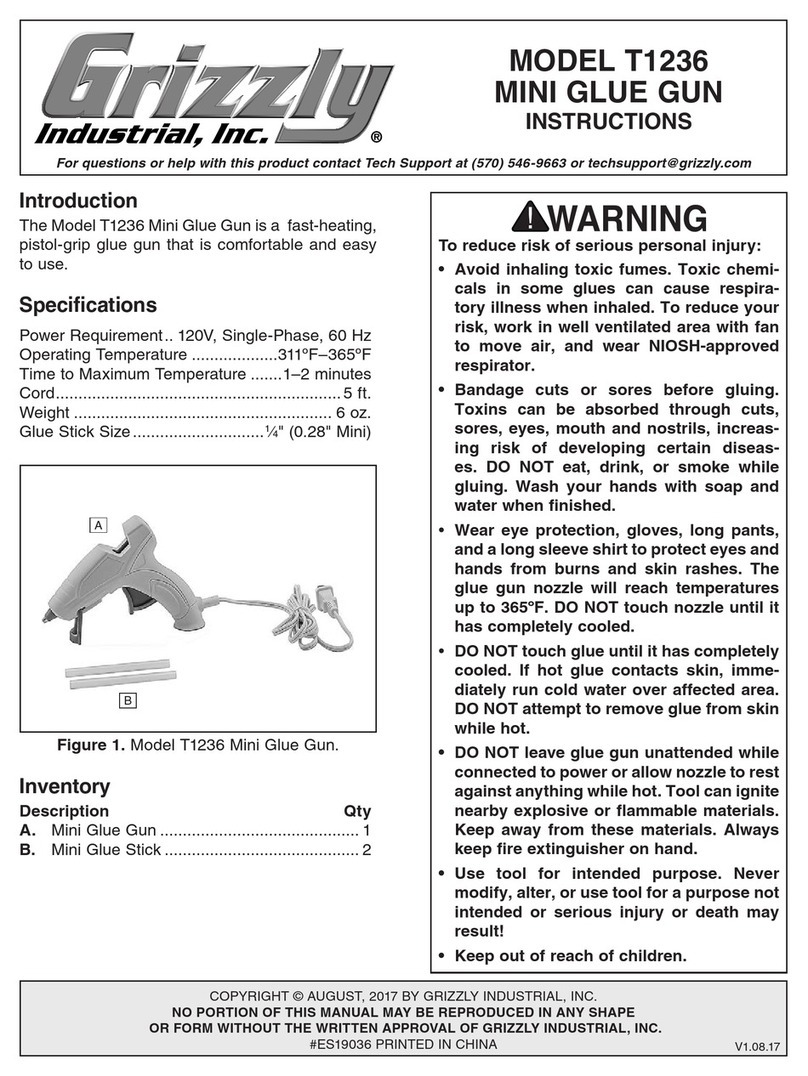

Wear protective gloves and safety

goggles whenever you work with the

applicator.

Never start working before fitting a nozzle

first.

Never direct the glue jet towards people!

If hot glue comes into contact with the

skin, cool it with cold water immediately.

Do not try to remove the hot-melt from the

skin first. If necessary, consult a doctor. If

hot glue comes into contact with the eyes,

immediately cool them under running

water for about 15 minutes and consult

your doctor at once.

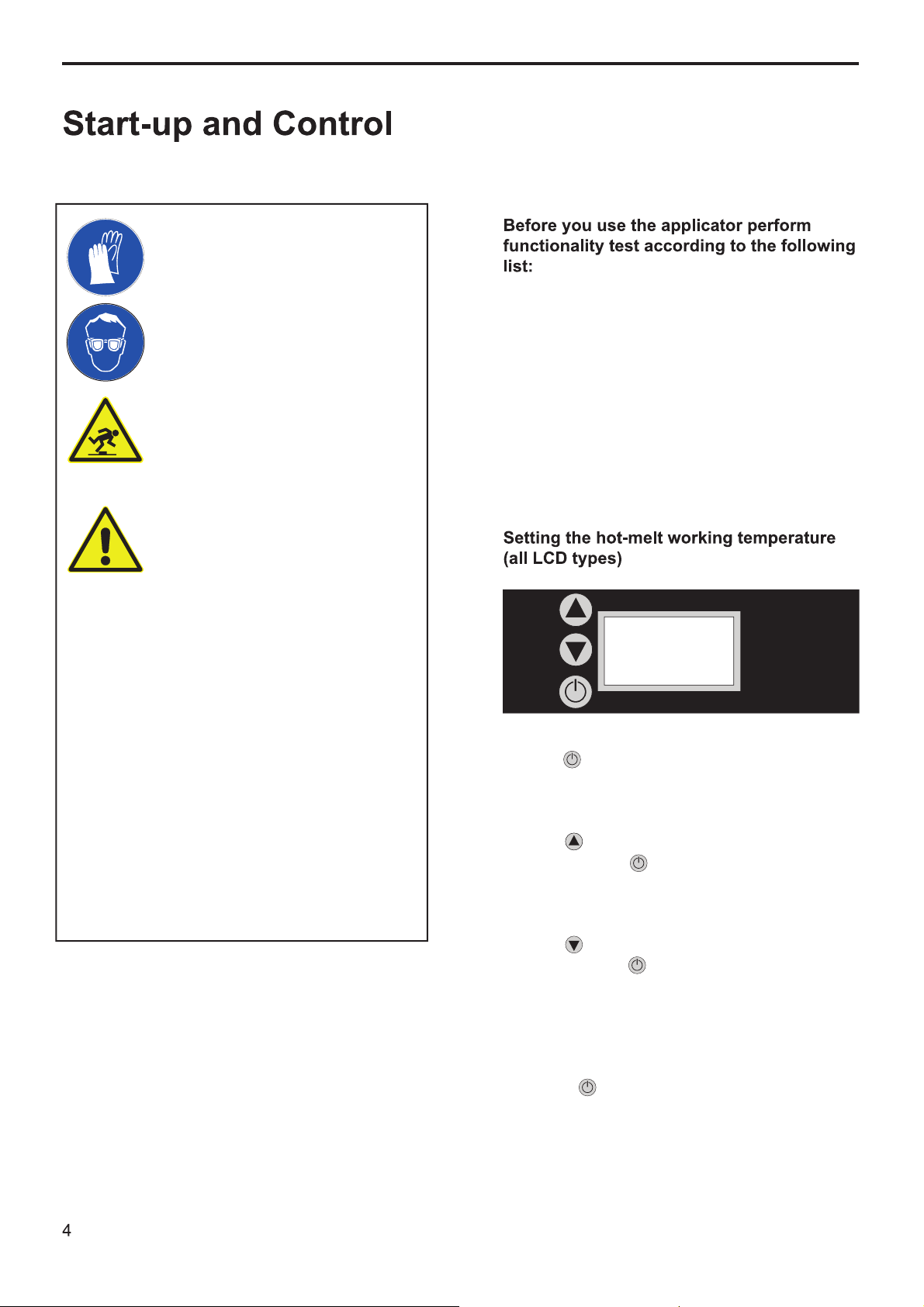

Make yourself familiar with the instrument first. Apply

a little glue in varying forms on a piece of paper or

cardboard. For example, lines, small or big spray or glue

points. Try to find out the correct quantity and the ideal

pattern by adjusting the air and glue quantities by means

of the pressure regulator at the stand (TR 60 / 80),

always observing the correct working temperatures of the

specific hot-melt. This temperature is indicated in the

technical datasheet of the respective hot-melt.

The supplied hot-spray systems TR 60 / 80 are designed

for spraying pressure-sensitive adhesives and PUR hot-

melt glues. Please check, whether the complete spray

head (drawing Detail Front) is fitted to the applicator; if

this is not the case, attach it. The spray cap (# 3088)

must be screwed on slightly by hand; never use any

tools. You are advised to wear protective gloves. Do not

turn off the spray air as long as a spray cap is fitted to

the glue gun.

For this, the complete spray head must be exchanged.

Please read the following chapter „Replacement of

Nozzles“ (see below).

The correct nozzle assembly is shown in the

attached drawing „Nozzle Assembly for Dot and Line

Application“. To apply dots and lines, the pressure

regulator for the spray air on the stand must be set to

zero pressure.

Warning: risk of burns!

If hot glue comes into contact with the

skin, cool it with cold water immediately.

Do not try to remove the hot-melt from the

skin first. If necessary, consult a doctor. If

hot glue comes into contact with the eyes,

immediately cool them under running

water for about 15 minutes and consult

your doctor at once.

For your own safety wear protective

gloves and safety goggles whenever you

work with the applicator.

Unplug the connecting cable before

replacing nozzles!

Only replace nozzles when the applicator is warm

(applicator temperature 60-80 °C) and the glue tank is

empty. Replacing a nozzle when the applicator is cold,

may damage the applicator. If the nozzle is replaced

when the applicator is too hot, liquid glue may leak out.

For the melting range and the melting point of the used

glue, please see the technical datasheet of the

respective glue.

Please unplug the device after working with it. Do not

unplug it by pulling the cord, pull the plug instead.