The equipment must only be used by trained, instructed

and authorized persons. These persons must have read

the operating instructions and be able to work

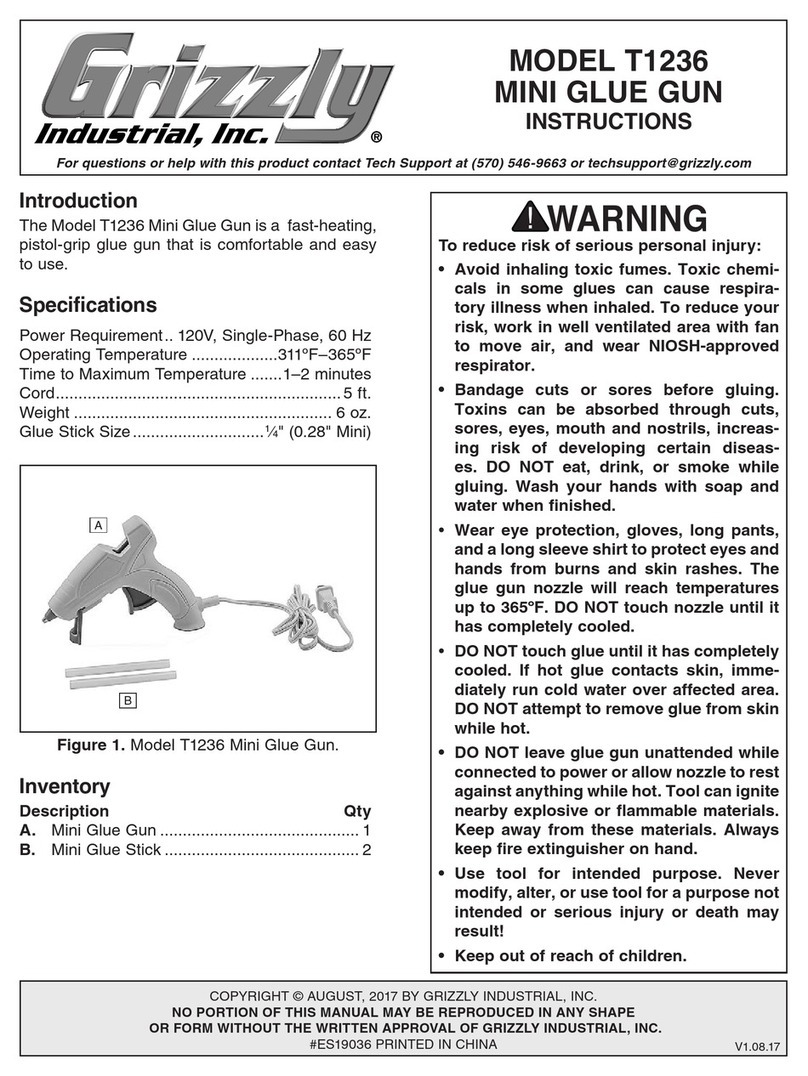

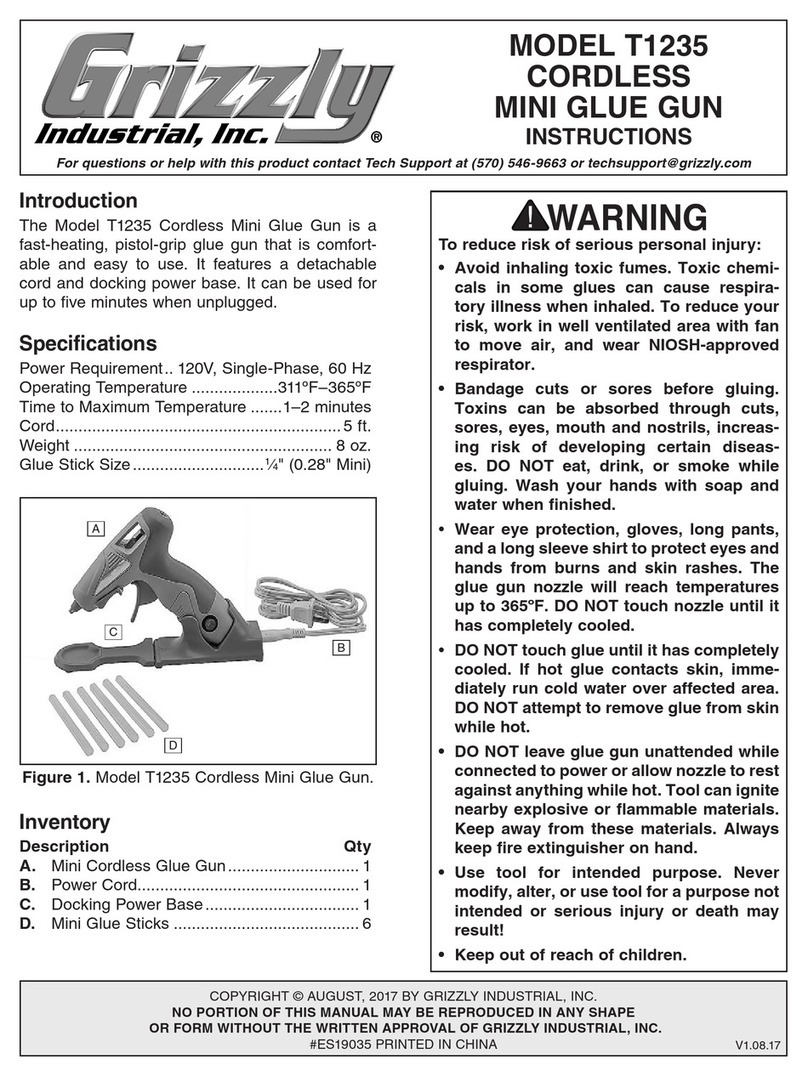

accordingly. Before using the applicator, check it for

visible damage and make sure that it is only used when

in proper and safe condition. Notify detected defects to

the appropriate person immediately.

Only fill the tank up to 1,5 cm (~0.6 inch) under the rim.

Never exceed the operating temperature of the hot melt.

This temperature is indicated in the technical datasheet

of the hot melt. Overheating may lead to decomposition

which may affect the health of the user as well as the

operability of the applicator.

The heating temperature should be lowered during longer

work breaks to preserve the hotmelt. Ongoing heating

makes the hotmelt coke and may also change its'

characteristics.

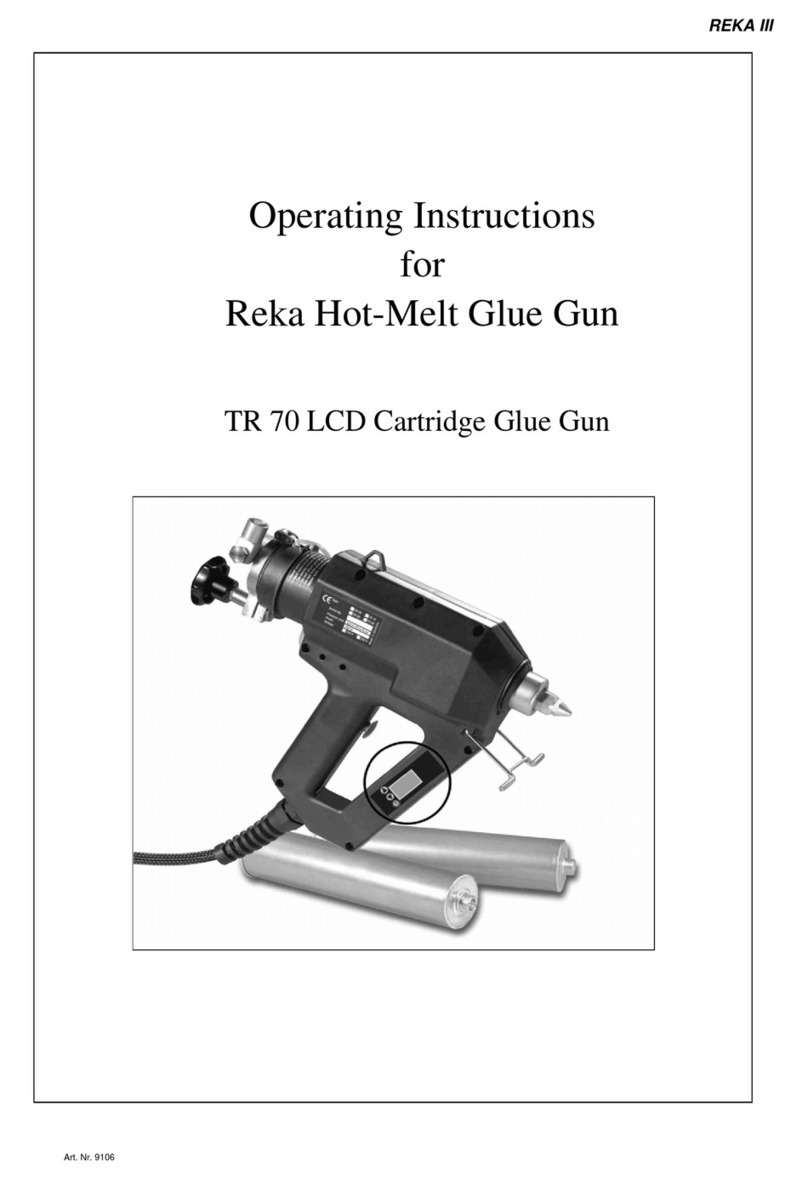

Once the applicator has warmed up, nozzle and lid are

very hot.

Never start working before fitting a nozzle first.

Only replace nozzle when applicator is warmed up.

Unplug the connecting cable, before replacing a nozzle.

Warning: risk of burns! When a nozzle is replaced, liquid

glue might leak out.

Never bring the hot nozzle into contact with the cable.

Never direct the glue jet towards people.

Wear protective gloves and safety

goggles whenever you work with the

applicator.

Avoid accidents by stumbling – Lay all

cables, hoses and conducts so that they

will not cause any risk of stumbling. For

this, install cable ducts and bridges.

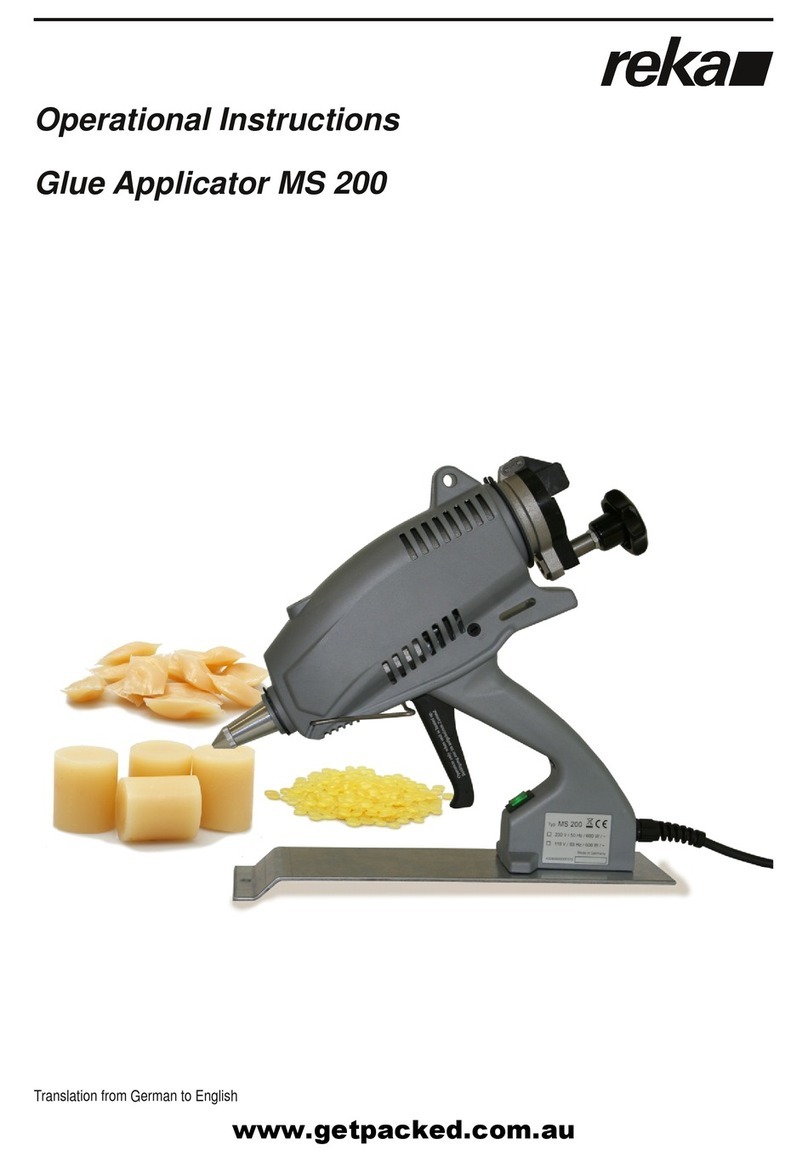

MS 200 only: The device uses a super

magnet. Keep magnets away from all

items and objects which can be damaged

by strong magnetic fields.

Magnets can influence the functionality of

pacemakers.

If hot glue comes into contact with the

skin, cool it with cold water immediately.

Do not try to remove the hot-melt from the

skin first. If necessary, consult a doctor. If

hot glue comes into contact with the eyes,

immediately cool them under running

water for about 15 minutes and consult

your doctor at once.

Always deposit the glue applicator on the wire stand or

the respective plate destined for this purpose.

Do not lay the applicator on its side.

Do not hold nozzle top upward for too long. If you do hold

it upward for too long, hot-melt will reach the lid and

might flow out when the applicator is opened the next

time.

Do not carry out overhead work.

Stop using the equipment immediately, if the casing is

damaged due to shock, breakage or heavy wear.

Never clean the applicator with solvents, benzine,

benzene, toluene, acetone, turpentine or paraffin. Risk of

explosion!