5

SPECIFICATIONS

HYDRAULIC SYSTEM ................ Open or Closed Center

MOTOR .........................................................Gear Driven

OPERATING PRESSURE ....................... 1,400-2,000 psi

FLOW RANGE .................................................... 4-7 gpm

OPTIMUM OPERATING PRESSURE ..1,800 psi @ 6 gpm

OUTPUT - FAST ADVANCE MODE ............. 305 in. 3/min

OUTPUT - HIGH PRESSURE MODE ............ 30 in. 3/min

RELIEF VALVE SETTING ................... 4,000 - 10,000 psi

HIGH PRESSURE PORT ............................... 3/8 in. NPT

INLET PORT................................................... 3/8 in. NPT

RETURN PORT .............................................. 3/8 in. NPT

SPECIAL FEATURES

HIGH PRESSURE COUPLER ............................Included

ADJUSTABLE MOUNTING BRACKETS .........Included

UL-BCA - MOUNTING BUCKET ......................Optional

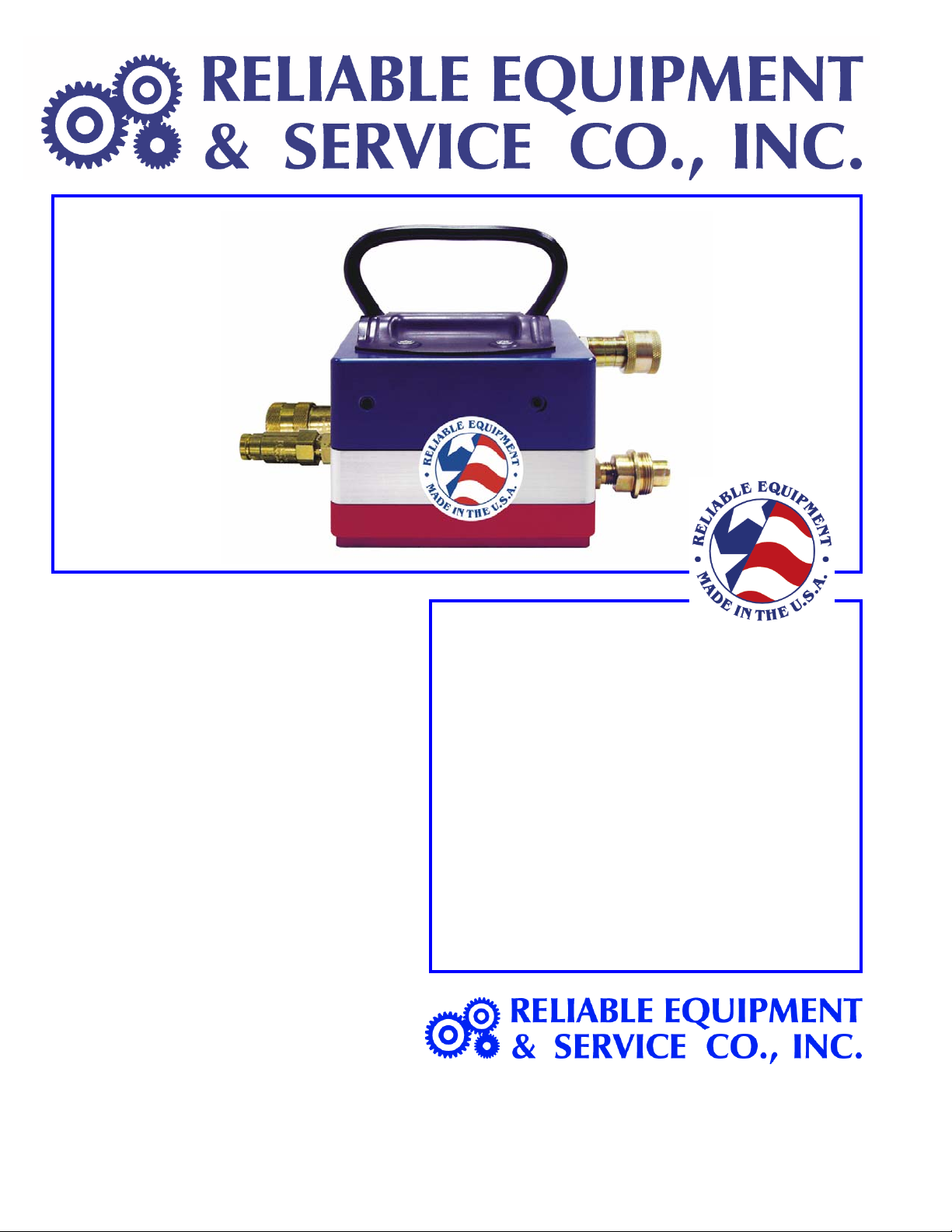

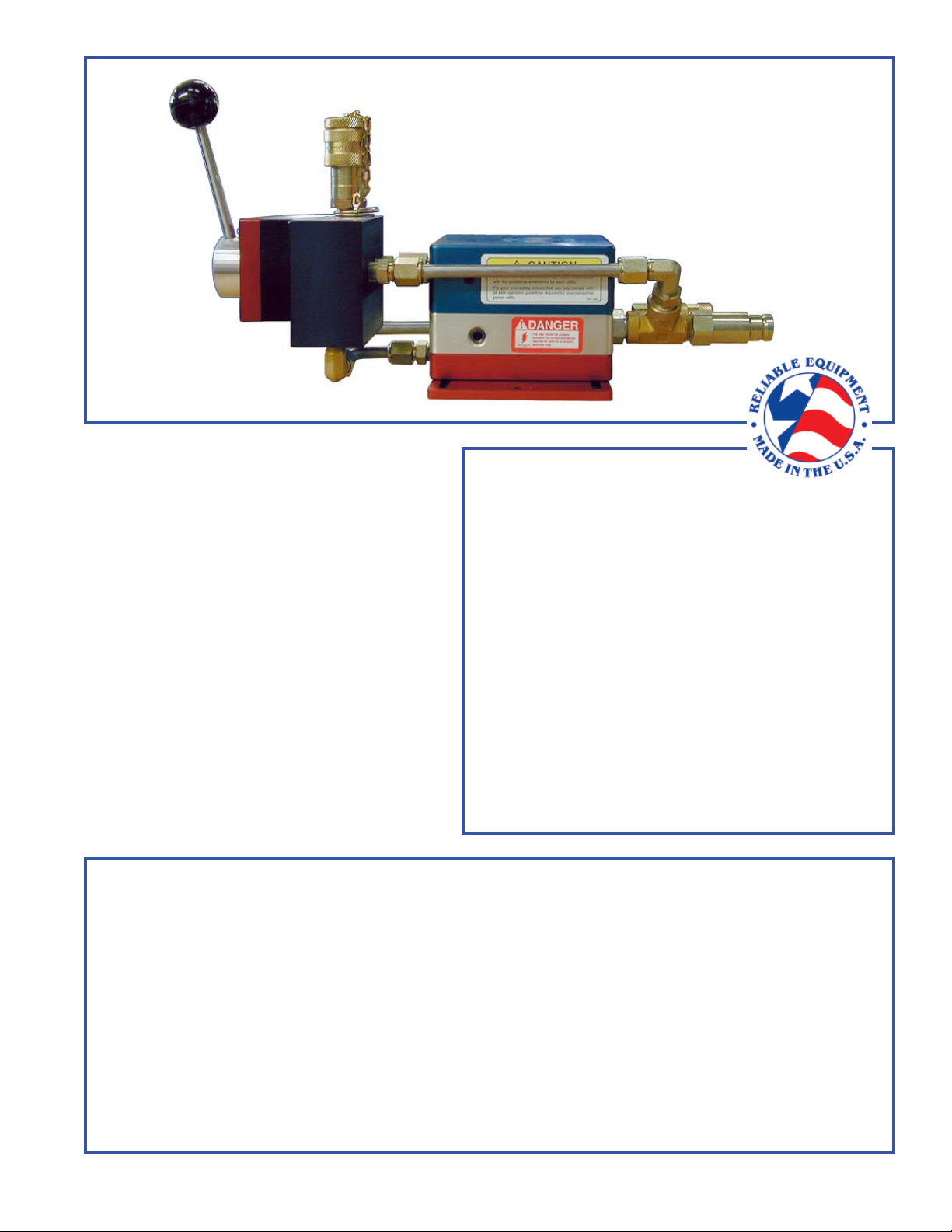

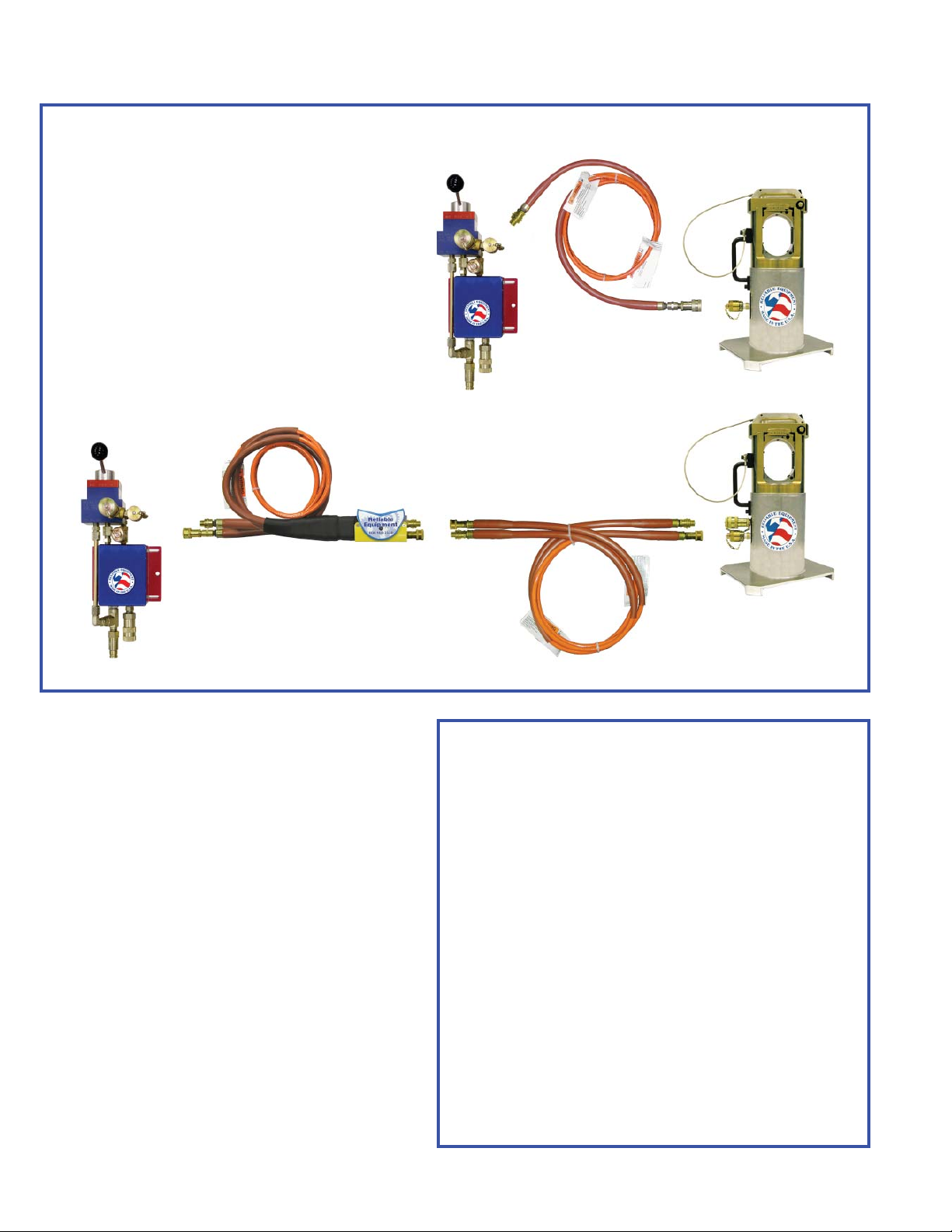

REL-10-I-SA

SINGLE ACTING 10,000

PSI

The REL-10-I-SA provides quick advance

and retract for high pressure (10,000 psi) single

acting spring return tools, without the need for

additional H/P hoses, couplers or an in-line

control valve.

This system combines the power of a high

pressure intensifi er with the simplicity of a fi xed

position three way control valve.

The REL-10-I intensifier will increase line

pressure to a maximum of 10,000 psi and is

fully compatible with all high pressure hydraulic

equipment.

The PVA-00L3 single-acting control valve,

provides 3-way control (Advance, Neutral,

Retract) direct from the high pressure source.

Together this intensifi er/valve package allows

return oil to bypass the intensifi er and return

directly to the tank (return) line, increasing tool

speed and performance.

SPECIFICATIONS - HYD. POWER SOURCE

200 PSI back pressure is the maximum agreed standard for the Hydraulic Tool Manufacturers Association (HTMA).

1. Maximum fluid temperature must not exceed 140OF (60OC) at the maximum expected

ambient temperature. A sufficient oil cooling capacity is needed to limit the fluid temperature.

2. Maximum fl ow must not exceed 8 GPM. Install a fl ow meter in the return line to test the rate of fl ow

in the system before working the tool.

3. Pressure relief valve must not exceed 2,200 PSI. The pressure relief valve must be located in the

supply circuit between the pump and the intensifi er to limit excessive pressure to the tool.

Any hydraulic power source used with this unit must meet the requirements above.

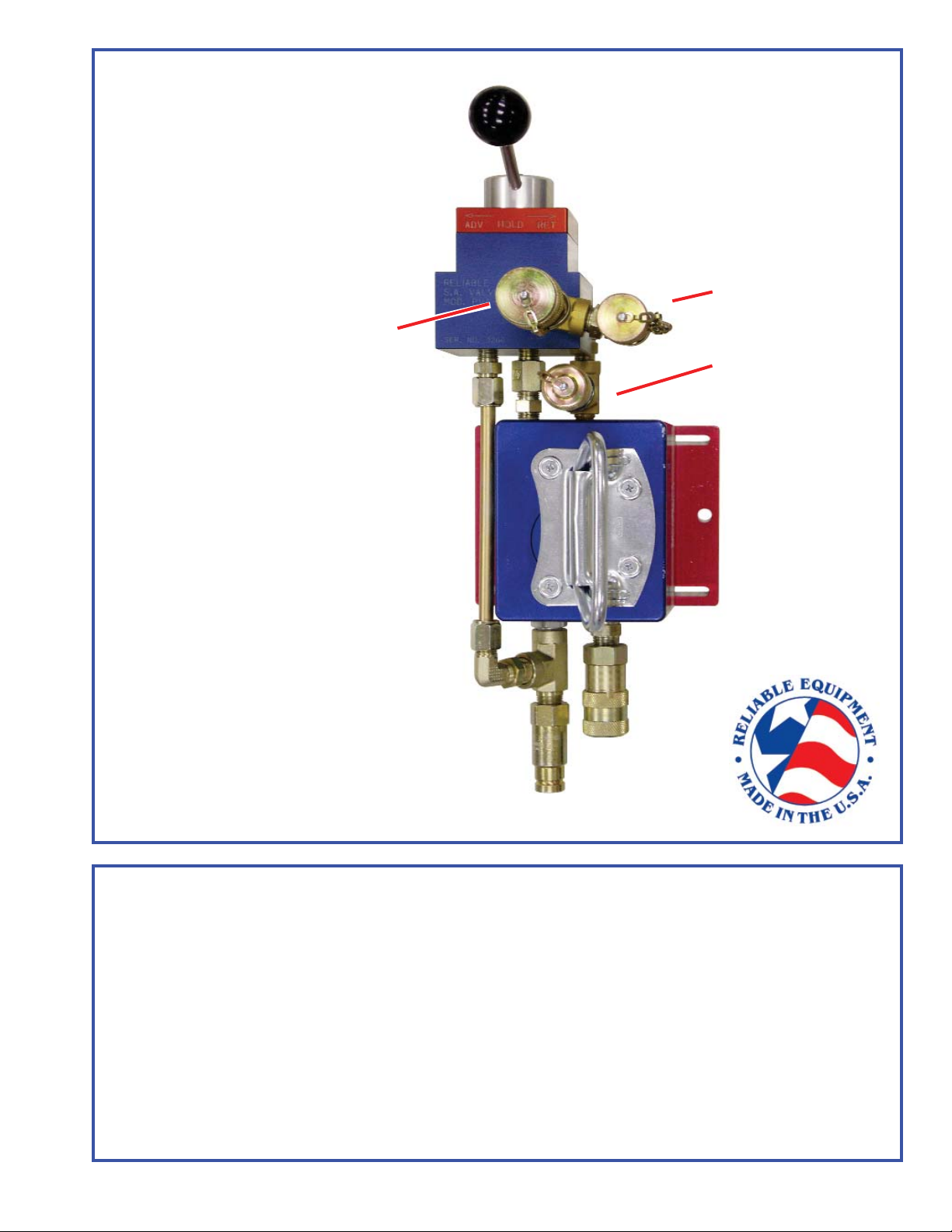

REL-10-I

INTENSIFIER

PVA-00L3

3-WAY VALVE