Hi-Force TWM1000 Series User manual

INSTRUCTION MANUAL:

Model Series: TWM1000, TWM1500, TWM2000

Hi-Force Limited –Prospect Way –Daventry –Northants NN11 8PL –United Kingdom

Tel: +44(0) 1327 301000: Fax: +44(0) 1327 706555: Website: www.hi-force.com

TWM –High Capacity Aluminium Manual

Torque Wrench Range

Important Note:

Before putting this Hand Torque Wrench into

operation, please validate the certificate

(provided along with this tool) by completing

the section “date of first issue, sign and stamp.”

1.0 Inspection of the product upon receipt:

On receipt of the product, visually inspect the

item for any evidence of shipping damage.

Please note shipping damage is not covered

by warranty. If shipping damage is found notify

the carrier immediately and refrain from putting

the product into service. The carrier is

responsible for repair and replacement costs

resulting from damage in transit shipment.

2.0 Safety Precautions:

Read and follow all the instructions and safety

warnings carefully prior to use of the equipment.

Failure to do so could result in equipment

damage or failure of the equipment or personal

injury. Hi-Force will not be held responsible for

any damage to the equipment or personal

injury resulting from unsafe use of the product,

lack of maintenance or incorrect operation. If in

doubt on the correct usage of any Hi-Force

equipment, contact your nearest Hi-Force office

or distributor. If the operator has not been

trained on high pressure hydraulic equipment

and its safe use consult your local Hi-Force sales

office who can offer you training courses for

operators.

All operators should ensure that all necessary

personal protective equipment as specified by

their employer is worn when operating any

hydraulic equipment. Safety shoes, safety

glasses/ visor and protective gloves should be

worn at all times. All relevant risk assessments

should be completed prior to use of the

equipment.

Available Models:

Safety

Read this entire manual before operating the

torque wrench.

Failure to observe the following warnings could

result in serious bodily injury.

These instructions are part of the torque

wrench. They must be kept in a safe place for

later use and be passed along with the torque

wrench if it is sold, loaned, or otherwise

transferred.

The torque wrench should be used only by

TRAINED PERSONNEL who have been taught

how to safely use and handle the torque

wrench. Using the torque wrench without

training may result in SERIOUS INJURIES or

DEATH.

Employers purchasing this torque wrench MUST

ensure employees using the torque wrench

have read and understood these Operating

Instructions prior to using the torque wrench.

The Operating Instructions MUST be available to

the employees for reference at all times.

OVERLOAD HAZARD

The torque wrench can be overloaded during

use and break causing SERIOUS INJURY or

DEATH.

ALWAYS use only original accessory parts.

Accessory parts not approved by the

manufacturer may cause the torque wrench to

overload or fail.

ALWAYS inspect the torque wrench for

damage BEFORE use.

NEVER use a damaged torque wrench.

NEVER use the torque wrench if it has been

dropped, used to strike other objects, or if

anything has fallen on it.

INSTRUCTION MANUAL:

Model Series: TWM1000, TWM1500, TWM2000

Hi-Force Limited –Prospect Way –Daventry –Northants NN11 8PL –United Kingdom

Tel: +44(0) 1327 301000: Fax: +44(0) 1327 706555: Website: www.hi-force.com

INACCURATE TORQUE SETTINGS

An out-of-calibration torque wrench can cause

part or tool breakage and inaccurate torque

settings, resulting in SERIOUS INJURY or DEATH.

ALWAYS use only tested and calibrated torque

wrenches, ALWAYS use an approved torque

tester.

EXPLOSION AND FIRE HAZARD

Sparks can occur when using the torque

wrench, which can cause an explosion or a fire

and can cause SERIOUS INJURY or DEATH.

NEVER use the torque wrench in areas where

sparks can cause explosions or fires.

TEMPERATURE WARNINGS

When the torque wrench is exposed to

temperatures below 64°F and above 82°F, or

high levels of humidity (above 90%), it may

cause inaccurate torque settings.

ALWAYS check the torque wrench with an

approved torque tester before and during use

in these conditions.

The torque wrench is designed to tighten bolts

and nuts to a specific tightening or torque

specification.

DO NOT use the torque wrench for

any other purpose.

MISUSE can lead to SERIOUS INJURY or

DEATH.

DO NOT allow children to use the

torque wrench.

NEVER use non-standard extension end fittings

with a torque wrench with a built-in ratchet or

ratchet adaptor.

Take the following safety precautions to

prevent injuries and damage caused by

improper handling and unsafe use of the

torque wrench:

NEVER use the torque wrench for

loosening bolts and nuts.

NEVER use a damaged torque

wrench.

NEVER modify any parts of the torque

wrench or accessory parts.

NEVER use a torque wrench or an

accessory part that has been

modified.

ALWAYS inspect the torque wrench,

especially the square drive and the

housing, for damage before use.

ALWAYS release the torque wrench

IMMEDIATELY after you hear the click

indicating that you have reached the

desired torque setting.

ALWAYS use the torque wrench ONLY

in the direction of rotation indicated

on the housing.

ALWAYS use only original accessory

parts or parts approved by the

manufacturer.

ALWAYS reset the torque wrench to

the lowest setting after each use or at

the end of the workday.

ALWAYS hold the torque wrench in the

center of the handle when using the

tool accessories.

ALWAYS transport the torque wrench

in the shockproof packaging material.

Product Description

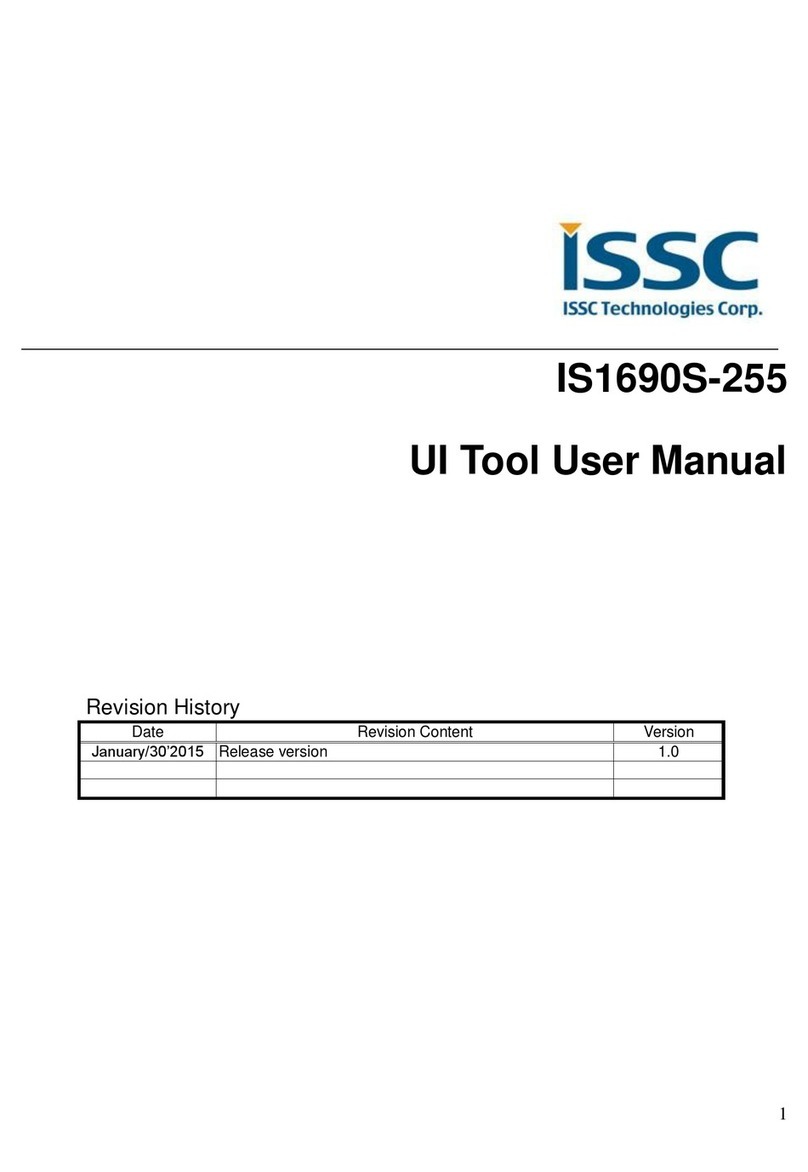

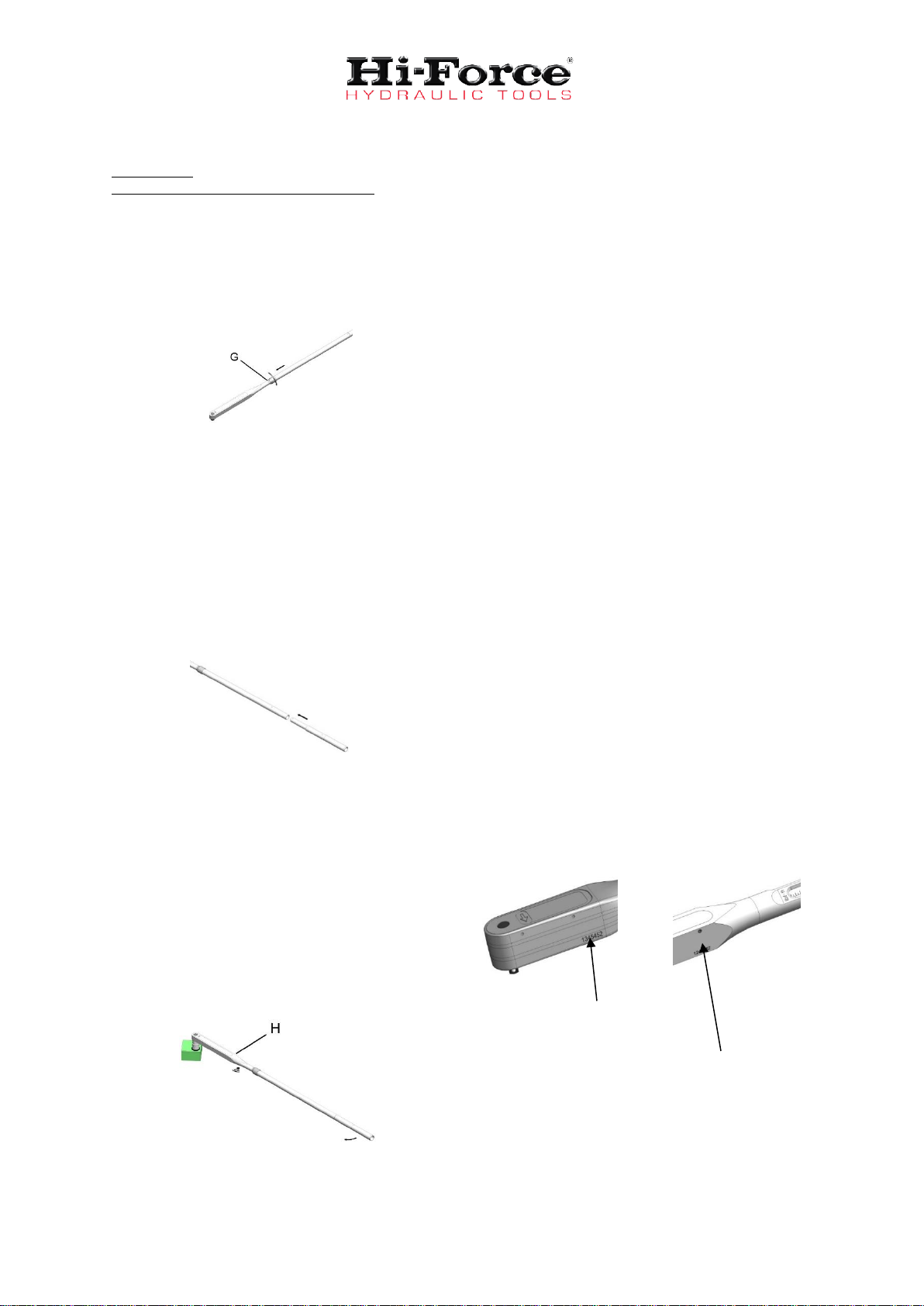

A: Hexagon Key B: End of the handle C: Scale

window F: Square drive G: Stop mark on

extension piece H: Torque wrench

I: Extension piece.

Using the Torque Wrench

ALWAYS read the Important Safety Information

(Section 1) BEFORE using the torque wrench.

These instructions describe the use of the

following product types:

Torque wrenches with aluminum alloy

housing

Torque wrench with plastic housing

ALWAYS use the torque wrench ONLY in the

direction of rotation indicated on the housing.

The specified direction of rotation is visibly

marked on the housing

Right-Handed and Left-Handed Tightening:

Single square drive for right-handed

tightening:

Double square drive for right- and left-

handed tightening*:

INSTRUCTION MANUAL:

Model Series: TWM1000, TWM1500, TWM2000

Hi-Force Limited –Prospect Way –Daventry –Northants NN11 8PL –United Kingdom

Tel: +44(0) 1327 301000: Fax: +44(0) 1327 706555: Website: www.hi-force.com

Important Note*: Only torque wrenches with

aluminum alloy housing are available with a

double square drive.

Throughout these Operating Instructions, the

procedures are described, and depicted

graphically for a torque wrench with a single

square drive. Please note that the procedures

are the same for torque wrenches with a double

square drive

Setting the Torque

ALWAYS make sure that you set the torque

wrench in the appropriate scale. Failure to use

the appropriate scale can result in incorrectly

torque loaded bolts causing DAMAGE.

The TWM1000 torque wrench is equipped with

a double scale (Nm / lbfft or lbfin). Check

the unit and scale. Familiarize yourself with the

torque wrench and its scales.

If using nonstandard extensions end fittings, the

torque wrench setting must be adjusted. Non-

standard extension end fittings increase the

effective length of the wrench. As a result, the

actual torque applied to the bolt you are

tightening will be higher than the setting on the

torque wrench.

ALWAYS set the desired torque before using the

torque wrench. The procedures for setting the

torque are different depending on type of

torque wrench you are using:

Aluminium alloy housing:

Pull out the Hexagon-Key (A) on the end of the

handle (B) and angle it up

Turn the Hexagon-Key (A) until the desired

torque in the particular scale (C) Nm or lbfft

corresponds with the mark on the housing.

(If using extension pieces, see section 3.4.)

Bring the Hexagon-Key (A) back into the

starting position and push it into the end of the

handle (B).

Working with Non-standard Extension End

Fittings

NEVER use non-standard extension end fittings

with a torque wrench with a built-in ratchet or

ratchet adaptor.

You must read and understand these

instructions before using non-standard

extension end fittings with the torque wrench.

Bolts incorrectly torque loaded can cause

DAMAGE and SERIOUS INJURY.

Non-standard extension end fittings increase

the effective length of the wrench. As a result,

the actual torque applied to the bolt you are

tightening will be higher than the setting on the

torque wrench.

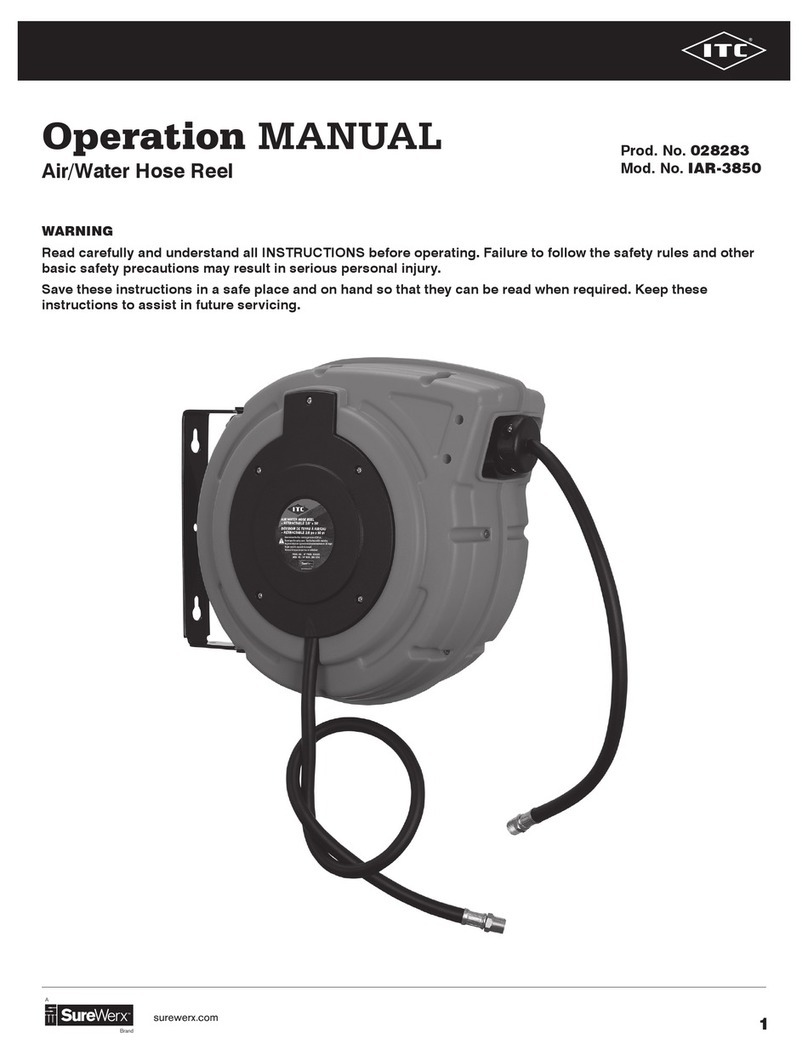

The new setting for the torque wrench (MxW)

must be calculated according to the following

formula:

MxW = Torque Wrench Setting: the torque

that has to be set on the torque

wrench scale.

MA= Desired Torque Setting: the torque

that the bolt or nut needs to be

tightened to.

Lw = Torque Wrench Length: the

distance between the center of the

torque wrench’s square drive and

the center of the handle (see table

in section 7).

Lx= Extension Length: the distance

between the center of the torque wrench’s

square drive and the center of the bolt or nut

(also called depth gauge of the end fitting

Tightening Bolts

OVERLOAD HAZARD

The torque wrench can overload during us and

break causing SERIOUS INJURY

ALWAYS use only original accessory parts.

wx

w

LL LM

M

A

xW

INSTRUCTION MANUAL:

Model Series: TWM1000, TWM1500, TWM2000

Hi-Force Limited –Prospect Way –Daventry –Northants NN11 8PL –United Kingdom

Tel: +44(0) 1327 301000: Fax: +44(0) 1327 706555: Website: www.hi-force.com

Accessory parts not approved by the

manufacturer may overload.

ALWAYS inspect the torque wrench for

damage BEFORE every use.

NEVER use a damaged torque wrench.

NEVER use the torque wrench if it has been

dropped, used to strike other objects, or if

anything has fallen on it.

ALWAYS IMMEDIATELY release the torque

wrench after you hear the click indicating that

you have reached the desired torque setting.

DO NOT continue to tighten the bolt after you

hear the click!

INACCURATE TORQUE SETTINGS

An out-of-calibration torque wrench can cause

part or tool breakage and inaccurate torque

settings,

ALWAYS use tested and calibrated torque

wrenches only. ALWAYS use an approved

torque tester.

Safety Precautions

Take the following safety precautions to

prevent injuries and damage when using the

torque wrench:

ALWAYS use only original accessory

parts or parts approved by the

manufacturer.

ALWAYS check the torque wrench for

the proper torque setting prior to

tightening every bolt.

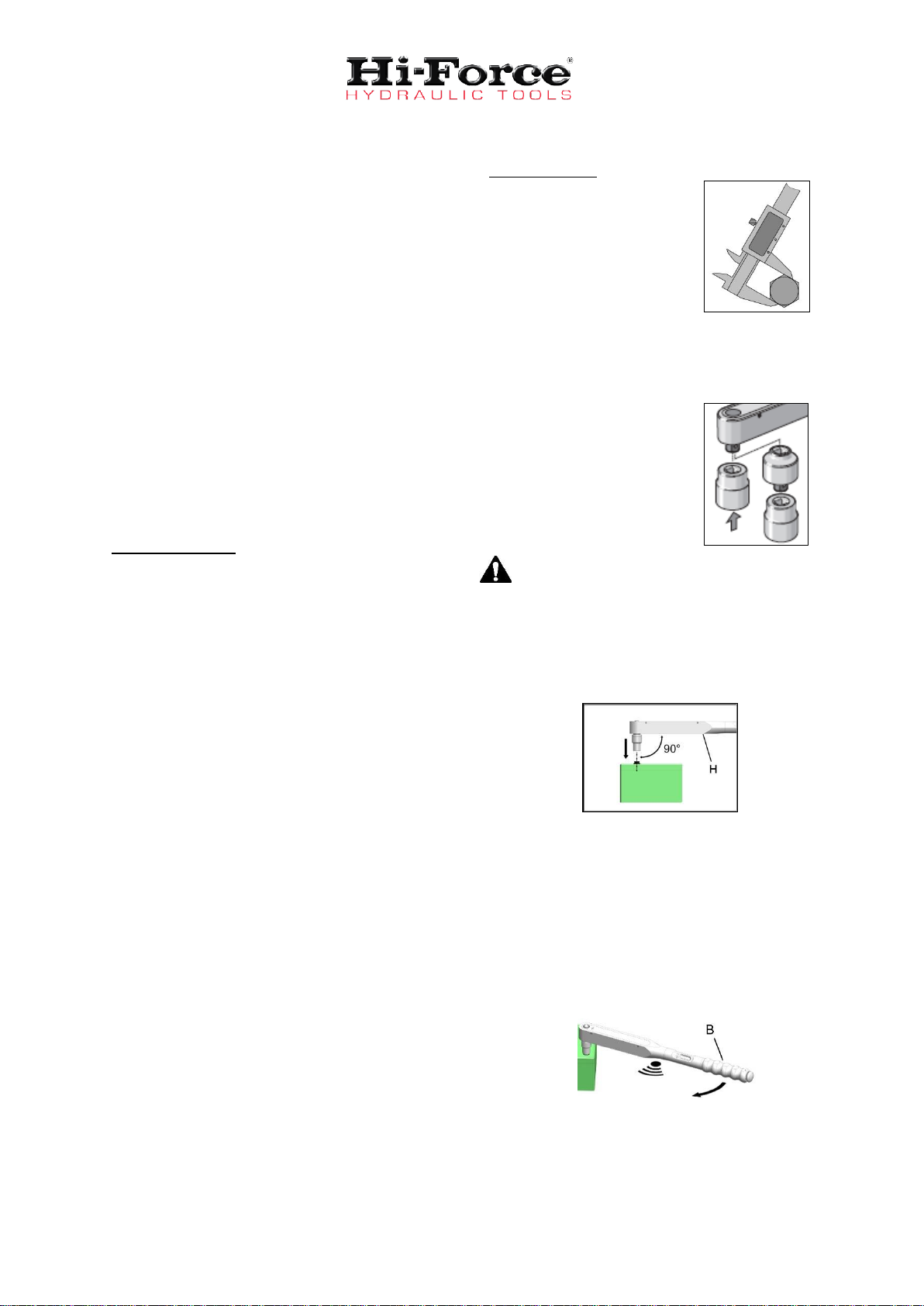

ALWAYS position the torque wrench

and socket extensions at a 90° angle.

Use ratchet adapters when working in

tight work areas. Reverse the torque

wrench without removing it.

When using ratchet adapters, e.g. for

deep seated bolt positions, ALWAYS

hold them for as short a time as

possible.

If the resistance changes

unexpectedly while tightening a bolt,

release the torque wrench

immediately. Check the torque

wrench and the bolt for damage.

NEVER use reducers with the torque

wrench. Reducers will not bear the

load of the forces created when using

the torque wrench.

Only turn the torque wrench in the

direction of the arrow on the housing

of the torque wrench.

When using non-standard extension

end fittings, always hold the torque

wrench tool in the center of the

handle.

Tightening Bolts:

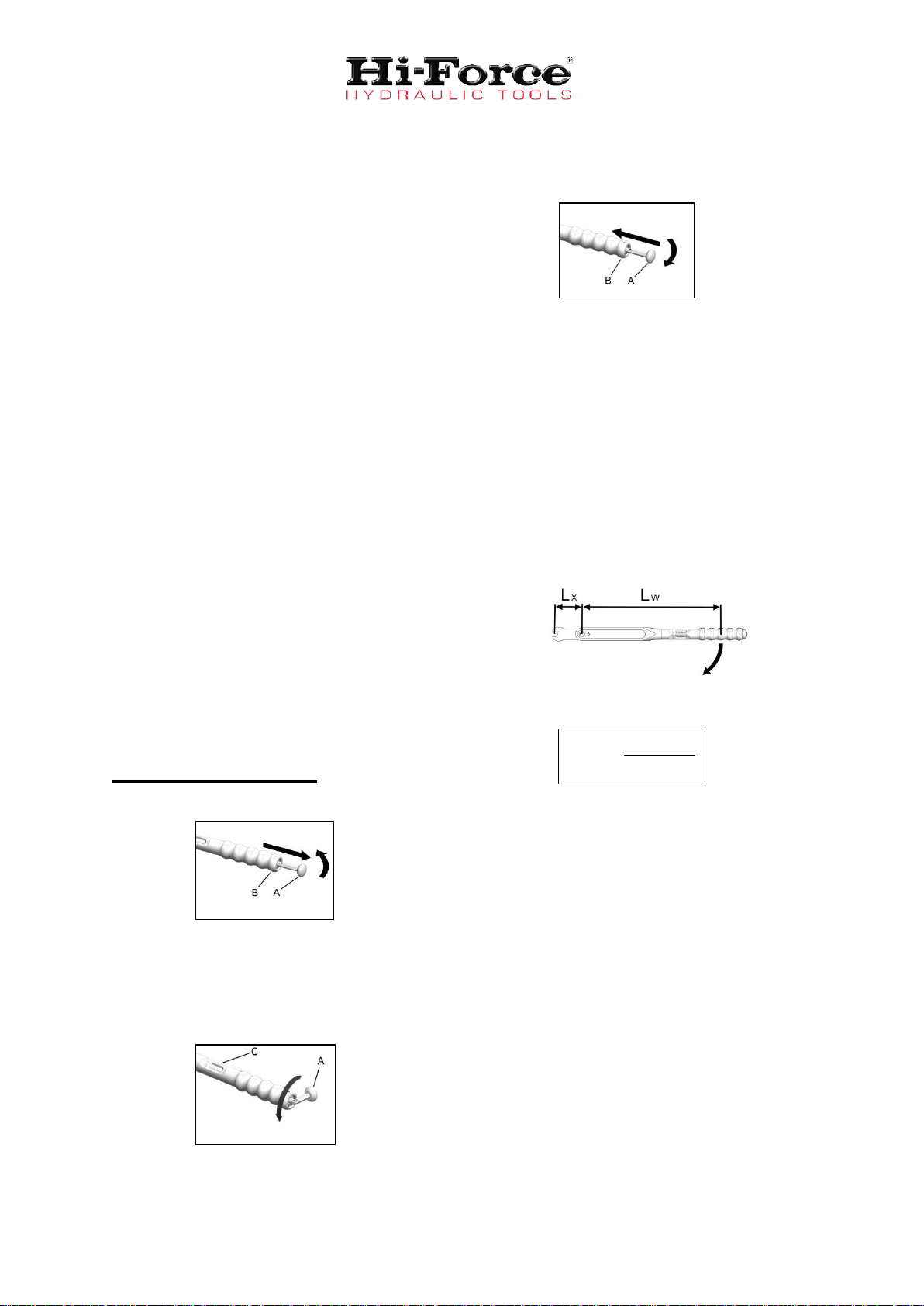

1) ALWAYS check the

bolt for damage

and excessive

wear.

2) ALWAYS determine

the width of the bolt

head before tightening the bolt.

3) ALWAYS select the appropriate socket

according to the width of the bolt.

4) Attach the socket

(or other accessory)

to the torque

wrench’s square

drive.

5) Make sure the connection between

the ratchet head and the socket (or

accessory) is secure by gently pulling

on it.

6) Place the torque wrench (H) with the

attached socket onto the bolt at a

90° angle.

7)Turn the torque wrench by the handle

(B) slowly and steadily in the direction of

the arrow indicated on the housing until

you hear a click and feel a slight jerk of

the handle.

IMMEDIATELY release the torque wrench after

you hear the click indicating that you have

reached the desired torque setting. DO NOT

continue to tighten the bolt after you hear the

click!

INSTRUCTION MANUAL:

Model Series: TWM1000, TWM1500, TWM2000

Hi-Force Limited –Prospect Way –Daventry –Northants NN11 8PL –United Kingdom

Tel: +44(0) 1327 301000: Fax: +44(0) 1327 706555: Website: www.hi-force.com

Section: 3.4.

Tightening Bolts Using Extension Pieces:

ALWAYS use only original extension pieces or

parts approved by the manufacturer.

1) Attach the extension piece to the

torque wrench by pushing it onto the

torque wrench until it reaches the

“stop mark” (G).

2) Secure the extension piece by turning

the clamping nut.

3) Make sure the connection between

the torque wrench and the extension

piece is secure by gently pulling on

the extension piece.

4) Torque wrenches with 1” and 1½”

drives only:

Insert the second extension piece into

the previously inserted extension

piece.

5) Turn the second extension piece until

the locking pin locks into place in the

hole on the first extension piece.

6) Clasp the torque wrench (H) with

extension piece on the knurled

section of the extension piece.

7) Turn the torque wrench slowly and

steadily in the direction of the arrow

indicated on the housing until you

hear a click and feel a slight jerk of

the handle.

IMMEDIATELY release the torque wrench after

you hear the click indicating that you have

reached the desired torque setting. DO NOT

continue to tighten the bolt after you hear the

click!

The torque wrench is immediately operational.

Maintenance

Checking and Calibrating

An out-of-calibration torque wrench can cause

part or tool breakage and inaccurate torque

settings.

ALWAYS use tested and calibrated torque

wrenches only. ALWAYS use an approved

torque tester.

During use, the torque wrench creates very

powerful forces. When torque wrenches are

not checked or not serviced there is a risk that

they will overload or indicate inaccurate

torque settings.

ALWAYS take the following safety precautions.

ALWAYS check the accuracy of the

torque wrench with an approved

torque tester before each use.

DO NOT use the torque wrench if

inaccurate.

ALWAYS have your torque wrench

periodically recalibrated.

According to DIN EN ISO 6789, the minimum

calibration interval requirement for a torque

wrench is one year or 5000 load cycles

(whichever occurs first). A firm’s own

specifications or quality requirements for

specific applications can lead to considerably

shorter calibration intervals.

DO NOT attempt to recalibrate your torque

wrench. Improper calibration can cause

damage to your torque wrench.

Calibration should be conducted by

authorized personnel ONLY, such as an

accredited calibration laboratory or the

manufacturer.

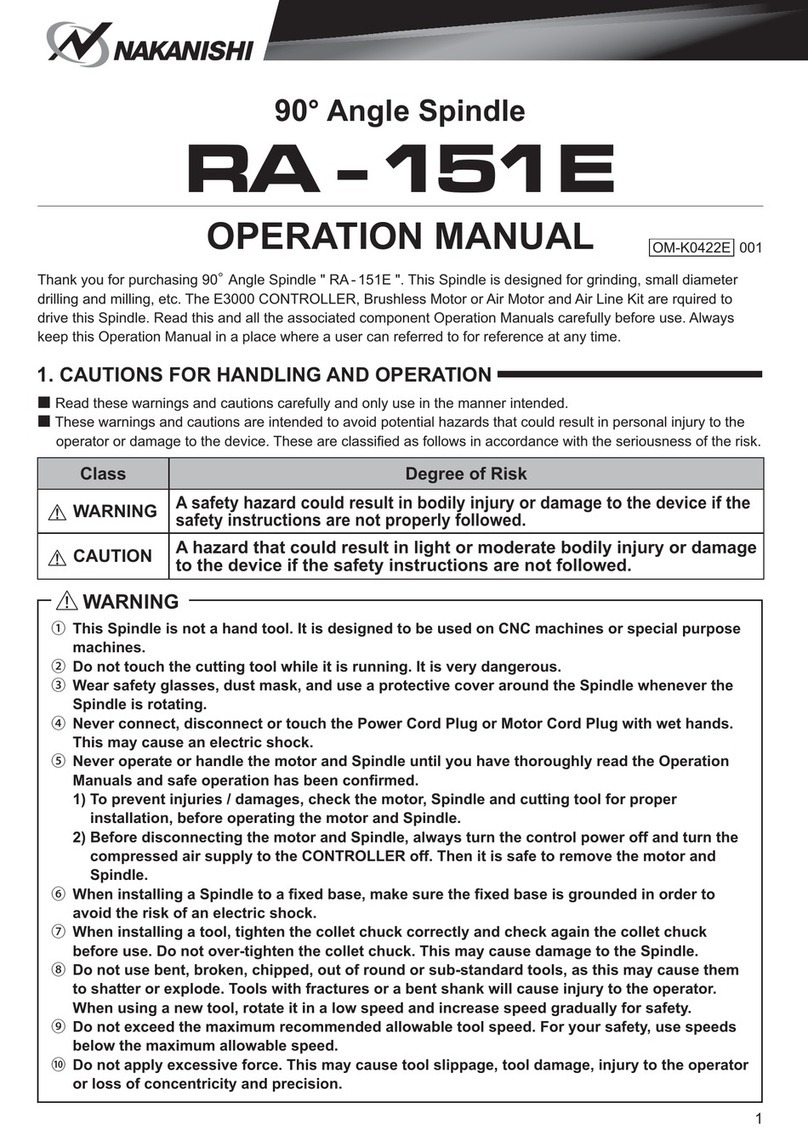

A calibration certificate as per DIN EN ISO 6789

comes with every new torque wrench. The

torque wrench and the calibration certificate

are labeled with the identical serial number.

Serial Number

Serial Number

This manual suits for next models

2

Table of contents

Other Hi-Force Tools manuals

Popular Tools manuals by other brands

PennEngineering

PennEngineering Atlas 801 operating instructions

Stahlwille

Stahlwille multipower MP100-1500 Instructions for use

Neilsen

Neilsen CT5202 quick start guide

Topmodel

Topmodel Finesse Max F3Q manual

Nakanishi

Nakanishi RA-151E Operation manual

Josef Kihlberg

Josef Kihlberg JK20A680 operating instructions