Quick Start

Quick Start

Instructions

Instructions

Wiring

Power Up

Parameter Setting

Reliance Electric Drives

SP600 AC Variable Frequency

Inverter - 1/2 to 20 HP

NEMA 4X/12 Washdown

Quick Start Instructions:

A quick reference to some basic

configurations and drive features.

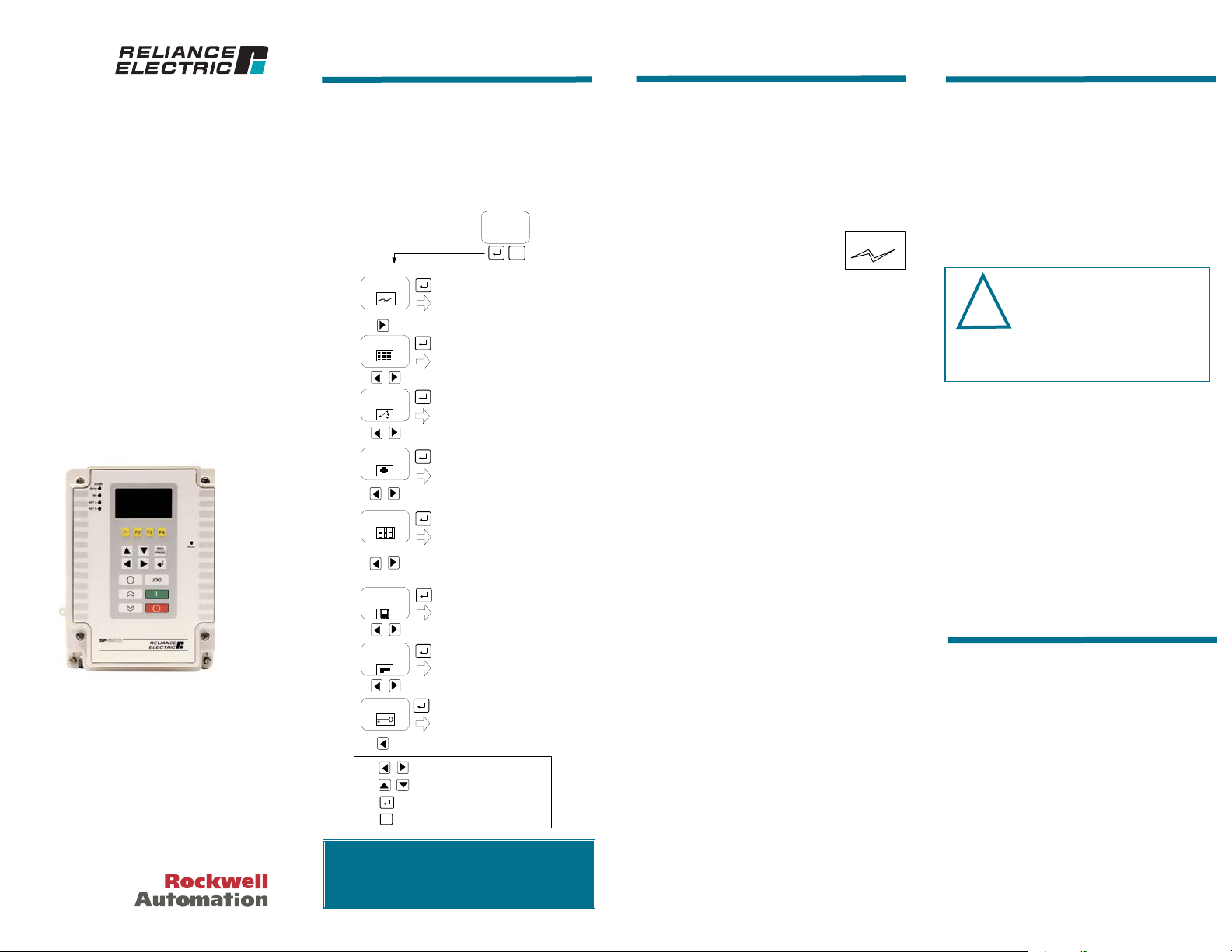

OIM Keypad and Display

The built-in keypad and display allow for

setup, parameter adjustment, monitoring

and diagnostics.

Operator Interface Module (OIM)

NOTE: This material is not intended to provide operational

instructions. Appropriate Reliance Electric Drives

instruction manuals precautions should be studied prior to

installation, operation, or maintenance of equipment.

Quick Start

OIM Quick Start Menu

The Quick Start Parameters can be

accessed via the keypad menu icon. Once

into the selection list the following

parameters can be set to configure the

drive to the installed motor.

1) QuickStart

•Stop Mode A (Ramp)

•Motor NP FLA (Drive Dependant)

•Minimum Speed (0.0 Hz)

•Maximum Speed (60.0 Hz)

•Accel. Time 1 (10.0 sec.)

•Decel. Time 1 (10.0 sec.)

•Speed Reference A select (OIM)

•Digital IN2 Select (Start)

(Defaults)

The default configuration is defined as:

Drive Voltage rating = Motor Voltage

Start/Stop control = OIM

Speed Reference = OIM

Control Mode = Sensorless Vector

If the drive default configuration is to be

used for initial startup then the above

parameters are the only settings required.

If the user needs to customize the drive

configuration different than the default

setting, then the user should verify

parameter settings accessible throughout

start-up menu.

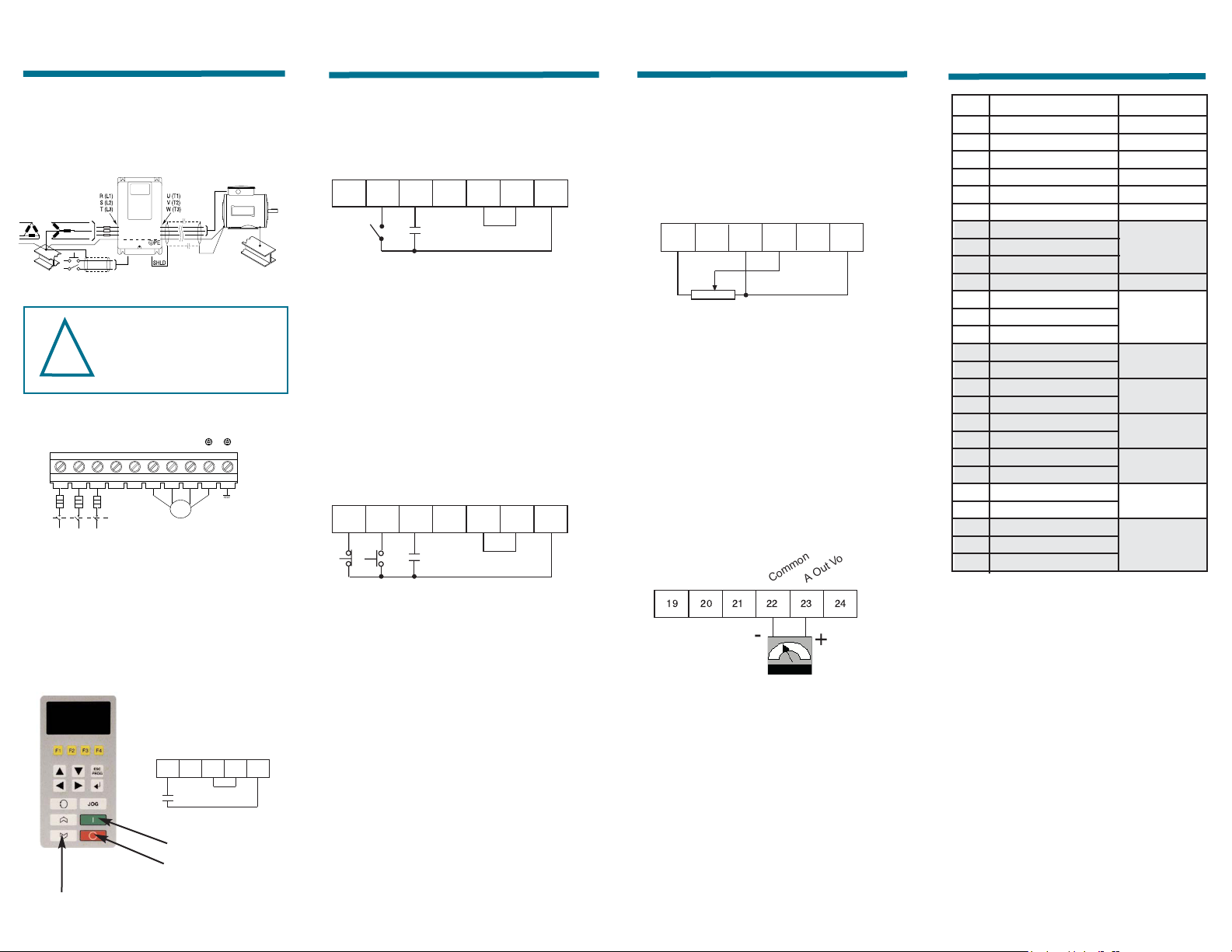

2) Input Voltages

•200/240, 400/480, and 575 VAC,

based on model number

3) Motor Nameplate Data

•Motor Power Units

•Motor Power

START-UP

Quick Start

3) Motor Nameplate Data cont’d

•Motor FLA

•Motor Volts

•Motor Hertz

•Motor RPM

4) Motor Tests

•Direction

•AutoTune

5) Speed Limits

•Minimum, Maximum

•Direction Limit

•Stop Mode

6) Reference Setup

•OIM Keypad, Terminal Block,

Network, Other

7) Configure I/O

•Digital Inputs/Outputs

•Analog Outputs

Control Mode

(P53) Torque Perf Mode

Control performance can be selected

from:

•Sensorless Vector (default)

Highest performance mode of control

•SV Economize

Sensorless Vector with energy saving

•Custom V/Hz

Basic open loop control. Multi-motor

application

•Fan/Pump: V/Hz

Provides for a Fan load V/Hz curve

ATTENTION: Rotation of the motor in an

undesired direction can occur during this

procedure Autotune (61) = Rotate Tune

(2). To guard against possible injury

and/or equipment damage, it is recommended that the

motor be disconnected from the load before

proceeding.

!

D-2992