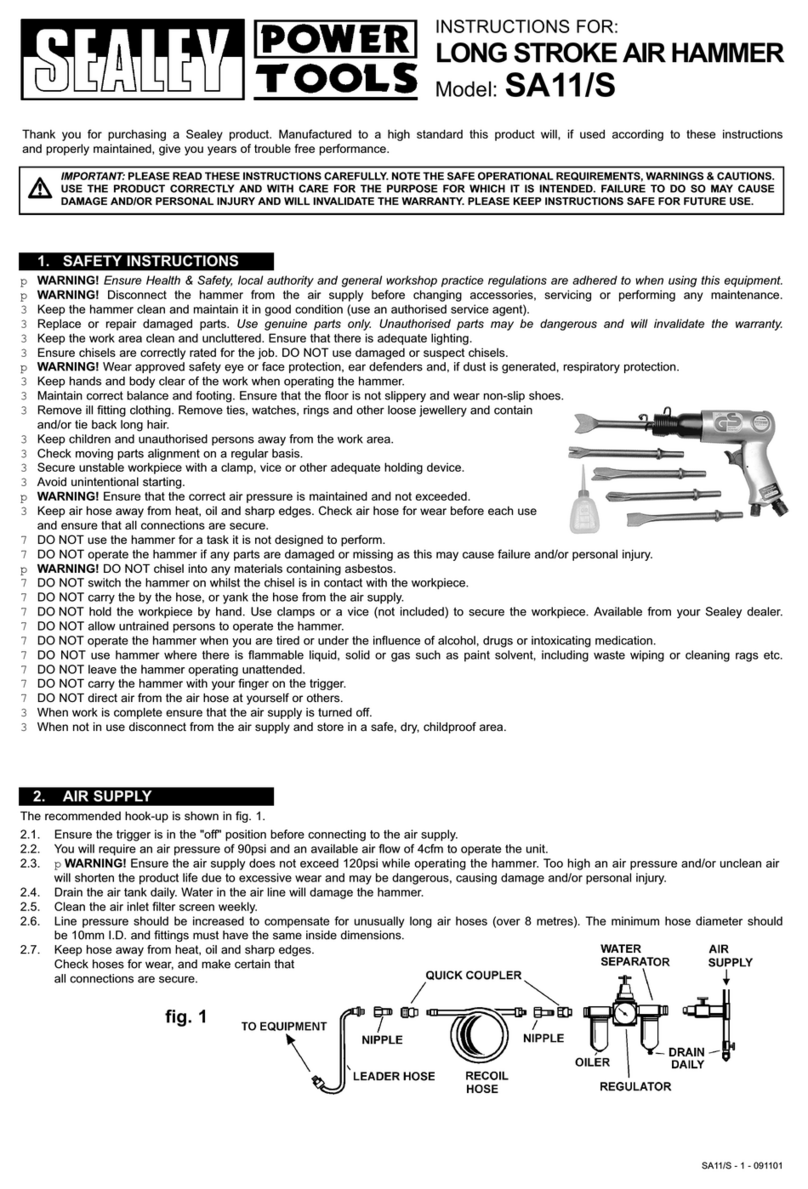

INSTRUCTIONS FOR

AIR GREASE GUN

MODEL NO: SA401.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

9Follow workshop Health & Safety rules, regulations and conditions when using the grease gun.

WARNING!Disconnect from air supply before changing accessories or servicing.

9Maintain the grease gun in good condition.

WARNING! Check that the correct air pressure is maintained and not exceeded.

9Keep air hose away from heat, oil and sharp edges. Check hose for wear before each use and ensure that all connections are secure.

9Wear appropriate protective clothing. When handling lubricants refer to manufacturer’s instructions and conform to local regulations.

9Dispose of waste grease in accordance with local authority regulations.

9Keep grease gun clean and in good working order for best and safest performance.

9Keep children and unauthorised persons away from the work area.

8DO NOT use the grease gun for a task it is not designed to perform.

8WARNING! DO NOT use gun if damaged or thought to be faulty. Contact your local service agent.

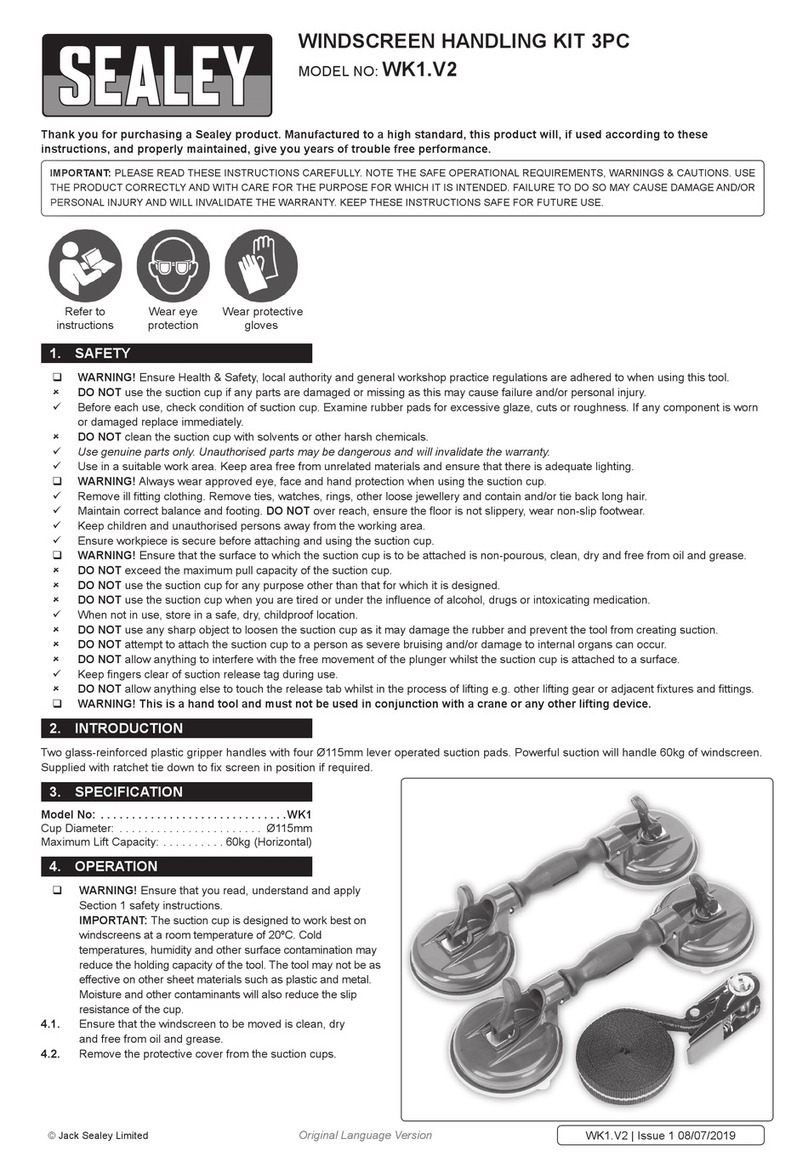

WARNING! Grease is delivered at high pressure. DO NOT point the grease nozzle at yourself or others.

9Ensure grease nipples are free from dirt or debris before connecting the grease gun.

8DO NOT operate the trigger until the nozzle is firmly attached to the receiving grease fitting.

8DO NOT drop, throw, or abuse, the grease gun.

8DO NOT carry the grease gun by the air hose, or yank the hose from the air supply.

8DO NOT operate grease gun if you are tired or under the influence of alcohol, drugs or intoxicating medication.

8DO NOT direct air from the air hose at yourself or others.

9When not in use, disconnect from air supply and store in a safe, dry, childproof location.

2. INTRODUCTION

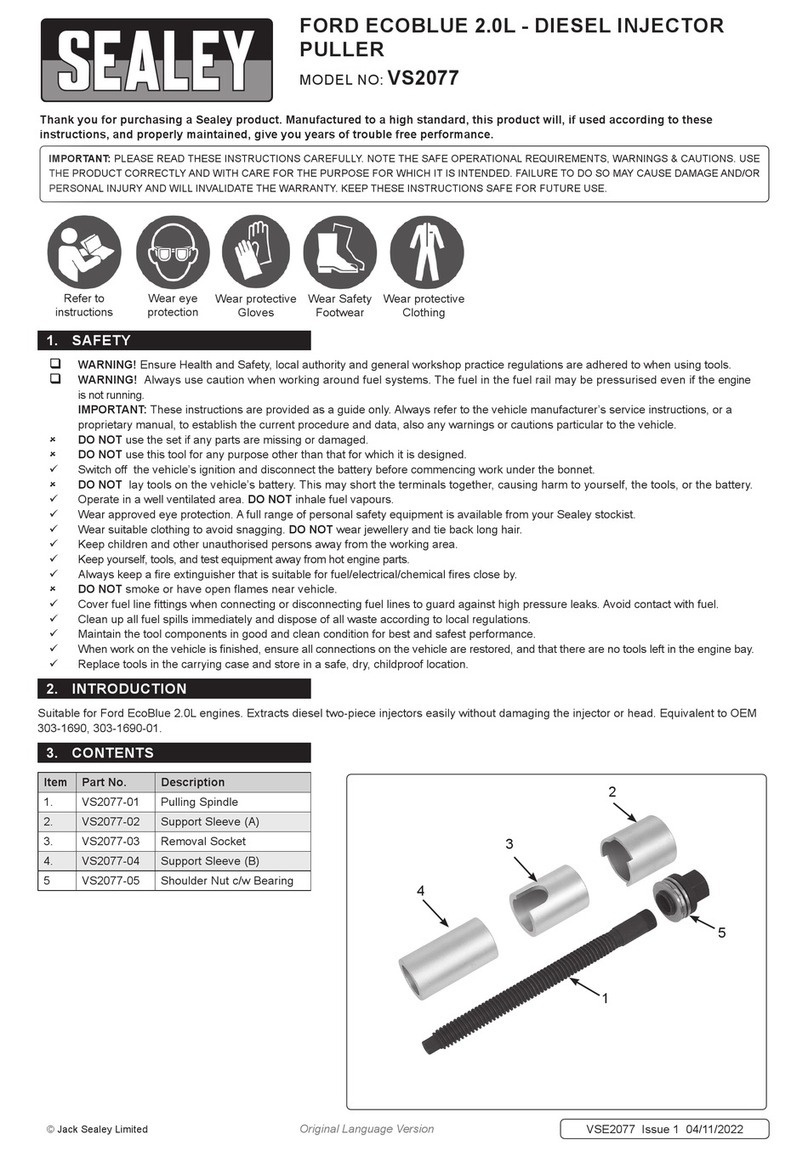

Die-cast head and body with chromed steel grease tube. Includes rigid extension tube and 4-jaw coupler. Trigger operated continuous flow gun with

3-way fill and air-bleed valve. Accepts 400g grease cartridges, bulk or manual fill.

3. SPECIFICATIONspecification

Model no:.........................................................................SA401.V2

Air pressure:.......................................................................60-150psi

Delivery pressure:....................................................... 1200-5000psi

Air inlet: ................................................................................ 1/4”BSP

Optional 230mm flexible extension tube: ........................ SA40/09A

4. PREPARATION FOR USEspreparation

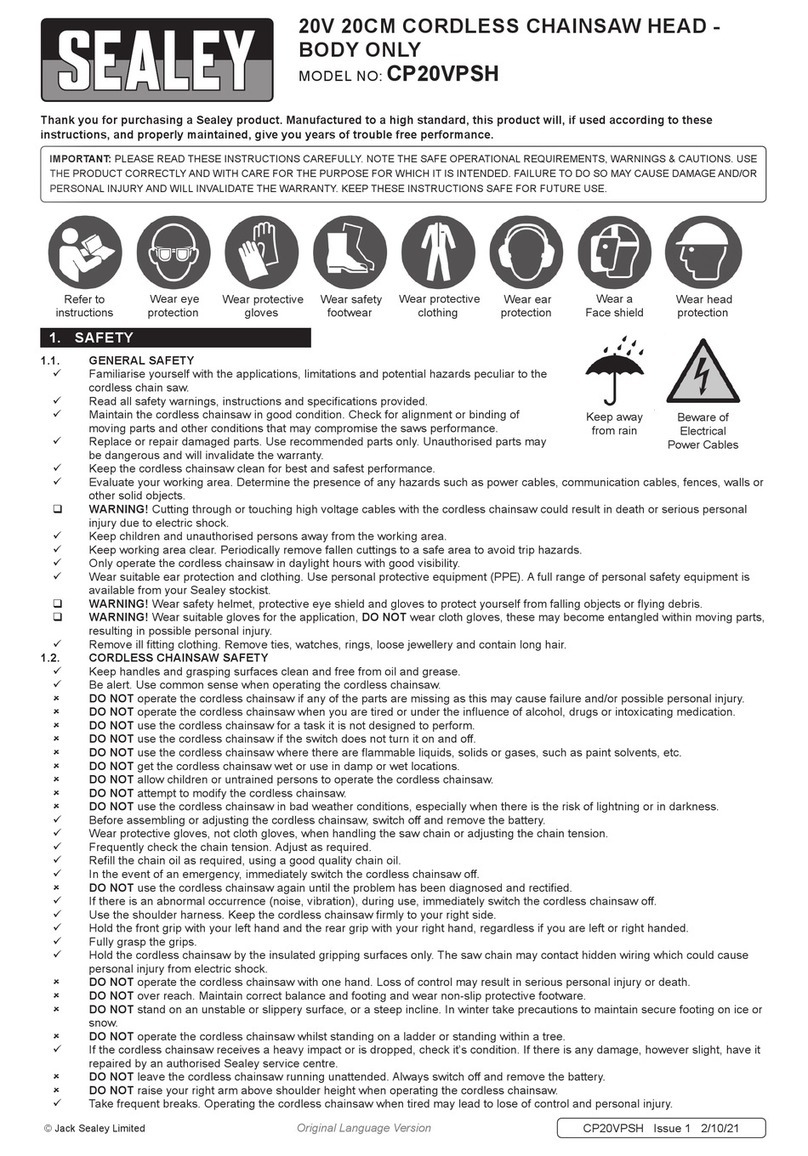

4.1. Air Supply

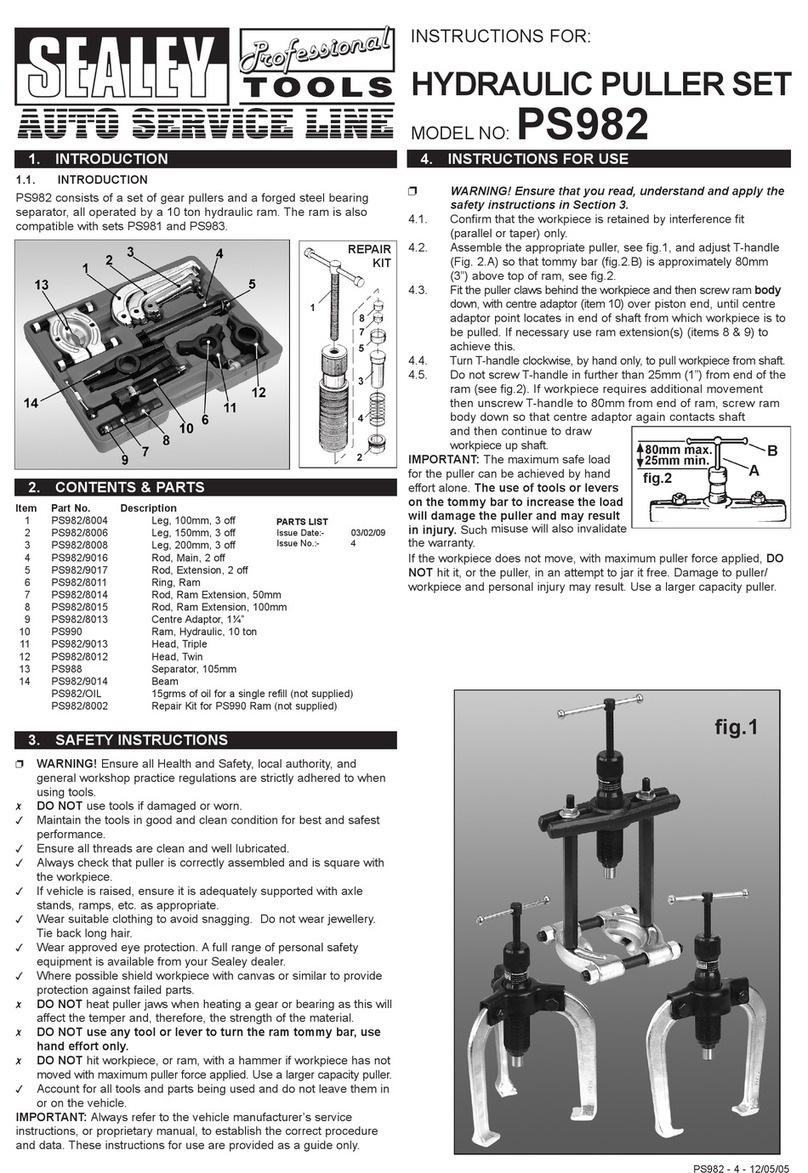

Recommended hook-up is shown in fig.1.

4.1.1. Ensure that the trigger is in the OFF position when connecting to the

air supply.

WARNING! Ensure that the air supply is clean and is between 60-150psi.

Too high an air pressure and/or unclean air will shorten the life of the gun

due to excessive wear, and may be dangerous, causing damage and/or

personal injury.

4.1.2. Drain the compressor air tank daily. Water in the air line will damage the gun.

4.1.3. Clean compressor air inlet filter weekly.

4.1.4. Line pressure should be increased to compensate for unusually long air hoses

(over 8 metres). The minimum hose size should be 1/4” internal diameter and

fittings must have compatible dimensions.

4.1.5. Keep hose away from heat, oil and sharp edges. Check hose for wear and

make certain that all connections are secure.

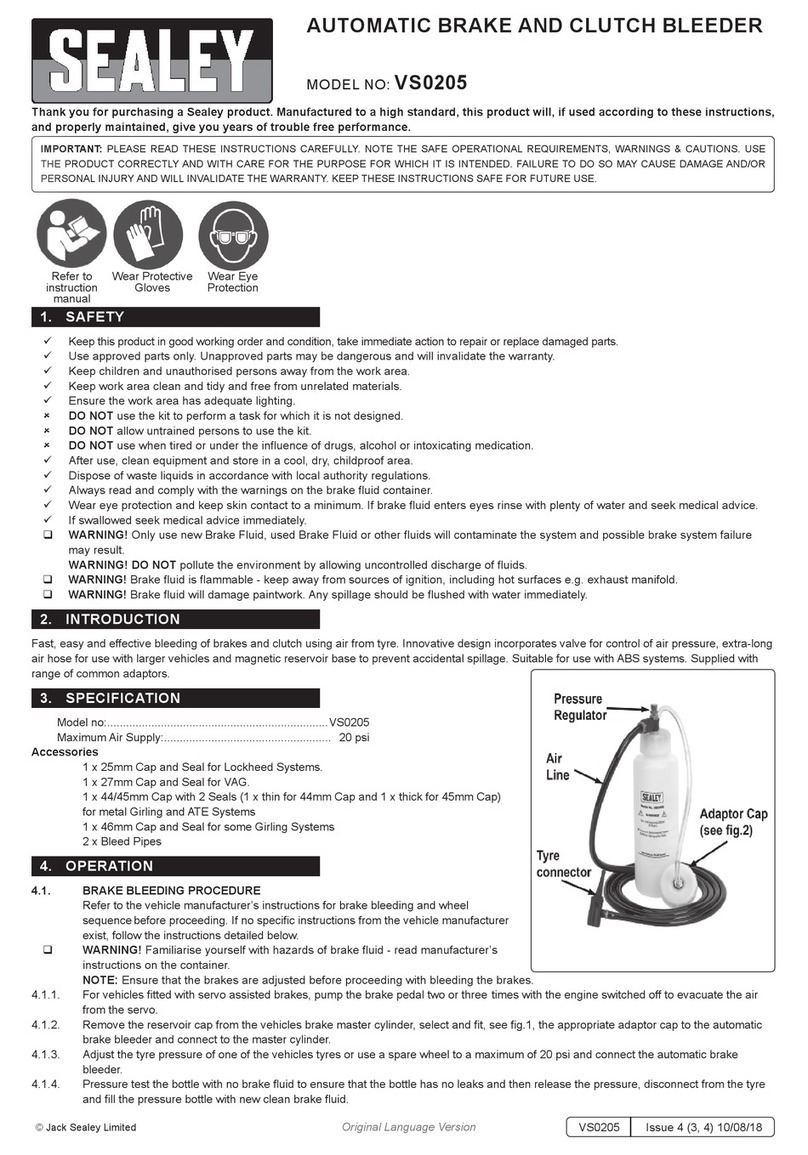

Wear eye

protection

Refer to

instruction

manual

SA401.V2| Issue 2(L) 10/11/15

Original Language Version

© Jack Sealey Limited