5

Description

Warranty

The warranty conditions are listed in the

"General terms and conditions".

Please contact your contractual partner

in the first instance.

Environmental pro-

tection and recycling

Disposing of packaging

All products are packed for transport

in environmentally friendly materials.

You can make a valuable contribution

to reducing waste and sustaining raw

materials by only disposing of packaging

at approved collection points.

Disposal of

components

The manufacturing process for the

units is subject to continuous qual-

ity control. Only high-grade materials are

processed, the majority of which

are recyclable. You can also

contribute to environmental protec-

tion by only disposing of components

in accordance with local regulations and

in an environmentally safe manner, e.g.

through authorised disposal and recycling

specialists or at collection

points.

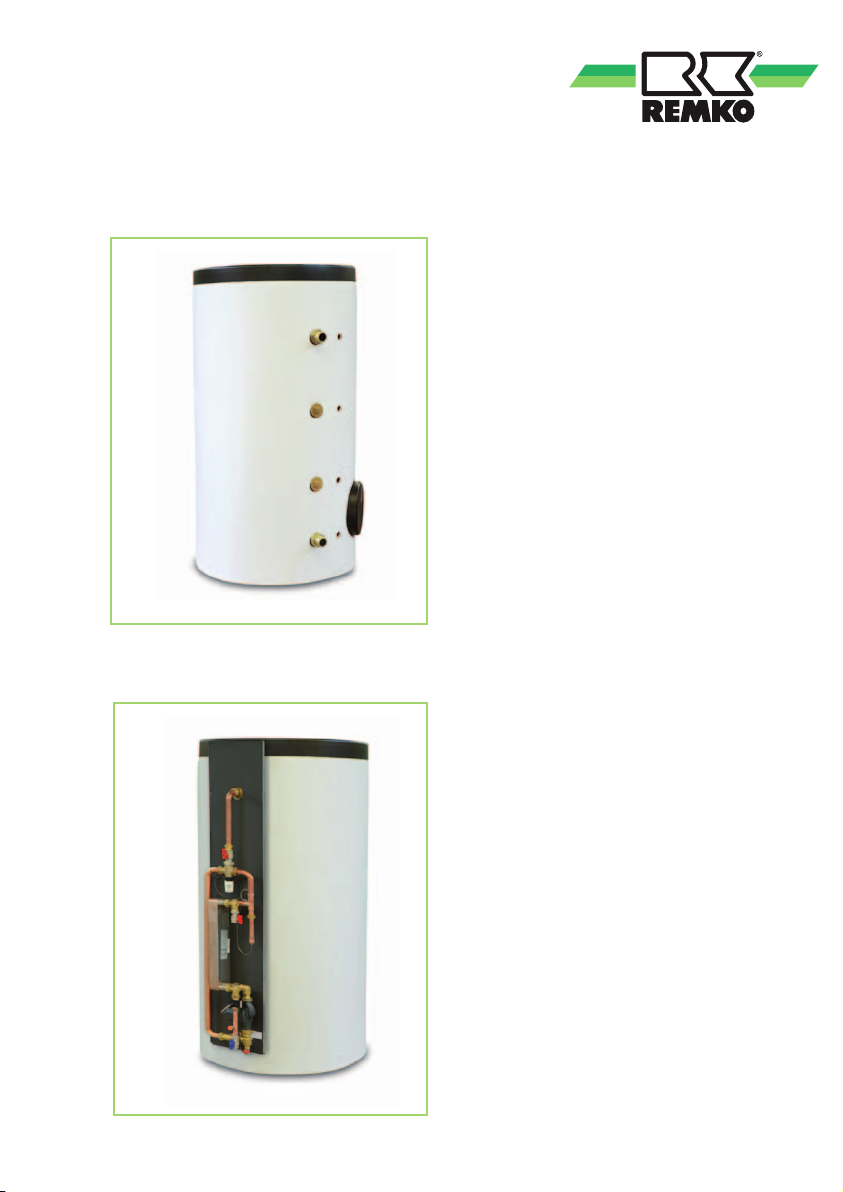

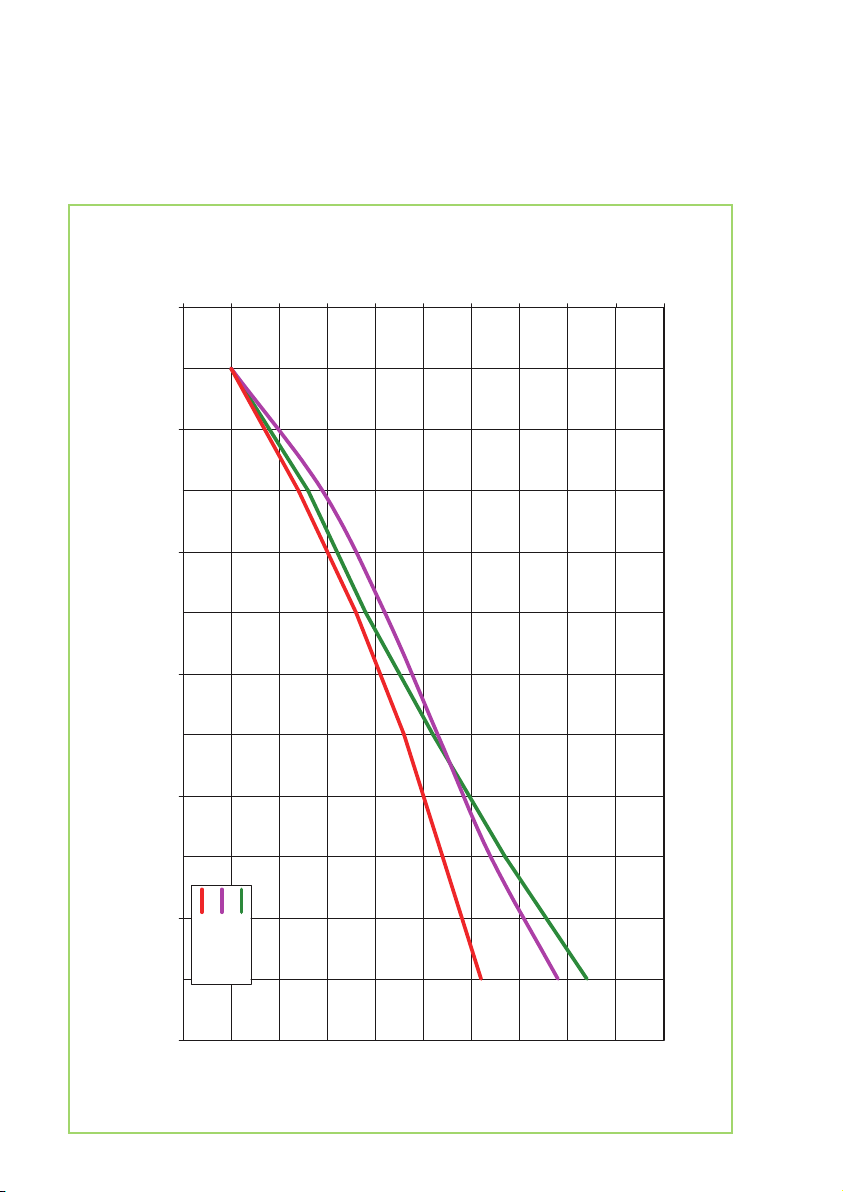

The fresh water station was developed

for use by regenerative heating appli-

ances, particularly for heat pumps. It can

supply one to two residential units with

fresh domestic hot water.

The domestic hot water is only heated

when there is demand, via a stainless

steel plate heat exchanger, in a hygienic

flow process.

The energy supply required for this is

provided as needed by a heating water

storage tank.

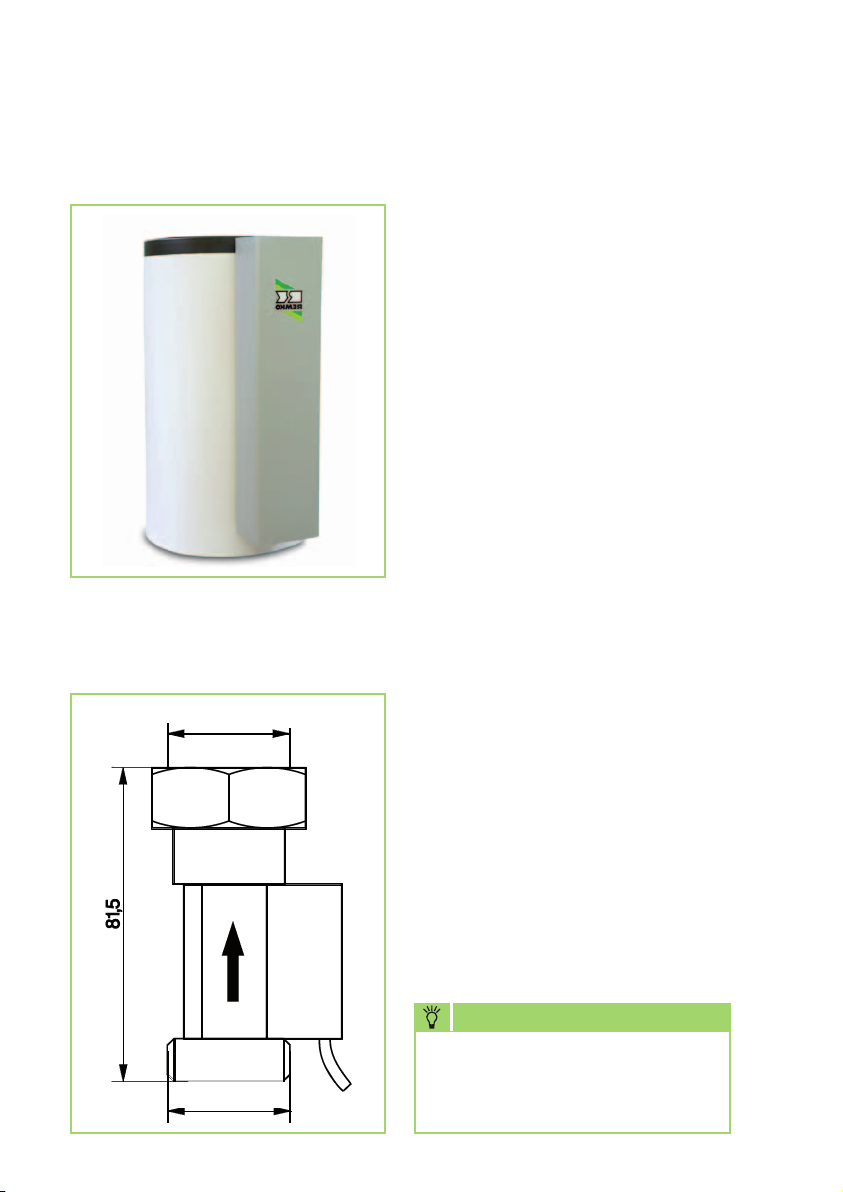

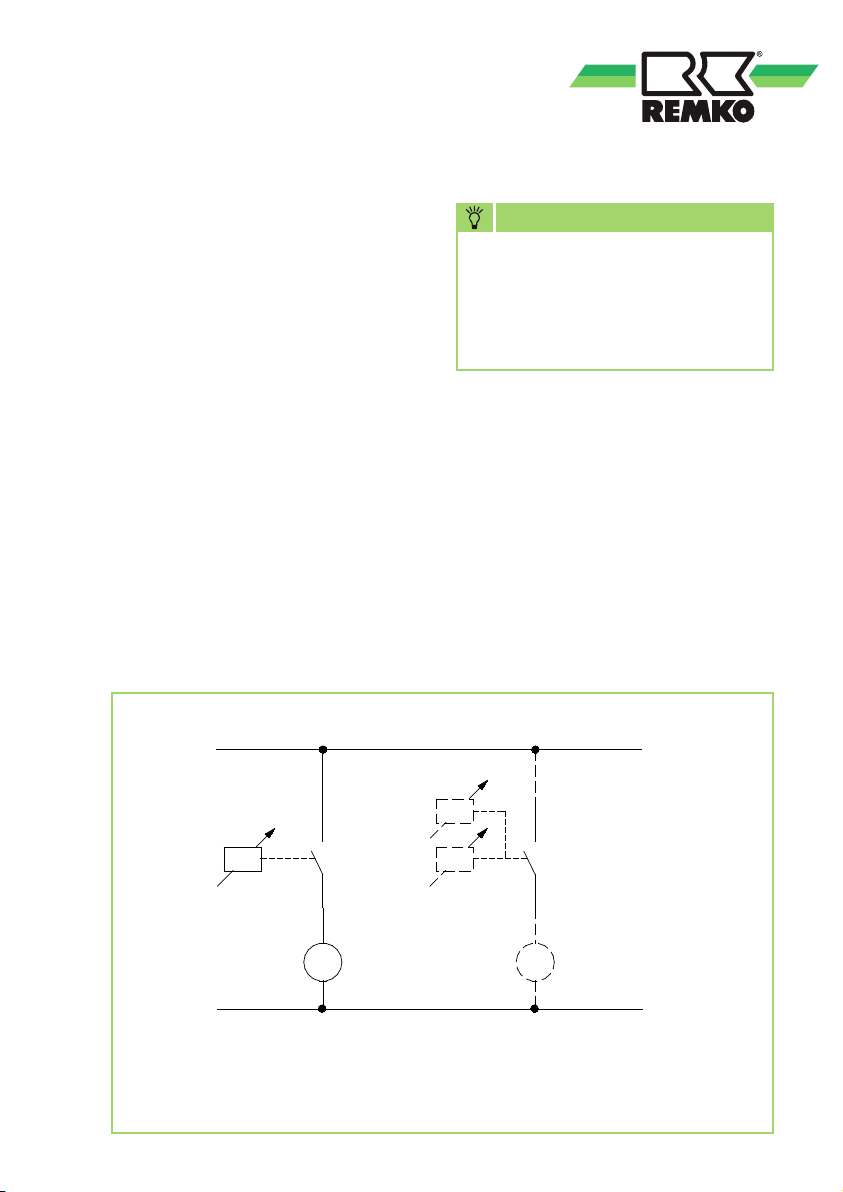

When the hot tap is opened, the in-

tegrated circulation pump is switched

on by a flow switch and heating water

is conveyed from the heating water

storage tank to the primary side of the

stainless steel plate heat exchanger,

causing the cold drinking water flowing

Intended use

The fresh water station was developed

for use by regenerative heating appli-

ances, particularly for heat pumps.

The domestic hot water is only heated

when there is demand, via a stainless

steel plate heat exchanger, in a hygienic

flow process.

The energy supply required for this is

provided as needed by a heating water

storage tank.SFlb

Any alternative or ad-

ditional use is classed as non-intended

use. The manufacturer/supplier assumes

no liability for damages arising from such

use. The user bears the sole risk in such

cases.

Intended use also includes working in ac-

cordance with the operating manual and

installation instructions and complying

with the maintenance requirements.