This document describes the Cyclic Mode and the Sequencer operation and relevant set up procedures through

EVK GUI for the ZSSC3240 resistive sensor conditioner.

It is highly recommended to read the following documents before using this manual:

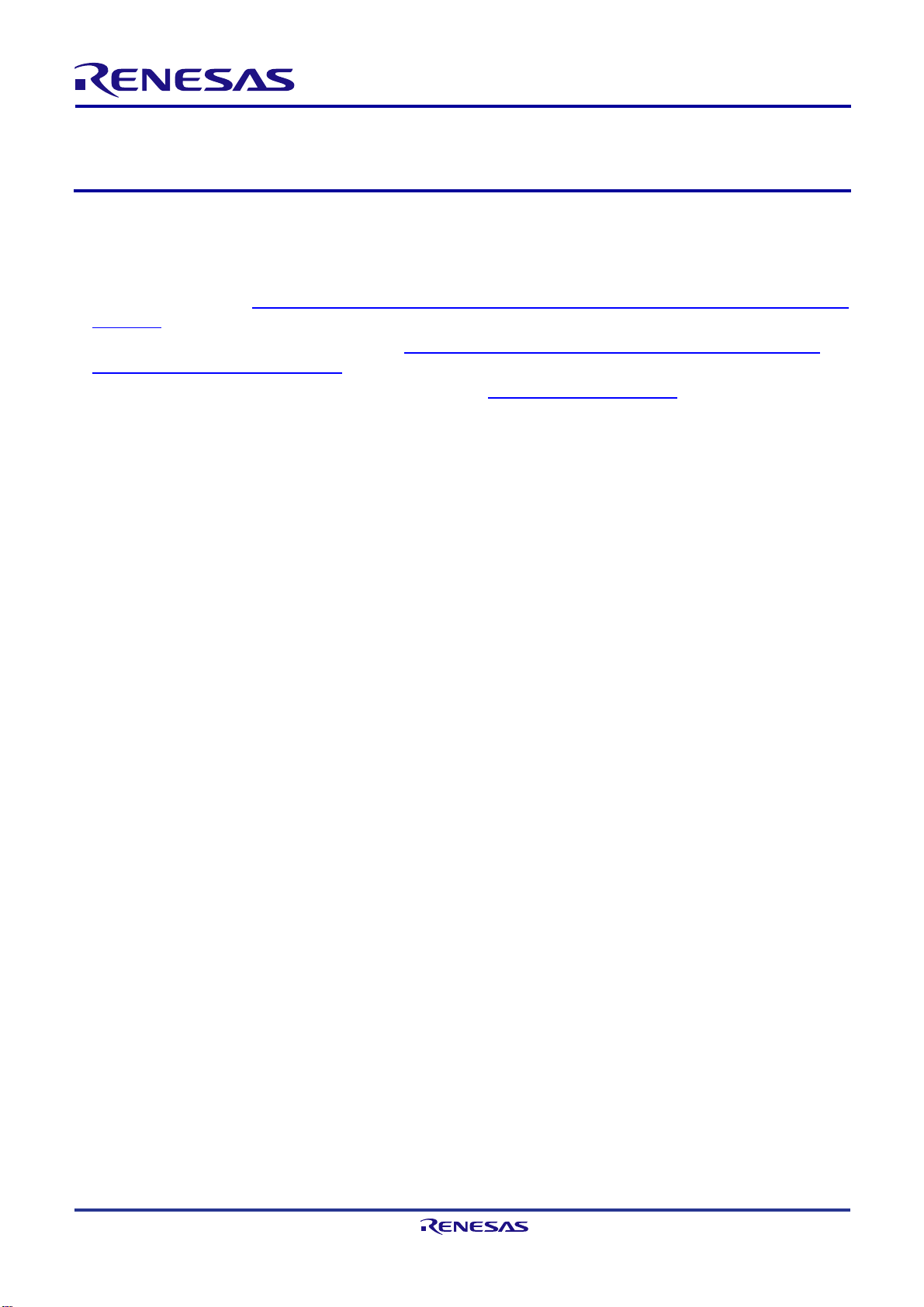

■ZSSC3240 Datasheet: ZSSC3240 - High-End 24-Bit Sensor Signal Conditioner with Analog and Digital Output

| Renesas.

■ZSSC3240 SSC Evaluation Kit User Manual: ZSSC3240 - High-End 24-Bit Sensor Signal Conditioner with

Analog and Digital Output | Renesas.

■SSC Communication board - SSCCOMMBOARDV4P1C: SSC Communication Board.

Contents

1. User Computer Requirements and Setup............................................................................................... 3

1.1 Computer Requirements................................................................................................................... 3

1.2 Evaluation Software Installation and Setup....................................................................................... 3

2. Hardware Requirements and Setup ........................................................................................................ 3

2.1 Boards ............................................................................................................................................. 3

2.2 Evaluation Board Jumpers Setup...................................................................................................... 4

2.3 Overall System Assembly................................................................................................................. 4

3. Cyclic Mode.............................................................................................................................................. 5

3.1 Setup ............................................................................................................................................... 5

3.2 Exit................................................................................................................................................... 6

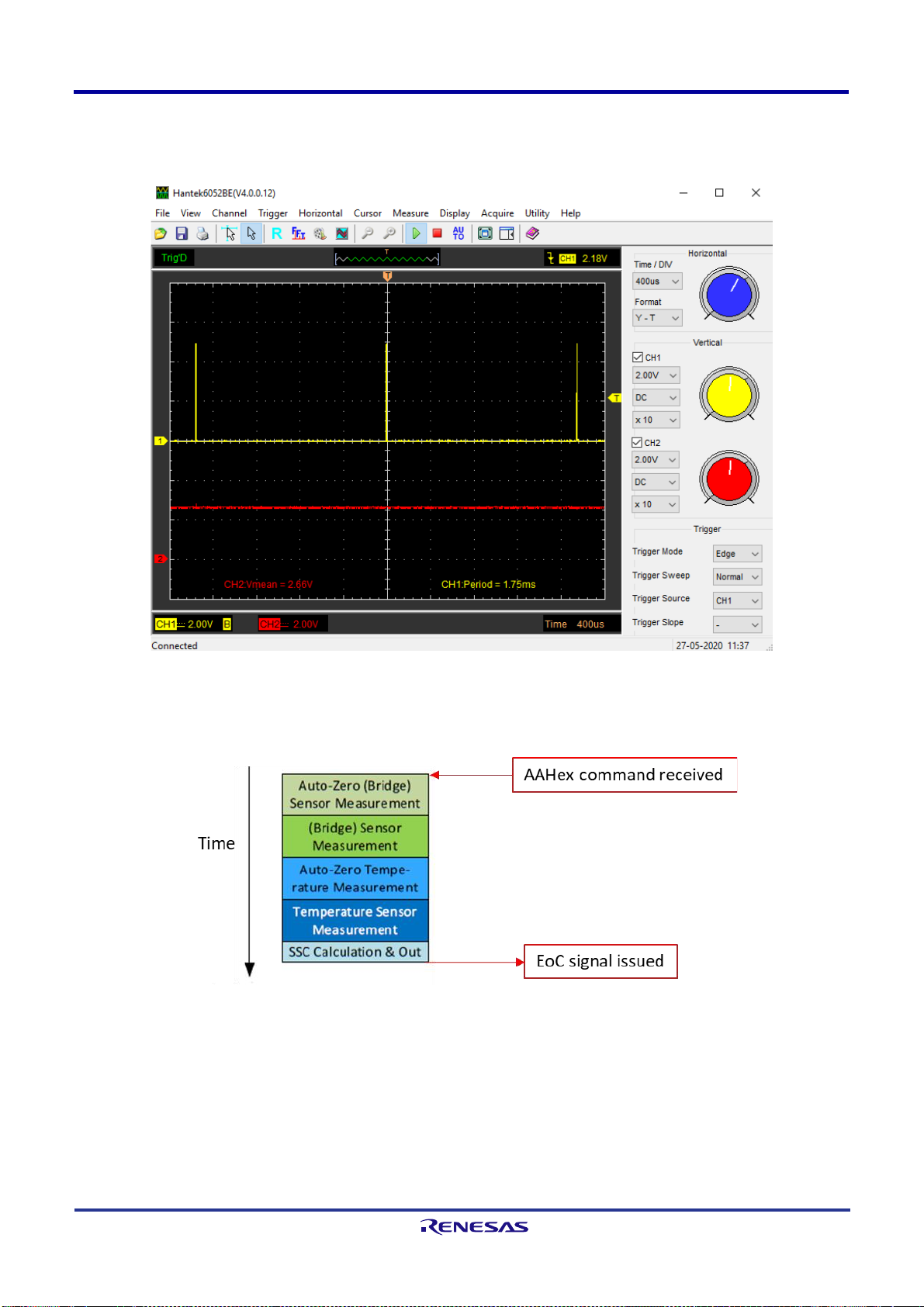

3.3 EOC Signal...................................................................................................................................... 6

3.4 Measurement Time Slot.................................................................................................................... 7

3.5 Analog Output Settings..................................................................................................................... 8

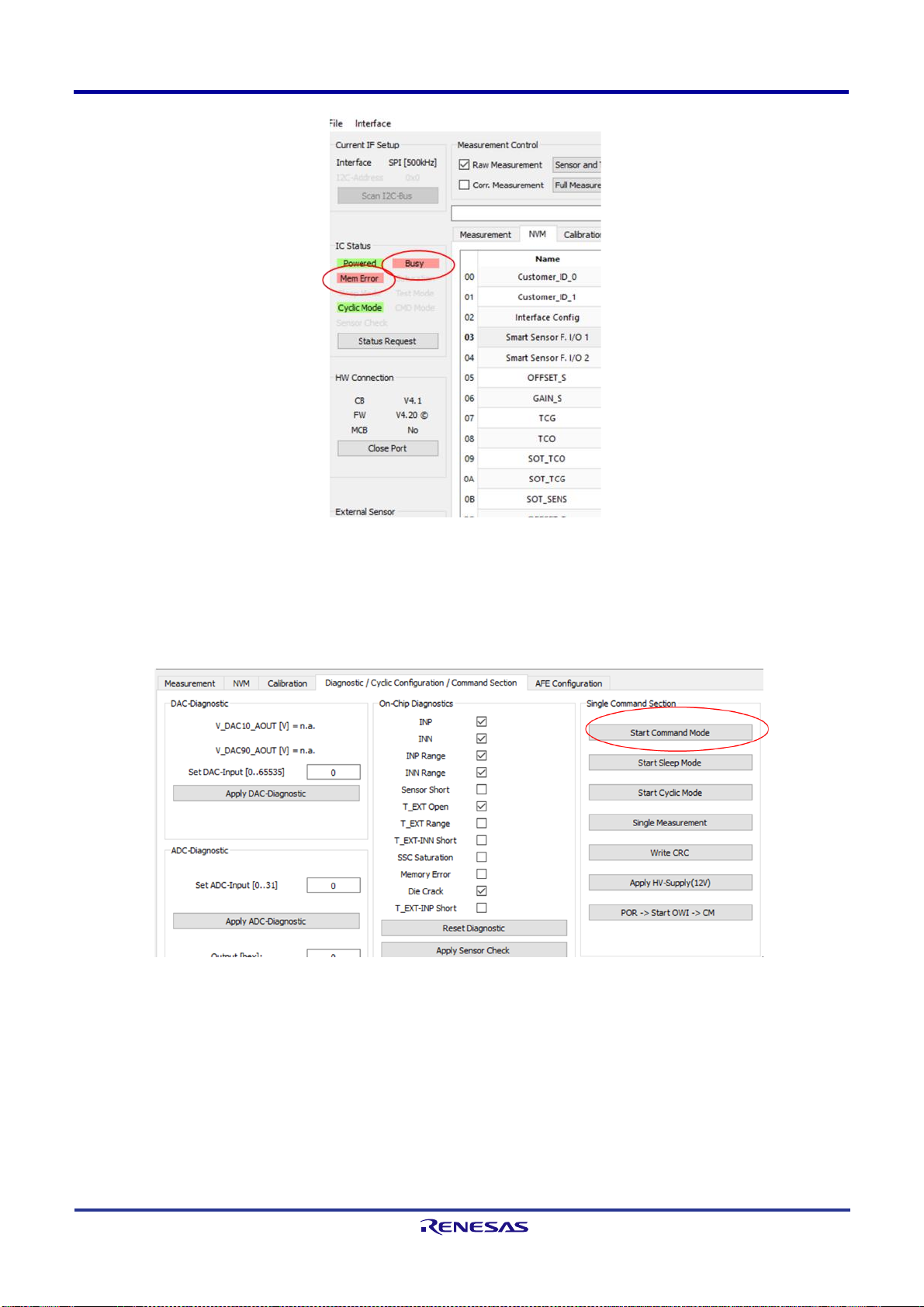

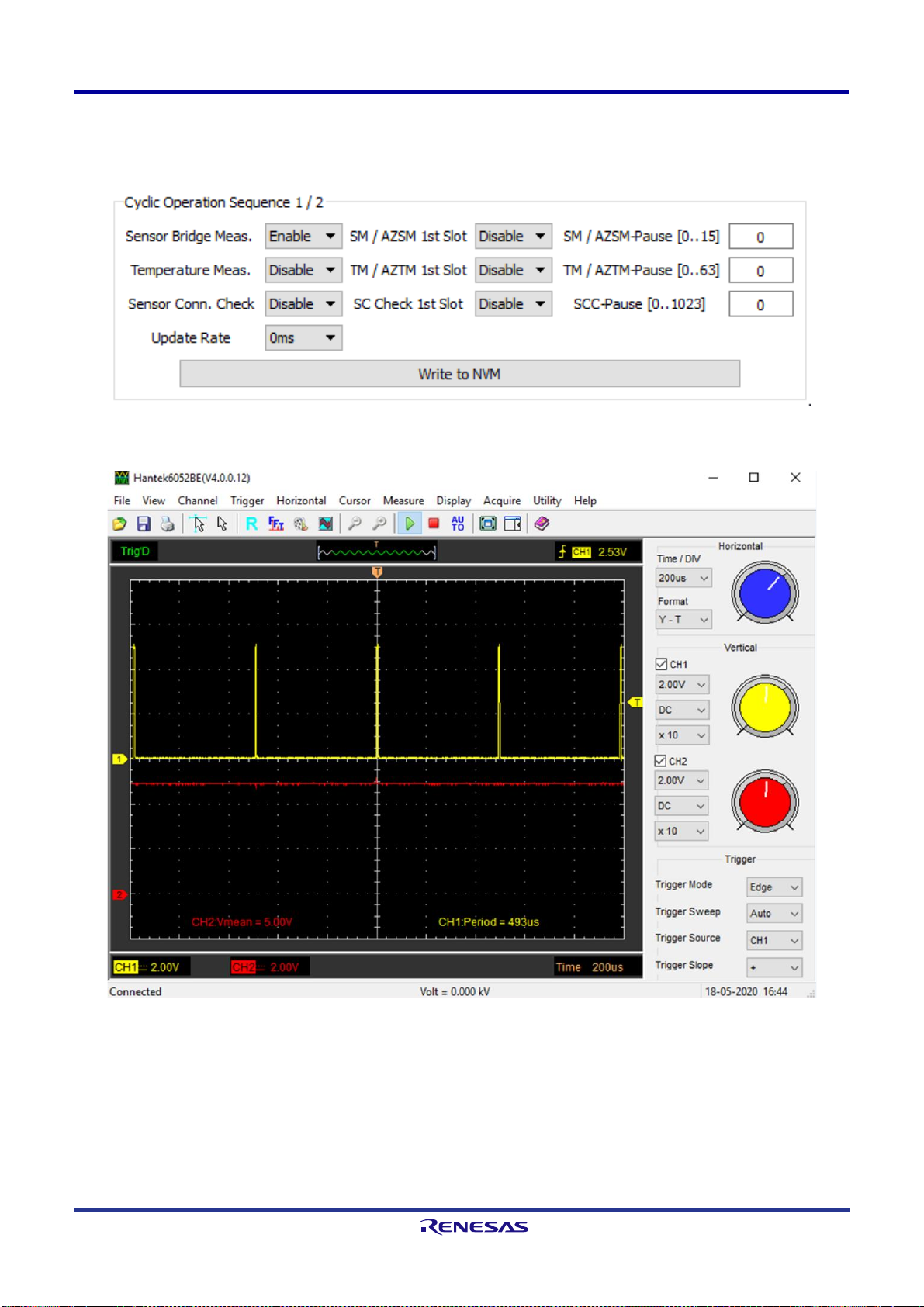

4. Scheduler GUI Control............................................................................................................................. 8

5. Scheduler Operation................................................................................................................................ 9

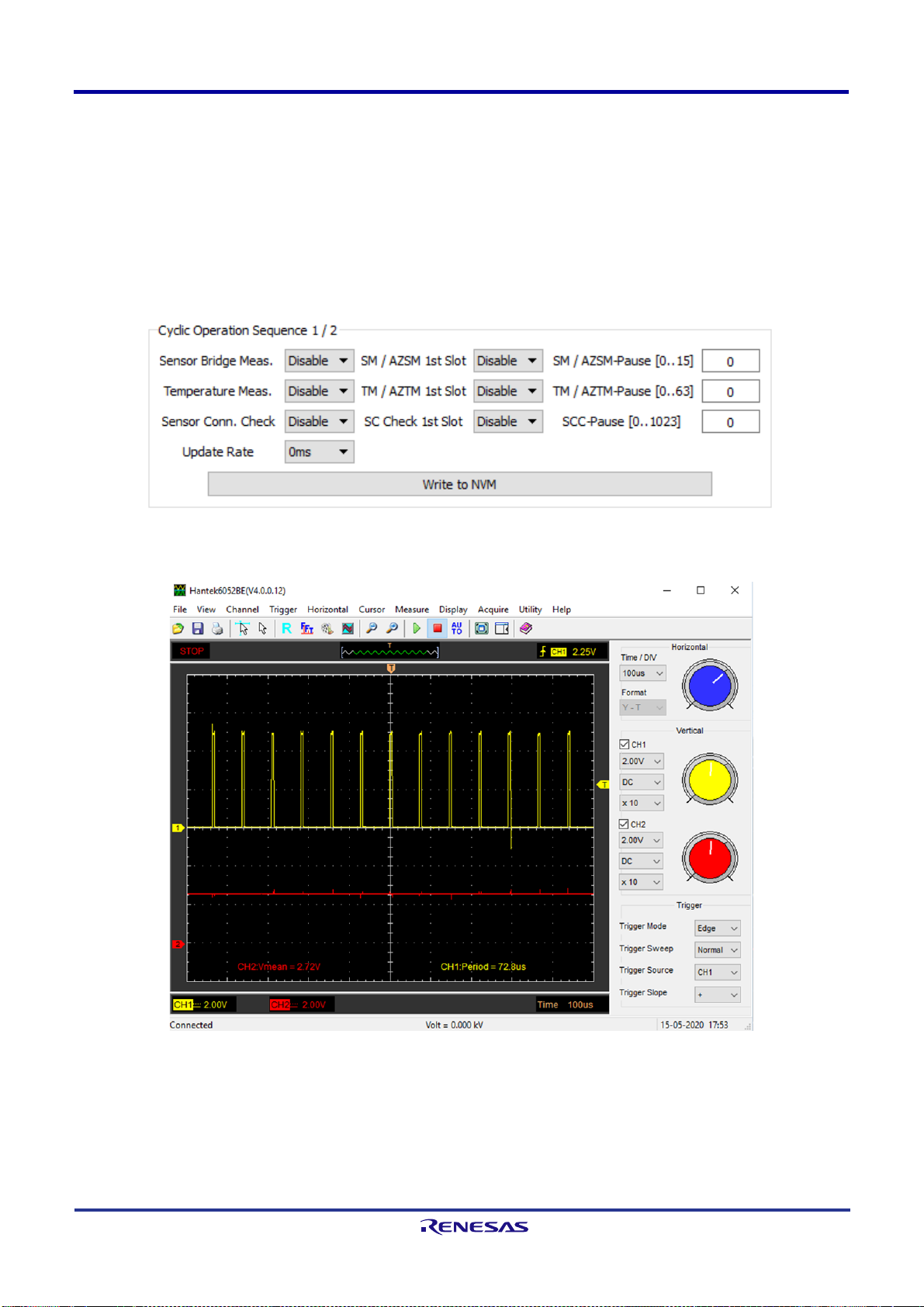

5.1 Scheduler without Configured Measurements................................................................................... 9

5.2 Scheduler with Activated SM.......................................................................................................... 10

5.3 Scheduler with AZSM + SM............................................................................................................ 11

5.4 Scheduler with External AZTM + TM............................................................................................... 11

5.5 Scheduler with AZSM, SM, AZTM and TM...................................................................................... 12

5.6 Sensor Connection Check.............................................................................................................. 13

5.7 Update Rate................................................................................................................................... 14

6. Scheduler Operation Examples............................................................................................................. 15

6.1 Example 1...................................................................................................................................... 15

6.2 Example 2...................................................................................................................................... 16

6.3 Example 3...................................................................................................................................... 18

7. Glossary ................................................................................................................................................. 19

8. Revision History..................................................................................................................................... 19