Translation of original - MU1H-1376GE23 R1020

Contents

1. Safety Guidelines............................................................................ 3

1.1 Safety instructions in this manual....................................................... 3

1.2 Safety instructions in the system........................................................ 3

1.3 General safety instructions................................................................ 3

1.4 Further safety regulations.................................................................. 3

1.5 Unauthorised operation types............................................................ 3

1.6 Software changes............................................................................. 3

1.7 Residual dangers in handling the compact booster unit ...................... 3

1 7.1 Mechanical residual dangers 4

1 7.2 Residual dangers pertaining to fluids 4

1 7.3 Residual electrical hazards 4

1 7.4 Residual biological hazards 4

1 7.5 Residual chemical hazards 4

1.7.6 Consequences and dangers that result from not observing the ma-

nual 4

1.8 Basic Safety Measures...................................................................... 5

1 8.1 Keep information available 5

1 8.2 For environmental protection 5

1 8.3 Modifications to the compact booster unit 5

1.9 Duty of due care of the operator ........................................................ 5

1.10Safety instructions for the operator/operating personnel ..................... 5

1.11Safety instructions for maintenance, inspections andassembly work .. 5

1.12Requirements for operating personnel ............................................... 5

1 12.1Operating personnel 5

1.13Personal safety equipment................................................................ 5

2. General information........................................................................ 6

2.1 Conformity with the following norms................................................... 6

2.2 Warranty and liability

......................................................................... 6

2.3 Storage and perfect condition............................................................ 6

2.4 Illustrations ....................................................................................... 6

2.5 Symbols ........................................................................................... 6

2.6 Other applicable documents.............................................................. 6

2.7 Glossary........................................................................................... 6

3. Description...................................................................................... 7

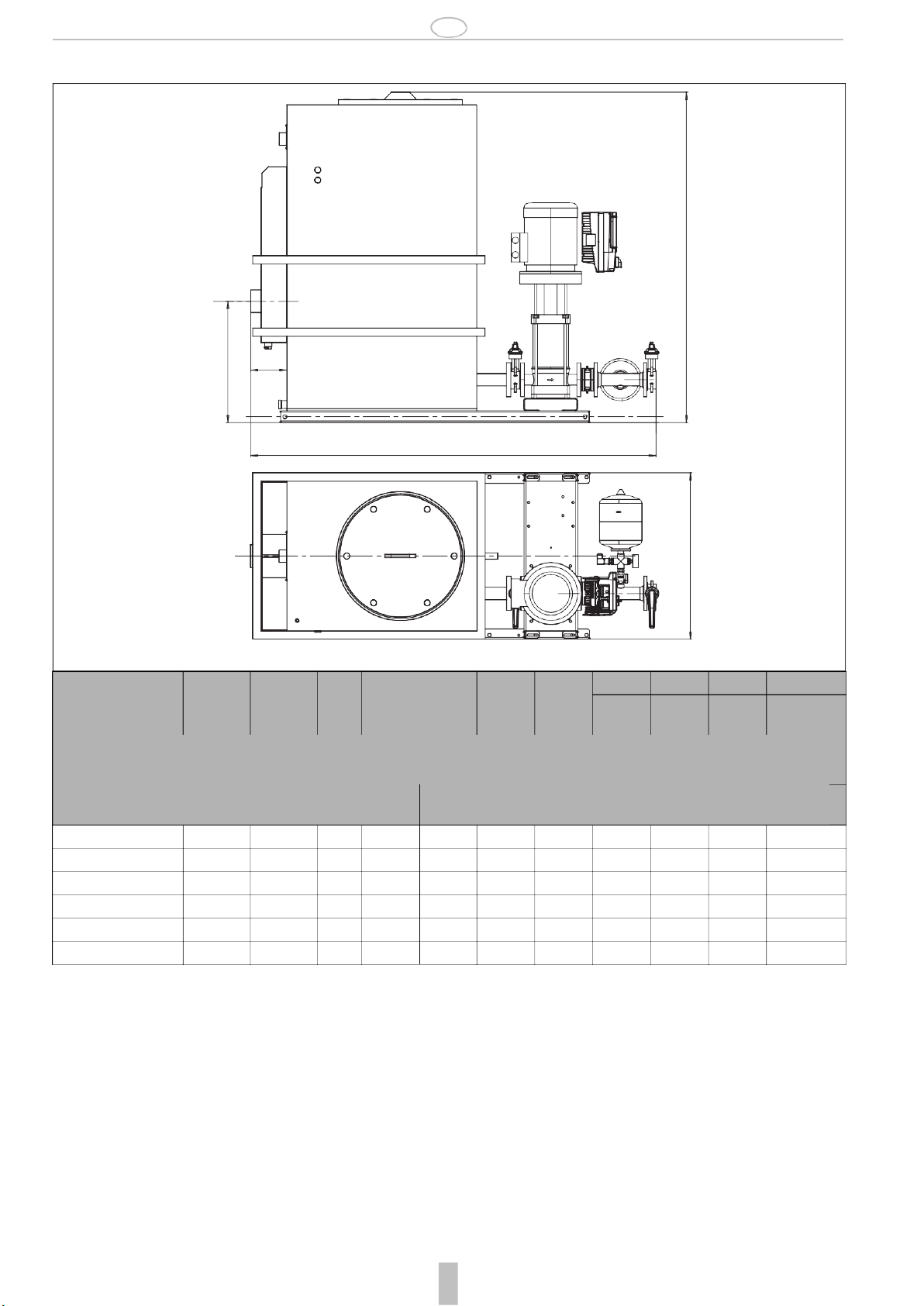

3.1 Overview .......................................................................................... 7

3 1.1 Installation type 7

3.2 Intended use..................................................................................... 7

3.3 Non-intended use.............................................................................. 7

3.4 Version............................................................................................. 8

3.5 Options............................................................................................. 8

4. Function.......................................................................................... 8

4.1 Inlet side........................................................................................... 8

4.2 Outlet side ........................................................................................ 8

4.3 Indicator LED.................................................................................... 8

4.4 Mode of operation............................................................................. 8

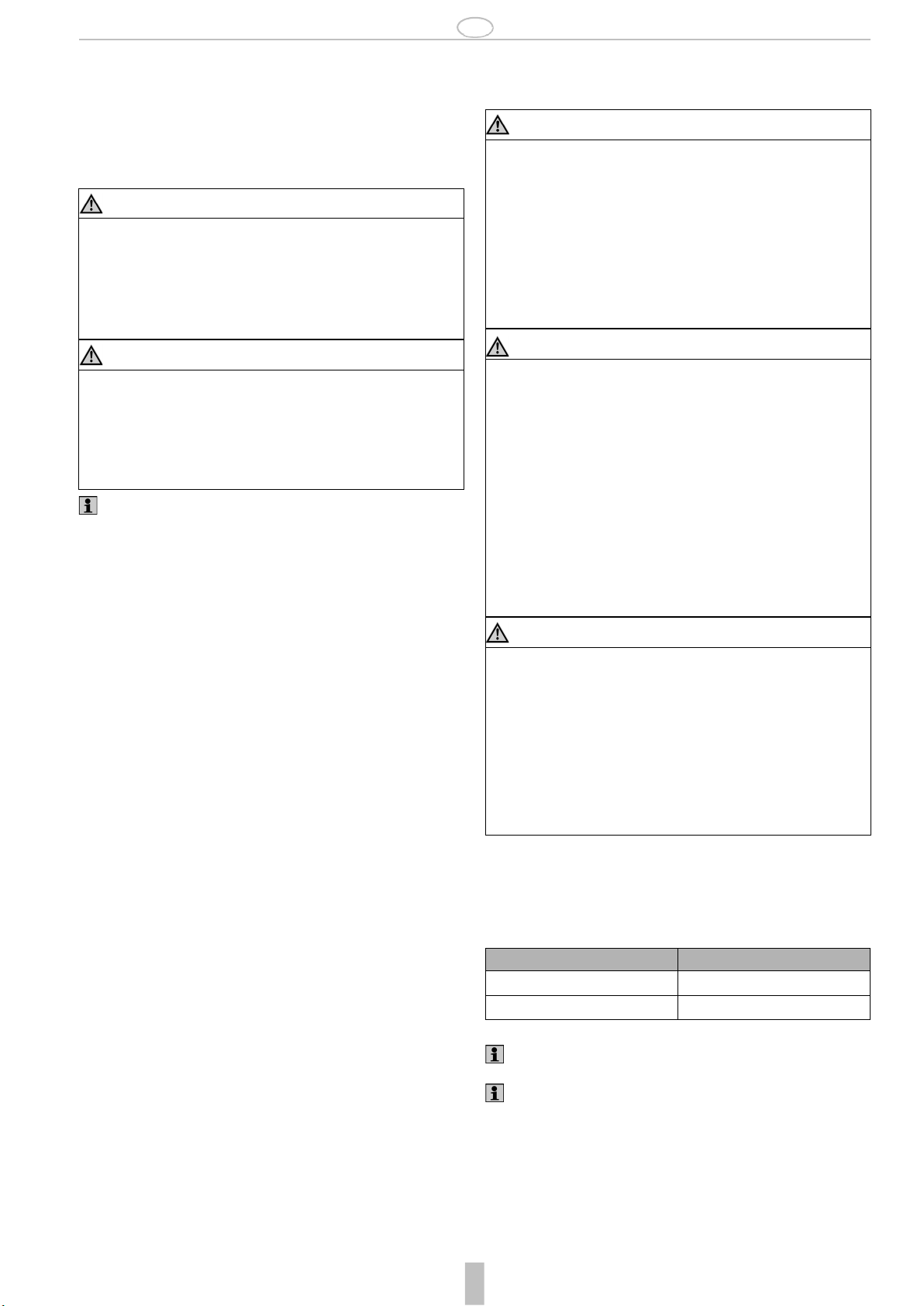

5. Technical data................................................................................. 9

5.1 Noise expectancy values................................................................... 9

5.2 Authorised environmental conditions ................................................. 9

6. Shipping........................................................................................ 10

6.1 Check condition upon delivery......................................................... 10

6.2 Transportation ................................................................................ 10

7. Assembly ...................................................................................... 10

7.1

General safety instructions...............................................................10

7.2 Installation according to EN1717......................................................10

7.3 Inspection before assembly .............................................................11

7.3.1 Installation site 11

7.4 Installing the compact booster unit ...................................................11

7.5 Installing the pipelines .....................................................................11

7.5.1 Connecting the overflow 11

7.5.2 Installing the compensator (optional) 11

7.6 Buffer tank ......................................................................................11

7.7 Installing valves...............................................................................11

7.8 Electrical connection........................................................................11

7.8.1Safety instructions 11

7.8.2Connection specifications 11

7.9 Standby indicator.............................................................................11

8. Start-up..........................................................................................12

8.1 Safety instructions for start-up..........................................................12

8.2 Start-up requirements......................................................................12

8.3 Initial operation................................................................................12

8. 3. 1

Change switch-on pressure 12

8.4 Switching the system on ..................................................................12

8.5 Start-up checklist.............................................................................13

9. Operation.......................................................................................13

9.1 Function of operating panel..............................................................13

10. Maintenance ..................................................................................13

10.1Safety instructions for maintenance..................................................13

10.2Inspection .......................................................................................13

10. 2. 1

Buffer tank 13

10. 2. 2

Monitoring Operation 13

10.2.3Checklist for Inspection 14

10.3Maintenance ...................................................................................14

10. 3. 1

Settingthe precharge pressure for the membrane pressure vessel

14

10. 3. 2

ning the dirt trap 14

10. 3. 3

Checklist for maintenance work 14

11. Troubleshooting............................................................................14

12. Shut-down, restart.........................................................................14

12.1Shutting down the compact booster unit ...........................................14

12.2Restarting the compact booster unit .................................................14

13. Storage ..........................................................................................14

13.1Short-term storage...........................................................................14

13.2Storage/Preservation.......................................................................14

13.3Storage conditions...........................................................................14

14. Disassembly, disposal ..................................................................15

14.1Safety instructions for disassembly...................................................15

15. Spare parts ....................................................................................15

16. Start-up protocol ...........................................................................16

17. Declaration of no objection ...........................................................17

18. Proof of Maintenance ....................................................................18