Content

1 Preface ................................................... Fehler! Textmarke nicht definiert.

1.1 Validity of these instructions .......................................................................4

1.2 Target group of this manual.........................................................................4

1.3 Intended use ................................................................................................4

1.4 Observance of the operating instructions ...................................................4

1.5 EC and VDE directives ..................................................................................5

1.6 Accident prevention (UVV) ..........................................................................5

2 For your safety .............................................................................................7

2.1 Convention...................................................................................................7

2.1.1 Pictograms....................................................................................................7

2.1.2 Display Types................................................................................................7

2.1.3 Warning signs...............................................................................................8

2.1.4 Prohibition signs...........................................................................................8

2.1.5 Mandatory sign ............................................................................................8

2.1.6 Information signs .........................................................................................8

2.2 Safety measures in the event of a malfunction ...........................................9

2.2.1 Safety-relevant environmental conditions ..................................................9

2.3 Possible sources of danger and protective measures................................10

2.3.1 Possible sources of danger.........................................................................10

2.3.2 Protective measures...................................................................................11

2.3.3 Check before each start of work................................................................12

2.4 Possible misuse ..........................................................................................12

2.5 Residual risks..............................................................................................12

3 Requirements for staff and operators .......................................................13

3.1 Operator.....................................................................................................13

3.2 Operator.....................................................................................................13

4 Warranty and liability.................................................................................13

4.1 Material defects .........................................................................................14

5 Technical Terms .........................................................................................14

6 Delivery, internal transport, unpacking .....................................................15

6.1 Delivery ......................................................................................................15

6.2 Unwrap.......................................................................................................15

6.2.1 Opening the euro plastic box.....................................................................15

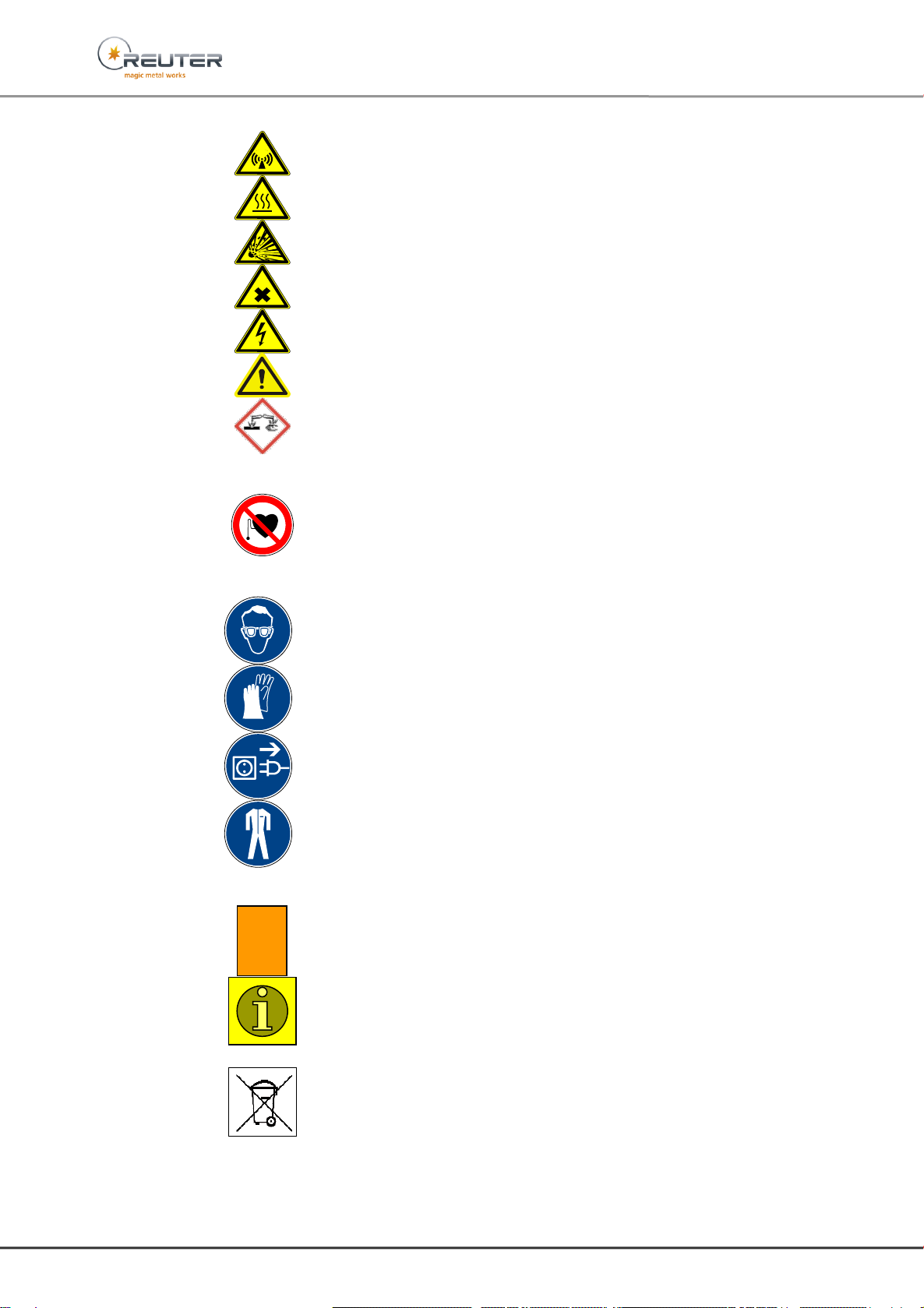

7 Scope of delivery Cleanox 5.0 device set...................................................15

7.1 Delivery listcleaning set "Cleanox 5.0".......................................................16

8 Storage .......................................................................................................18

9 Installation conditions................................................................................18

9.1 Safety..........................................................................................................18

10 Decommissioning / Storage .......................................................................18

11 Storage .......................................................................................................18

12 Equipment technology...............................................................................19

12.1 Cleanox 5.0.................................................................................................19

12.2 Application .................................................................................................20

12.3 Cooling and safety shutdown.....................................................................20

13 Front panel controls and controls..............................................................21

13.1 Circuit breaker (Overload FUSE).................................................................21

13.2 High-current sockets ..................................................................................22

13.3 IQS-Connector............................................................................................22

13.4 Elements on the back.................................................................................23

14 Accessories.................................................................................................23

14.1 Teflon handle with cable and plug for manual operation .........................23

14.2 AutoFeed handle for Cleanox 5.0...............................................................24