Ku nst sto ffschwei ßtechni k

Contents

03.03.2009 orking Instructions IDOS PSM 15 with pneumatic clamping Page 4 of 33

1.

DESCRIPTION OF PRODUCT ............................................................................................. 6

1.1.

Usage and non-intended use ..........................................................................................6

1.2.

Sa ety measures ..............................................................................................................6

1.3.

Con ormity........................................................................................................................6

1.4.

Designation o the product..............................................................................................7

1.4.1.

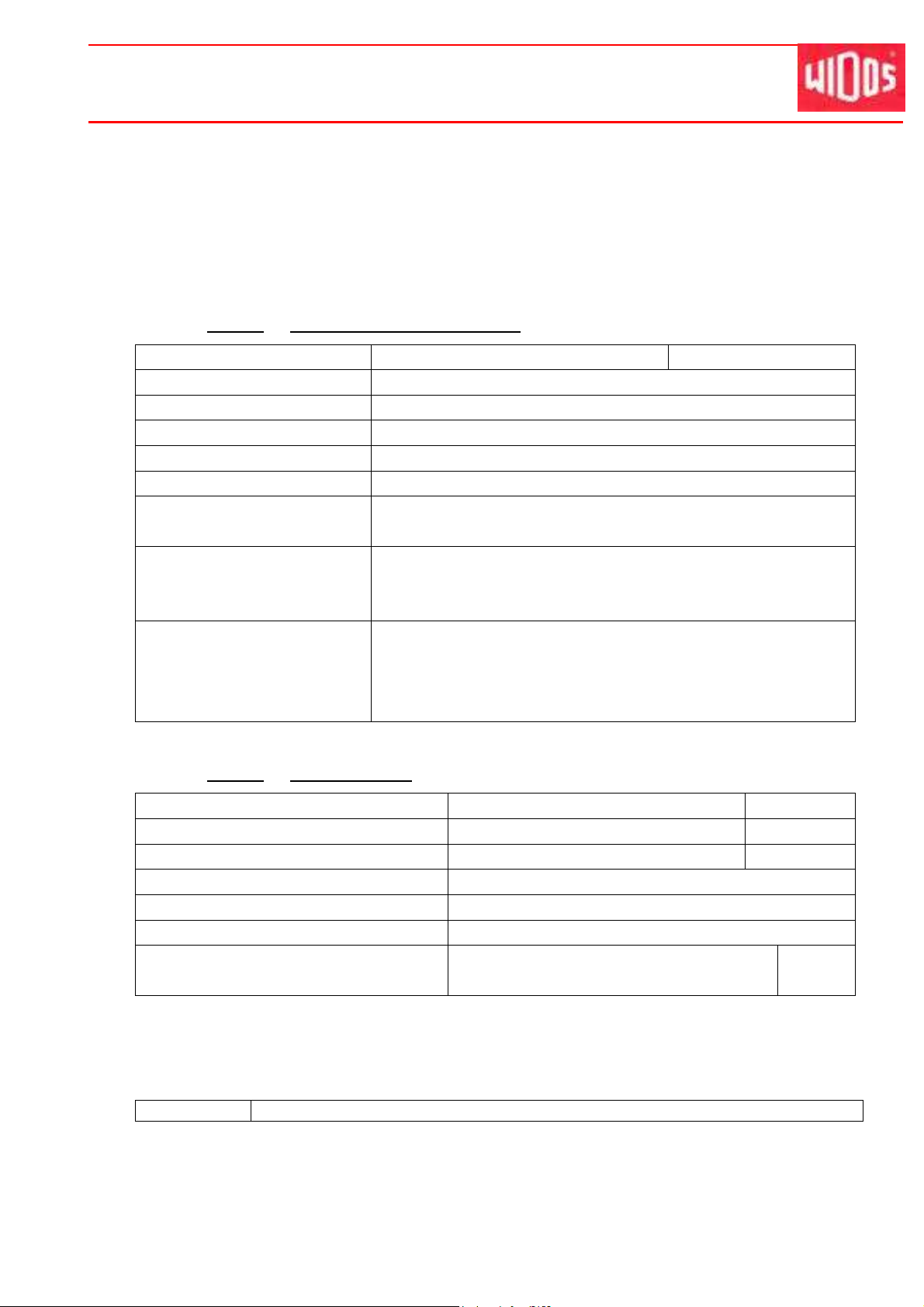

Technical data ...........................................................................................................7

1.4.1.1.

IDOS PSM 15 general data ...............................................................................7

1.4.1.2.

Heating element.....................................................................................................7

1.4.2.

Accessories...............................................................................................................7

2.

SAFETY RULES..................................................................................................................... 8

2.1.

Explication o the di erent symbols ...............................................................................8

2.2.

Obligations o the operator .............................................................................................9

2.3.

Obligations o the worker ................................................................................................9

2.4.

Measures o organization ................................................................................................9

2.5.

In ormation on sa ety precautions..................................................................................9

2.6.

Instructions or the sta ..................................................................................................9

2.7.

Dangers while handling the machine............................................................................10

2.8.

Special dangers .............................................................................................................10

2.8.1.

Danger of stumbling over pneumatic and electric wires ............................................10

2.8.2.

Danger of combustion at heating element resp. welding area ...................................10

2.8.3.

Danger of crushing near and between the clamping beams ......................................11

2.9.

Structural modi ications on the machine .....................................................................11

2.10.

Cleaning the machine ....................................................................................................11

2.11.

Warranty and liability .....................................................................................................11

3.

FUNCTIONAL DESCRIPTION............................................................................................ 12

4.

OPERATING AND INDICATING ELEMENTS .................................................................. 13

4.1.

Components at the heating element ............................................................................14

4.2.

How to clamp the sheet .................................................................................................15

4.3.

Service unit ....................................................................................................................16

4.4.

How to clamp sheets or angle welding ........................................................................17

5.

STARTING AND OPERATING........................................................................................... 18

5.1.

Starting ...........................................................................................................................18

5.2.

Welding process ............................................................................................................19

6.

WELDING TABLES ............................................................................................................. 21

7.

MAINTENANCE / STORAGE / TRANSPORT.................................................................. 24