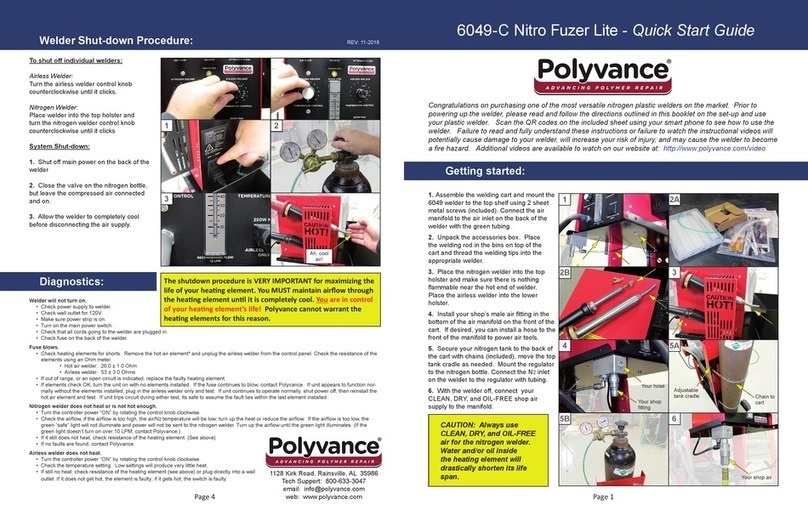

Page 6

When you return the torch to the holster, the welder will start its automatic cooldown pro-

cess. The air pump remains on to cool the heating element. You will see the temperature

reduce. Once it returns to 100°C (212°F), the air pump will automatically turn o. The LCD

screen will return to showing three dashes and the words “HOT AIR”, indicating that the

torch is ready to use once you pick it up from the holster.

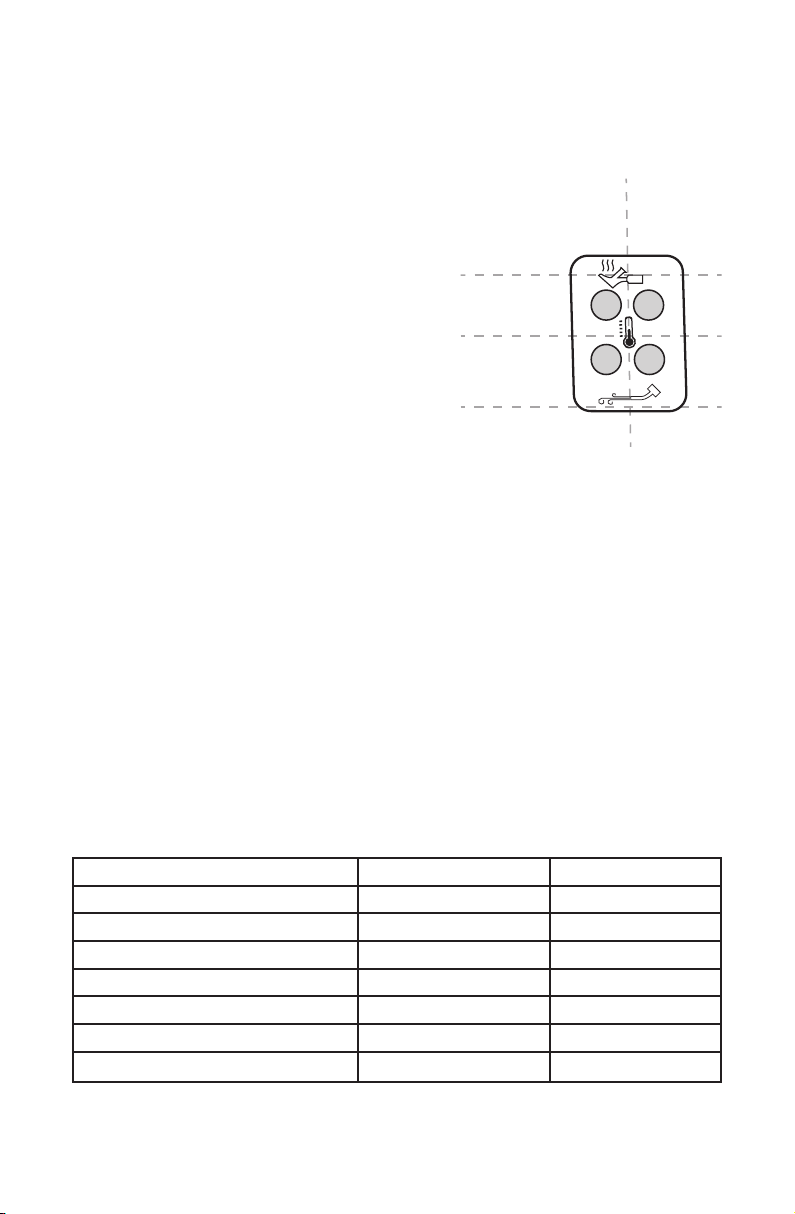

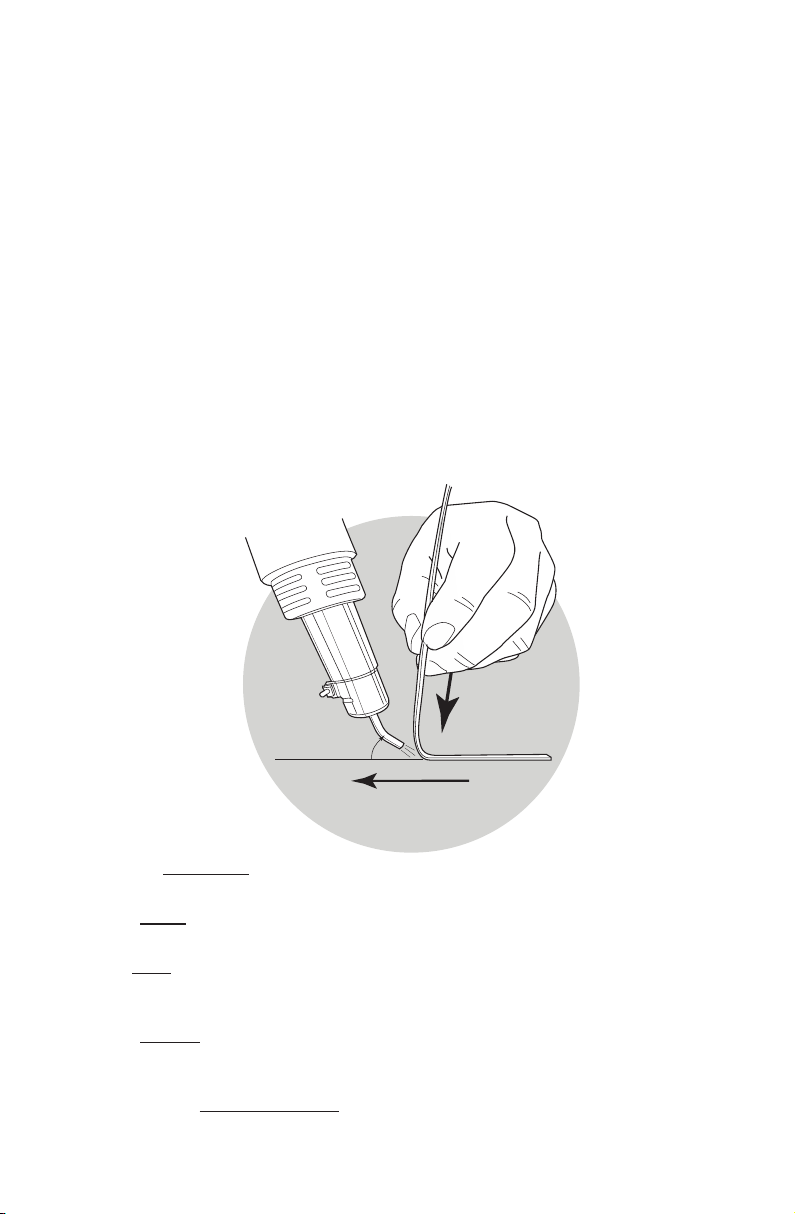

6.2.1 Adjusting Welder Temperature - To adjust the

welder temperature, push the appropriate buttons on

the control panel as shown in the image to the right.

6.2.2 Adjusting Hot Air Welder Airow - Rotate the

airow control knob clockwise to increase ow and

counterclockwise to reduce ow. The graphic on the

LCD screen gives a visual indication of the relative

ow rate. The ow rate may be adjusted to suit the

thickness of plastic being welded. Typically, thicker

plastics will need higher ow and thinner plastics will

need lower ow.

6.2.3 Toggling Hot Air Welder Power - Pushing the

airow control knob will toggle power to the hot air

torch. Push the knob once and you will see the words “HOT AIR” on the LCD screen turn

o and you will see the temperature readout start to come down. The air pump will remain

on until the heating element is cooled down. Push the knob again and the words “HOT AIR”

on the LCD screen will turn on and the temperature will start to rise toward the setpoint.

Returning the torch to the holster will start the automatic cooldown process, so toggling the

power with the knob is not needed in most situations.

7.0 SETTING MEMORY BUTTONS

You may save your preferred welder settings with one of the three memory buttons, labeled

M1, M2, and M3. To save preferred welder settings, adjust the welder’s parameters (airow,

hot air welder temperature, airless welder temperature, and C°/F°) to the settings you want

to save. Press and hold the memory button to which you would like to save these settings

for two seconds, until you hear a beep. These settings are now saved to that button.

Airow setting depends on the thickness of the plastic you are welding. Reduce airow

when welding thin plastics. Increase airow when welding thick plastics.

Temperature setting depends on the type of plastic you are welding. Use the settings in the

below table as a guide for welding various common plastics. Adjust up or down as neces-

sary to suit your need.

Plastic Type Hot Air Temp. Setting Airless Temp. Setting

ABS - acrylonitrile butadiene styrene 325°C / 620 °F 325°C / 620 °F

HDPE – high density polyethylene 400°C / 750 °F 400°C / 750 °F

LDPE – low density polyethylene 375°C / 700 °F 375°C / 700 °F

PA – polyamide (nylon) 450°C / 840 °F 450°C / 840 °F

PC - polycarbonate 350°C / 660 °F 350°C / 660 °F

PP – polypropylene 400°C / 750 °F 400°C / 750 °F

PUR - polyurethane (do not use hot air on PUR) 290°C / 550°F

-+

Hot Air

Airless

-+

irless welder

temperature

adjustment buttons

Hot air welder

temperature

adjustment buttons

Press left

button to

reduce

temperature

Press right

button to

increase

temperature