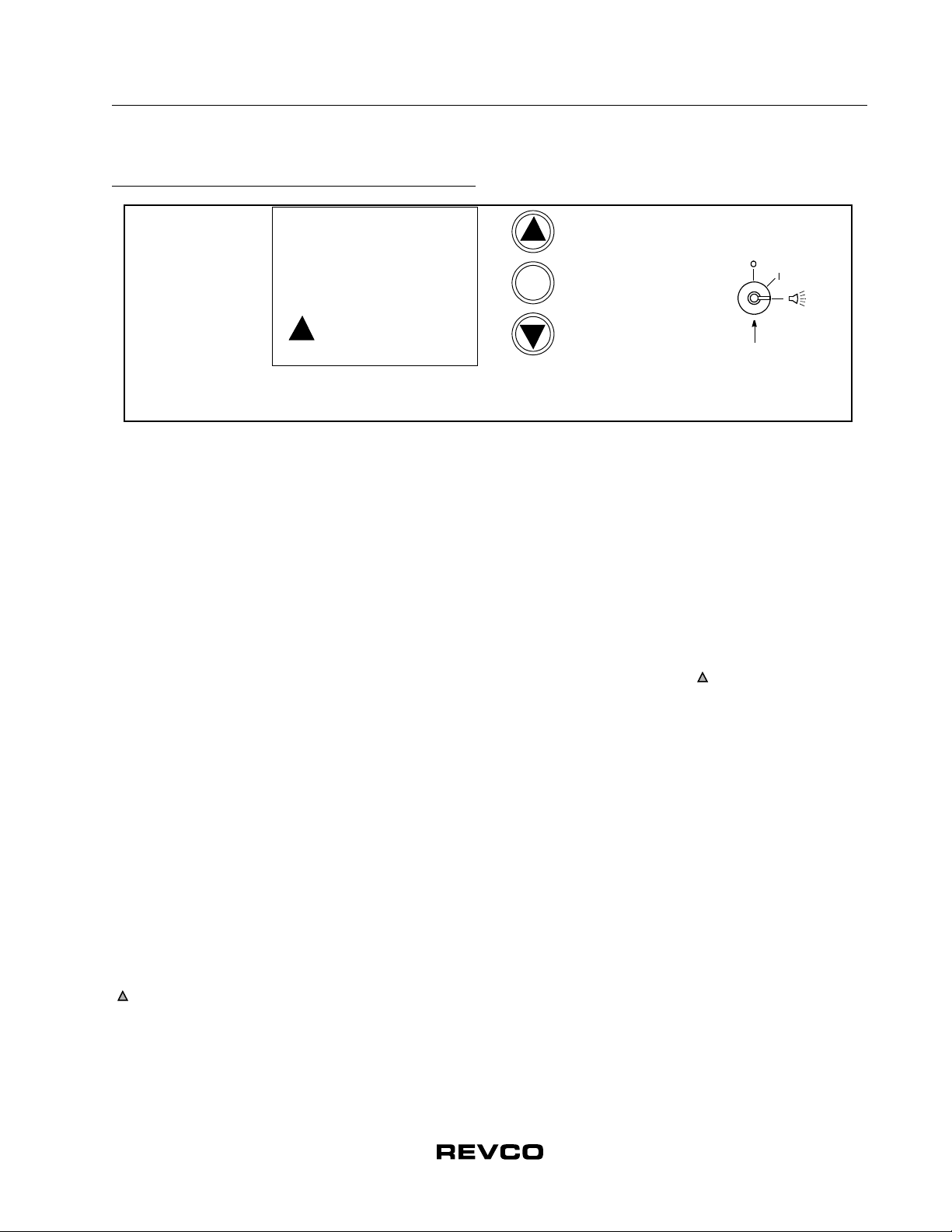

Installation and Operation

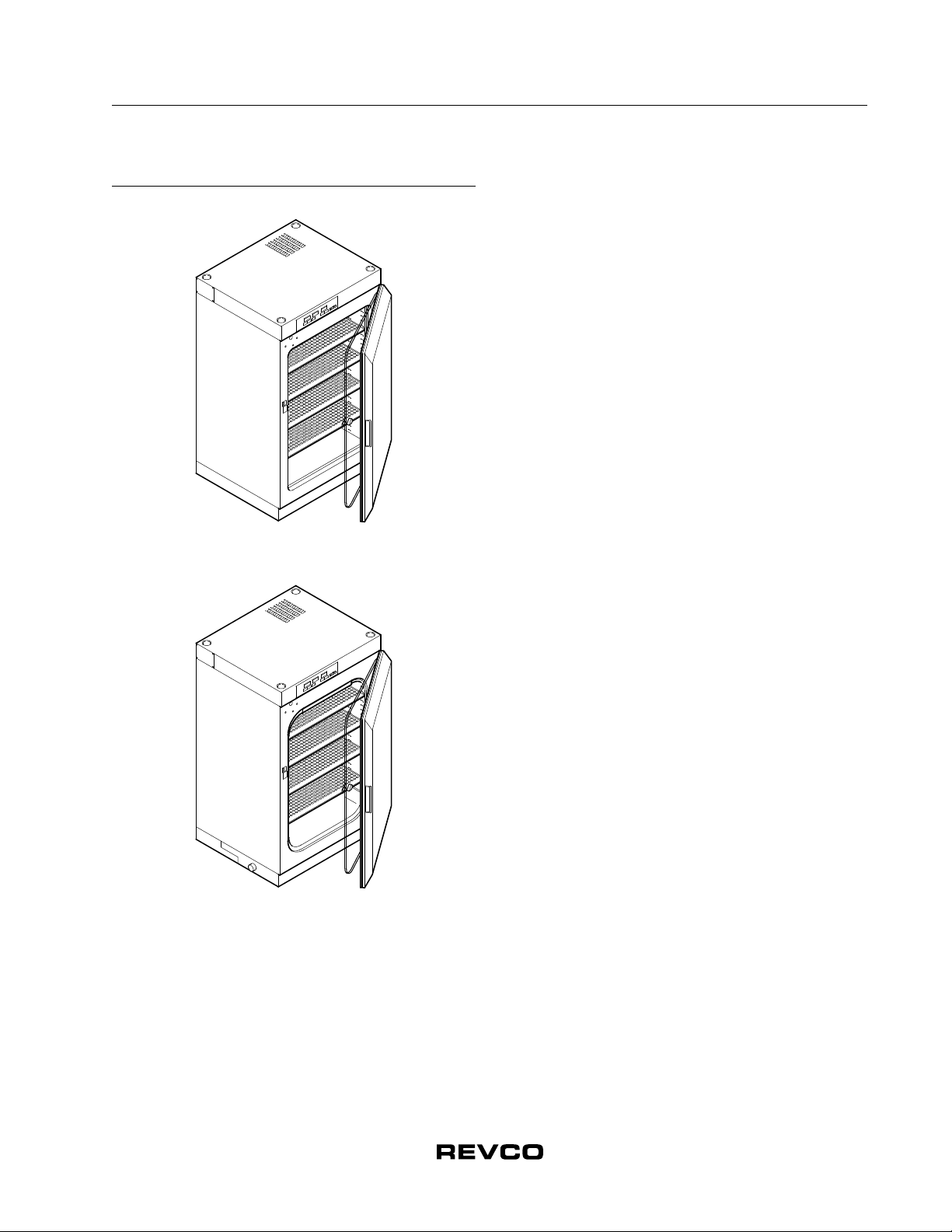

Ultima II and Elite II Incubators

2

2 Safety Precautions

In this manual and on labels attached to this product, the words

WARNING and CAUTION mean the following:

•WARNING: a potentially hazardous situation which, if not

avoided, could result in serious injury or death.

•CAUTION: a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury or damage to

the equipment.

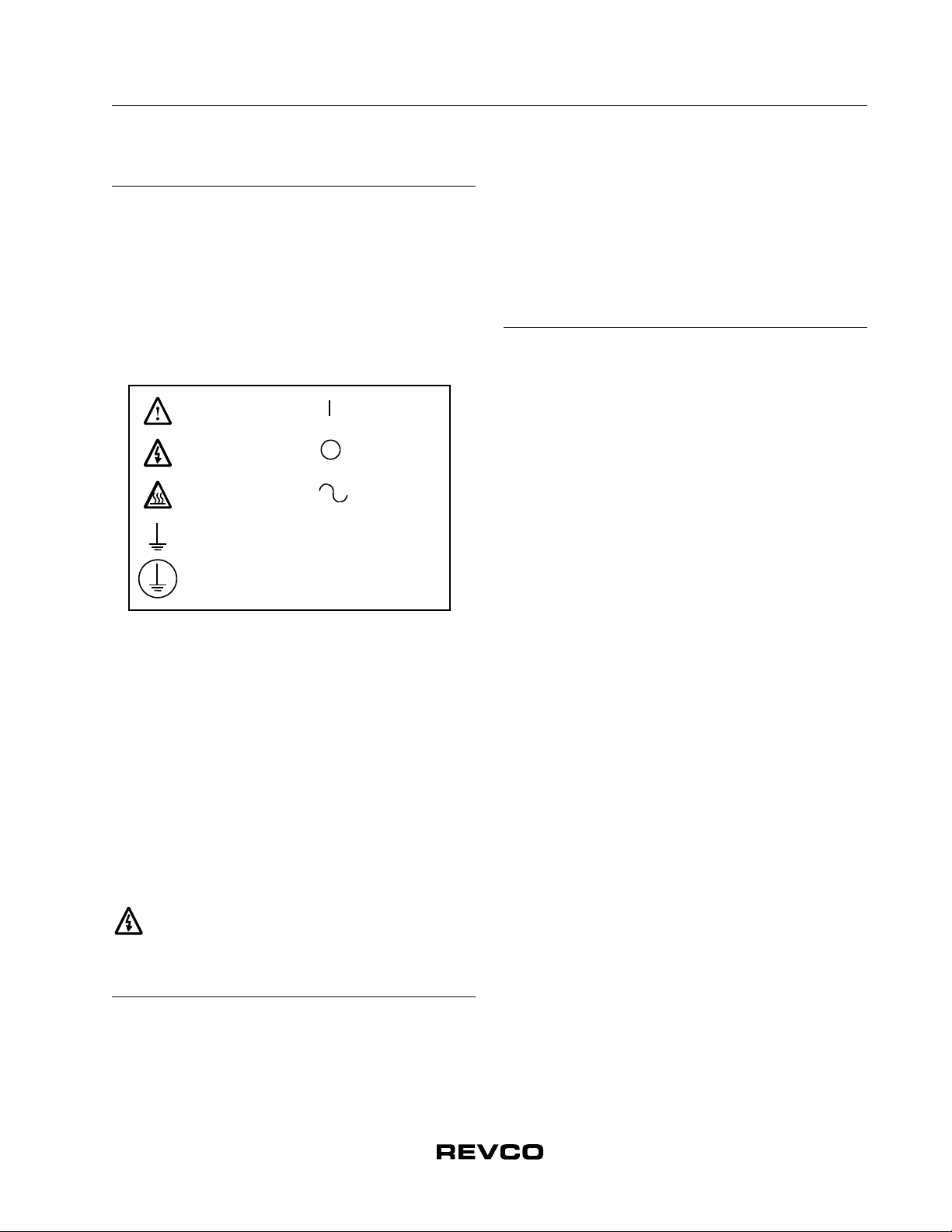

The following symbols are used in caution, warning and

informational labels attached to the incubator:

Before installing, using or maintaining this product, please be sure

to read this manual and product warning labels carefully. Failure to

follow these instructions may cause this product to malfunction,

which could result in injury or damage.

Below are important safety precautions that apply to this product:

•Use this product only in the way described in the product

literature and in this manual. Before using it, verify that this

product is suitable for its intended use.

•Do not modify system components, especially the controller.

Use OEM exact replacement equipment or parts. Before use,

confirm that the product has not been altered in any way.

•Disconnect the unit from all power sources before cleaning,

troubleshooting, or performing other maintenance on the

product or its controls. To disconnect power supply to the

incubator, unplug the supply cord at the back of the incubator.

Note that turning the key switch on the front control panel to

the Off position is not sufficient to disconnect power.

WARNING! The user is responsible for carrying out

appropriate decontamination procedures when

hazardous materials are spilled on or inside the

incubator.

3 Operating Standards

The incubators described in this manual are classified for use as

stationary equipment in a Pollution Degree 2 and Overvoltage

Category II environment, according to the UL61010A-1 and IEC

664 standards.

These units are designed to operate under the following

environmental conditions:

•Indoor use

•Altitude up to 2000m

•Maximum relative humidity 80% for temperatures up to 31ºC

•Main supply voltage fluctuations not to exceed 10% of the

nominal voltage.

4 Pre-Installation

4.1 Unpacking

At delivery, examine the exterior for physical damage while the

carrier’s representative is present. If exterior damage is present,

carefully unpack and inspect the unit and all accessories for

damage. If there is no exterior damage, unpack and inspect the

equipment within five days of delivery. If you find any damage,

keep the packing materials and immediately report the damage to

the carrier. Do not return goods to the manufacturer without

written authorization. When submitting a claim for shipping

damage, request that the carrier inspect the shipping container

and equipment.

4.1.1 Included Parts

The following items are packaged and shipped inside the

incubator cabinet:

•Shelves and shelf brackets

•3/16 in. (476 mm) ID clear tubing for the gas connection (a Y

fitting is also supplied with dual-chamber units)

•Decontamination kit: 0.3 micron gas filter, replacement

Blower Wheel, CO2Sensor gasket, and Injection Port

Assembly gasket

•Tubing, funnel, and bottle of water conditioning crystals for

filling the water jacket

•Humidity pan

•HEPA filter (if one comes with your unit)

•A thin, 1/2” open-end wrench to adjust leveling legs and

relocate the outer door hinge

•Stacking brackets (for dual models)

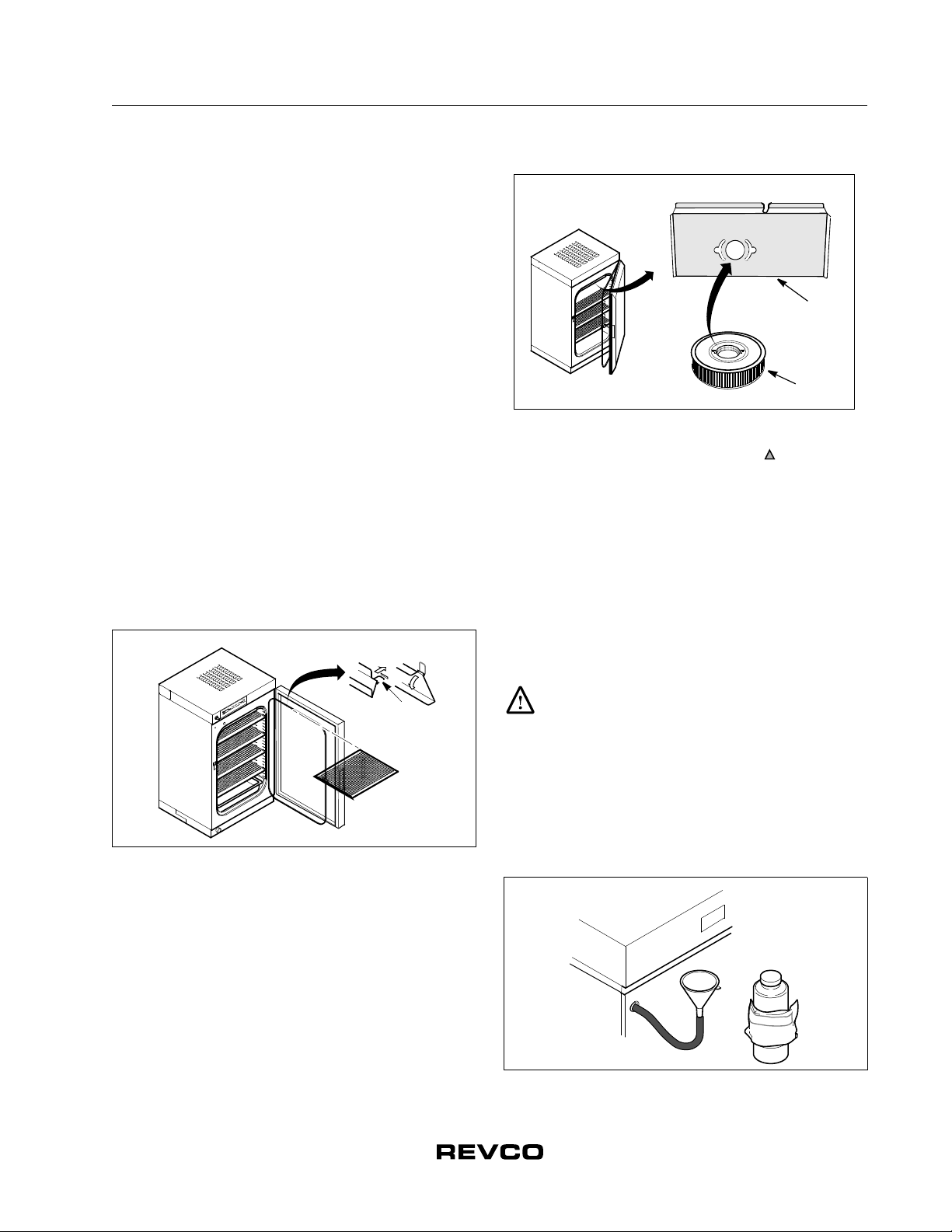

4.2 Set-up

Remove shelves from the inside of the incubator and clean the

incubator (refer to Section 8.1 on page 14). The shelves and

brackets can be autoclaved at this time.

4.3 Location

Install the unit in a level area free from vibration with a minimum

of three inches (7.6 cm) of space on the sides and rear and

12 inches (30.5 cm) at the top. The floor must be able to support

40 PSI (single chamber incubator) or 75 PSI (double chamber

incubator).

Be sure to position the incubator so that the power cord can

easily be reached to disconnect power. Do not position the

equipment in direct sunlight or near any HVAC duct/diffusers.

The ambient temperature range at the location must be 59 to

90°F (15 to 32°C).

caution, info

electrical hazard

hot surface

earth ground

protective conductor terminal

on

off

alternating

current