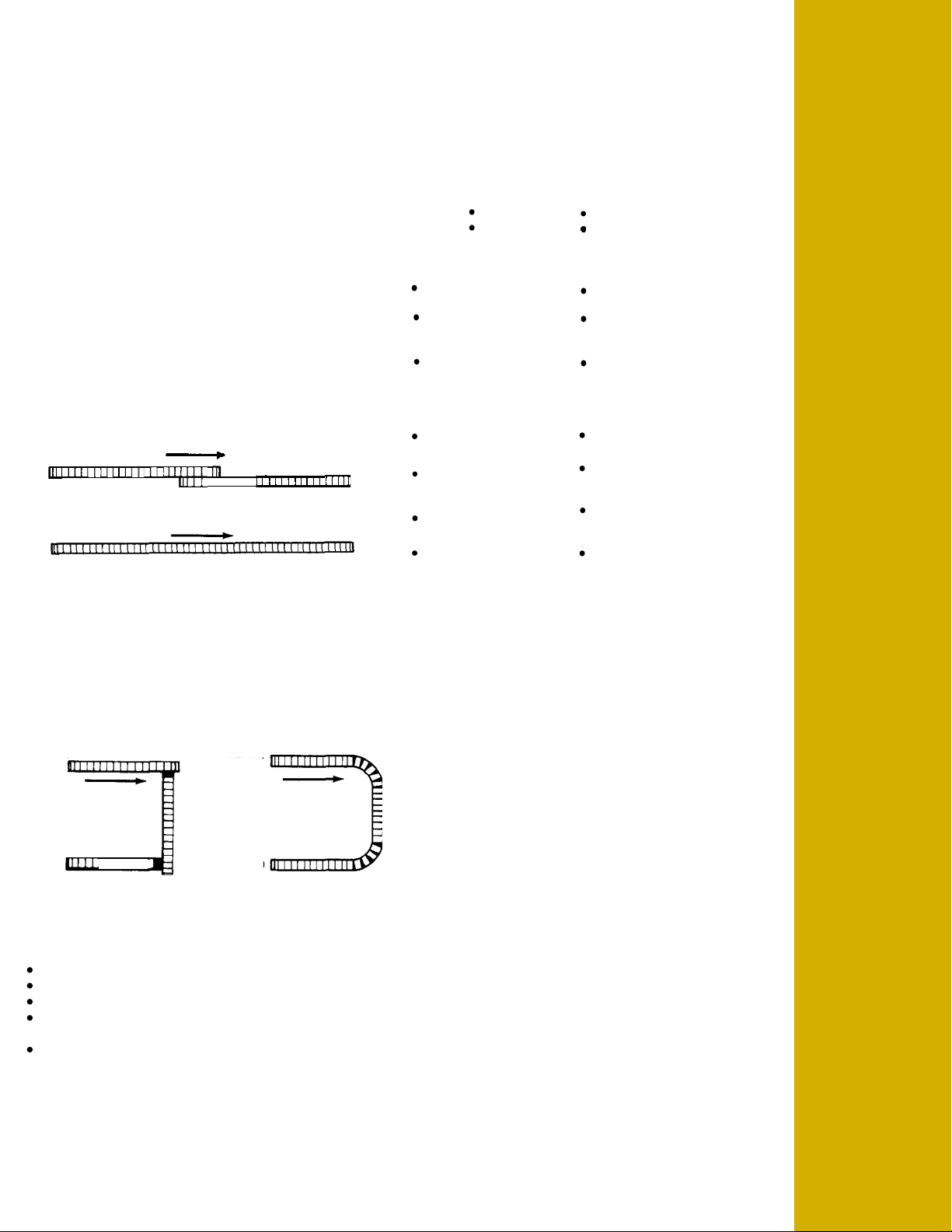

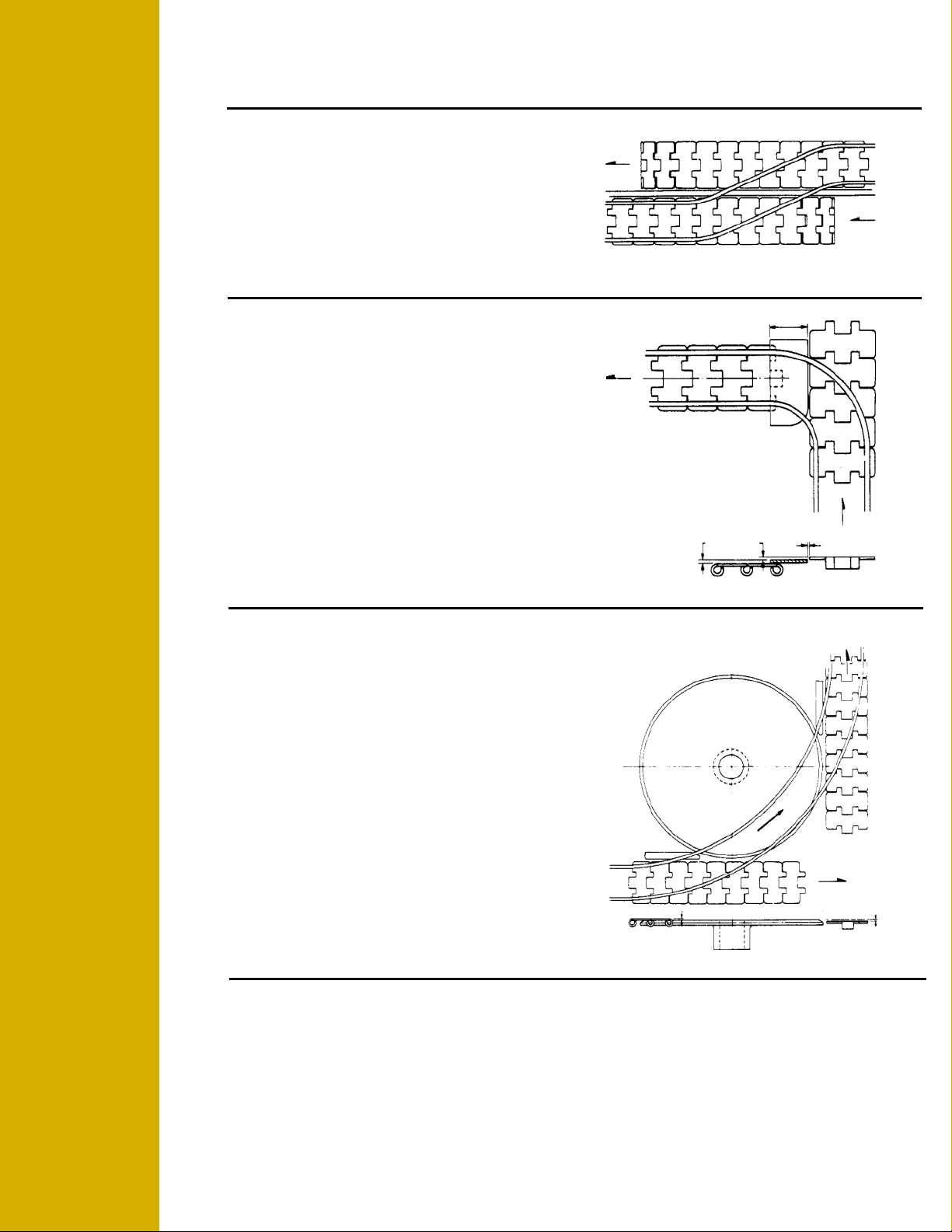

CONVEYOR LENGTH AND CONFIGURATION

STRAIGHT -

TRANSFER END

START

Figure A

Figure B

- A B

START START

END I I I I I I I END

Figure A Figure B

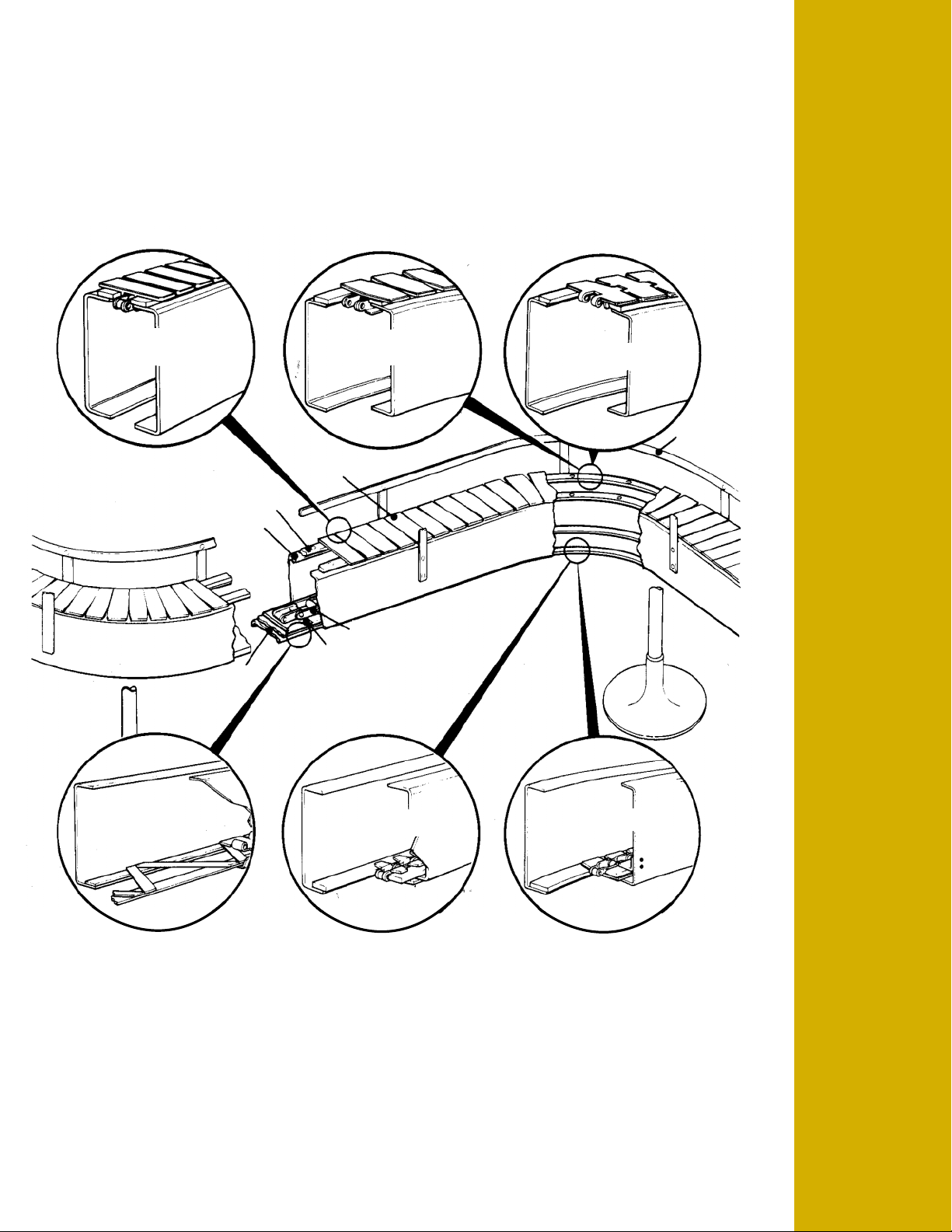

SIDEFLEXING VS

A B

VS

END

START

Rexnord does not build conveyors which use TableTop®chains,

nor does it specify one conveyor design over another. However,

based on many years of application experience, Rexnord is well

qualified to point out general guidelines and alternatives in

conveyor systems design, chain application and chain selection.

Conveyor systems design consists of Systems Economics and

Cost which involves:

1. Conveyor Length and Configuration

2. Chain Width and Speed

3. Overall Conveyor Cost

4. Maintenance

Begin with a review of the overall layout including space

available, structural obstructions and process machinery and the

relative positions of different machines. Then, using the following

considerations, arrive at the optimum machinery and conveyor

layout for proper utilization of TableTop®chains.

The longest, simplest configuration possible, (Fig B) is always

the best. However, sometimes short conveyors with several

transfers must be used to change speeds, change inclines,

accumulate, etc.

Use sideflexing chains and run as far as possible. This

alternative (Fig B) offers the following advantages over Figure A:

Elimination of transfers over dead-plates and turntables.

Less tipping and jamming, less noise.

Elimination of product slippage at transfer points.

Reduction of expense for attendant machinery including motors,

sprockets, etc.

Reduction of expense for attendant machinery including dead-

plates and turntables.

The criteria for conveyor width and speed is the number of

products which must be delivered to a location per unit of time.

The infeed and outfeed of each process machine will dictate

product flow width at the machines. But in-between, the

alternatives range from high speed-single file to intermediate

speed-multiple file on one wide chain to slow speed-multiple file

on multiple wide strands.

Weigh the advantages and disadvantages of each:

Single File Multiple File

High Speed Slow Speed

ADVANTAGES

Less expensive chain Longer chain life due to

slow speed

Less expensive initial Less chance of product

conveyor cost tippage

Longer runs In-line accumulation

less noise

DISADVANTAGES

Faster chain wear More expensive chain

More wear on products More expensive initial

when slippage occurs conveyor cost

More chance of product Shorter runs

tippage and jam-ups

Noisier Multiple chain strands may

cause transfer problems

To determine chain widths and see Page 14, Multiflex.

OVERALL CONVEYOR COST

Overall conveyor cost includes:

1. The cost of one chain versus another.

2. The cost of more efficient chains versus the cost of drives

and transfer equipment.

3. The cost of structural components of one system versus

another.

MAINTENANCE

Of course, keep in mind the future conveyor maintenance. A

system which is less expensive initially will usually require more

maintenance later on.

IN CONCLUSION

There may be more than one right way to utilize TableTop®

chains. Consider the alternatives of length, configuration, width,

speed and cost to design a system which is both economical for

the fabricator and the user.

Rex

®

Engineering Manual TT-1

INTRODUCTION

Rex®TableTop®Chains