F3788-7-04 Safety Section 1-2

SAFETY PRECAUTIONS

Safety of the operator was a prime

consideration in the design of this

backhoe. Proper shielding convenient

controls, simple adjustments and other

safety features have been built into this

backhoe.

Accidents can be avoided if the following safety rules are

observed:

PREPARATION

Do not operate backhoe unless it is rigidly attached to the

tractor.

Know your controls. Read this operators manual and the

manual provided with your tractor. Learn how to stop the

tractor; the engine; and the backhoe quickly in an

emergency.

Provide adequate front end weight to counter balance the

backhoe at all times.

Be sure the area is clear of underground utilities or other

hazards.

Position a barricade around the work area.

Keep all bystanders a safe distance away.

OPERATION

Never allow anyone to operate the backhoe who is not

familiar with safe operating practices.

Do not attempt to enter operators platform by using

stabilizers as a step.

Operate from the backhoe operators seat only.

Allow only one person to operate the backhoe at a time.

Never dig with backhoe unless stabilizers are properly

set.

Do not dig under stabilizers or tractor with backhoe. Soft

ground or sandy soil can cause cave-ins.

Always swing bucket uphill to dump when on a hillside,

Keep loaded bucket low.

Set brakes and lock wheels when operating on hills and

banks to avoid dangerous run-away.

Watch for overhead wires. Do not touch wires with any

part of backhoe.

Never allow a person to work under a raised bucket.

Never lift a person with backhoe.

Do not use bucket as a battering ram.

Always lower bucket to ground when not digging.

Never leave tractor unattended with engine running.

TRANSPORTATION

Do not drive tractor near the edge of a ditch or excavation.

Always use accessory lights when transporting on a road

or highway to warn operators of other vehicles.

Check your local government regulations.

Be sure that slow moving vehicle emblem is visible to the

rear.

ADJUSTMENTS AND INSPECTION

Check pins and hardware that attach backhoe to tractor

and all pivot pins for tightness several times daily.

Replace any parts which are bent, broken or missing.

Do not oil, grease or adjust backhoe while it is in motion.

Do not change any backhoe relief valve settings. They are

factory set for best backhoe performance and safety.

CAUTION: Escaping hydraulic fluid under

pressure can penetrate skin causing

serious personal injury.

•DO NOT use your hand to check for leaks. Use

a piece of cardboard or paper to search for

leaks.

•Stop engine and relieve pressure before

connecting or disconnecting hydraulic lines.

•Tighten all connections before starting engine or

pressurizing lines.

•If any fluid is injected into skin, obtain medical

attention immediately or gangrene may result.

Be sure to relieve all pressure before disconnecting lines.

Be sure all connections are tight and that lines, pipes and

hoses are not damaged before applying pressure to the

system.

Do not remove any guards on backhoe or tractor.

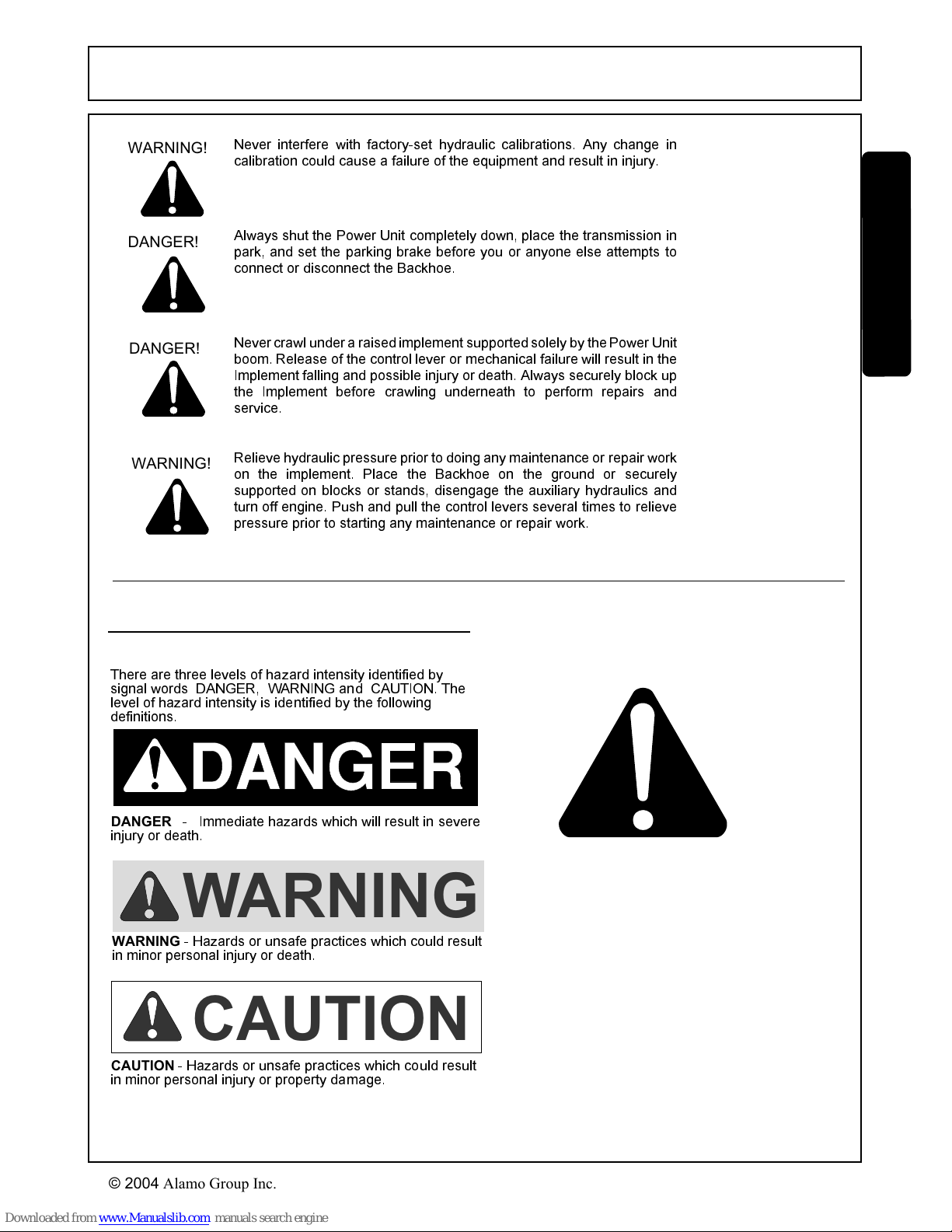

SAFETY

Whenever you see this symbol It means: ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

SAFETY

© 2004 Alamo Group Inc.