1. Safety instructions

• Switch main power off and wait 5 minutes before making any connection or

disconnection on the device. Danger of serious injury or property damage!

• To guarantee sufficient convection cooling, please keep a distance of 50 mm [1.97 in]

above and below the device as well as a lateral distance of 20 mm [0.79 in] to other units.

• Please note, that the enclosure of the device can become very hot depending on

the ambient temperature and load of the power supply. Risk of burns!

• Only plug in and unplug connectors when power is turned off!

• Do not introduce any objects into the unit!

• Dangerous voltage present for at least 5 minutes after disconnecting all sources of power.

• To protect against access to live parts the power supply unit (PSU) must be installed

in a protective enclosure.

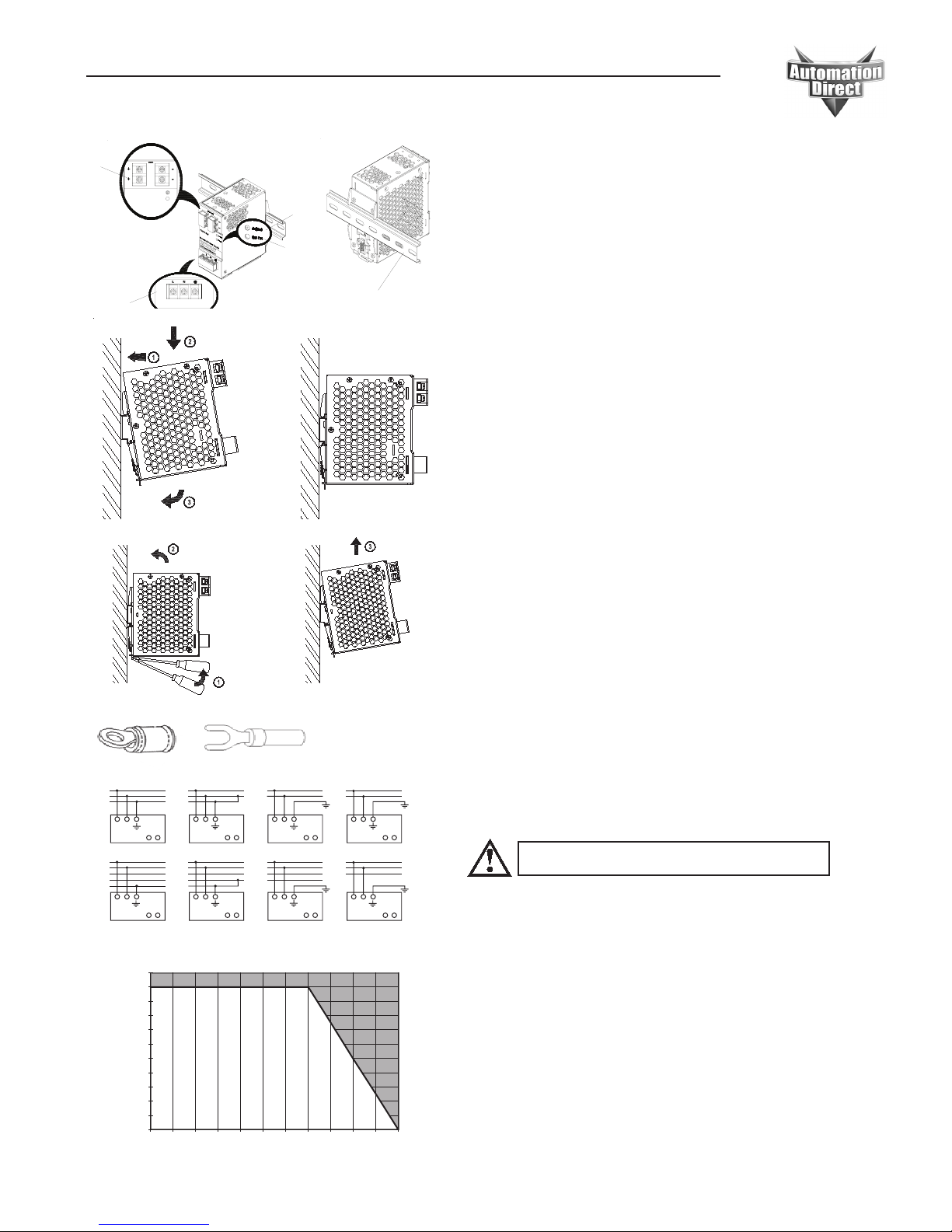

2. Device description (Fig. 1)

(1) Input terminal block connector

(2) Output terminal block connector

(3) DC voltage adjustment potentiometer

(4) DC OK control LED (green)

(5) 35mm DIN rail mounting (DIN rail sold separately)

3. Mounting (Fig. 2)

The power supply unit can be mounted on 35 mm DIN rails in accordance with EN60715.

The device should be installed with input terminal blocks on the bottom.

Each device is delivered ready to install.

Snap on the DIN rail as shown in Fig. 2:

1. Tilt the unit slightly upwards and put it onto the DIN rail.

2. Push downwards until stopped.

3. Press against the bottom front side for locking.

4. Shake the unit slightly to ensure that it is secured.

4. Dismounting (Fig. 3)

To uninstall, pull or slide down the latch as shown in Fig. 3. Then, slide the PSU in the opposite

direction, release the latch and pull out the PSU from the rail.

5. Connection

The terminal block connectors allow easy and fast wiring. A plastic cover provides the necessary

isolation of the electric connection.

You can use flexible (stranded wire) or solid wire with cross section 0.32-2.1 mm²(AWG 22-14)

and torque of 0.78-0.98Nm (6.94-8.68lb in). To secure reliable and shock proof connections, the

stripping length should be 7 mm [0.28 in].

In accordance to EN 60950 / UL 60950, flexible wires require ferrules.

Use appropriate copper wire that is designed to sustain operating temperature of at least 75°C

[167°F] or more to fulfill UL requirements.

For stranded wires it is recommended to use suitable lug (ADC P/N BM-00120) to crimp wires (see

Fig. 4).

5.1. Input connection (Fig. 1, Fig. 5)

Use L, N and GND connections of input terminal connector (see Fig. 1 (1)) to establish the 100-240

VAC connection.

For 3-phase systems just use two phases for the connection to L and N. Need to connect GND and

provide an isolation facility for all poles. The unit is protected with internal fuse (not replaceable)

at L pin and it has been tested and approved on 20A (UL) and 16A (IEC) branch circuits without

additional protection device. An external protection device is only required if the supplying

branch has an ampacity greater than above. Thus, if an external protective device is necessary, or,

utilized, a minimum value of 20A B- or 13A C- characteristic breaker should be used.

The internal fuse must not be replaced by the user. In case of internal

defect, the unit must be discarded or returned if still under warranty

5.2. Output connection (Fig. 1 (2))

Use the “+” and “-“ screw connections to establish the 24 VDC connection. The output provides 24

VDC. The output voltage can be adjusted from 22 to 28 VDC on the potentiometer.

The green LED DC OK displays correct function of the output (Fig. 1 (4)).

The device has a short circuit and overload protection and an overvoltage protection limited to 35

VDC.

5.3. Output characteristic curve

The device functions normal under operating line and load conditions. In the event of a short

circuit or over load the output voltage and current collapses (IO/L or IS/C is > Isurge (150%)). The

secondary voltage is reduced and bounces until short circuit or overload on the secondary side

has been removed.

5.4. Thermal behavior (Fig. 6)

In the case of ambient temperatures above +50°C [122°F], the output capacity has to be reduced

as shown in Figure 6. If the output capacity is not reduced when TAmb > 50°C [122°F] device will

switch into thermal protection mode. The device will cycle output on and off to maintain internal

power dissipation and will recover when ambient temperature is lowered or load is reduced as

far as necessary to keep device in a normal operating mode.

FOR TECHNICAL ASSISTANCE CALL 770-844-4200

RHINO Installation Instructions for PSB24-120 Power Supply

READ INSTRUCTIONS BEFORE INSTALLING OR OPERATING THIS DEVICE. KEEP FOR FUTURE REFERENCE.