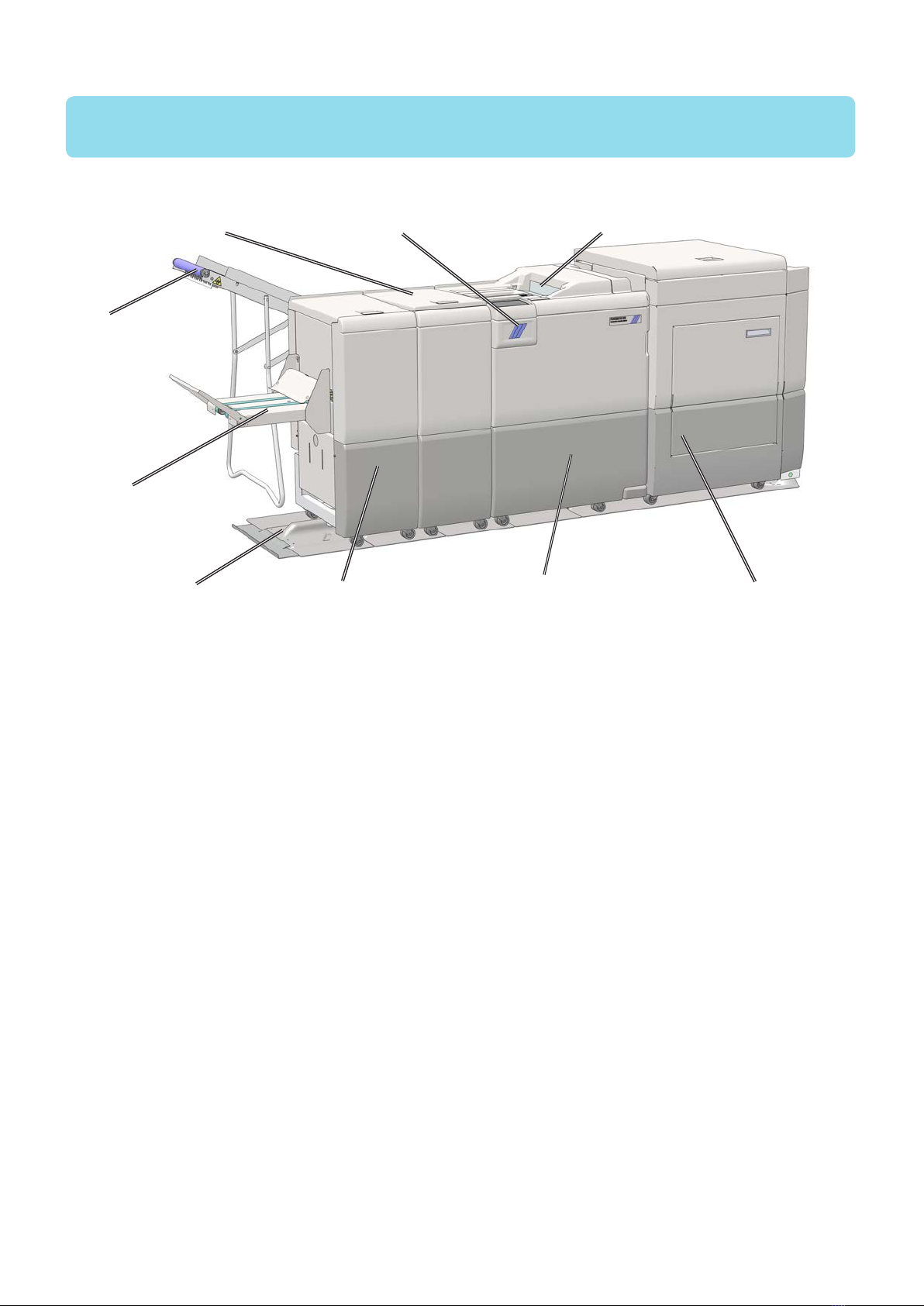

CIP Training Plockmatic 350/500 Production Booklet Maker

Guide To Components

User Interface

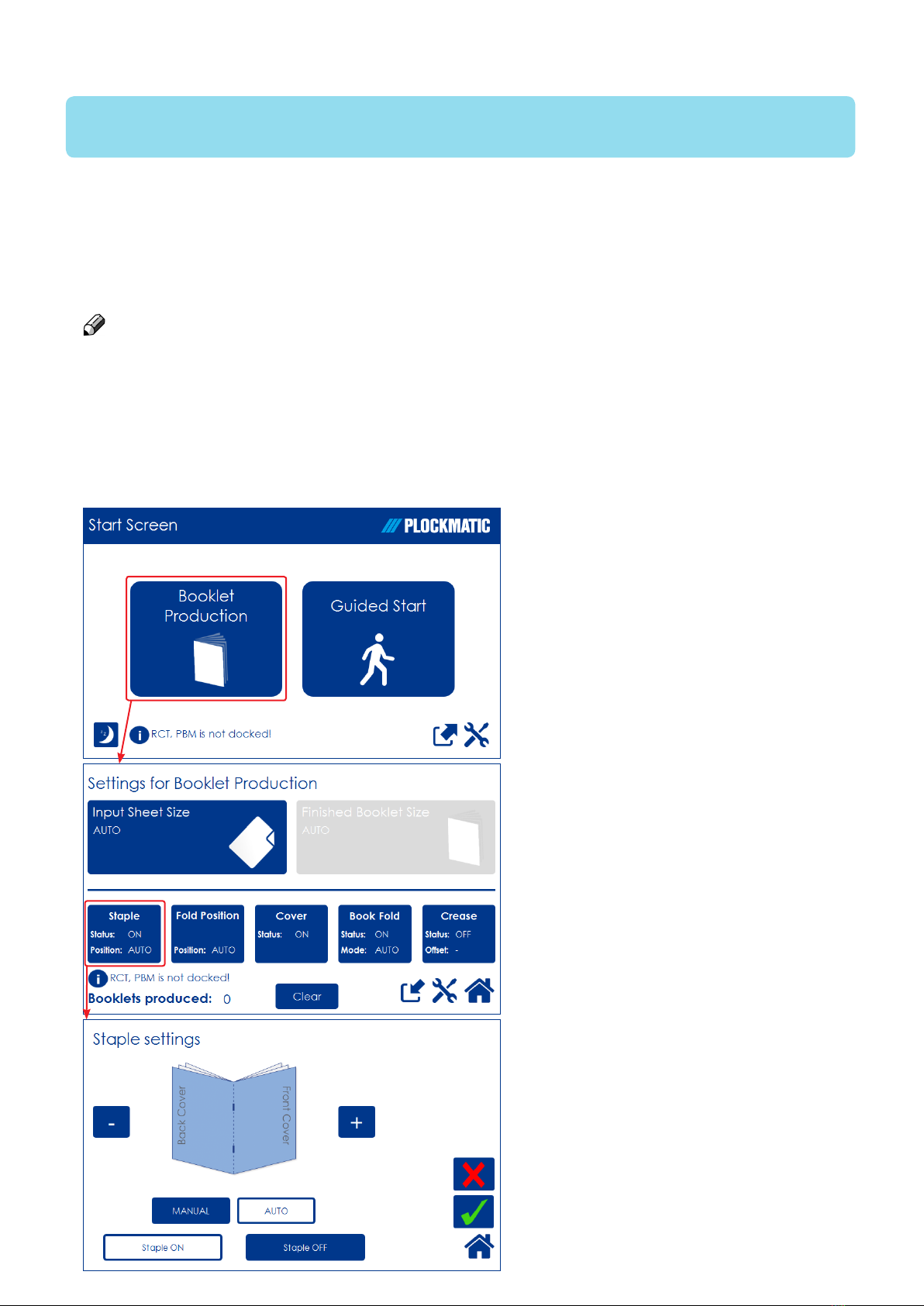

The Start Screen

When the system power is switched

on, the Start screen will be shown.

From here you can choose to set up

Booklet Production, perform a Guided

Start, retrieve stored jobs or access the

General System Settings.

If the Booklet Maker and/or the RCT is

not docked, it will be shown here.

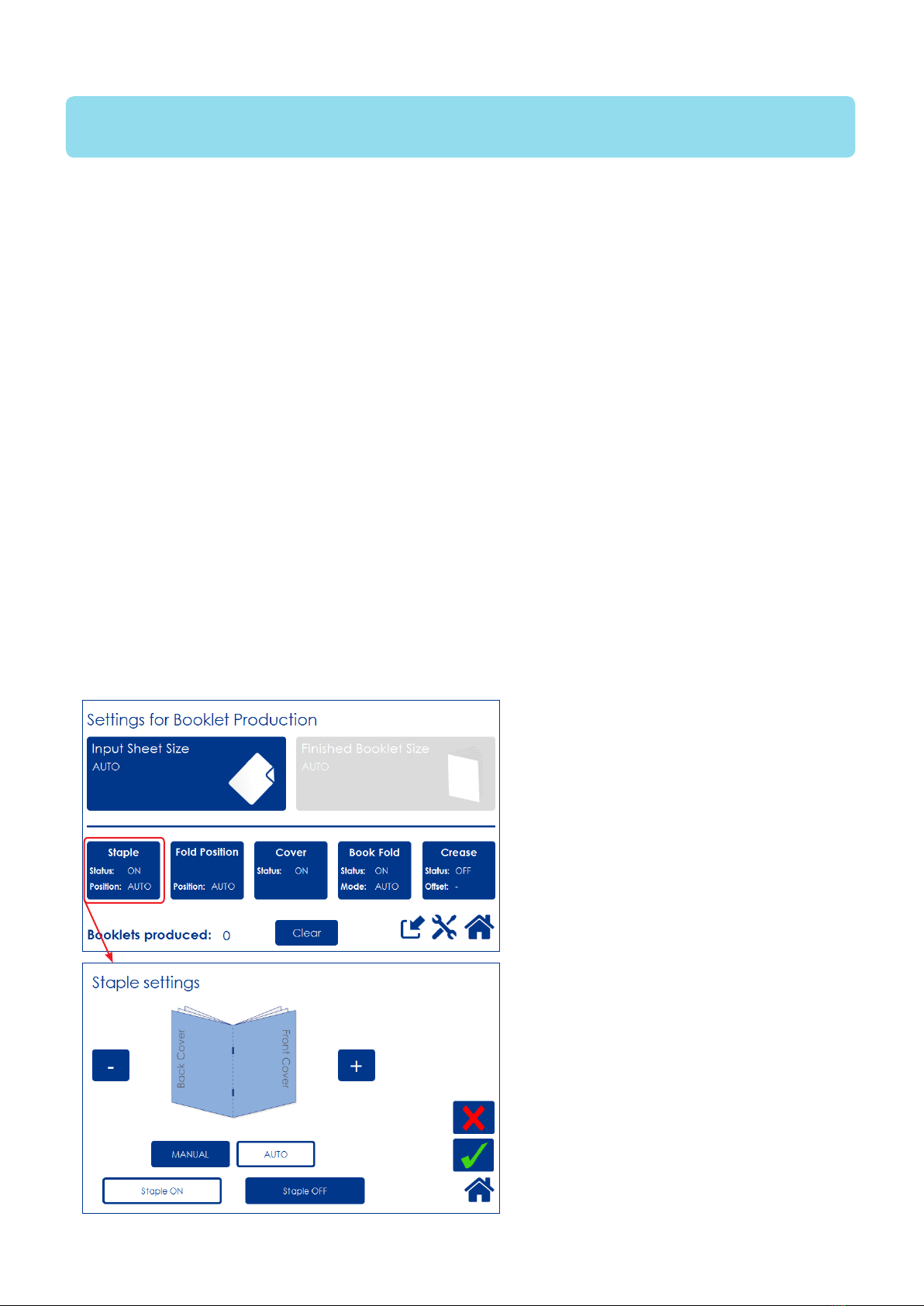

Settings for Booklet Production

Pressing the [Booklet Production]

button in the Start Screen opens the

Settings for Booklet Production screen.

From here you can reach all detailed

settings for setting up the job.

A counter shows the number of

booklets produced. Clear will reset.

If the Booklet Maker and/or the RCT is

not docked, it will be shown here.

Detailed Settings

Pressing, for example, the [Staple]

button in the Settings for Booklet

Production screen opens the Staple

settings screen. Here you can perform

detailed settings concerning stapling.

Explore this and other settings more

thoroughly in section 2, “Making

Booklets.”

The control panel is of touch screen type. Point at the screen and press the “button” to

reach the desired function or change the desired setting.

The Plockmatic 500 or 350 Production Booklet Maker System is controlled from a panel

located on the Booklet Maker. The control panel will allow you to set up, adjust and operate

the complete system. An optional “Alive logo” makes the state of system visible from a

distance.

NOTE:

Depending on modules and features installed, the screen may look different from what you

see here. Some functions are greyed out or not visible at all and remaining buttons may

stretch to fit the screen. This manual will most often show a fully configured system.

Control Panel