ENGINE OIL LEAK INSPECTION

Begin with a thorough visual inspection of the engine, particularly at the area of the suspected lea . If an oil

lea source is not readily identifiable, the following steps should be followed:

1. Do not clean or degrease the engine at this time because some solvents may cause rubber to swell,

temporarily stopping the lea .

2. Add an oil soluble dye (use as recommended by manufacturer). Start the engine and let idle for

approximately 15 minutes. Chec the oil level indicator to ma e sure the dye is thoroughly mixed as

indicated with a bright yellow color under a blac light.

3. Using a blac light, inspect the entire engine for fluorescent dye, particularly at the suspected area of oil

lea . If the oil lea is found and identified, repair as necessary.

4. If dye is not observed, drive the vehicle at various speeds for approximately 24 m (15 miles), and repeat

inspection.

5. If the oil leak source is not positively identified at this time , proceed with the AIR LEAK

DETECTION TEST METHOD as follows:

Disconnect the fresh air hose (ma e-up air) at the cylinder head cover and plug or cap the outlet on

the cover.

Remove the PCV valve hose from the cylinder head cover. Cap or plug the PCV valve outlet on the

cover.

Attach an air hose with pressure gauge and regulator to the oil level indicator tube.

Gradually apply air pressure from 1 psi to 2.5 psi maximum while applying soapy water at the

suspected source. Adjust the regulator to the suitable test pressure that provides the best bubbles

which will pinpoint the lea source. If the oil lea is detected and identified, repair per service

information procedures.

If the lea age occurs at the cran shaft rear oil seal area, refer to INSPECTION FOR REAR

SEAL AREA LEAKS.

6. If no lea s are detected, turn off the air supply. Remove the air hose, all plugs, and caps. Install the PCV

valve and fresh air hose (ma e-up air). Proceed to next step.

7. Clean the oil off the suspect oil lea area using a suitable solvent. Drive the vehicle at various speeds

approximately 24 m (15 miles). Inspect the engine for signs of an oil lea by using a blac light.

assembly.

6. Valve stem seal(s) worn or

damaged.

6. Replace seal(s).

CAUTION: Do not subject the engine assembly to more than 20.6 k a (3

SI) of test pressure.

NOTE: If oil leakage is observed at the oil level indicator tube to block location;

remove the tube, clean and reseal using Mopar® Stud AND Bearing Mount

(press fit tube applications only), and for O-ring style tubes, remove tube

and replace the O-ring seal.

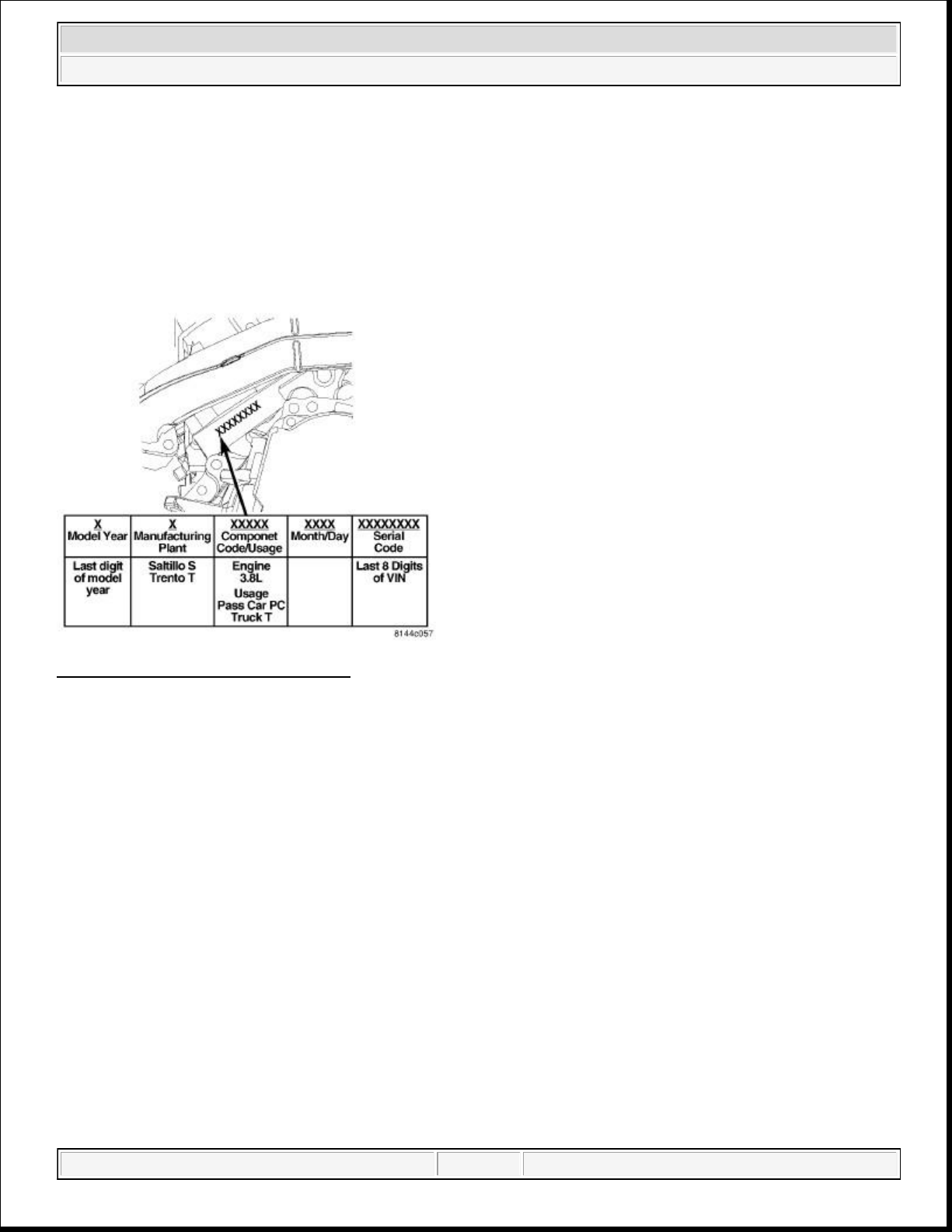

2010 Jeep Wrangler Sport

2010 ENGINE 3.8L - Service Information - Wrangler

viernes, 1 de oct bre de 2021 05:18:29 p. m. Page 6 © 2011 Mitchell Repair Information Company, LLC.