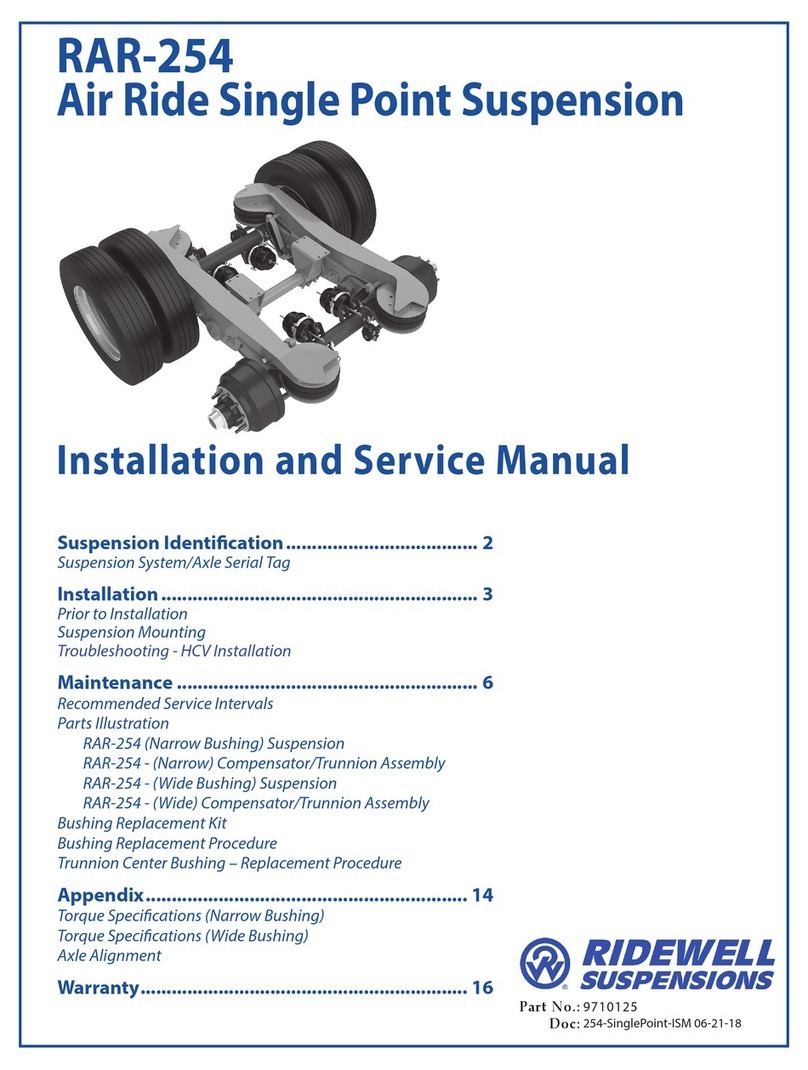

ENG Page 8 RAR-200-Trailer-ISM-RevA-06-07-18

MAINTENANCE

A visual inspection of the suspension structure should be performed during each pre-trip/safety inspection.

Ridewell Suspensions recommends the following minimum service intervals for standard duty, on-highway

usage applications. More frequent intervals are recommended for heavier duty applications.

Daily/Pre-Trip Inspections

___ Check tires for proper ination, damage or

excessive wear.

___ Check wheel-ends for obvious signs of lubricant

leakage. Check for missing components.

___ Check

axle assemblies for damage or loose

components.

___ Visually inspect suspension structure for signs

of damage or excessive wear.

___ Check for loose or missing bolts/nuts. Check for

irregular movement in suspension components.

___ Make sure air controls are operating properly.

Drain all moisture from air reservoirs.

First 6,000 miles of use

___ Torque all suspension component bolts/nuts to

specications (pg 10/Engineering drawing).

___ Verify that the suspension is operating at the

installed ride height.

Every 12,000 miles of use

___ Inspect air springs for any damage or excessive

wear. Torque air spring bolts/nuts to specications

(pg 10/Engineering drawing).

___ Check air lines and connections for leaks.

Every 50,000 miles of use

___ Torque all suspension component bolts/nuts to

specications (pg 10/Engineering drawing).

Annually/100,000 miles of use

___ Inspect pivot connection for worn pivot bushing

and wear washers. Replace components, if neces-

sary. Torque suspension component bolts/nuts to

specications (pg 10/Engineering drawing).

___ Check arm beam-to-

axle connection welds.

___ Check lubrication level in wheel ends:

1) Oil-Filled Wheel Ends:

Refill/Replace lubricant as needed (Refer to

TMC RP 631 “100K/Annual Inspection”).

2) Semi-Fluid Grease:

Pull outer bearing and visually inspect lubrica-

tion level. Rell/Replace as needed

(Refer to TMC RP 631 “Level 3 Lubrication Level

Inspection” and TMC RP 618 “Wheel Bearing

Adjustment Procedure”).

___ Check air lines and connections for leaks.

___ Test air control system pressure protection valve

(PPV), if equipped.

___ Check height control valve (HCV) adjustment.

___ Verify that the suspension is operating at the

installed ride height.

Failure to torque the bolts/nuts of suspen-

sion components to specications can result in failure

of the suspension and voiding of the warranty.

Park the unloaded trailer on a level surface. Set the

brakes and chock the tires so vehicle cannot move

during inspection.

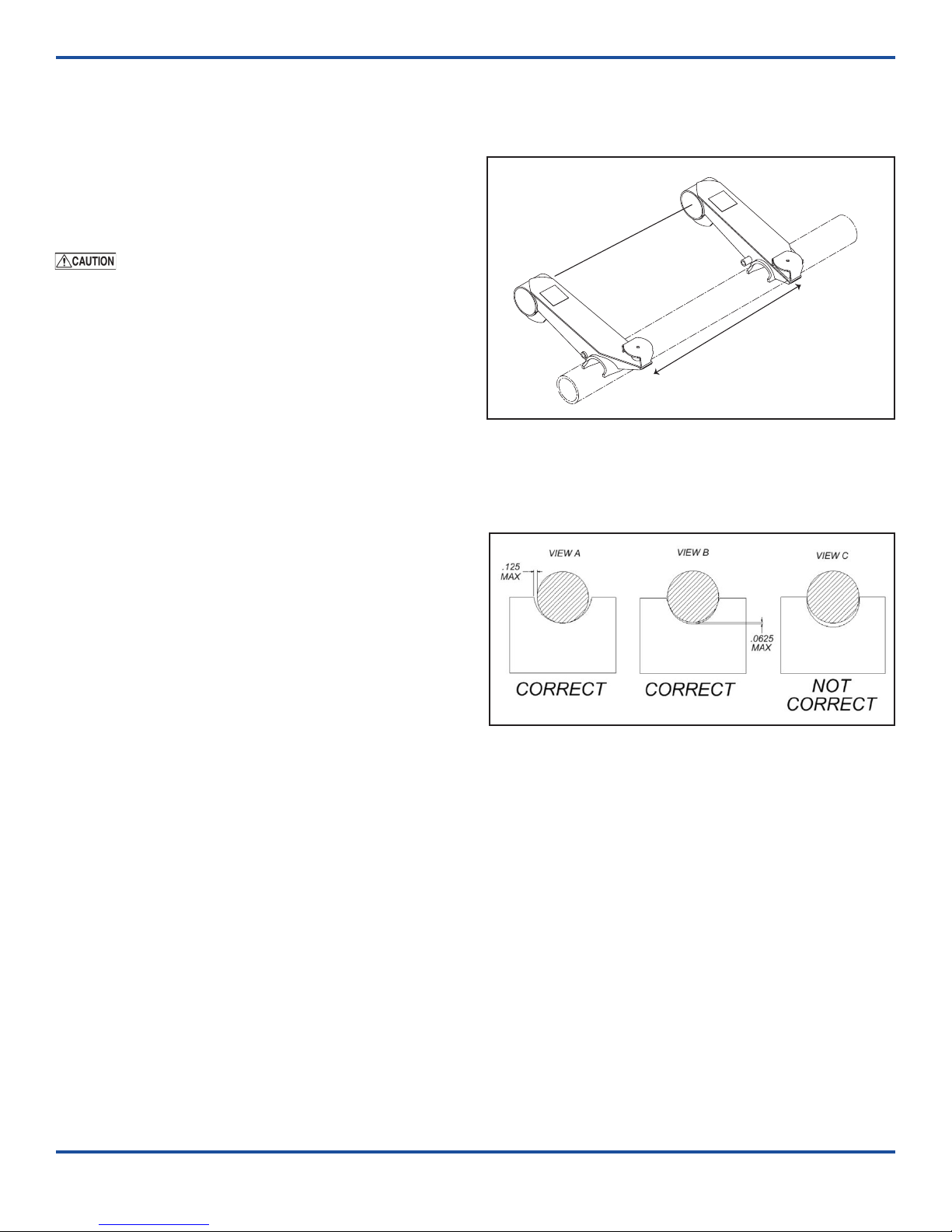

Insert the at end of a pry-bar between one side of

the hanger sidewall and the wear washers. Move the

pry-bar back-and-forth and look for excessive move-

ment of the beam (NOTE: A small amount of beam

Pivot Bushing Inspection Procedure

movement because of the rubber exing is normal).

Inspect the wear washers for excessive wear/damage.

Repeat the pry-bar process and wear washer inspec-

tion on the other side of the hanger. If any large/easy

movement or damaged wear washers is observed,

drop the beams for further inspection. Replace com-

ponents as necessary.

Refer to the following Technology &

Maintenance Council (TMC) publications

for additional maintenance information:

TMC RP 609 Self-Adjusting and Manual Brake

Adjuster Removal, Installation

and Maintenance

TMC RP 618 Wheel Bearing

Adjustment Procedure

TMC RP 619 Air System Inspection Procedure

TMC RP 622 Wheel Seal and Bearing Removal,

Installation, and Maintenance

TMC RP 631 Recommendations for

Wheel End Lubrication

TMC RP 643 Air Ride Suspension

Maintenance Guidelines

TMC RP 728 Trailer Axle Maintenance