ENG Page 4 254-Single Point-ISM-06-21-18

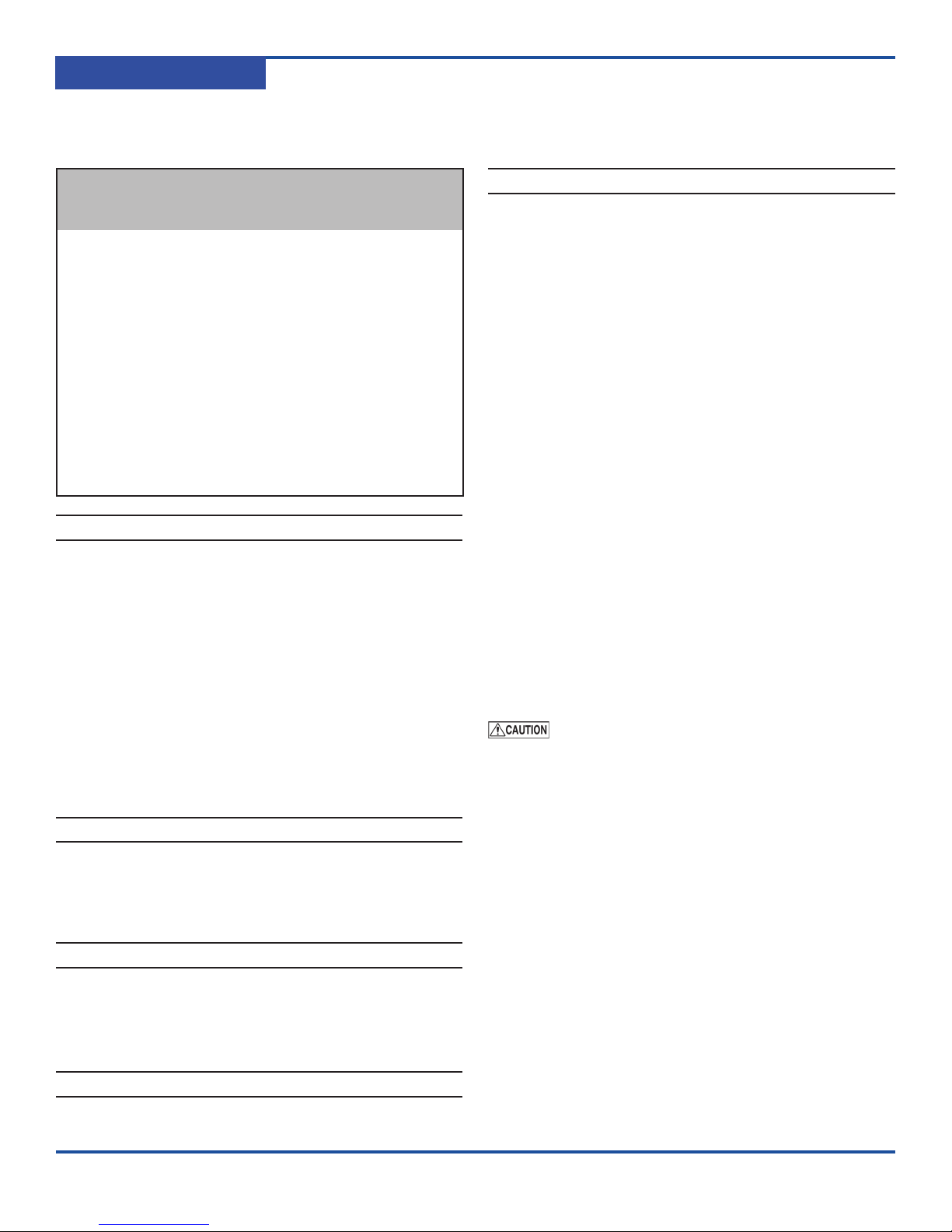

Mounting the suspension to the frame

Refer to the engineering drawing for the range of

available ride heights, torque values, spacing and

clearance requirements of the suspension.

The suspension installer has the nal responsibility

of aaching the suspension to the vehicle frame.

Main pivot fasteners are shipped with minimal

torque applied. It is the installer’s responsibility to

properly torque fasteners after the axle(s) is aligned.

Installation Procedure

Before installation, check to make sure that wires,

hoses or other components will not be aected by

drilling into the frame rail. Check the location for

necessary clearances.

Bolts/nuts for aaching the suspension to the ve-

hicle are supplied by the installer. Grade 8 bolts and

anged lock nuts or lock nuts with hardened washers

are recommended.

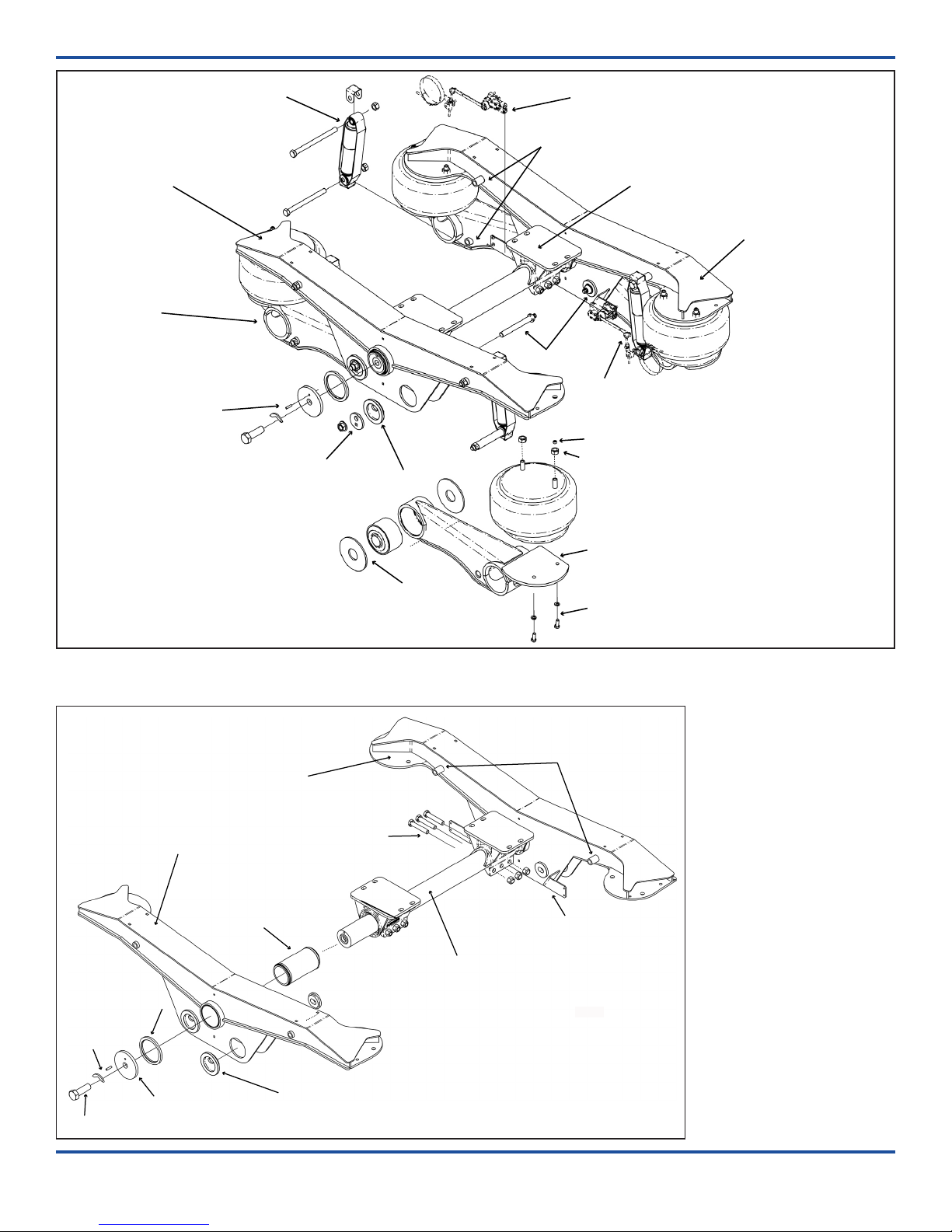

1. Bolt the trunnion hangers to the mounting

brackets or trailer frame. Tighten bolts until

hanger plate is resting on mounting bracket/

trailer frame, but suspension location can still

be adjusted. Do not apply nal torque.

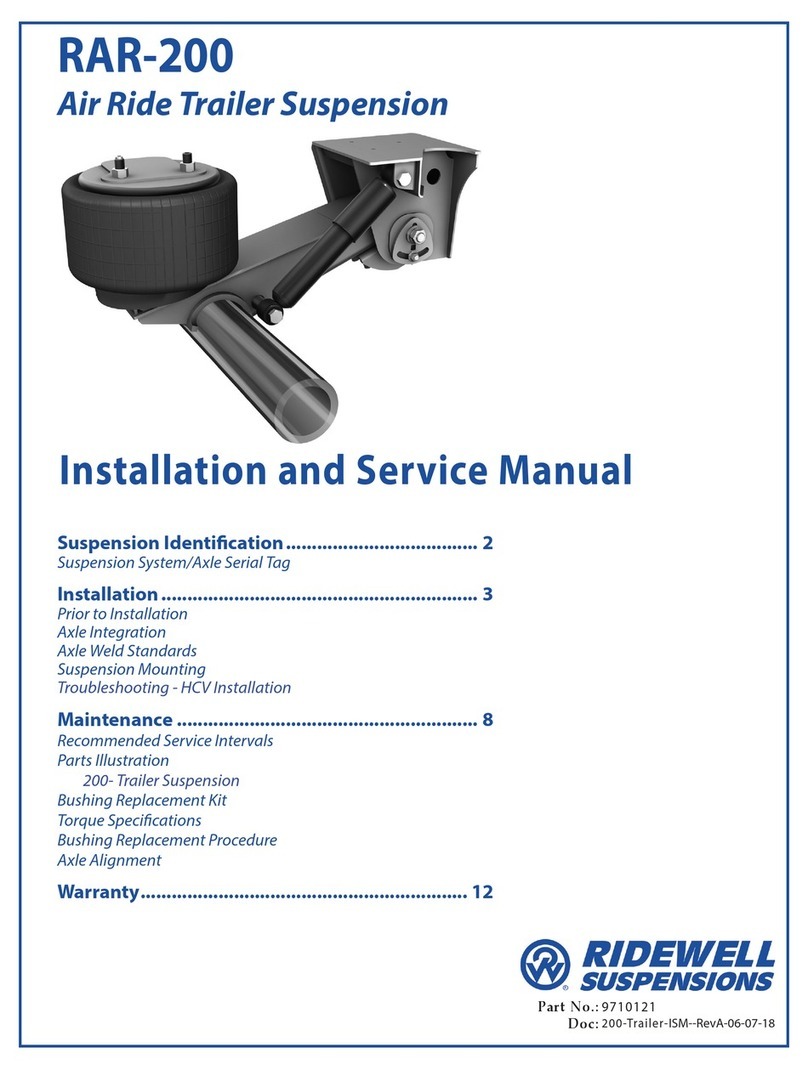

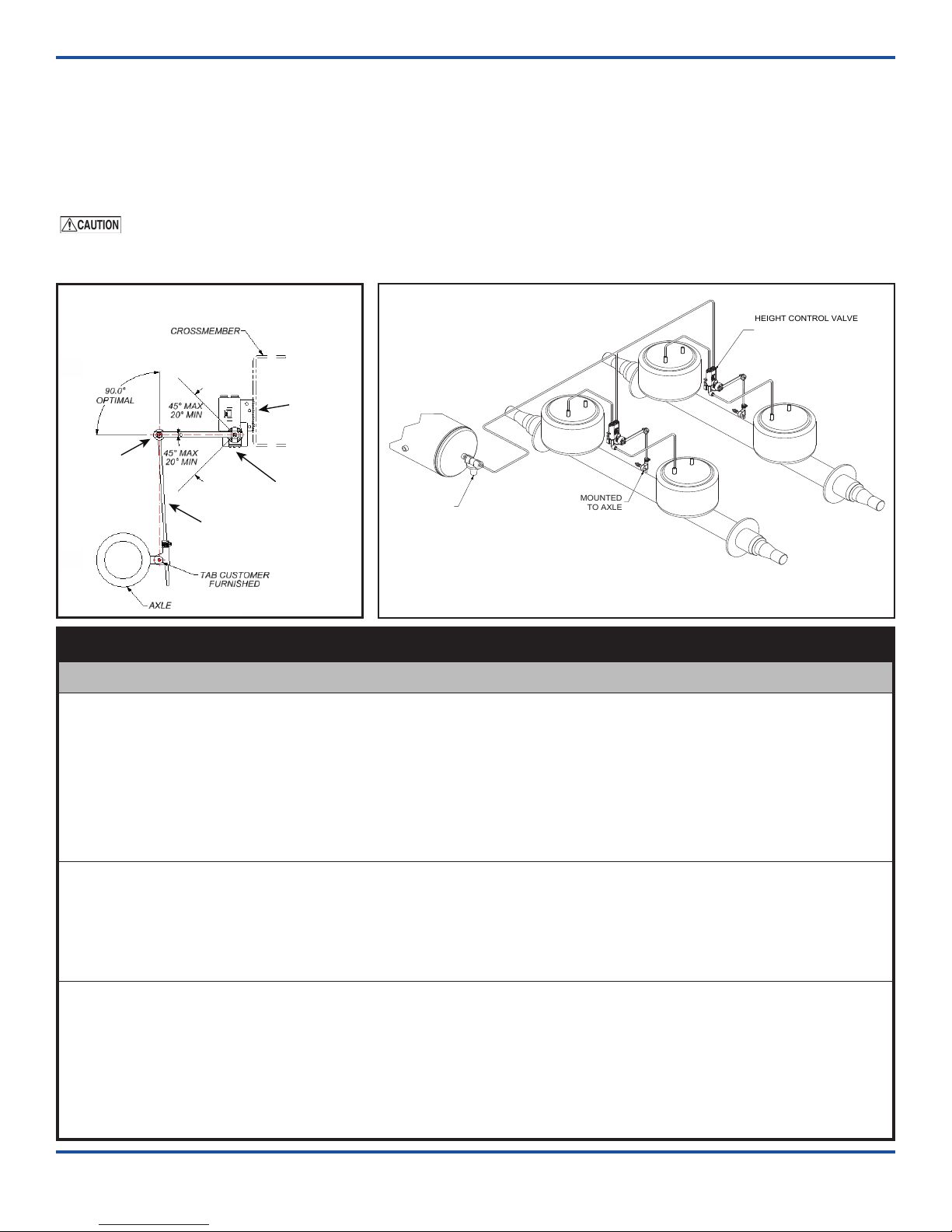

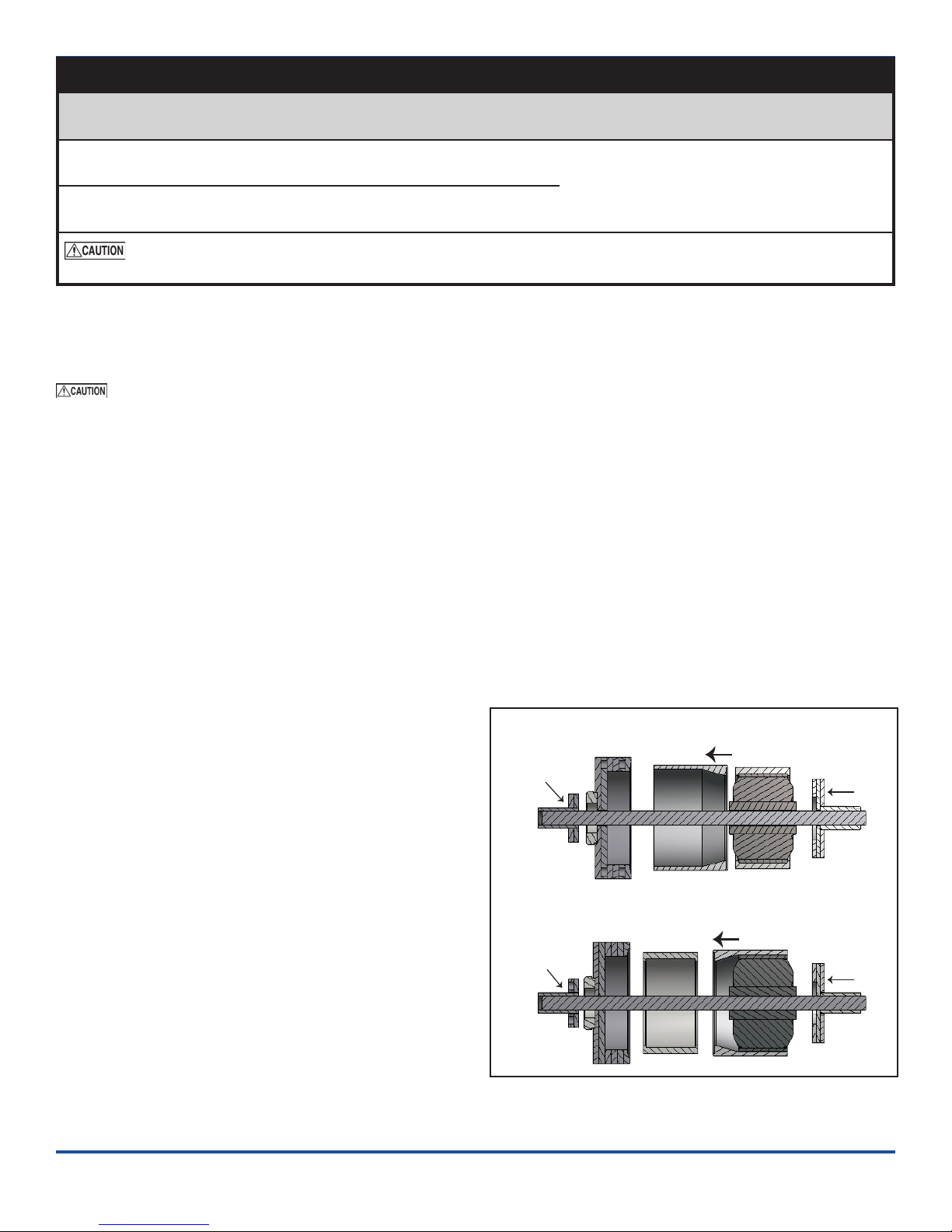

2. Align the trunnion tube with the kingpin. Trun-

nion aligment dimensions “T1” and “T2” shown

on the illustration must be equal (Figure 3).

3. Tighten the trunnion hanger fasteners to speci-

cation. Check trunnion alignment and realign

trunnion tube, if necessary..

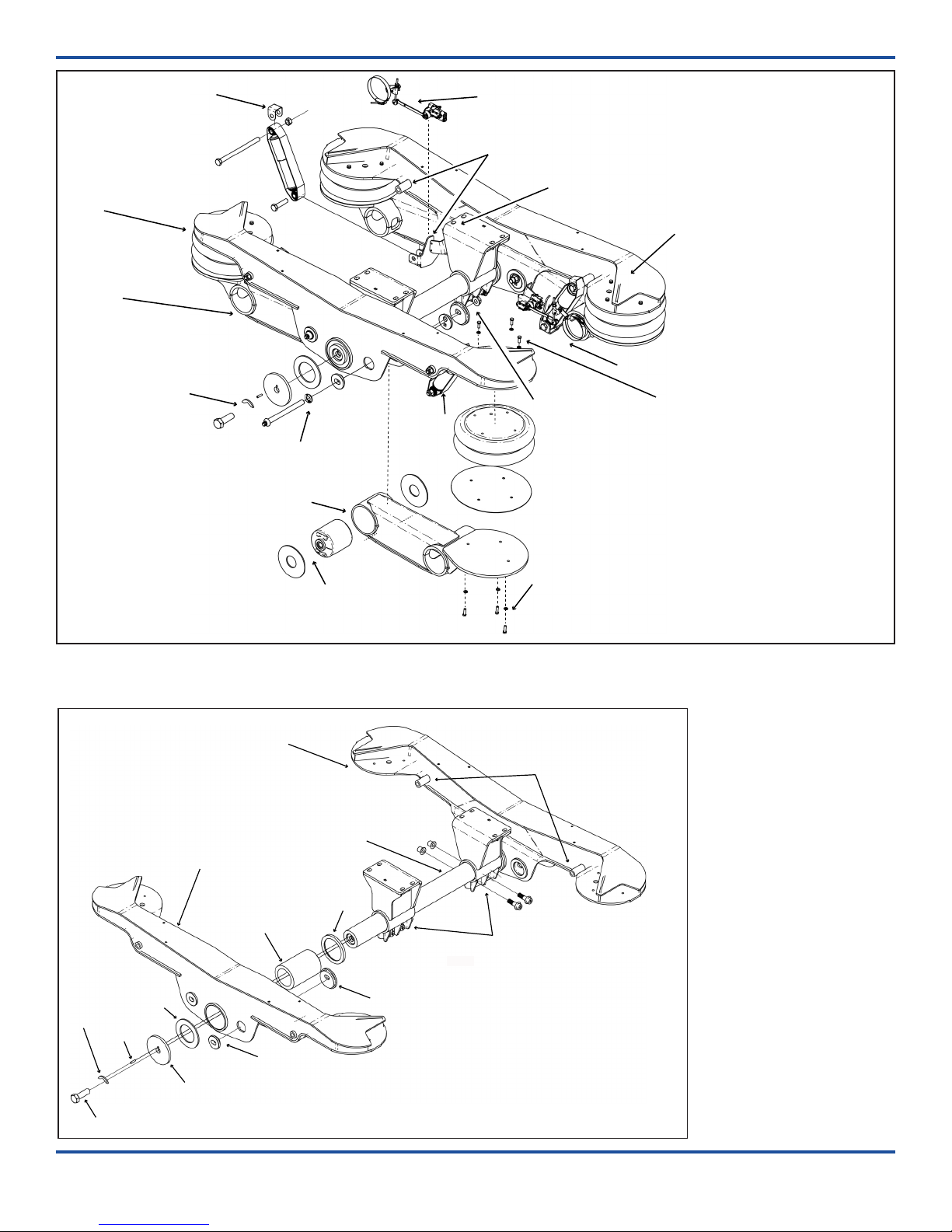

4. Using 1/2”-drive breaker bar, rotate the front axle

beam alignment plate in the opposite direction of

desired axle movement.

Make sure that the alignment plate and align-

ment washer have moved in unison. It is impor-

tant that the pivot bushing is not skewed in the

hanger prior to tightening.

5. Check that axle alignment dimensions “A” and

“B” are equal to +/- 1/8”. Snug the four pivot fas-

teners and recheck alignment (Figure 3).

6. Repeat alignment process on rear axle, ensuring

that rear axle alignment dimensions “C” and “D”

are equal to +/- 1/16”.

7. Check dimension “E”, the lateral centerline rela-

tionship of the trailer body and axles. Dimension

“E” must not exceed 1/4 of an inch.

8. Recheck the alignment of the front axle with the

kingpin. Recheck alignment of the rear axle with

the front axle.

9. After trunnion and axle alignments have been

completed, torque the four pivot bolts using a

1” drive impact wrench and #6100054 E-20 Torx

socket (or equivalent) until the Torx head shears

o from the bolt.

NOTE: Check shear-o. Remove any rough or

jagged fragments so the round pivot bolt head

is completely smooth.

10. Weld the trunnion hanger to the mounting

bracket or trailer frame and frame member with

a 5/16” llet weld.

NOTE: Welding the adjuster plates or the align-

ment washers to the hanger sidewalls is not

required or recommended.

Install/connect the height control kits on the compen-

sator/trunnion assembly. Check the air system tubing

and ings after installation for leaks (Page 5).

Failure to torque bolts/nuts of suspension

components to specications can result in failure of

the suspension and void the warranty.

Welding method must use a minimum weld

tensile strength of 70,000 psi, per AWS specications.

Trunnion Alignment

Axle Alignment

Figure 3.

Measurements for trunnion and axle alignment.

Axle Alignment