ENG Page 6 251-Trailer-ISM 09-13-18

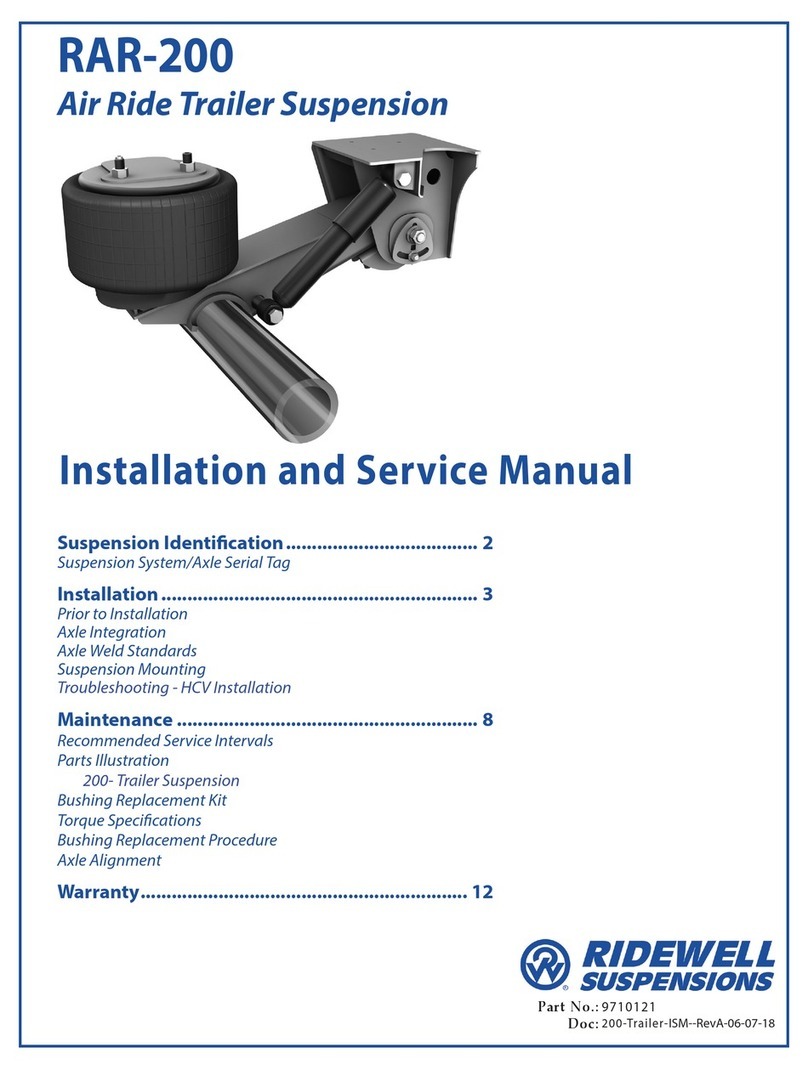

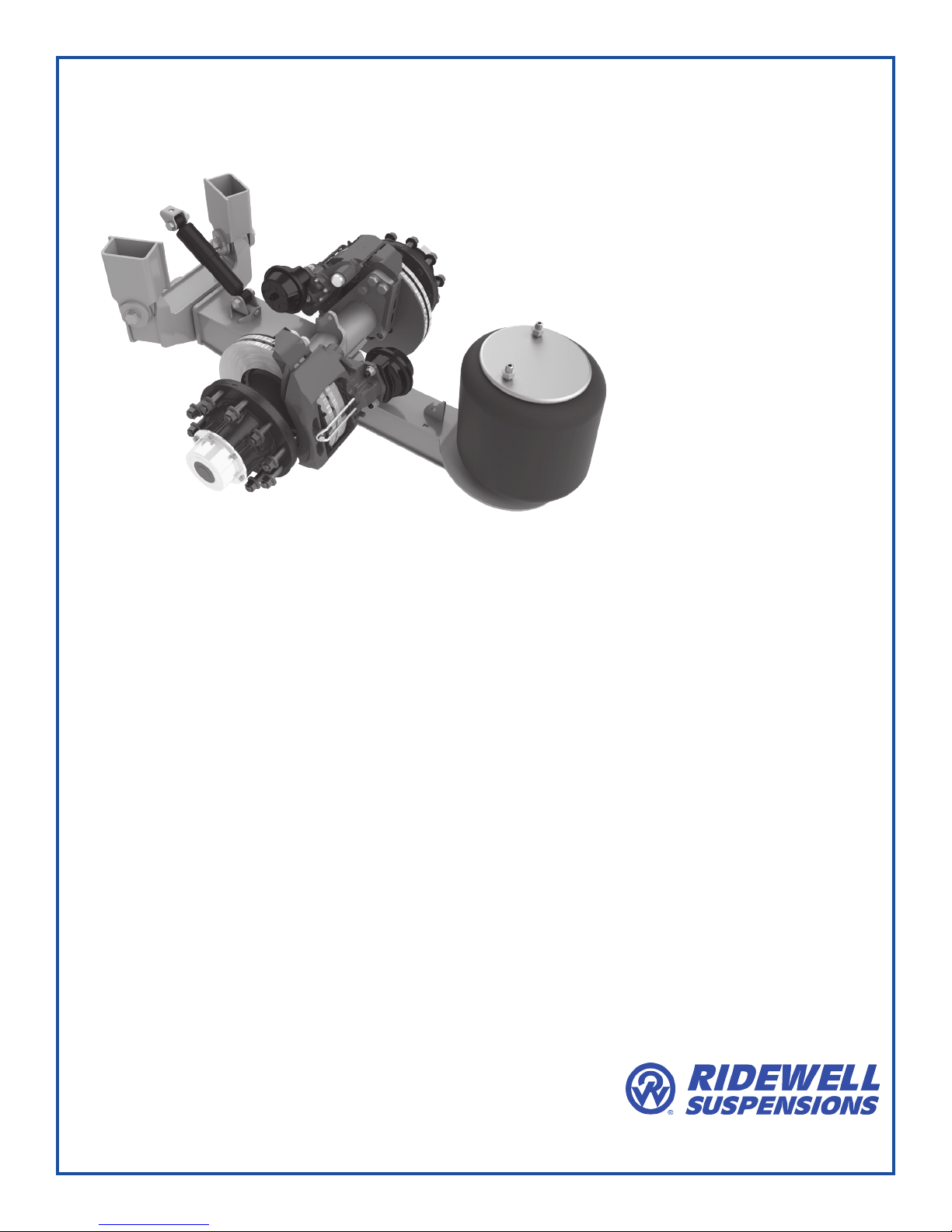

Mounting the suspension to the frame

Refer to the engineering drawing for the range of ride

heights available, torque values, spacing and clear-

ance requirements of the suspension.

Frame hangers are an optional component of the

RAR-251 Trailer Suspension. Ridewell can design a

suspension hanger for a specic application.

It is the responsibility of the trailer OEM to design

a hanger and alignment mechanism that ts to the

trailer frame.

The suspension installer has the nal responsibility

of aaching the suspension to the vehicle frame.

(Optional Hanger) Weld-On Installation

Check that the location provides adequate clearance

for suspension components.

Hangers and air spring mounting plates should be

perpendicular to the chassis frame and in alignment

with each other.

1. Mark the desired location of the hangers on

the vehicle frame. Hangers must be installed as

shown on the engineering drawing for proper

axle alignment.

2. Weld the hangers to the frame with 1/4” llet

welds completely around the hangers. Stop the

welds 1/2” from the corners and edges.

3. Mark the desired location of the air spring

mounting plates on the frame. A minimum 0.75-

inch clearance must be maintained around the air

spring when it is at maximum diameter.

4. Weld the air spring mounting plates to the frame

with 3/16” llet welds.

Stub axle suspensions are designed with a roll joint.

Roll stops are not provided in this suspension. Tire

rub plates must be installed on the trailer frame to

limit roll to 10-degrees or less.

Final Assembly and Inspection

• Verify the welds of the hanger and air spring

mounting plates.

• Brake chamber clamps and ports must be clocked

(rotated) to prevent interference with surround-

ing components.

• Aach pivot assemblies to hangers.

Note: Do not fully torque pivot hardware until

axle alignment is completed.

• Installer must set the suspension to the specied

mounting height before torquing the pivot bolt to

prevent pre-loading the rubber in the bushing.

• Dowel pin must be installed in roll joint before

welding on anti-turn washer. Anti-turn washer

must cover dowel pin.

• Refer to engineering drawing to install shock

absorber. Torque to specications (Page 7).

• Complete assembly and installation of air springs

as shown on the engineering drawing. Torque to

specications (Page 7).

• Install/connect the height control valve (HCV), if

applicable. Check the air system tubing and t-

tings after installation for leaks.

• Verify the suspension ride height is adjusted

within the range shown on the engineering draw-

ing and complete axle alignment procedure.

The Limiter Chain connection point shown on the

drawing is for reference only. Locate the chain so that

chain can not interfere with the axle assembly, the

brake chambers or the wheels or tires.

Frame tab should be placed after suspension installa-

tion and with the suspension in full rebound posi-

tion. Limiter Chain must be travel limiter.

Failure to torque bolts/nuts of suspension

components to specications can result in failure of

the suspension and void the warranty.