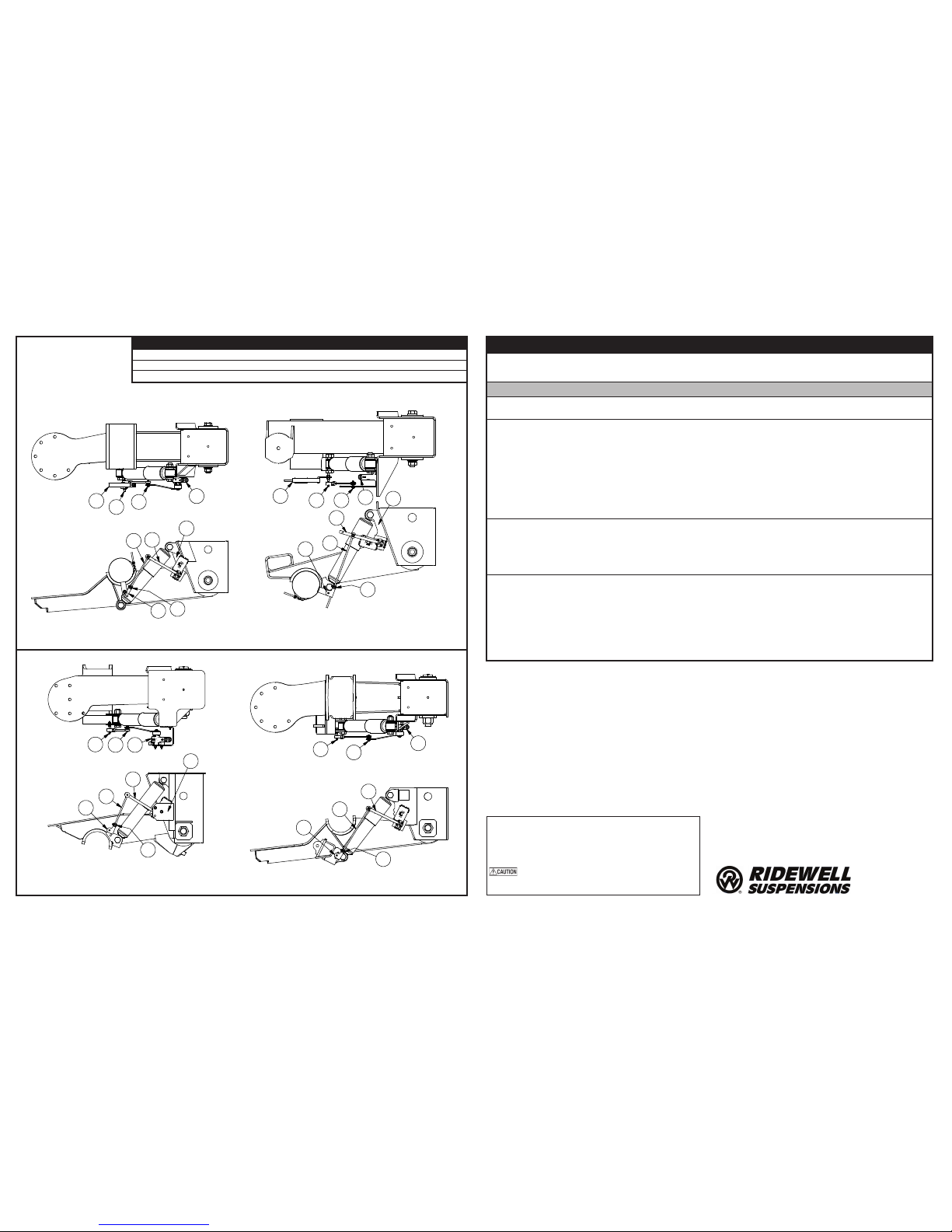

RAR-240 15K, 25K, 30K UNDERSLUNG

RAR-243 25K UNDERSLUNG

RAR-240 25K OVERSLUNG

2

4

7

5

6

2

4

6

5

7

9

3

31

1

8

7

1

3

9

56

42

RAR-260 25K AND 30K UNDERSLUNG

87 3 19

5

6

4

2

RAR-260 25K AND 30K OVERSLUNG

RAR-266 23K AND 25K OVERSLUNG

Figure 6. Troubleshooting Height Control Valve Installation

Height Control Valve - A “bad HCV” is a common misdiagnosis of the air system not working. Most problems can

be traced to other parts of the system. Pinched/damaged lines or loose component fittings are often the cause of an

air leak that causes the HCV to not work as it should. Repair any problems before continuing with troubleshooting.

Problem Possible Cause Corrective Action

Ride Height too high

or too low.

— HCV out of adjustment or

not installed correctly. — Refer to engineering drawing for ride height

specifications. Check adjustment of HCV.

HCV is not

receiving air or is not

delivering air to the

air springs.

— Blocked air supply line.

— Air tank is not filling/

reaching set pressure.

— Pressure Protection Valve

(PPV) not working correctly.

— Pilot port is not plumbed or

is plumbed incorrectly.

— Verify air lines are pressurized by removing

supply line at HCV. Check for pinched lines.

— Verify air tank pressure with manual/in-line

pressure gauge.

— Check PPV operation by making sure that

valve opens when system reaches the desired

pressure setpoint (usually greater than 70 psi).

— Check HCV configuration – Non-Dump;

Pressure-Dump (Normally Open);

Zero-Pressure Dump (Normally Closed).

Reinstall, if necessary.

Air springs ll

but do not exhaust.

— Obstructed air line.

— HCV installed backwards.

— Supply line installed in

suspension port

— Disconnect linkage and rotate actuating lever

to down position (exhaust). If springs remain

inflated, check for pinched/blocked lines.

— Check installation. Reinstall, if necessary.

— Move air supply line to HCV supply port.

Air system leaks

down in a short

period of time.

— HCV installed backwards.

— Leak in air system beyond

accepted standards.

— Disconnect HCV linkage and rotate actuating

lever to the up position (fill). If air springs do

not inflate, reinstall HCV.

— To find leak in the HCV area, pressurize

system and spray soapy water solution onto

the valve and lines. Check for bubbles (leaks):

No leak found – Do not remove valve, check

the rest of the system for leaks.

Check that tubing cuts are straight and

smooth. Re-cut and reassemble if necessary.

Warranty

The Ridewell Corporation warrants the Automatic Height and

Leveling Air Control Valve manufactured by it to be free from

defects in material and workmanship for a period of 1 year

from the date code molded into the body.

Warranty coverage is limited to the repair/replacement of valve

parts. Coverage applies only to valves that have been properly

installed, maintained and operated. No warranty applies to air

lines, ings, mounting hardware, actuating arm, linkage, or

axle aachments.

Ridewell reserves the right to require any valve to be returned

for inspection before claim is obtained. All returns must have

No.Description No.Description No.Description

1Height Control Valve 4Vertical Link 7Lower Pin Assembly

2Lever 5“P” Connector 8Lower Mounting Bracket

3Upper Pin Assembly 6Clamp 9Upper Mounting Bracket

transportation charges prepaid by the customer and accompa-

nied with a complete wrien explanation of claimed defects and

the circumstances of operational failure.

This non-transferable warranty is in lieu of all other expressed

or implied warranties or representations, including any implied

warranties of merchantability or tness or any obligations on

the part of Ridewell.

Ridewell will not be liable for any business interruptions, loss

of prots, personal injury, any costs of travel delays or for any

other special, indirect, incidental or consequential losses, costs

or damages caused by Ridewell.

Figure 5.

EXAMPLES: Common

Height Control Kit (HCK)

installations.

Notes and Cautions

This instruction uses two types of service notes:

“NOTE”: Provides additional instructions or procedures

to complete work tasks and make sure that the component

functions properly.

Indicates a hazardous situation or unsafe practice

that, if not avoided, could result in equipment damage

and serious injury.

Springeld, MO USA

800-641-4122

www.ridewellcorp.com