micro DM-100 Digital Multimeter

2

Lifetime Warranty...................................................................................................... Back Cover

*Original instructions

Table of Contents

Table of Contents........................................................................................................................... 2

Safety Symbols................................................................................................................................ 3

General Safety Rules.................................................................................................................... 3

Work Area Safety.......................................................................................................................... 3

Electrical Safety............................................................................................................................. 3

Personal Safety.............................................................................................................................. 3

Equipment Use and Care.......................................................................................................... 4

Service.............................................................................................................................................. 4

Specic Safety Information...................................................................................................... 4

Multimeter Safety ........................................................................................................................ 4

Description, Specications And Standard Equipment.............................................. 5

Description ..................................................................................................................................... 5

Specications................................................................................................................................. 5

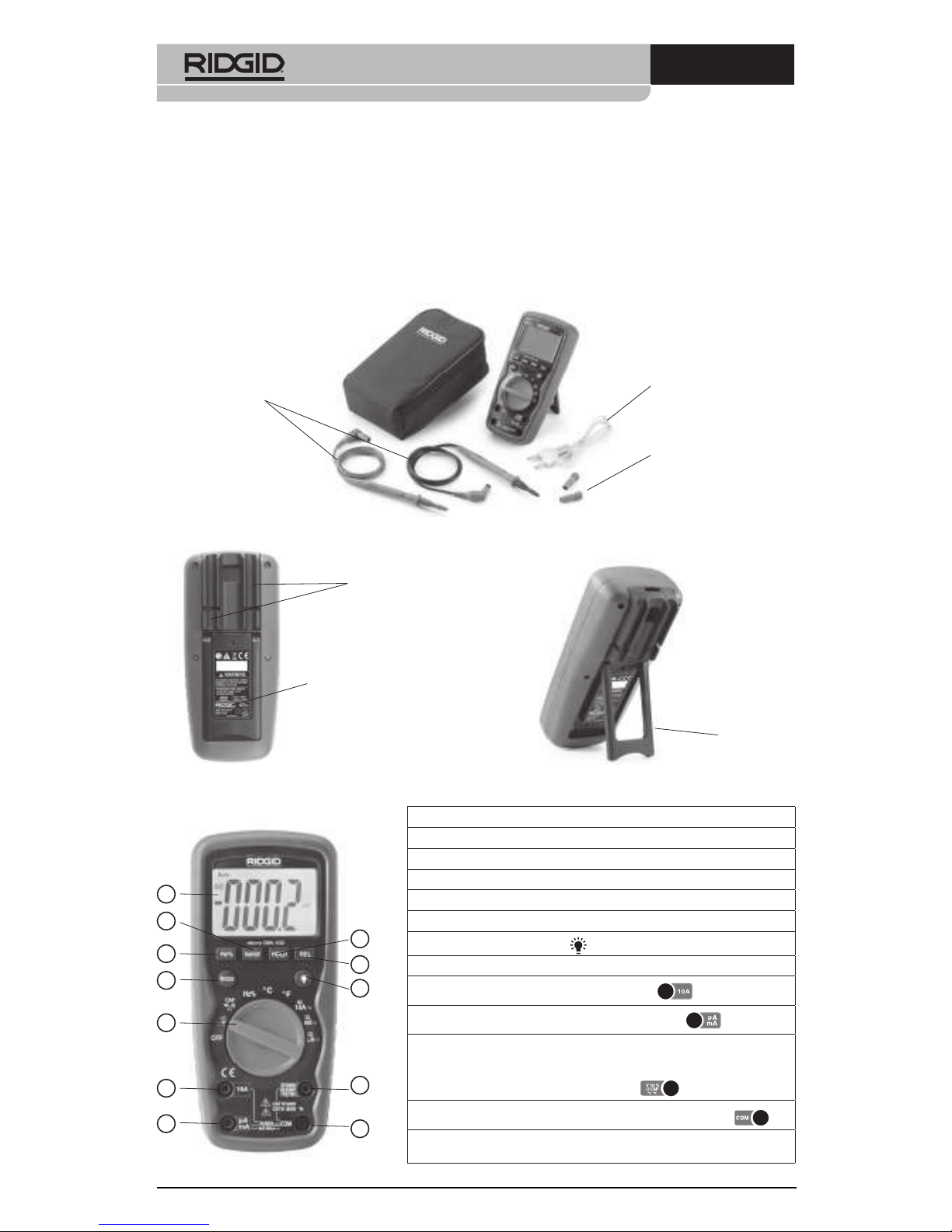

Standard Equipment .................................................................................................................. 8

Controls............................................................................................................................................ 8

Icons .................................................................................................................................................. 9

FCC Statement...............................................................................................................................10

Electromagnetic Compatibility (EMC)..............................................................................10

Changing/Installing Batteries...............................................................................................10

Pre-Operation Inspection .......................................................................................................11

Set-Up and Operation ...............................................................................................................12

Rotary Function Switch................................................................................................................13

Input Terminals ...........................................................................................................................13

Pushbuttons.................................................................................................................................14

DC/AC Voltage Measurement...............................................................................................14

DC/AC Current Measurement...............................................................................................15

Resistance Measurement........................................................................................................15

Diode Test......................................................................................................................................16

Continuity Check........................................................................................................................16

Capacitance Measurement....................................................................................................16

Frequency Measurement........................................................................................................17

Temperature Measurement...................................................................................................17

Maintenance Instructions .......................................................................................................18

Cleaning.........................................................................................................................................18

Calibration.....................................................................................................................................18

Fuse Replacement .....................................................................................................................18

Accessories......................................................................................................................................18

Storage ..............................................................................................................................................19

Service and Repair.......................................................................................................................19

Disposal.............................................................................................................................................19

Battery Disposal...........................................................................................................................19

Troubleshooting...........................................................................................................................20