Attention!

The operating conditions of the Detector in a controlled

environment must exclude the presence of substances

that reduce the catalytic activity of sensitive elements and

corrosive substances: acid and alkali vapors, halogens,

fumes of silicon, phosphorus, silicone lubricants, varnishes,

sealants, etc.

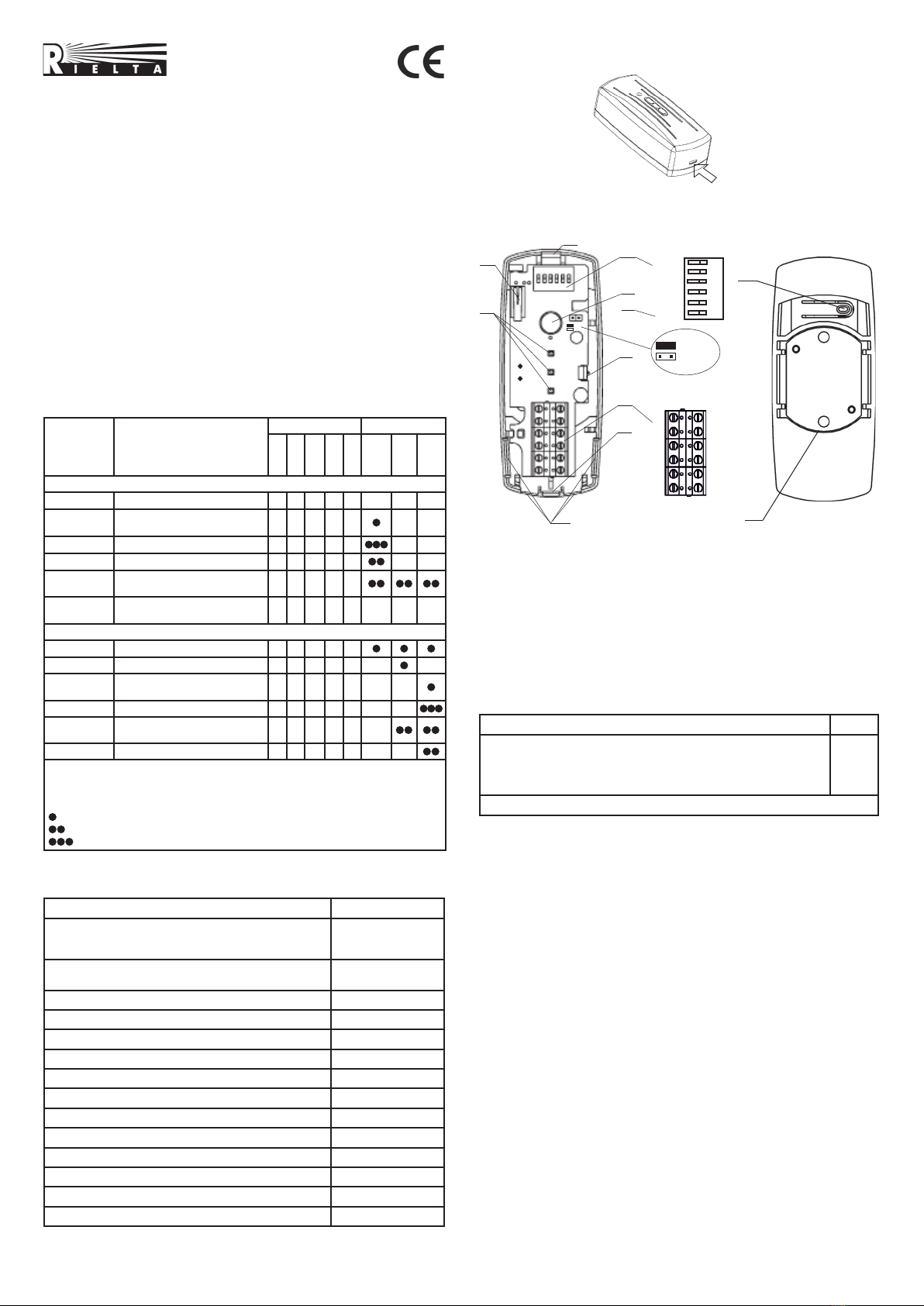

7 Connection

The Detector connection to data transmission system (DTS) or control

panel (CP) terminal device (TD) should be fulfilled in accordance with

connection pattern contained in relevant TD, DTS or CP exploitation

documents as per the Detector terminal blocks marking (see Figure 2,

position 6). Two openable holes (see Figure 2, position 8) are available

for wiring.

8 The Detector Controls

The IND DIP-switch is used for the Detector LED indication switching

ON.

The ATM DIP-switch is intended for choosing the signal processing

algorithm depending on type of secured construction (See Table 4).

Table 4

Secured construction ATM switch position

Safe or metal construction (cabinet, door, lattice) OFF

Automated Teller Machine (ATM) ON

DIP-switches S1, S2, S3 are intended for adjustment of destruction

channel sensitivity (see Table 5).

Table 5

DIP-switches Sensitivity

S1 S2 S3

ON ON ON Maximum

Minimum

ON ON OFF

ON OFF ON

ON OFF OFF

OFF ON ON

OFF ON OFF

OFF OFF ON

OFF OFF OFF User-operating mode (see Cl. 10)

9 Adjustment Procedure

Remove the housing cover and set the IND DIP-switch to ON position.

Set switch ATM to the position corresponding to the material of the

protected structure (see Table 4).

Switches S1, S2, S3 – in position ON, ON, ON (maximum sensitivity

level).

Switch on the power supply and check the formation of the LED

indication «Power on» and the «Normal» message. The presence of

the indication «Vibration» in the standby mode and the absence of

the effects listed in Table 4 display too high level of interference on

the protected object. If possible, eliminate the source of interference.

Set the MEM switch to ON position, switches S1, S2, S3 to OFF, OFF,

ON (minimum sensitivity level).

At the boundary of the protected area, apply a simulating

impact corresponding to the type of the protected structure (see

Table 6). If the «Destruction» message is generated and after it the

«Memory-destruction» LED indication (see Table 1) is ON, the sensitivity

adjustment can be considered completed.

In the absence of the notice «Destruction» – perform a step-by-

step sensitivity increase (see Table 5) until «Destruction» message is

generated after imitating impact.

When the sensitivity level is set, the Detector should not generate a

«Vibration» indication in the absence of any effects on the protected

structure.

After adjustment fulfillment, it is necessary to set the IND and MEM

switches in accordance with the security tactics chosen for the object.

Table 6

Methodic of a simulating impact

applying during sensitivity

adjustment

Supplementary technical data

Apply a steel plate to the surface

of the protected structure at the

outermost point of the controlled

area. Drill several holes in the

plate with a depth of 2 – 3 mm.

For each drilling, observe the LED

indication «Vibration», and after

the third one – «Destruction»

LED indication.

Cordless drill, drill ∅ (4 ± 0,5) mm, the

time of one drilling is not less than 10 sec.

Pause between drilling not more than

10 sec.

Electric drill, drill ∅ (4 ± 0,5) mm, the time

of one drilling is not less than 10 sec.

Pause between drilling not more than

10 sec.

10 User-operating mode

The user-operating mode, activated by DIP-switches (see Table 5),

is designed to adapt the Detector to a severe interference conditions

on a secured object by means of individual sensitivity adjustment to

different types of attacks.

In this mode, sensitivity adjustment is carried out by means of a

personal computer connected to the Detector via the serial interface

module «US-PI» (supplied by «RIELTA» JSC on a special order).

The procedure of the Detector adjustment in User mode is given in

the accompanying documentation for «US-PI».

11 Storage and Transportation

11.1 During the transportation the Detector in the package withstands:

- transport jolting with acceleration up to 30 m/sec2at impacts

frequency range from 10 to 120 per minute or 15.000 impacts with

the same acceleration;

- ambient temperature from minus 50 to plus 50 оС;

- relative air humidity up to 100 % at temperature plus 25 оС.

11.2 The Detector in original package may be transported by any

means of transportation in closed vehicles over any distances in

compliance with the existing shipping rules concerning the respective

means of transportation.

11.3 After transportation under the conditions different to exploitation

conditions the Detector shall be ready for operation after a maximum

of six hours.

11.4 The storage package shall be free from silica gel.

12 Manufacturer’s Guarantees

12.1 The Manufacturer guarantees conformity of the Detector to the

requirements of Specifications provided the transportation, storage,

installation and operation conditions are observed.

12.2 The guaranteed storage term of the Detector is 15 months since

the date of manufacture.

12.3 The guaranteed useful life is 12 months since the day of putting

into operation within the storage term guaranteed.

12.4 If non-conformity of the Detector to technical requirements

is detected during the guaranteed period if rules of operation are

observed, it shall be repaired by the Manufacturer.

13 Packing Certificate

Atm security vibration, tilt and gas detector «SH-VTG» has been

manufactured in compliance with the active technical documentation

and classified as fit for operation and packed by «RIELTA» JSC.

Packing date _______________________________

month, year

Rev. 4 of 17.03.20

v.2.3/v.2.3R

«RIELTA» JSC, www.rielta.com

Tel./fax: +7 (812) 233-03-02, +7 (812) 703-13-60,

Made in Russia