Electronstandart Pribor PGA-ESP BESTia User manual

PORTABLE GAS DETECTOR PGA-ESP

«BESTia»

Operating Manual

413411.001 OM

Saint Petersburg, 2019

Orginal Inv

Signature and date

Instead of №

Conv. Inv. №

Signature and date

GSKF.002.025.100 OM

Sheet

2

Rev

.

Document №

Signature

Date

Sheet

Content

1. Introduction..............................................................................................3

2. Designation................................................................................................3

3. Technical charactristics...........................................................................7

4. PGA-ESP explosionproof protection .....................................................8

5. Detector description and principle of operation ..................................8

6. Pre-operation procedures ..................................................................... 11

6.1. PGA-ESP turning on procedure ........................................................11

6.2. Gas detector adjustment.....................................................................12

7. PGA-ESP operation...............................................................................19

8. Connection of PGA-ESP to PC.............................................................20

9. Software ESP_config ............................................................................. 21

10. PGA-ESP calibration with SW ..........................................................25

11. Graphics................................................................................................27

12. Battery charging ..................................................................................31

13. Component parts and delivery set......................................................32

14. Service maintenance ............................................................................32

15. Verification ...........................................................................................32

16. Transportation and storage regulations............................................33

17. Marking ................................................................................................34

18. Acceptance certificate..........................................................................35

19. Certificate of Conservation.................................................................36

20. Manufacturer's warranty....................................................................37

21. Complaint Details.................................................................................38

Appendix А. PGA-ESP overall dimensions drawing.......................................39

Record of Revisions ............................................................................................40

Orginal Inv

Signature and date

Instead of №

Conv. Inv. №

Signature and date

GSKF.002.025.100 OM

Sheet

3

Rev

.

Document №

Signature

Date

Sheet

1. Introduction

1.1. This operation manual (OM) is a document confirming the main parameters and technical

characteristics of the PGA-ESP “BESTia” portable gas detector (hereinafter –PGA-ESP),

guaranteed by the manufacturer of JSC “Electronstandart-Pribor”.

1.2. OM is intended to familiarize with the device and the principle of operation of PGA-

ESP, as well as sets the rules for its operation.

1.3. Before you start using PGA-ESP, you must carefully read this operating manual.

ATTENTION! PGA-ESP should only be used for the following purposes and under the

conditions defined in this manual. Any external modification of the device, use in a

defective form or use of equipment not included in the delivery during installation - entails

the termination of the warranty.

2. Designation

Portable explosion-proof gas analyzers PGA-ESP "BESTia" are designed to measure the

concentration of flammable gases by volume fraction of oxygen, sulfur dioxide, nitrogen dioxide,

nitric oxide, hydrogen sulfide, carbon monoxide, chlorine in the air of the working area and signaling

when threshold values are exceeded.

The gas analyzer is an automatic device for personal protection of continuous operation.

Features and benefits

•Determination of gas concentrations vital for humans in the working area;

•User friendly screen interface;

•Application of 4 types of sensors at the same time to obtain data on -

omeasuring channel for combustible gases - infrared, thermocatalytic;

omeasuring channel of oxygen, hydrogen and toxic gases - electrochemical;

omeasuring channel LEL hydrocarbons - photoionization.

Field of application

PGA-ESP gas detectors are available in explosion-proof design and can be used in hazardous

areas of buildings and in open facilities in accordance with the explosion protection marking of the

device and regulatory documents governing the use of electrical equipment in hazardous areas.

Tables No. 1, No. 2, No. 3 and No. 4 show the conversion ranges and the limits of the

permissible basic error of the gas analyzer for all types of sensors used.

Orginal Inv

Signature and date

Instead of №

Conv. Inv. №

Signature and date

GSKF.002.025.100 OM

Sheet

4

Rev

.

Document №

Signature

Date

Sheet

Table №1

Measurement ranges and error limits for gas with

thermocatalytic sensors (transducers)

Transducer type

Detected gas

The range of

indications of

the volume

fraction of the

determined

component, %

Range of

measurements

of the volume

fraction of the

determined

component, %

Permissible limits

basic absolute

errors, volume

fraction of the

determined component,

%

PGT-methane

СН4

0 to 4,4

0 to 2,2

±0,22

PGT-propane

С3Н8

0 to 1,7

0 to 0,85

±0,085

PGT-hydrogen

Н2

0 to 4

0 to 2

±0,2

PGT-acetylene

С2Н2

0 to 2,3

0 to 1,15

±0,115

Notes:

1) The measurement range in units of volume fraction of the determined component, %,

corresponds to the range of indications of the pre-explosive concentration of the determined

component from 0 to 100% LEL.

2) The measurement range in units of volume fraction of the determined component, %,

corresponds to the measurement range of the pre-explosive concentration of the determined

component from 0 to 50% LEL.

3) LEL values for the determined components according to GOST 30852.19-2002.

Table № 2

Measurement ranges and error limits for gas with

optical sensors (transducers)

Transducer type

Detected gas

The range of

indications of

the content of

the determined

component

Measuring

range of the

content of the

component to

be determined

Basic error limits

Absolute

Relative

PGO-methane

СН4

From 0 to 4,4 %

vol.

(from 0 to 100 %

LEL)

0 to 2,2 % vol

above 2,2 to

4,4 % vol.

±0,22 %

vol.

-

-

±10 %

PGO-propane

С3Н8

From 0 to 1,7 %

vol.

(from0 to 100

% LEL)

0 to 0,85 %

vol.

above 0,85 to

1,7 % vol.

±0,085 %

vol.

-

-

±10 %

Orginal Inv

Signature and date

Instead of №

Conv. Inv. №

Signature and date

GSKF.002.025.100 OM

Sheet

5

Rev

.

Document №

Signature

Date

Sheet

Table № 3

Measurement ranges and error limits for gas with

electrochemical sensors (transducers)

Transducer type

Detected gas

Range of measurements of the

content of the determined

component

Limits

basic error

ppm

mass

concentration,

mg/m3

absolute

relative

PGE- hydrogen

sulfide

H2S

from 0 to 7

ppm incld.

above 7 to 32

ppm

from 0 to 10

incld.

above

10 to 45

±2,5 mg/m3

-

-

±25 %

PGE- oxygen

О2

from 0 to 30 %

-

±(0,2+0,04С

Х) %

-

PGE-

carbon monoxide

СО

from 0 to 17

ppm incld.

above

17 to 103 ppm

От 0 to 20

incld. Above

20 to 120

±5 mg/m3

-

-

±25 %

PGE-nitrogen

dioxide

NO2

from 0 to 1

ppm incld.

above 1 to 10,5

ppm

От 0 to 2

incld.

above 2 to 20

±0,5 mg/m3

-

-

±25 %

PGE-

sulfur dioxide

SО2

from 0 to 3,8

ppm incld.

above

3,8 to 18,8

ppm

От 0 to 10

incld.

above 10

to 50

±2,5 mg/m3

-

-

±25 %

PGE- ammonia

NH3

from 0 to 28

ppm incld.

above

28 to 99 ppm

from 0 to 20

incld.

above 20

to 70

±5 mg/m3

-

-

±25 %

PGE-chlorine

Cl2

from 0

to 0,33 ppm

incld.

above 0,33

v 10 ppm

from 0 to 1

incld. above

1 to 30

±0,25

mg/m3

-

-

±25 %

PGE- Nitric oxide

NO

from 0 to 4

ppm incld.

above

4 to 100 ppm

from 0 to 5

incld.

above. 5

to 125

±1,25

mg/m3

-

-

±25 %

Orginal Inv

Signature and date

Instead of №

Conv. Inv. №

Signature and date

GSKF.002.025.100 OM

Sheet

6

Rev

.

Document №

Signature

Date

Sheet

Table № 4

Measurement ranges and error limits for gas with

photoionized sensors (transducers)

Transducer type

Detected gas

Range of measurements of the

content of the determined

component

Limits of

basic error

ppm

mass

concentration,

mg/m3

absolute

relative

PGF-

isobutylene-0-20

i-С4Н8

From 0 to 19,3

ppm

From 0 to 45

±12 mg/m3

-

PGF-isobutylene-0-

200

From 0 до 43

ppm incld.

Above 43 to 172

ppm

From 0 to 100

incld. Above

100

до 400

±25 mg/m3

-

-

±25 %

PGF-isobutylene-0-

2000

From 0 to 43

ppm incld.

Above

43 to 2000 ppm

From 0 to 100

incld. Above

100 to 4660

±25 mg/m3

-

-

±25 %

PGF - ethylene

С2Н4

From 0 to 86

ppm incld.

Above 86 to

171 ppm

From 0 to 100

incld. Above

100 to 200

±25 mg/m3

-

-

±25 %

PGF- benzene

С6Н6

From 0 to 1,5

ppm incld.

Above

1,5 to 9,3 ppm

From 0 to 5

incld. Above

5 to 30

±1,25 mg/m3

-

-

±25 %

PGF-methyl

mercaptan

СН3SН

From 0 to 0,4

ppm incld.

Above

0,4 to 3,9 ppm

From 0 to 1,0

incld. Above

1,0 to 10,0

±0,25 mg/m3

-

-

±25 %

PGF- diethylamine

С2Н5SН

From 0 to 0,4

ppm incld.

Above

0,4 to 3,9 ppm

From 0 to 1,0

incld. Above

1,0 to 10,0

±0,25 mg/m3

-

-

±25 %

PGF- diethylamine

С4Н11N

From 0 to 9,8

ppm incld.

Above

9,8 to 50 ppm

From 0 to 30

incld. Above

30 to 150

±7,5 mg/m3

-

-

±25 %

PGF- carbon

disulfide

СS2

From 0 to 3,1

ppm incld.

Above 3,1 to

15 ppm

From 0 to 10

incld. Above

10 to 47

±2,5 mg/m3

-

-

±25 %

PGF-903U - phenol

С6H6O

From 0 to 0,25

ppm incld.

Above

0,25 to 4 ppm

From 0 to 1

incld. Above 1

to 15,6

±0,25 mg/m3

-

-

±25 %

Orginal Inv

Signature and date

Instead of №

Conv. Inv. №

Signature and date

GSKF.002.025.100 OM

Sheet

7

Rev

.

Document №

Signature

Date

Sheet

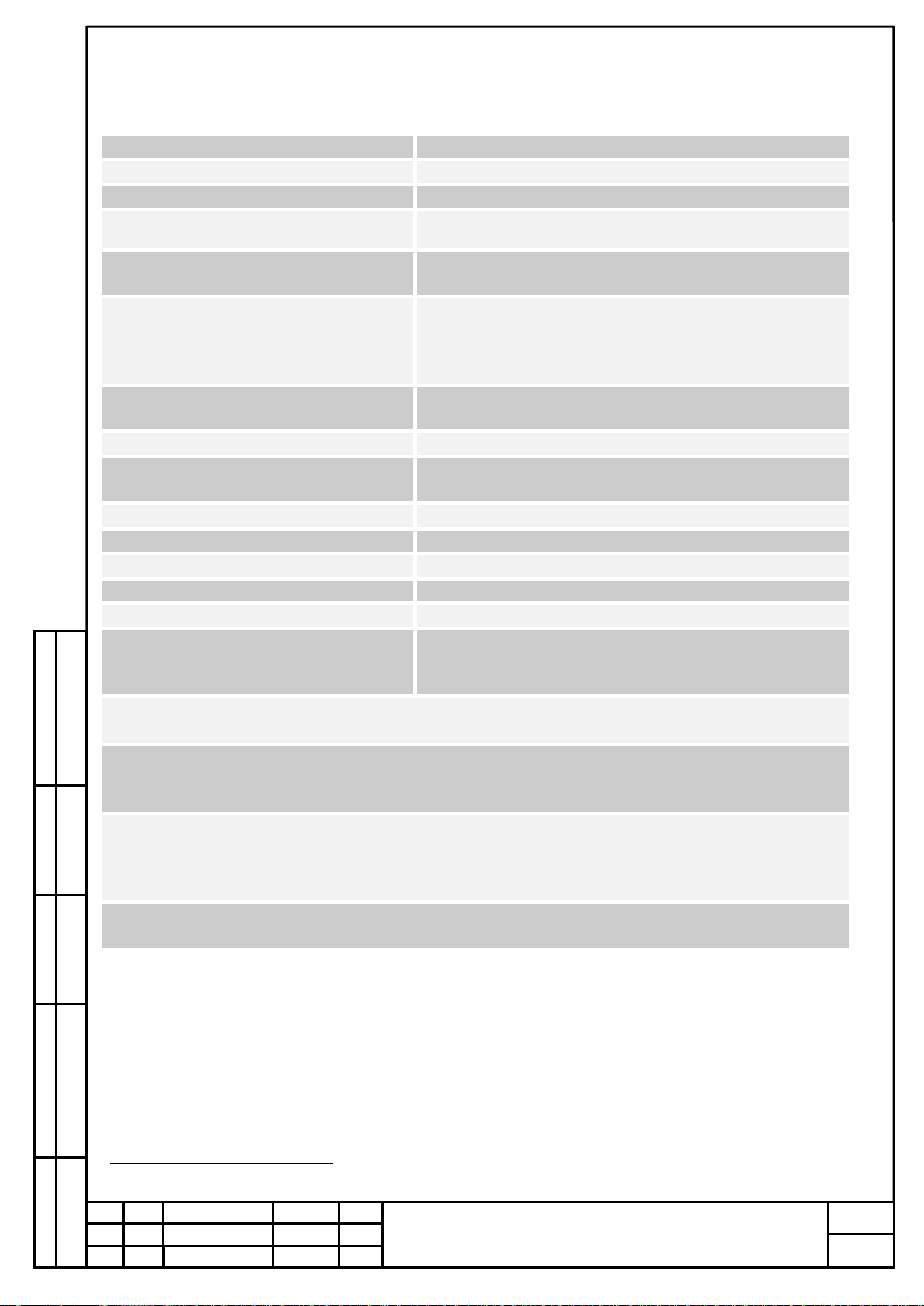

3. Technical characteristics

1

group P-1 of GOST 13320-81

2

group P-1 og GOST 13320-81

Overall dimensions

72х94х46 mm

Power consumption

not more 0,2 Watt in standby mode

Weight

not more 0,21 kg

Measuring ranges

See tables 1,2,3,4

Measurement ranges and basic error

limits

See tables 1,2,3,4

Gas detector provides vibration and

light-sound signaling when the

concentration of monitored gases

reaches fixed alarm thresholds

- sound signal 90 dB;

- LED indicators;

- display of symbols indicating the alarm

Output settling time

- no more than 30sec for combustible gases

- no more than 60 sec for toxic gases

Warm up time

no more than 10 min 1

Limits of permissible variation of

indications

no more than 0.2 in fractions from the limits of the

permissible basic error

Storage temperature

from - 50C to + 50 C

Power Supply

Ni-Mh batteries, ААА, 2 pcs.

Uptime

Not less 12 hours

MTBF

Not less 35 000 hours

Average life

Not less 10 years

The probability of trouble-free

operation of the gas analyzer in time

(running hours) 1 year

Not less 0,95

Limits of additional error from changes in ambient temperature for every 10C in the range from

minus 40 to 50C no more than 0.2 in fractions from the limits of the permissible basic error

The limits of the permissible additional error of gas analyzers from the influence of changes in

atmospheric pressure for every 10 kPa within the operating conditions of operation, 0.2 in fractions

of the limits of the permissible basic error

The limits of the permissible additional error of gas analyzers from the influence of changes in the

relative humidity of the analyzed medium, for every 10% within the operating conditions of

operation, 0.2 in fractions of the limits of the permissible basic error. Warming up time no more

than 10 min2

The gas detector is resistant to increased humidity of ambient air that meets the operating and

transportation conditions, up to 100% (non-condensing) at a temperature of 35 C

Orginal Inv

Signature and date

Instead of №

Conv. Inv. №

Signature and date

GSKF.002.025.100 OM

Sheet

8

Rev

.

Document №

Signature

Date

Sheet

4. PGA-ESP explosionproof protection

4.1 Explosion protection of detectors is ensured by the type of explosion protection

intrinsically safe electric circuit “ia”according to GOST R 31610.11-2014 (IEC 60079-11: 2011).

4.2. Explosionproof marking - Ex ia I / 0Ex ia IIСT4.

4.3. The degree of protection of the body of the gas analyzer from access to hazardous parts

(unit batteries) and from ingress of external solid objects and IP67 water in accordance with GOST

14254-2015.

4.4. On the back cover there is a warning sign «In hazardous areas DO NOT OPEN». Do NOT

charge the battery in a hazardous area. The battery must be charged outside the hazardous area.

Using the charger supplied along with the gas detector.

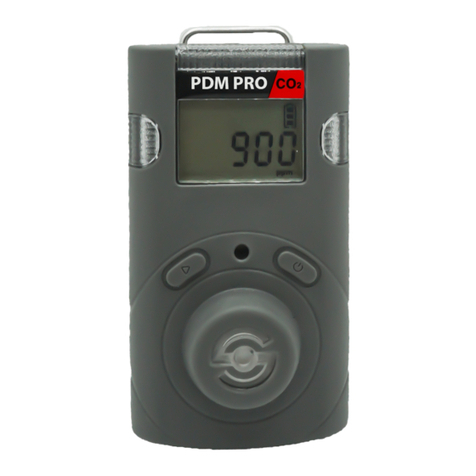

5. Detector description and principle of operation

The principle of operation of the gas detector is based on the conversion of the concentration

of the monitored gas with the help of gas thermocatalytic PGT transducers, of electrochemical PGEs,

optical PGOs into a DC voltage proportional to the concentration being converted, converting it to a

digital code and comparing it with predetermined threshold values.

Structurally, the gas detector is made in a single-block, proprietary plastic housing of

increased strength with protection from radio frequency interference. It has an ergonomic design,

rubberized side inserts for a comfortable grip, hold and prevent slipping, and also protects against

mechanical damage.

The button interface is designed for thumb control of both the left and the right hand.

On the front panel of the case are located:

- LCD display;

- protected keypad (4 buttons);

- two-color LEDs;

- sound emitter.

A strap mount is provided on the rear panel of the case, as well as a half-ring belt with a

fastener. On the bottom of the case is a protected USB connector for communication with a PC.

Orginal Inv

Signature and date

Instead of №

Conv. Inv. №

Signature and date

GSKF.002.025.100 OM

Sheet

9

Rev

.

Document №

Signature

Date

Sheet

The gas analyzer PGA-ESP has the following types of software:

- integrated firmware;

- Esp_Config for working with PC.

Integrated firmware performs the following functions:

- calculation of measurement results of the content of the determined components according

to data from the primary measuring transducer;

- diagnostics of hardware and software parts of the gas analyzer;

- maintaining and storing the event log (1000 unique records with the ability to automatically

replace old events with new ones);

- data exchange with PC via MODBUS-RTU protocol;

- comparison of measurement results with predetermined threshold values.

1. LED window

2. LCD backlit display

3. “UP”button

4. “Enter” button

5. Sound emitter

6. “Power” button

7. “Down” button

8. Sensors’ cell

9. Vibration emitter

10. Fixing clip

11. Electrochemical sensors

12. Thermocatalytic sensor

13. Sensor О2

14. Protection net

1

2

3

9

8

7

6

5

4

10

11

12

13

14

Orginal Inv

Signature and date

Instead of №

Conv. Inv. №

Signature and date

GSKF.002.025.100 OM

Sheet

10

Rev

.

Document №

Signature

Date

Sheet

Esp_Config for working with PC

The gas detector PGA-ESP has the ability to connect to a personal computer or laptop to work

with the Esp_Config software based on the Microsoft Windows OS. A detailed description of working

with the ESP_Config program is given in paragraph 9 of this operating manual.

.

Orginal Inv

Signature and date

Instead of №

Conv. Inv. №

Signature and date

GSKF.002.025.100 OM

Sheet

11

Rev

.

Document №

Signature

Date

Sheet

6. Pre-operation procedure

6.1. PGA-ESP turning on procedure

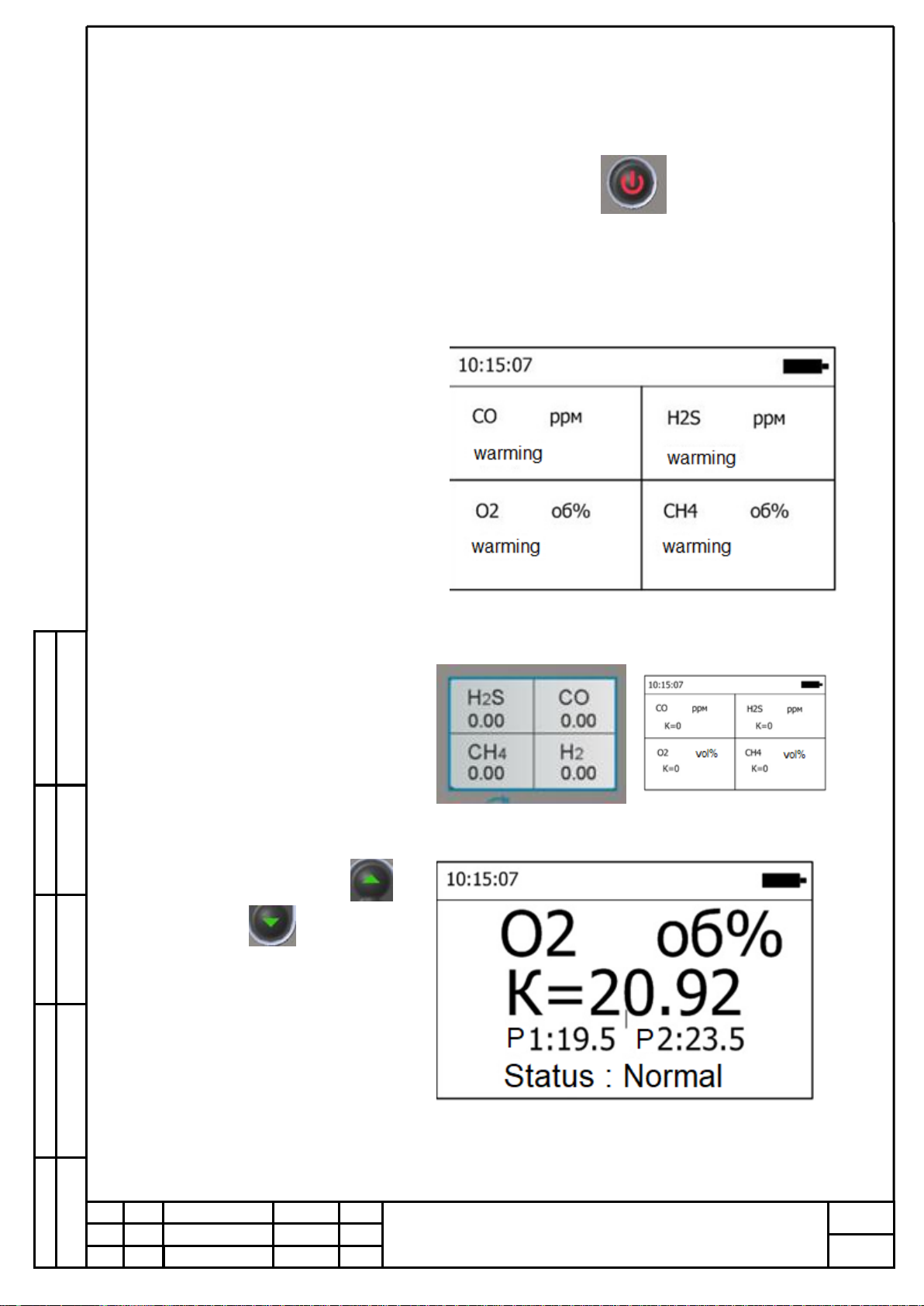

6.1.1 Detector is turned on by the

“Power” button

6.1.2. Alarm Checking:

A short beep sounds

Display flashes backlight

Blinking green LEDs

6.1.3. «Warm-up» mode

In this mode, transients end in the

sensors and constant values of the

output signals are set.

The channel measuring methane or

other explosive gas will be in the

“warm-up” mode longer than others

- this is normal

6.1.4. «Standby»Mode

In standby mode, the current

measured data, time, gas, units,

time, battery status should be

displayed

6.1.5. Using bottons “UP”

and “Down”can be selected

information for a specific selected

channel.

Information is displayed

sequentially for each channel from

the first to the fourth.

Orginal Inv

Signature and date

Instead of №

Conv. Inv. №

Signature and date

GSKF.002.025.100 OM

Sheet

12

Rev

.

Document №

Signature

Date

Sheet

6.2. Gas detector adjustment

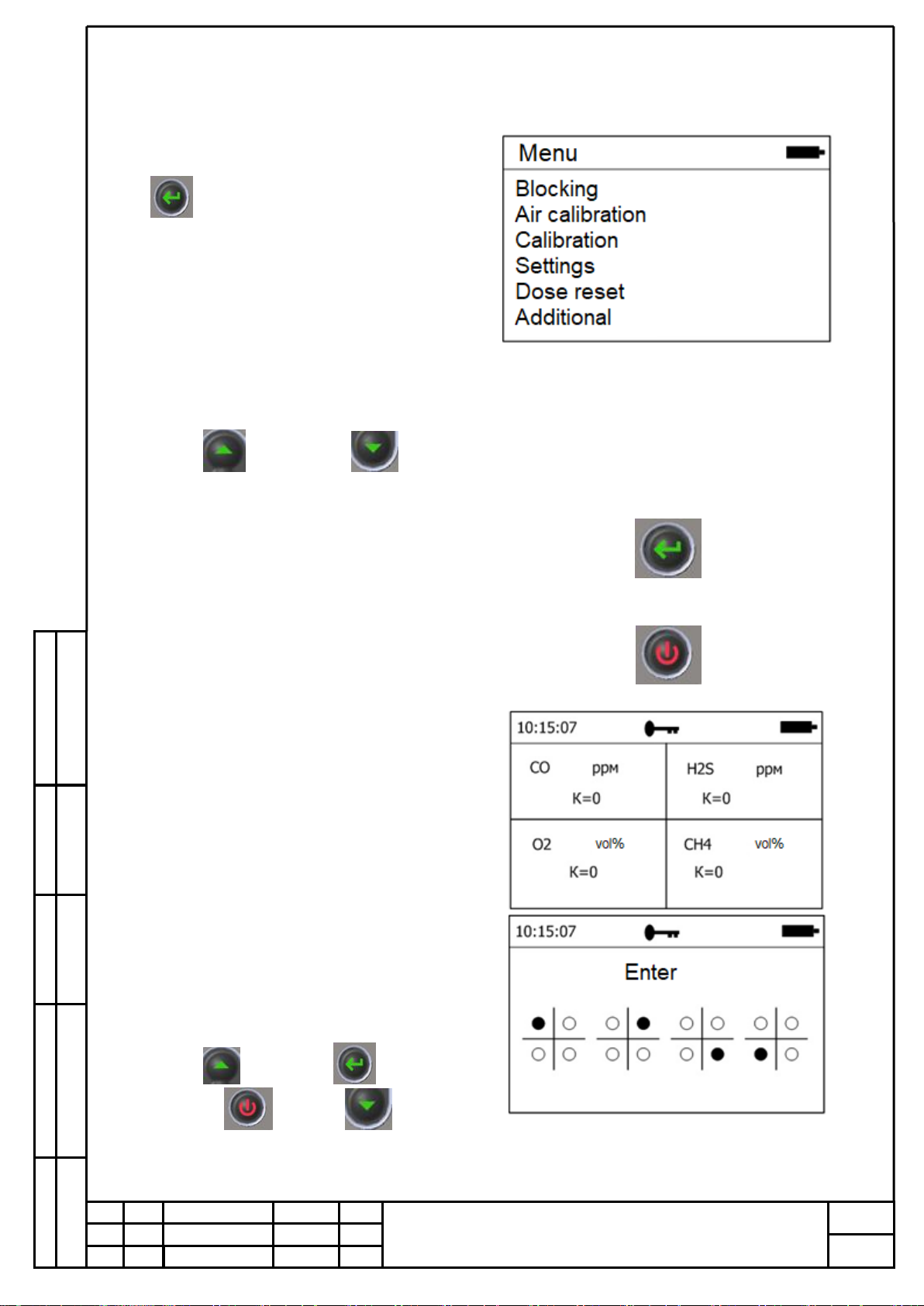

6.2.1. Go to the main menu of the device

settings by pressing the "Enter" button

6.2.2. The selection of items in the main

menu is carried out using the buttons

«UP»and «Down»

6.2.3. Selection confirmation –button

“Enter”

6.2.4. Cancel, exit to a higher level in the

menu through the "Power" button

6.2.5. «Lock»item allows you to block

accidental button clicks.

When locked in the status bar, we see the

key symbol.

When you click on any button, the

“unlock” window will open

Unlocking is carried out according to the

prompts displayed on the screen.

In order to unlock the device, you must

press the prompted buttons

«UP»«Enter»

«Power» «Down»

Orginal Inv

Signature and date

Instead of №

Conv. Inv. №

Signature and date

GSKF.002.025.100 OM

Sheet

13

Rev

.

Document №

Signature

Date

Sheet

6.2.6. The item “Calibr by air” sets the

level “0” for all channels except oxygen

according to the current state of the

environment. It establishes a normal

concentration of oxygen in the

environment - 20.95 ppm. Use only in the

“clean” zone, knowing in advance that

there are no additional impurities of

suspended gases in the environment, etc.

Choose by butoon

«Yes»and press

Air calibration done.

6.2.7. When selecting “Calibration”, a

window for selecting a channel for

calibration will open

After selecting a channel, the “action

selection” window appears

Where the channel number and type of

gas are indicated in the status window.

Orginal Inv

Signature and date

Instead of №

Conv. Inv. №

Signature and date

GSKF.002.025.100 OM

Sheet

14

Rev

.

Document №

Signature

Date

Sheet

6.2.8. “Zero” menu item

This is a zero concentration setting.

If you select “Yes”, a zero calibration is

performed.

If “No” is selected, the calibration value

remains unchanged.

6.2.9. “Concentration” menu item

Allows calibration using an arbitrary

concentration value. The value of the last

calibration concentration value is saved

(it is not necessary to enter the value for

the same cylinder each time).

Where: Кт –current concentration value

Uт–the current value of the signal on the ADC. It is convenient to use during calibration

to determine the end of calibration.

К- set value of the new concentration.

To enter the calibration concentration value, the number of decimal places is determined

by the measurement range and does not change manually.

The concentration input is carried out exclusively by the buttons of the selection buttons

«Up»and «Down»

When pressed once, the least significant digit changes by one in the corresponding

direction.

When holding the button, the least significant bit begins to change on its own.

Further holding the button accelerates changes and moves to the next digit.

The value increases to the upper value of the measuring range and so on in a circle.

When you release the button at the right time, we get the right number. If necessary, it

can easily be edited with a single click.

Orginal Inv

Signature and date

Instead of №

Conv. Inv. №

Signature and date

GSKF.002.025.100 OM

Sheet

15

Rev

.

Document №

Signature

Date

Sheet

To go to the “calibration” action, press the “select” button and use the buttons to

select:

“Yes” to calibrate or

“No” to exit to the “action selection” menu.

The device allows you to have up to 5 calibration points. This allows you to split the

measuring range up to four subranges. When the calibrated concentration falls into one of the

ranges where there is already a calibration point, an automatic replacement occurs. Necessary

and sufficient for work are 2 points, one of which is required calibration "0". You can calibrate

multiple times.

If, with a calibrated device, mix and set a low concentration, if the signal value is greater

than or equal to the value of high concentration (the same millivolt value), then calibration will

not be performed. The message “Invalid calibr” will be displayed on the screen.

Example.

The device is calibrated:

К=0 vol % U=10mV;

К=21 vol % U=1000mV;

Let's try to calibrate:

К=7 vol % U=1000mV;( or any number greater than 1000)

We get the answer:

“Invalid calibr”

6.2.10. “View”menu item

Allows you to view the current

calibration points and delete them if

incorrect calibration

To do this, select the point to be deleted

and press the “select" button »

In the window that appears, select “yes”

to delete or “no” if you want to leave the

calibration point unchanged

Orginal Inv

Signature and date

Instead of №

Conv. Inv. №

Signature and date

GSKF.002.025.100 OM

Sheet

16

Rev

.

Document №

Signature

Date

Sheet

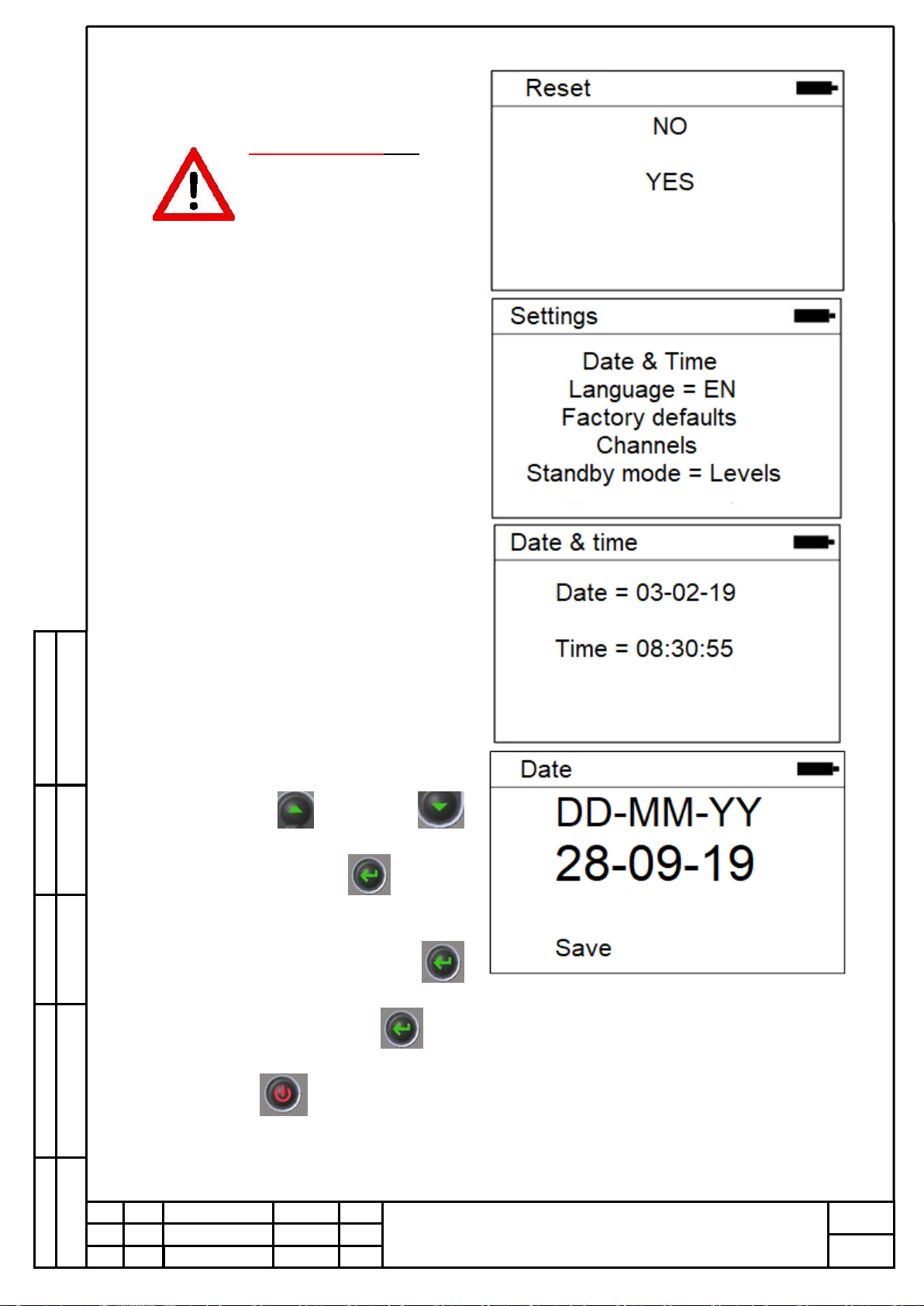

6.2.11. The menu item "Reset"

ATTENTION!!! This

menu item will reset all

instrument calibration

points when selecting

“YES”

6.2.12. The menu item "Settings"

6.2.13. Menu item "Date & time"

The item "Date and time" allows you to

set the current date and time

Menu item "Date ..."

When the window is opened with the “up”

selection buttons and “down”

set the day of the month.

Use the "selection" button go to the

month setting. Then, in the same way, go

and set the current year.

The next press on the “selection”

will lead to the item “Save”. To save the

entered settings, press “select”

To correct the entered values, press the

cancel button. .

Also, using this button, you exit back to

the previous menu.

Orginal Inv

Signature and date

Instead of №

Conv. Inv. №

Signature and date

GSKF.002.025.100 OM

Sheet

17

Rev

.

Document №

Signature

Date

Sheet

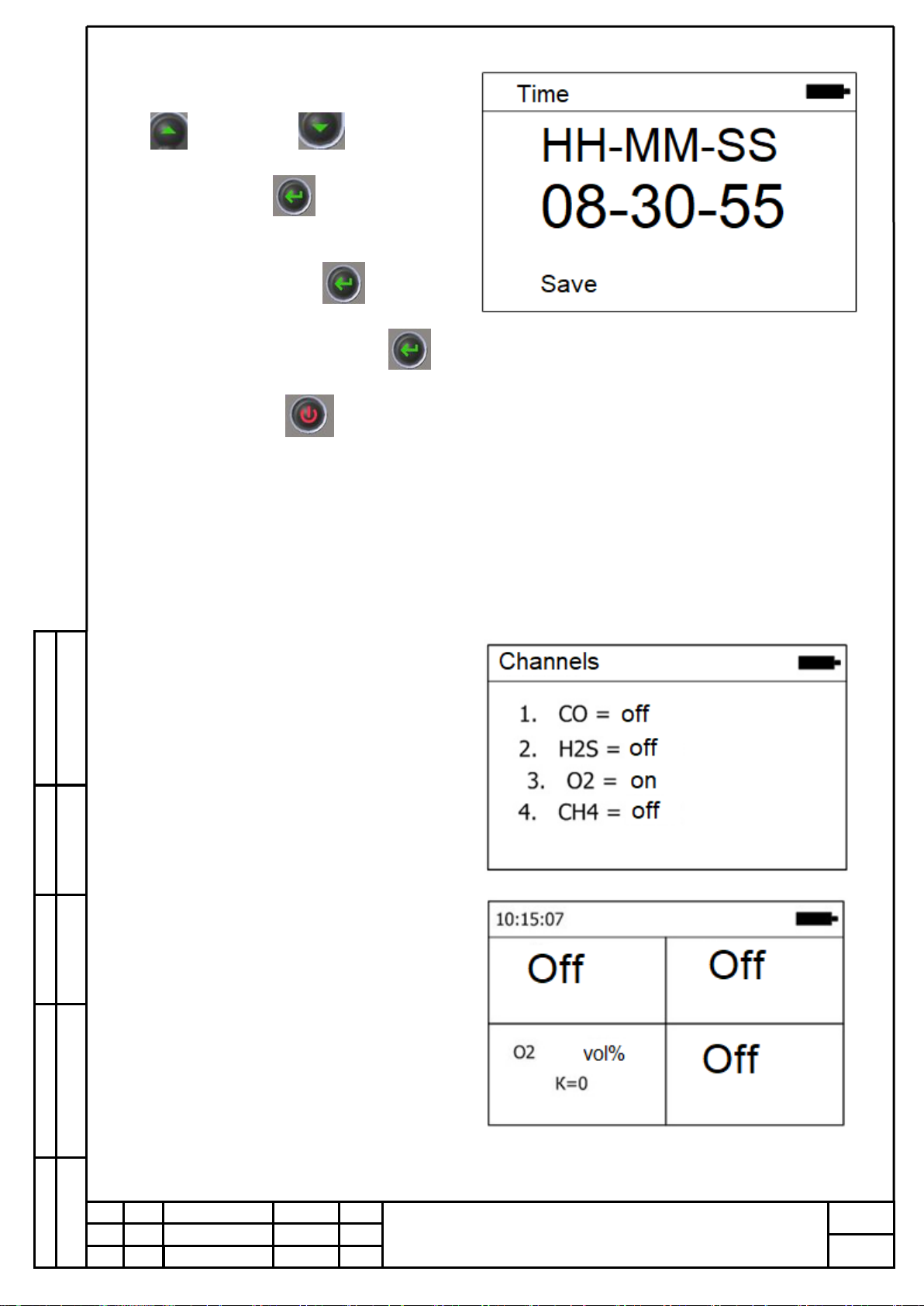

Menu item "Time"

When the window is opened, the “Up”

and “Down” selection

buttons set the clock in 24-hour format.

Button "Select"

proceed to setting the minutes. Next, in

the same way, go and set the seconds.

Next click on "Select"

will lead to the “Save” item. To save the

entered settings, press “Select”.

To correct the entered values, click on the

“Cancel” button. . Так-же с

помощью этой кнопки происходит

выход обратно к предыдущему меню.

6.2.14. Menu item "Language"

Sets the interface language.

"RU" - Russian language

"EN" - English

Menu item "Factory defaults"

Returns instrument settings, including

calibrations, to factory settings.

6.2.15. “Channel”menu item

Allows you to block a particular channel

if necessary. If the channel is disabled, no

alarm on this channel works, on the

screen in standby mode - an empty sector

with the inscription “Off”.

Orginal Inv

Signature and date

Instead of №

Conv. Inv. №

Signature and date

GSKF.002.025.100 OM

Sheet

18

Rev

.

Document №

Signature

Date

Sheet

6.2.16. The menu item "Stanby Mode "=

Thresholds

Must remain in the preset position.

Thresholds do not change. A change can

only be entered with the shell.

6.2.17. The menu item "Additional"

6.2.18 Menu item "Info"

Displays information about the device

and its firmware version

6.2.19. Menu item “Archive”

Allows you to display messages about the

status of the device recorded in the

archive. After equality, the number of

entries in the archive is displayed. When

selecting the "Archive ..." item, we can

display one archive entry per screen. The

command line displays the sequence

number of the entry. Below is the date,

time and the recorded event itself.

For example, calibration channel number

3

The maximum number of records is

1000. The recording goes in a ring.

Record No. 1001 erases the events of

record No. 1 and becomes record No. 1

Orginal Inv

Signature and date

Instead of №

Conv. Inv. №

Signature and date

GSKF.002.025.100 OM

Sheet

19

Rev

.

Document №

Signature

Date

Sheet

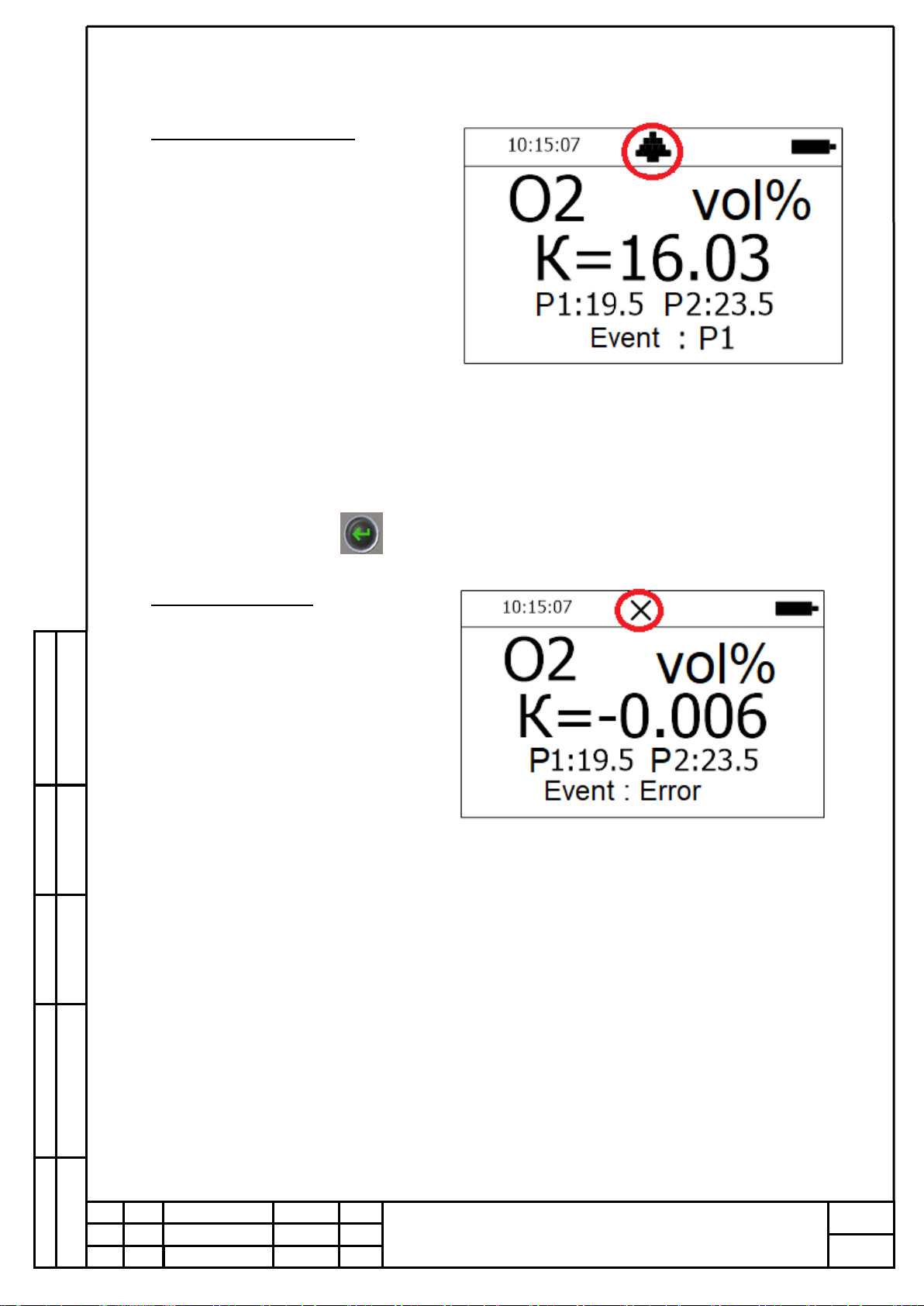

7. PGA-ESP detector operation

7.1. Alarm threshold exceeded.

When the alarm threshold is

exceeded, the light, sound, vibration alarms

are automatically turned on. The command

line displays Pictogram.

For the first threshold “Bell”, for the

second threshold “Three exclamation

points”.

The display automatically switches to a

single window of an activated alarm.

If the threshold is exceeded for more than 5

seconds, the threshold “clicks”. And until

the user manually resets the event message,

the alarm will remind him of it. There may

be several events. To return to standby

mode, the user must view all events. View

events by clicking the button

7.2. Internal malfunction

If there is an internal malfunction, the

“Cross” icon appears in the status bar.

And the message appears: “Event: error”

Orginal Inv

Signature and date

Instead of №

Conv. Inv. №

Signature and date

GSKF.002.025.100 OM

Sheet

20

Rev

.

Document №

Signature

Date

Sheet

8. Connection PGA-ESP to PC

Communication with a personal computer is carried out using the ESP-config program when

the device is placed in a USB adapter. To connect to a computer, a common micro-USB

connection cable is required.

The ESP-config software is designed to configure, check and calibrate the device at the

factory, as well as calibrate the device by the consumer.

Attention! Calibration of the device is allowed only outside the hazardous

area!

USB Adapter PGA-ESP

Micro-USB cable connector

Table of contents