2

Laser Triangulation Sensors. RF602 Series

RF602 [Revision 1.2.0] 28.01.2019

Contents

.............................................................................................................................................41. Safety precautions

.............................................................................................................................................42. CE сompliance

.............................................................................................................................................43. Laser safety

.............................................................................................................................................44. General information

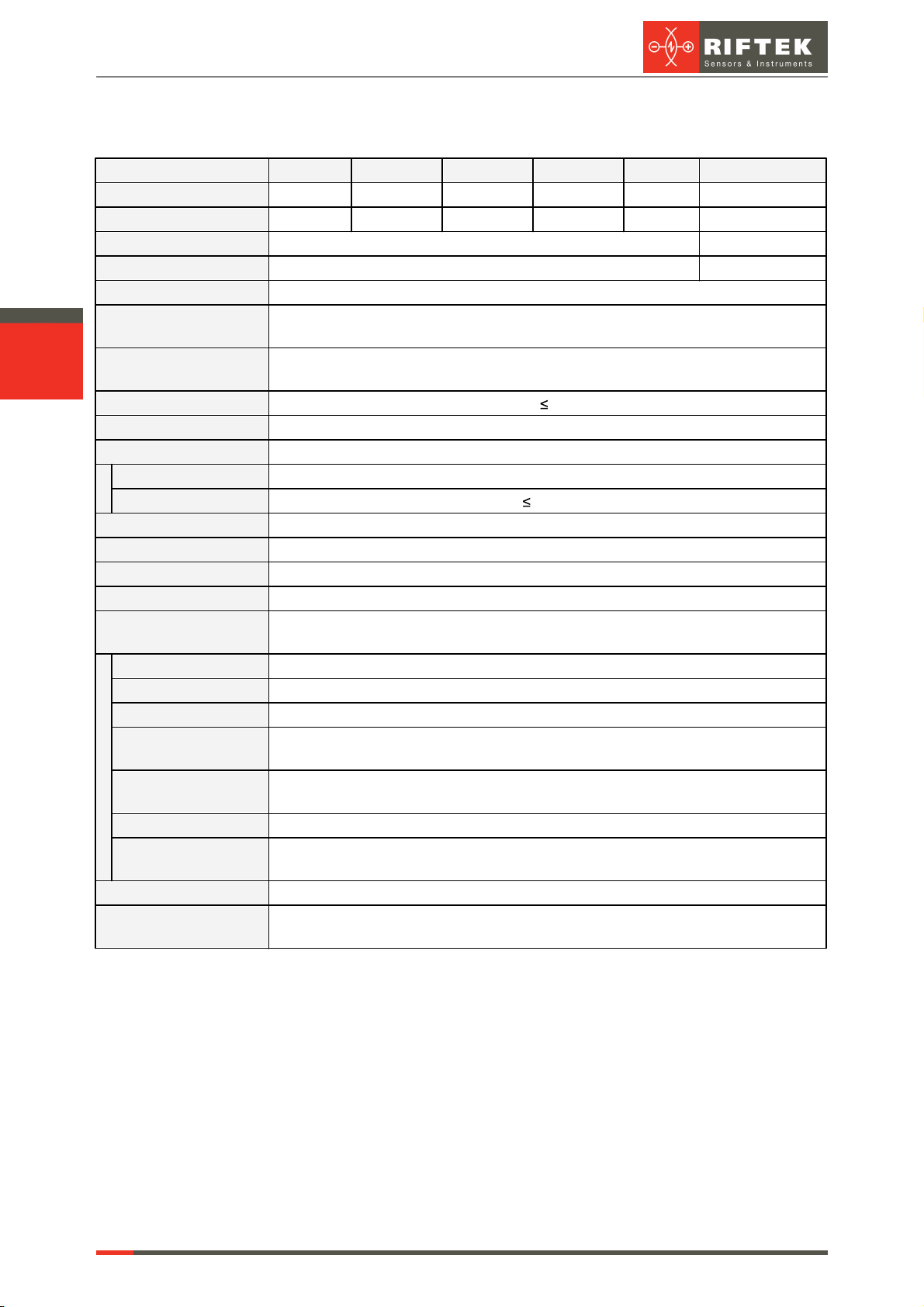

.............................................................................................................................................55. Basic technical data

.............................................................................................................................................66. Example of item designation when ordering

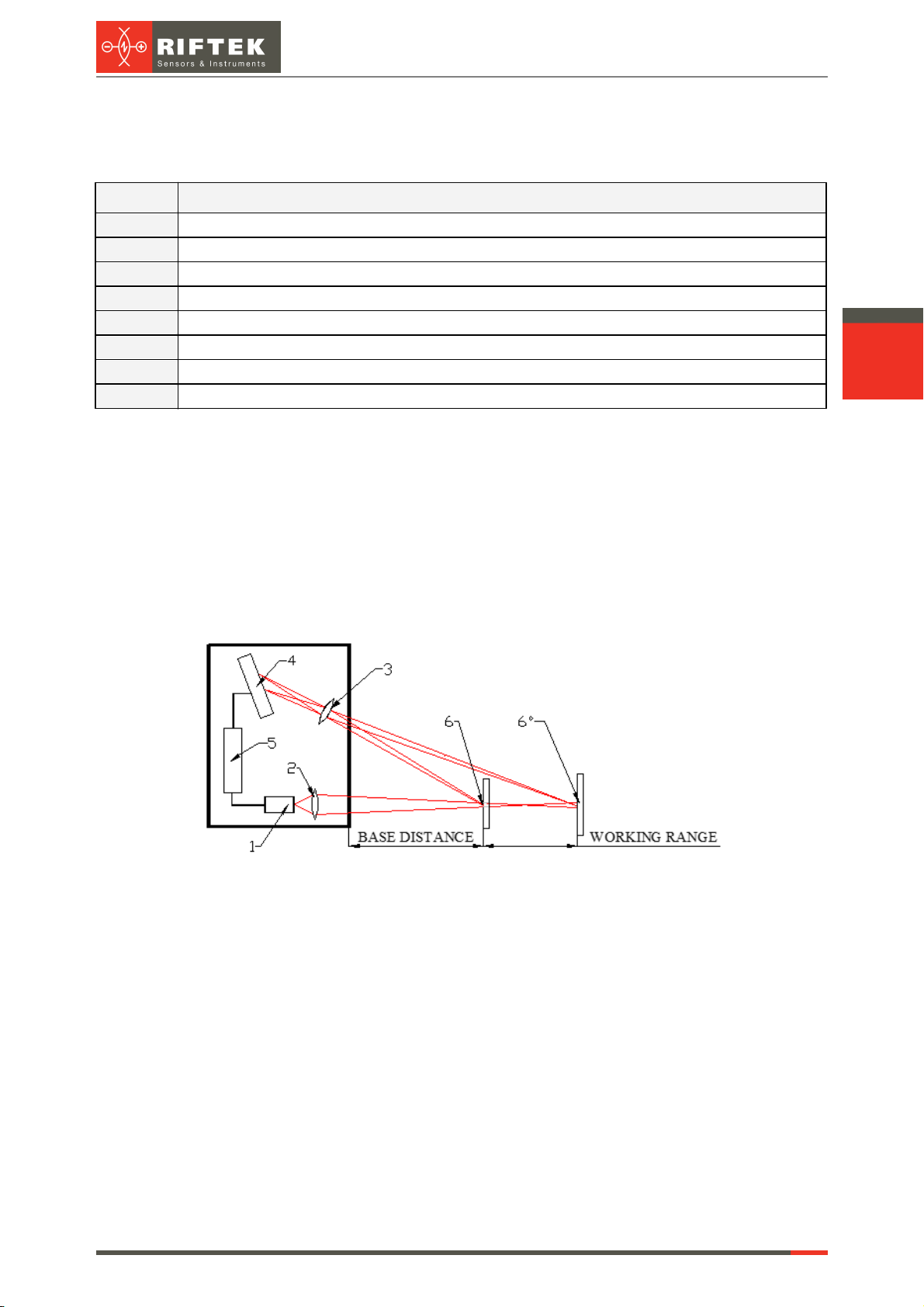

.............................................................................................................................................67. Structure and operational principle

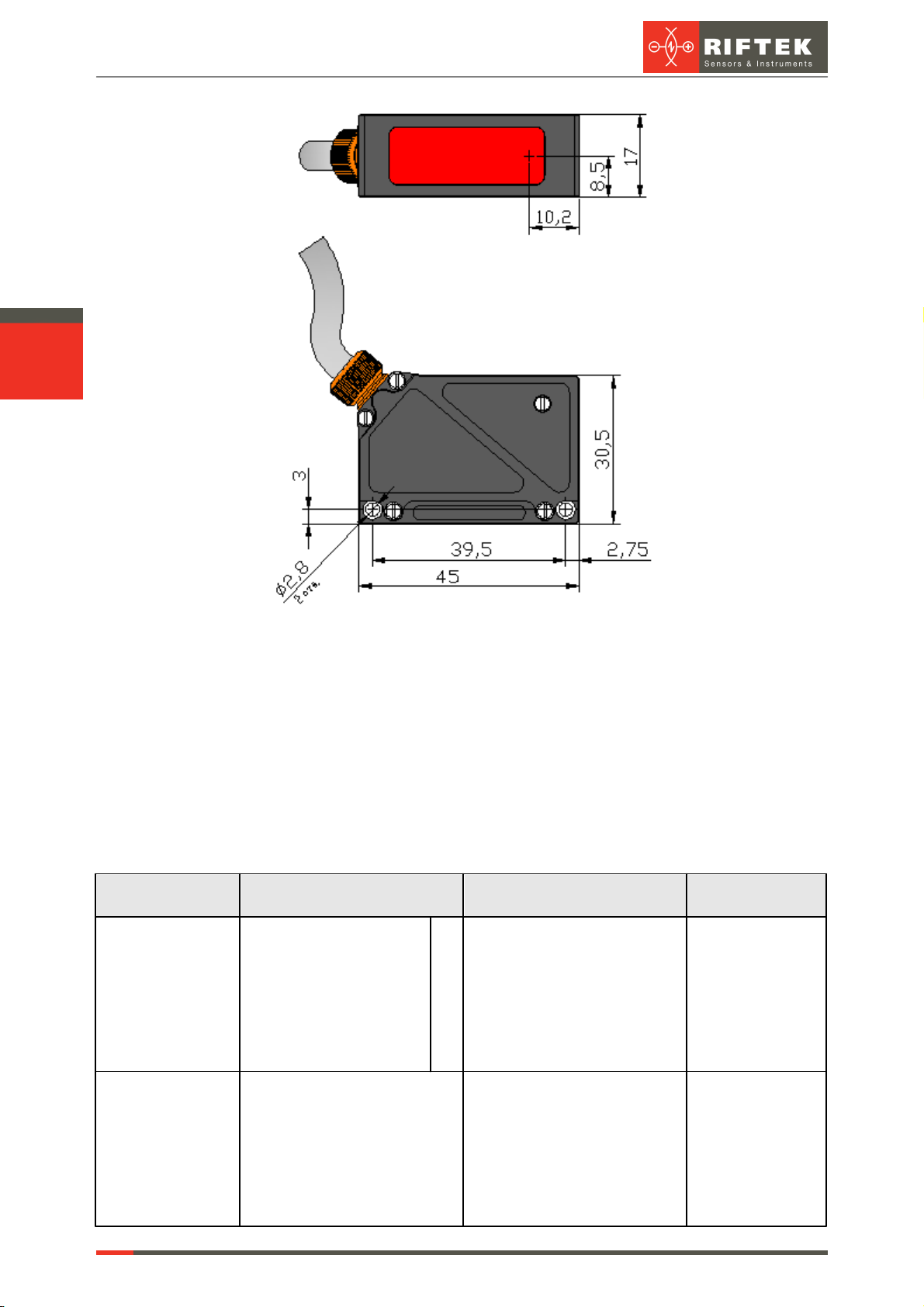

.............................................................................................................................................68. Dimensions and mounting

........................................................................................................................................... 68.1. Overall and mounting dimensions

........................................................................................................................................... 78.2. Overall demands for mounting

.............................................................................................................................................79. Connection

.............................................................................................................................................810. Configuration parameters

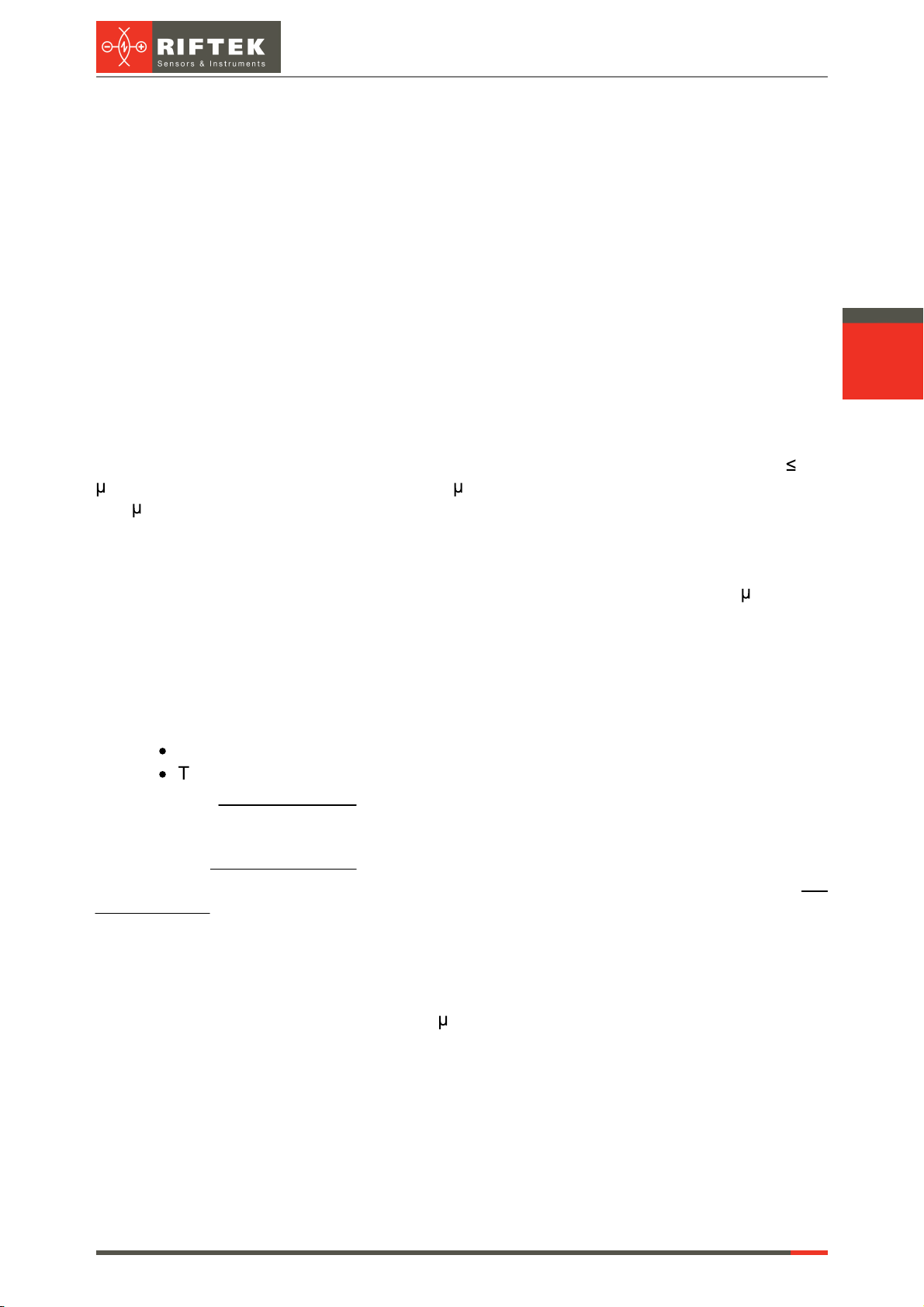

........................................................................................................................................... 810.1. Time limit for integration

........................................................................................................................................... 810.2. Sampling mode

........................................................................................................................................... 810.3. Sampling period

........................................................................................................................................... 910.4. Zero point

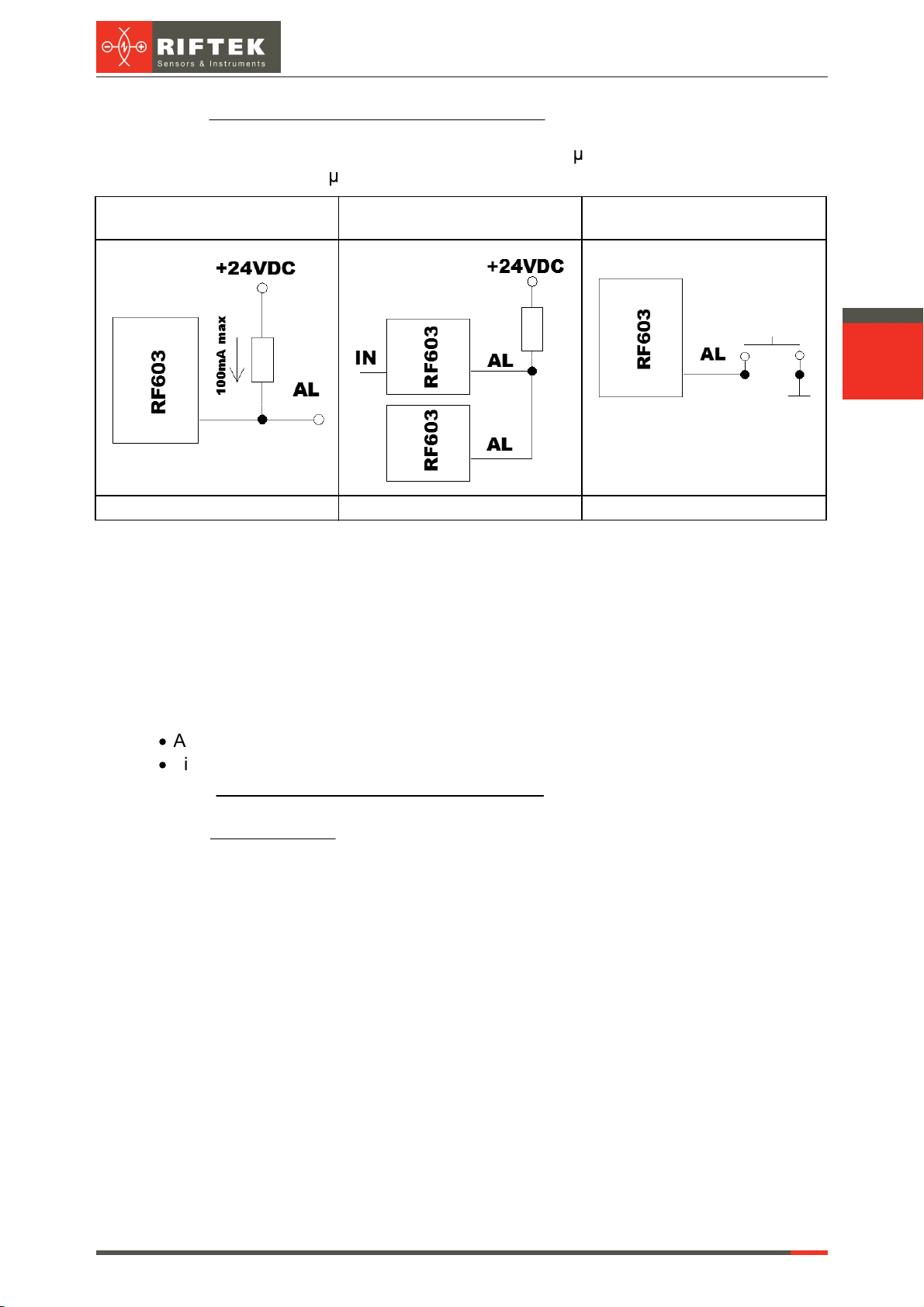

........................................................................................................................................... 910.5. Line AL operation mode

........................................................................................................................................... 1010.6. Time lock of the result

........................................................................................................................................... 1010.7. Method of results averaging

........................................................................................................................................... 1010.8. Number of averaged values/time of averaging

........................................................................................................................................... 1110.9. Factory parameters table

.............................................................................................................................................1111. Description of RS232 and RS485 interfaces

........................................................................................................................................... 1111.1. RS232 port

........................................................................................................................................... 1111.2. RS485 port

........................................................................................................................................... 1111.3. Serial data transmission format

........................................................................................................................................... 1111.4. Modes of data transfer

........................................................................................................................................... 1111.5. Communication sessions types

........................................................................................................................................... 1211.6. Configuration parameters

................................................................................................................. 1211.6.1. Rate of data transfer through serial port

................................................................................................................. 1211.6.2. Net address

................................................................................................................. 1211.6.3. Factory parameters table

........................................................................................................................................... 1211.7. RIFTEK protocol (binary format)

................................................................................................................. 1211.7.1. Request ................................................................................................................. 1311.7.2. Answer ................................................................................................................. 1311.7.3. Data stream

................................................................................................................. 1311.7.4. Output rate

................................................................................................................. 1311.7.5. Request codes table

................................................................................................................. 1411.7.6. List of parameters

................................................................................................................. 1511.7.7. Notes ................................................................................................................. 1511.7.8. Examples of communication sessions

........................................................................................................................................... 1811.8. Modbus RTU protocol (binary format)

................................................................................................................. 1811.8.1. Input Registers (Read only)

................................................................................................................. 1811.8.2. Holding Registers (Read / Write)

........................................................................................................................................... 1911.9. ASCII format

.............................................................................................................................................2012. Analog outputs

........................................................................................................................................... 2012.1. Current output 4…20 mA

........................................................................................................................................... 2112.2. Voltage output 0…10 V

........................................................................................................................................... 2112.3. Configuration parameters

................................................................................................................. 2112.3.1. Range of the analog output

................................................................................................................. 2112.3.2. Analog output operation mode

........................................................................................................................................... 2112.4. Factory parameters table

.............................................................................................................................................2113. Parameterization program