1Date of Origin – 02/24/11

Updated – 02/03/20

TABLE OF CONTENTS

NORMAL TRAILER OPERATION ..................................................................................................................................................................................................................3

SAFETY ................................................................................................................................................................................................................................................4

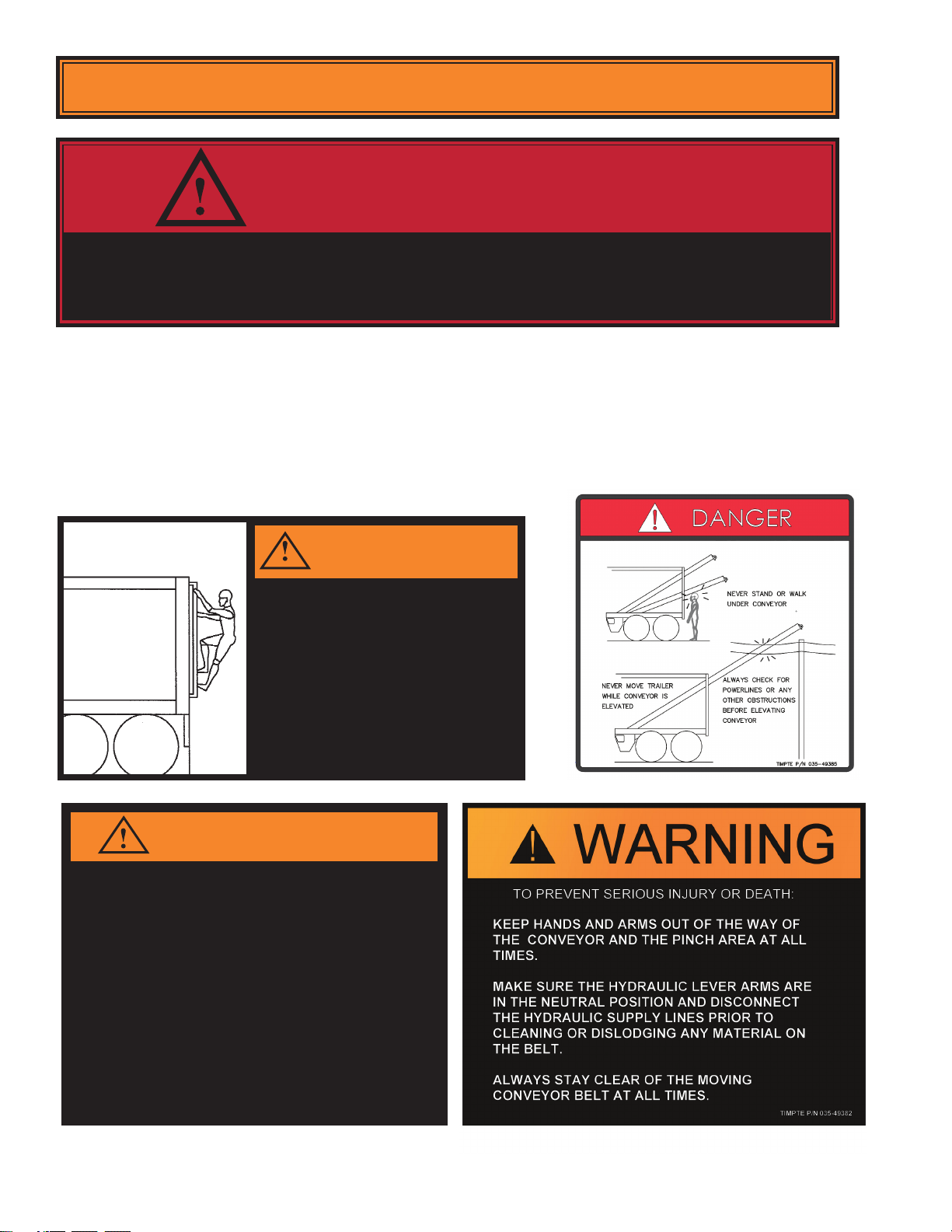

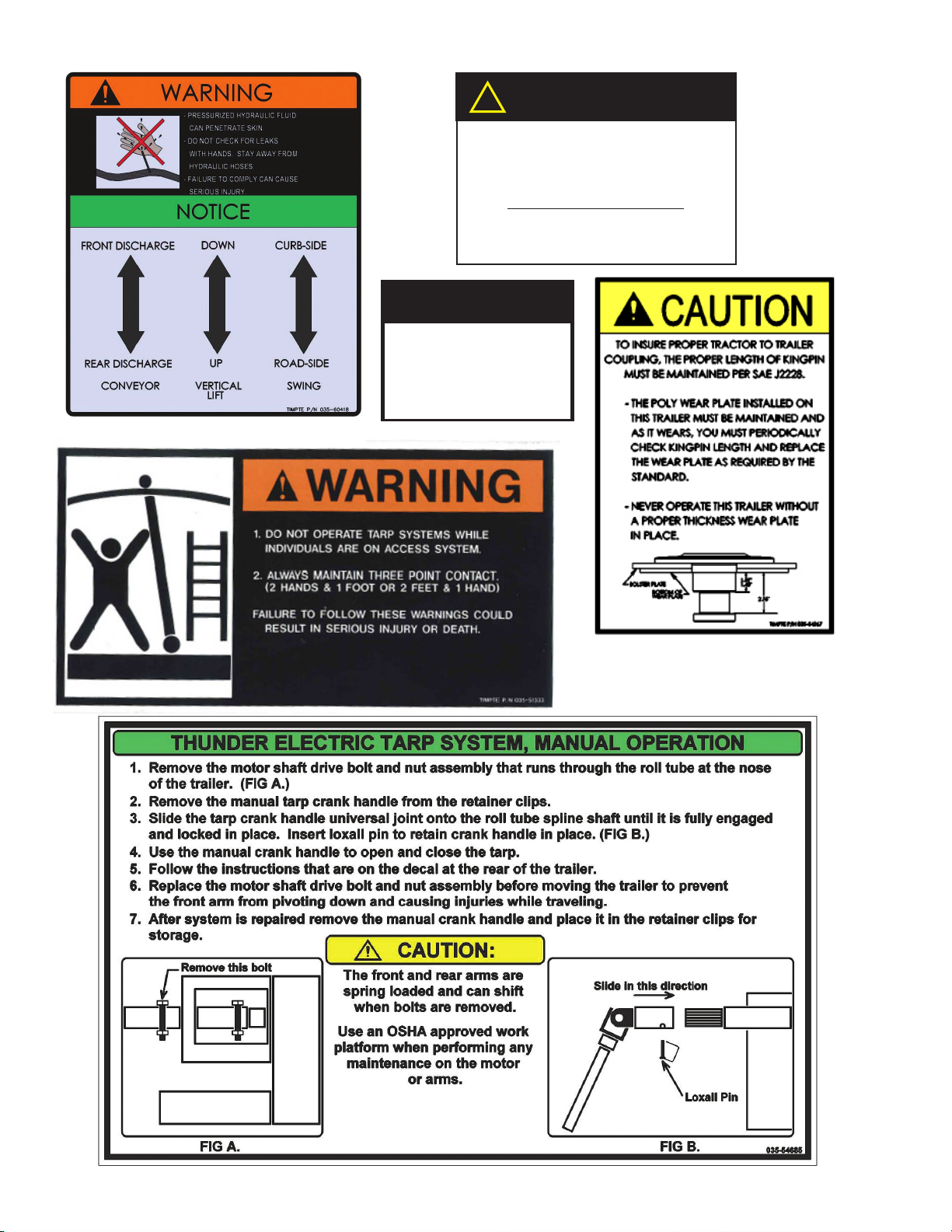

DECALS & WARNINGS.........................................................................................................................................................................................................4, 5, 6, 7

AIR BRAKE SYSTEM.........................................................................................................................................................................................................................8

WHEEL NUT TORQUE ......................................................................................................................................................................................................................8

ABS BRAKING SYSTEM ...................................................................................................................................................................................................................9

BACKUP WARNING SYSTEM...........................................................................................................................................................................................................9

CONTROL OF SAFE OPERATION .................................................................................................................................................................................................10

TRAILER KINGPIN WEAR............................................................................................................................................................................................................... 11

INSPECTION PROCEDURES BEFORE EACH TRIP .................................................................................................................................................................................12

LEGAL REQUIREMENT FMCS 49 CFR 392.7................................................................................................................................................................................12

LIGHTS AND REFLECTORS...........................................................................................................................................................................................................13

ELECTRICAL WIRING.....................................................................................................................................................................................................................13

FIFTH WHEEL AND KING PIN ENGAGEMENT..............................................................................................................................................................................13

TIRES ..............................................................................................................................................................................................................................................13

MUD FLAPS .................................................................................................................................................................................................................................... 13

TARP SYSTEM ................................................................................................................................................................................................................................ 13

LANDING GEAR .............................................................................................................................................................................................................................. 13

HUB MAINTENANCE...................................................................................................................................................................................................................... 13

WHEELS AND RIMS........................................................................................................................................................................................................................ 14

HUB LUBRICANT.............................................................................................................................................................................................................................14

SIDE STRUCTURES........................................................................................................................................................................................................................ 15

SUSPENSION AND SUSPENSION SUBFRAME ...........................................................................................................................................................................15

OPERATING INSTRUCTIONS.....................................................................................................................................................................................................................16

PARKING/EMERGENCY BRAKING SYSTEM.................................................................................................................................................................................16

OPERATING YOUR TIMPTE TENDER .......................................................................................................................................................................................................17

DUAL PURPOSE TENDER TRAILER OPERATING INSTRUCTIONS............................................................................................................................................ 17

TRAILER LOADING..............................................................................................................................................................................................................17

TRAILER UNLOADING.........................................................................................................................................................................................................18

SELF-CONTAINED POWER UNIT OPERATION............................................................................................................................................................................. 19

THUNDER ELECTRIC TARP SYSTEM ........................................................................................................................................................................................... 20

PROGRAMMING REMOTE TO WORK WITH THE THUNDER ELECTRIC TARP SYSTEM ..............................................................................................20

PROGRAMMING REMOTE TO WORK WITH THE EZ FLOW TRAP SYSTEM ..................................................................................................................21

THUNDER ELECTRIC TARP SYSTEM, MANUAL OPERATION .........................................................................................................................................22

TROUBLESHOOTING GUIDE..............................................................................................................................................................................................23

EZ-FLOW HYDRAULIC DOOR TROUBLESHOOTING GUIDE ......................................................................................................................................................25

PRESSURE RELIEF ADJUSTMENT ...............................................................................................................................................................................................26

EZ-FLOW QUICK RELEASE SYSTEM............................................................................................................................................................................................27

TRACTOR PTO SYSTEM “WET KIT” SPECIFICATIONS ...............................................................................................................................................................28

TENDER HYDRAULIC SYSTEM MAINTENANCE..........................................................................................................................................................................28

TIMPE TENDER TRAILER HYDRAULIC SCHEMATIC 577-60478.................................................................................................................................................29

SELF-CONTAINED TIMPTE TENDER TRAILER HYDRAULIC SCHEMATIC 577-60429............................................................................................................... 31

TENDER HYDRAULIC TESTING PROCEDURE ............................................................................................................................................................................ 33

CONVEYOR BELT TENSION AND TRACKING .............................................................................................................................................................................. 39

CONVEYOR BELT TRACKING ADJUSTMENT............................................................................................................................................................................... 40

GENERAL MAINTENANCE ......................................................................................................................................................................................................................... 41

AVOIDING CONTAMINATION.......................................................................................................................................................................................................... 41

TRAILER WASHING ........................................................................................................................................................................................................................ 41

CORROSIVE DETERIORATION...................................................................................................................................................................................................... 41

AIR HAMMER (VIBRATOR) MAINTENANCE..................................................................................................................................................................................42

HUB MAINTENANCE.......................................................................................................................................................................................................................44

WHEEL BEARING INSPECTION.....................................................................................................................................................................................................44

WHEEL BEARING ADJUSTMENT...................................................................................................................................................................................................44

BEARING LUBRICANT....................................................................................................................................................................................................................44

BRAKES...........................................................................................................................................................................................................................................46

AIR BRAKE SYSTEM - TROUBLESHOOTING ............................................................................................................................................................................... 47

BRAKE CONTROLS ........................................................................................................................................................................................................................48

AIR SYSTEM COLD WEATHER OPERATION ................................................................................................................................................................................48

AIR BRAKE PIPING SCHEMATIC .............................................................................................................................................................................................49, 50

CHECKING SPRING BRAKES ........................................................................................................................................................................................................51

AUTOMATIC SLACK ADJUSTERS..................................................................................................................................................................................................51

WHEEL ASSEMBLIES .....................................................................................................................................................................................................................52

WHEEL INSTALLATION...................................................................................................................................................................................................................52

TIRE CHANGE PROCEDURE.........................................................................................................................................................................................................53

AXLE ALIGNMENT...........................................................................................................................................................................................................................54

AIR-RIDE SUSPENSION SYSTEM ................................................................................................................................................................................................. 54

AIR-RIDE SUSPENSION SCHEMATIC ...........................................................................................................................................................................................55

ELECTRICAL SYSTEM DIAGRAM .....................................................................................................................................................................................57, 58, 59

LANDING LEGS...............................................................................................................................................................................................................................60

MAINTENANCE SCHEDULE - TENDER...............................................................................................................................................................................................61, 62

TIMPTE TENDER REFERNCE GUIDE .......................................................................................................................................................................................................63

REPORTING SAFETY DEFECTS - 49CFR 575.6 (a)(2)(ii).........................................................................................................................................................................64

TIMPTE “PEACE OF MIND” LIMITED WARRANTY....................................................................................................................................................................................65

TIMPTE BELT CONVEYOR SYSTEM WARRANTY COVERAGE & EXCLUSIONS ...................................................................................................................................66

FILING A WARRANTY CLAIM......................................................................................................................................................................................................................69