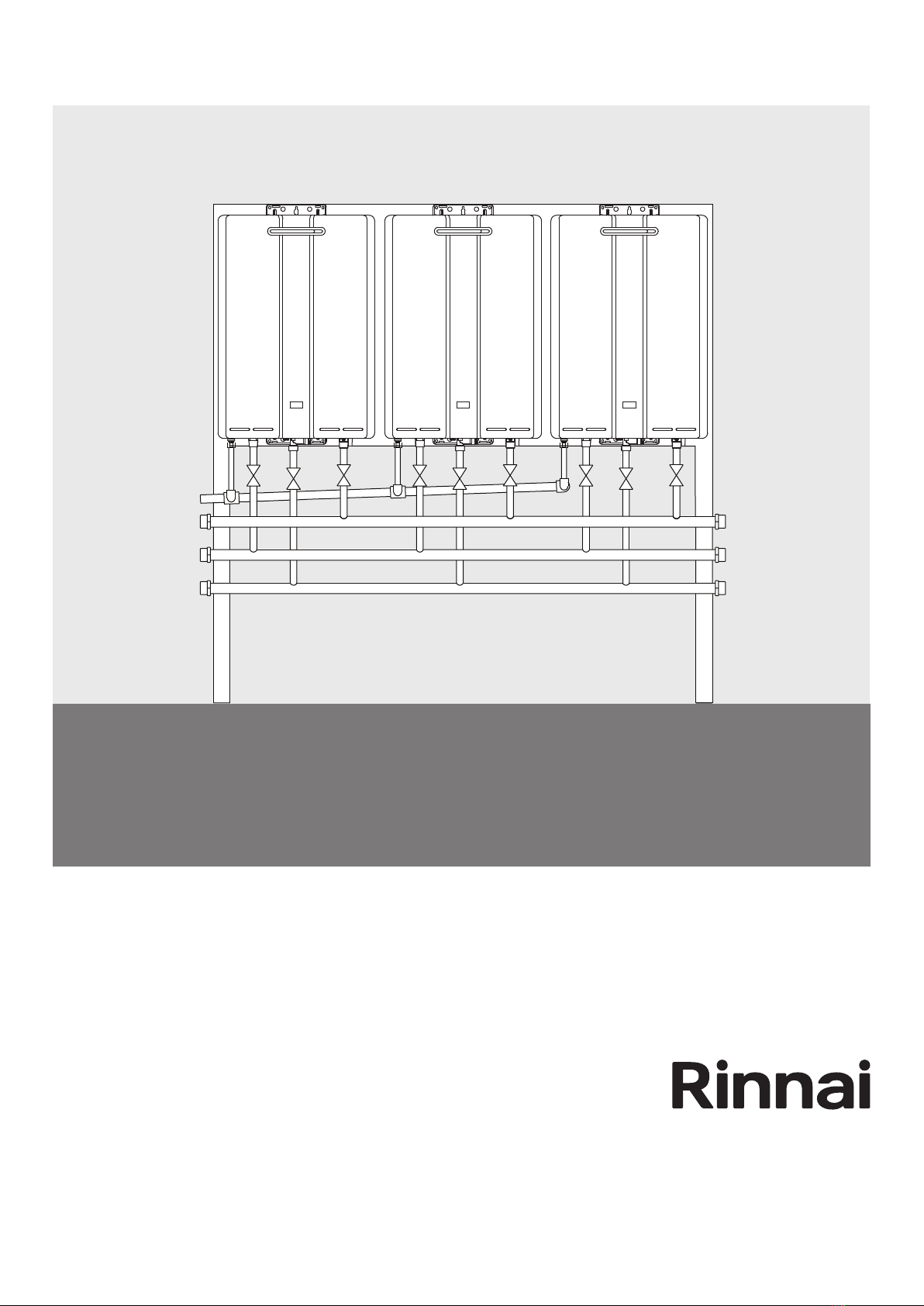

Rinnai 5 Commercial Manifold Pack OIM

INSTALLATION, SERVICE AND REMOVAL MUST BE BY AN AUTHORISED PERSON ONLY.

AS/NZS 5601 was current at the time of printing but may have been superseded. It is the Installer's

responsibility to ensure current requirements are met.

Remove transit protection lm. Check for damage, if any is found DO NOT install and contact supplier.

MODEL RANGE OVERVIEW

MP2200, MP2250, MP2210, ACMP2 200 either external or internal in NG or LPG

MP3200, MP3250, MP3210, ACMP3 200 either external or internal in NG or LPG

MP4200, MP4250, MP4210, ACMP4 200 either external or internal in NG or LPG

MP5200, MP5250, MP5210, ACMP5 200 either external or internal in NG or LPG

MP6200, MP6250, MP6210, ACMP6 200 either external or internal in NG or LPG

Rinnai Commercial Manifold Pack hot water systems must only be installed, commissioned, service and removed

by an authorised person in accordance with these instructions, AS/NZS 5601, AS/NZS 3000, AS/NZS 3500 and

local regulations and municipal building codes including local OH&S requirements.

Rinnai Manifold Pack hot water systems are not suitable or approved as a pool heater.

Read these instructions carefully before proceeding with the installation.

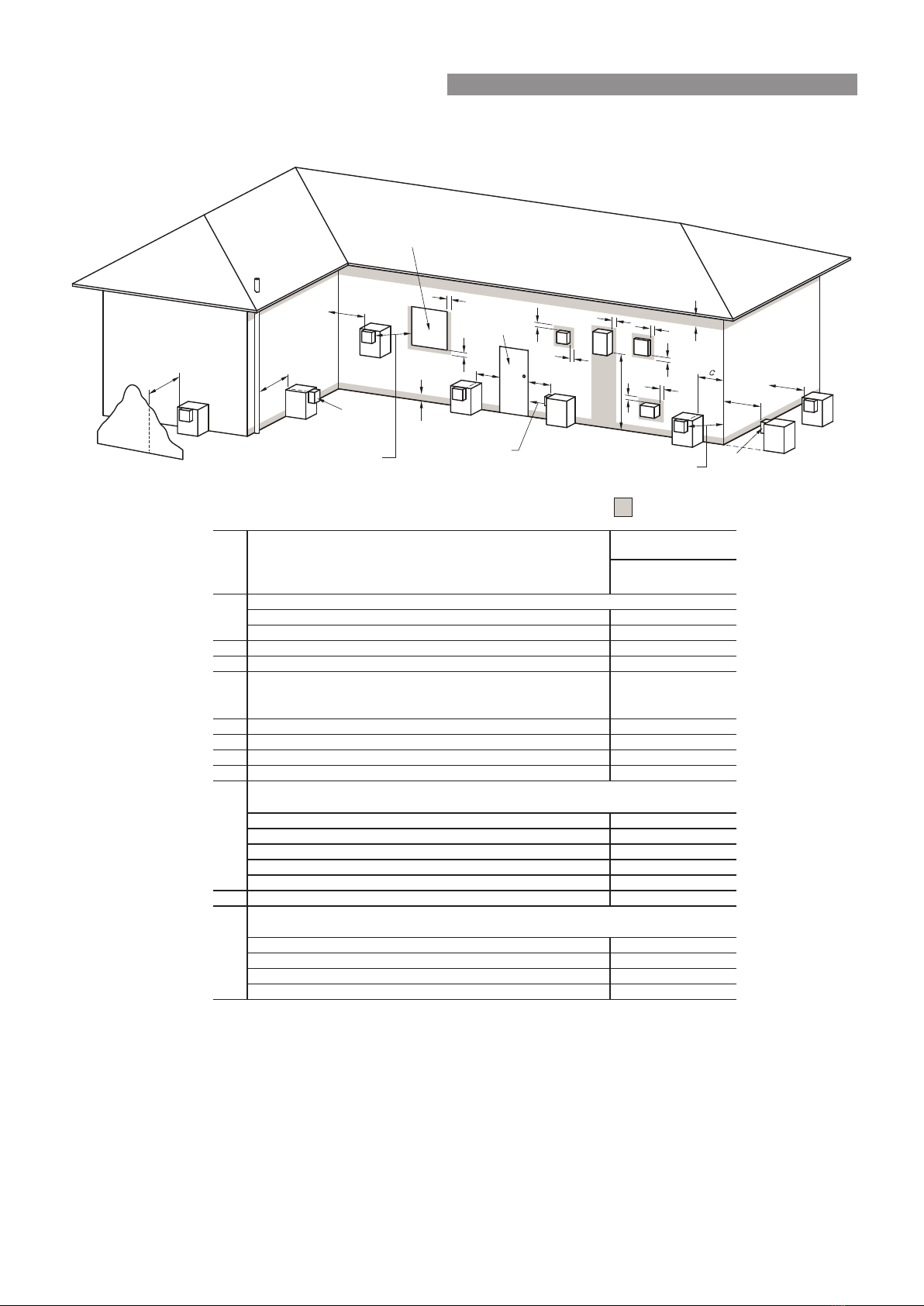

LOCATION

Ensure reasonable access for installation, servicing and removal. All valves, controls and pumps etc must be

easily accessible.

When using free standing frames the system must be mounted on a solid level base, capable of supporting the

weight of the appliance when full of water. Ensure components are not allowed to stand in water.

Manifold Pack can be plumbed “left handed”, “right handed” or “equal ow” as staging determines operating

sequence of heaters, not the plumbing. Stage-less or larger systems may need to be “equal ow”, contact Rinnai

Commercial for assistance.

Gas booster ue terminals must be located in accordance with AS/NZS 5601 Fig 6.2 “Location of balanced ue

terminals”.

Rinnai HD units are fan assisted appliances and thus have lower clearances than a natural draft appliance of the

same MJ rating.

HD200e, HD250e, HD210e (External Models)

This appliance is designed for 'Outdoor' Installation only. As such,it must be located in an above ground open

air situation with natural ventilation, without stagnant areas, where gas leakage and products of combustion are

rapidly dispersed by wind and natural convection.

This appliance must be mounted on a vertical structure with the water and gas connections on the underside

pointing downwards. For appliances installed on elevated structures or under oors specic requirements apply.

Refer to AS/NZS 5601 Section 6 for details.

This appliance must not be used as a domestic spa or swimming pool heater.

Location of the appliance ue terminal must be in accordance with Section 6 and Figure 6.2 of AS/NZS 5601.

Figure 6.2 is reproduced in the 'Horizontal Flue Terminal Clearances' section of these instructions.

Note: that AS/NZS 5601 is current at the time of printing. It is the Installers' responsibility to ensure current

requirements are met.

HD200i, HD210i (Internal Models)

This appliance is designed for 'Indoor' installation only. It may be installed 'Outdoors' in an enclosure if the

requirements of AS/NZS 5601 Section 6 are satised. An enclosure is dened as a compartment, enclosed area

of partitioned o space primarily used for the installing of the appliance.

WARNINGS & IMPORTANT INFORMATION