SAFETY INFORMATION

Read, understand, and follow all safety information contained in these

instructions prior to the use of this 3M™Liqui-Cel™Membrane Contactor.

Retain these instructions for future reference.

Intended Use:

This Liqui-Cel Membrane Contactor is intended to add to or remove

dissolved gases from non-dangerous liquid streams. It is expected that all

users be fully trained in the safe operation of membrane contactors.

Membrane contactors are intended for installation and operation by

qualied installers and operators in accordance with all operating

guidelines, installation instructions, and any other industry requirements.

Use in any other application may not have been evaluated by 3M and may

lead to an unsafe condition.

WARNING

To reduce the risks associated with explosion:

• Only use replacement parts supplied by 3M for this product.

To reduce the risks associated with crush or impact related injuries:

• Always ensure the membrane contactor is properly secured. Be sure the

membrane contactor cannot tip, roll, fall, slide or make any movement that

may cause injury or damage to other system components.

• No liquid, vacuum or sweep gas should be running through the contactor

when changing cartridges or other parts. Membrane contactors should be

completely drained of liquid before attempting to service.

• Care must be taken not to hit or jar (shock) the membrane contactor.

To reduce the risks associated with lifting or moving:

• Always consult the product datasheet or operating guide for membrane

contactor weights. Use appropriately rated lifting equipment for lifting or

moving heavy membrane contactors.

• Drain liquid from the contactor before moving. Do not move a membrane

contactor while it contains liquid.

CAUTION

To reduce the risks associated with environmental contamination:

• At the end of useable life, dispose of the membrane contactor or cartridges

in accordance with local regulations and laws.

NOTICE

• The membrane contactor(s) should not be stored where they are exposed to

direct sunlight. Membrane contactors should always be stored in sealed bags

or shrink wrap material and in the original box or other opaque box.

• Store dry membrane contactor(s) at temperatures < 49° C(120° F) with low to

moderate humidity levels (<60% relative humidity).

• Avoid contact with surfactants/solvents or oxidants (e.g. ozone, chlorine) to

prevent wet-out or oxidation of the hydrophobic membrane.

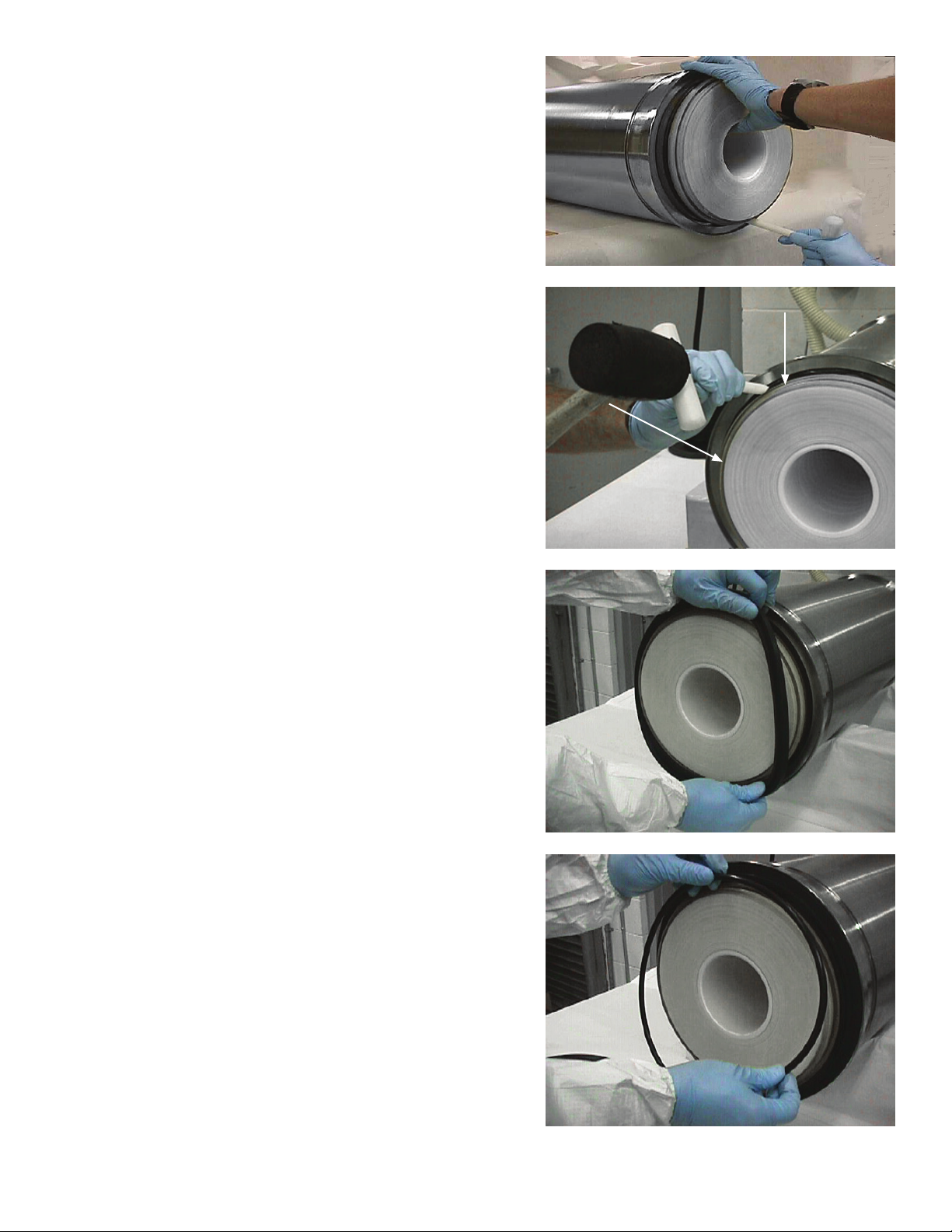

• To avoid contamination, gloves are recommended when handling the

membrane cartridges.

• Do not use dope or metal connections to connect to plastic connections of

the membrane contactor.

• Failure to follow any instructions in this guide will void any warranty, if any

exists.

EXPLANATION OF SIGNAL WORD CONSEQUENCES

WARNING Indicates a potentially hazardous situation, which, if not avoided, could result in death or serious injury and/or property damage.

CAUTION Indicates a potentially hazardous situation, which, if not avoided, could result in minor or moderate injury and/or property damage.

NOTICE Indicates a potentially hazardous situation, which, if not avoided, could result in property damage.

EXPLANATION OF SAFETY AND RELATED SYMBOLS

Warning: Explosion

Warning: Crush or Impact

Caution: Lifting or Moving Hazard

Caution: Possible Environmental Impact

3