WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION,

SERVICE OR MAINTENANCE CAN CAUSE PROPERTY

DAMAGE, PERSONAL INJURY OR LOSS OF LIFE, REFER

TO THE OWNER'S INFORMATION MANUAL PROVIDED

WITH THIS APPLIANCE. INSTALLATION AND SERVICE

MUST BE PERFORMED BY A QUALIFIED INSTALLER,

SERVICE AGENCY OR THE GAS SUPPLIER.

ENERGYSAVER RHFE-431FA

Operation Manual

Table of Contents

Page

FEATURES OF THE RHFE-431FA UNITS ........................................................1

SAFETY DEVICES ................................................................................................1

IMPORTANT POINTS / USAGE AND INSTALLATION MUSTS ............................3

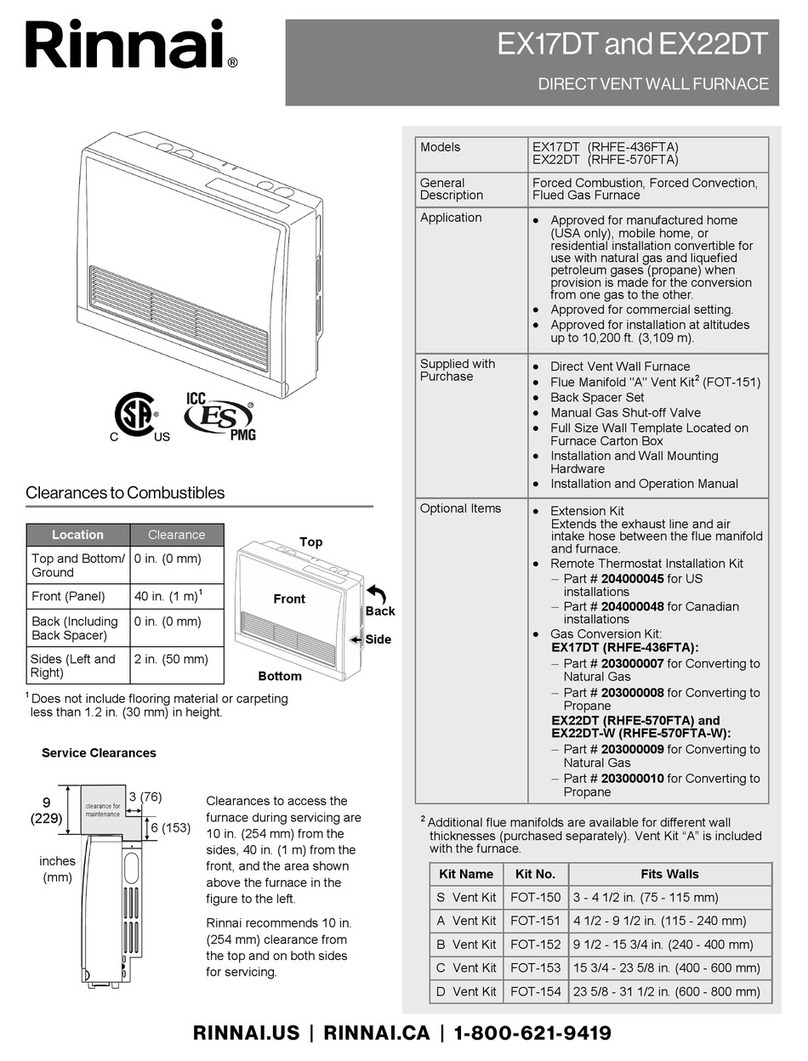

DIMENSIONS ........................................................................................................5

SPECIFICATIONS .................................................................................................6

SAFETY POINTS ..................................................................................................8

GETTING TO KNOW YOUR NEW RHFE-431FA ..............................................10

CONTROL PANEL .................................................................................................11

CUT-AWAY DIAGRAM ...........................................................................................12

NOTICE BEFORE INSTALLATION .......................................................................13

INSTALLATION INSTRUCTIONS ..........................................................................14

GAS CONNECTION ..............................................................................................15

VENT LOCATION ..................................................................................................16

FITTING TOP SPACER + WALL CLIP ..................................................................16

VENT TERMINATION CLEARANCES ..................................................................17

LOCATION / CLEARANCES .................................................................................18

SLEEVE AND MANIFOLD INSTALLATION ...........................................................20

FITTING UNIT .......................................................................................................22

OPERATING INSTRUCTION LABEL ....................................................................24

ADDITIONAL CUSTOMER OPERATING INFORMATION ....................................25

TESTING ...............................................................................................................32

CHECK ..................................................................................................................32

PRE-SERVICE CHECK .........................................................................................33

TROUBLE SHOOTING ..........................................................................................34

MAINTENANCE / SERVICE ..................................................................................35

CONSUMER SUPPORT ........................................................................................37

SCHEMATIC DIAGRAM ........................................................................................39

PARTS LIST ...........................................................................................................44

RHFE-431FA FLOW DIAGRAM .........................................................................50

EXTENDED FLUE PIPE KIT .................................................................................51

TECHNICAL DATA ................................................................................................56