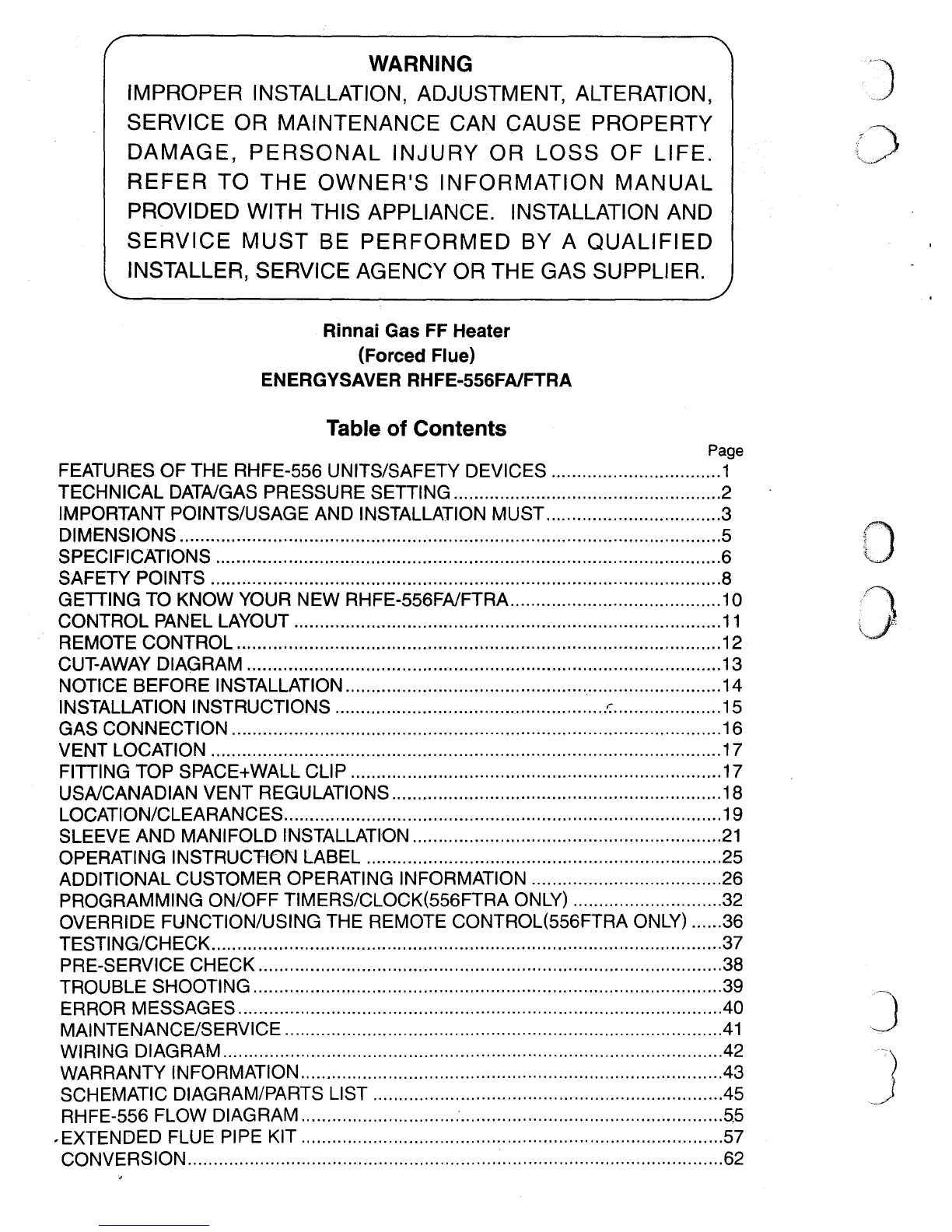

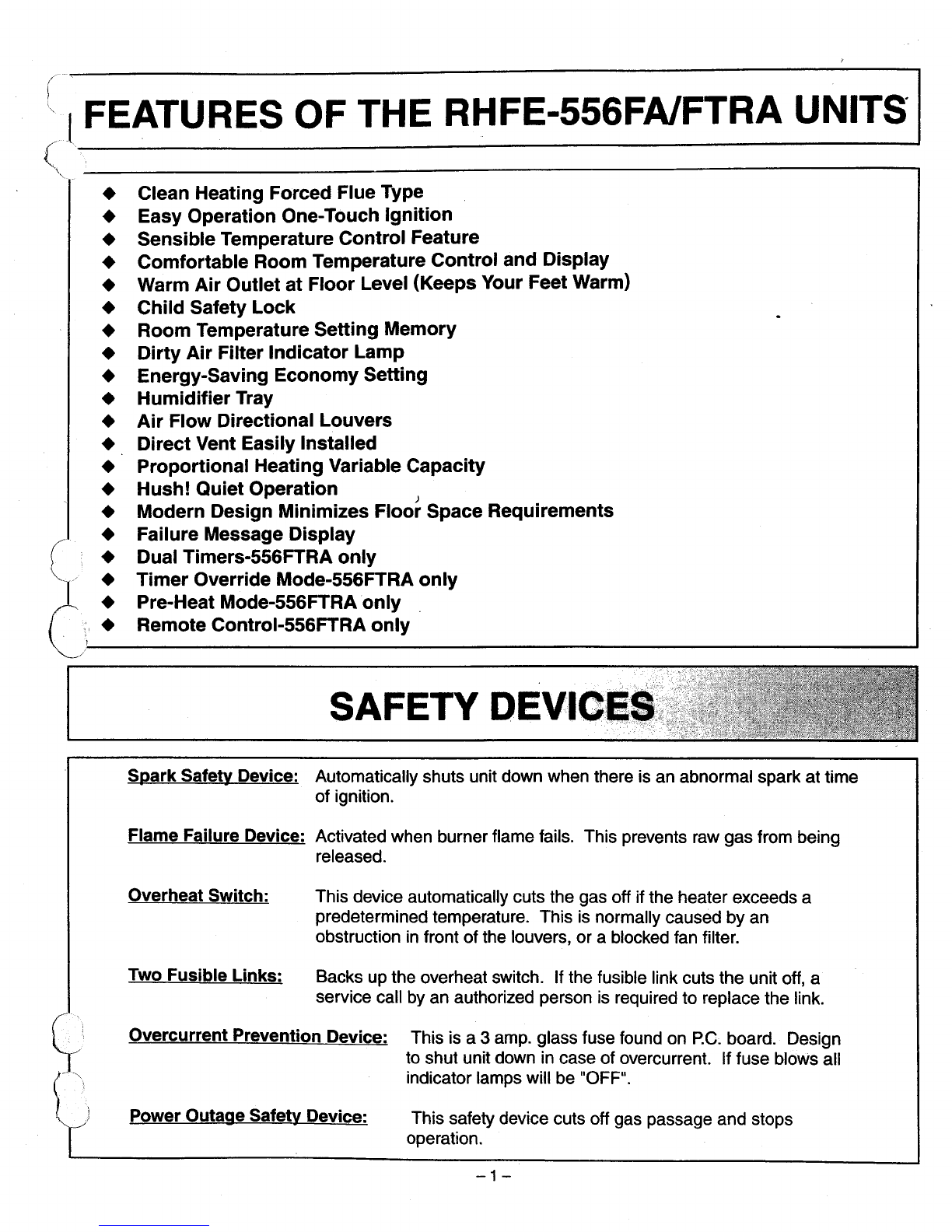

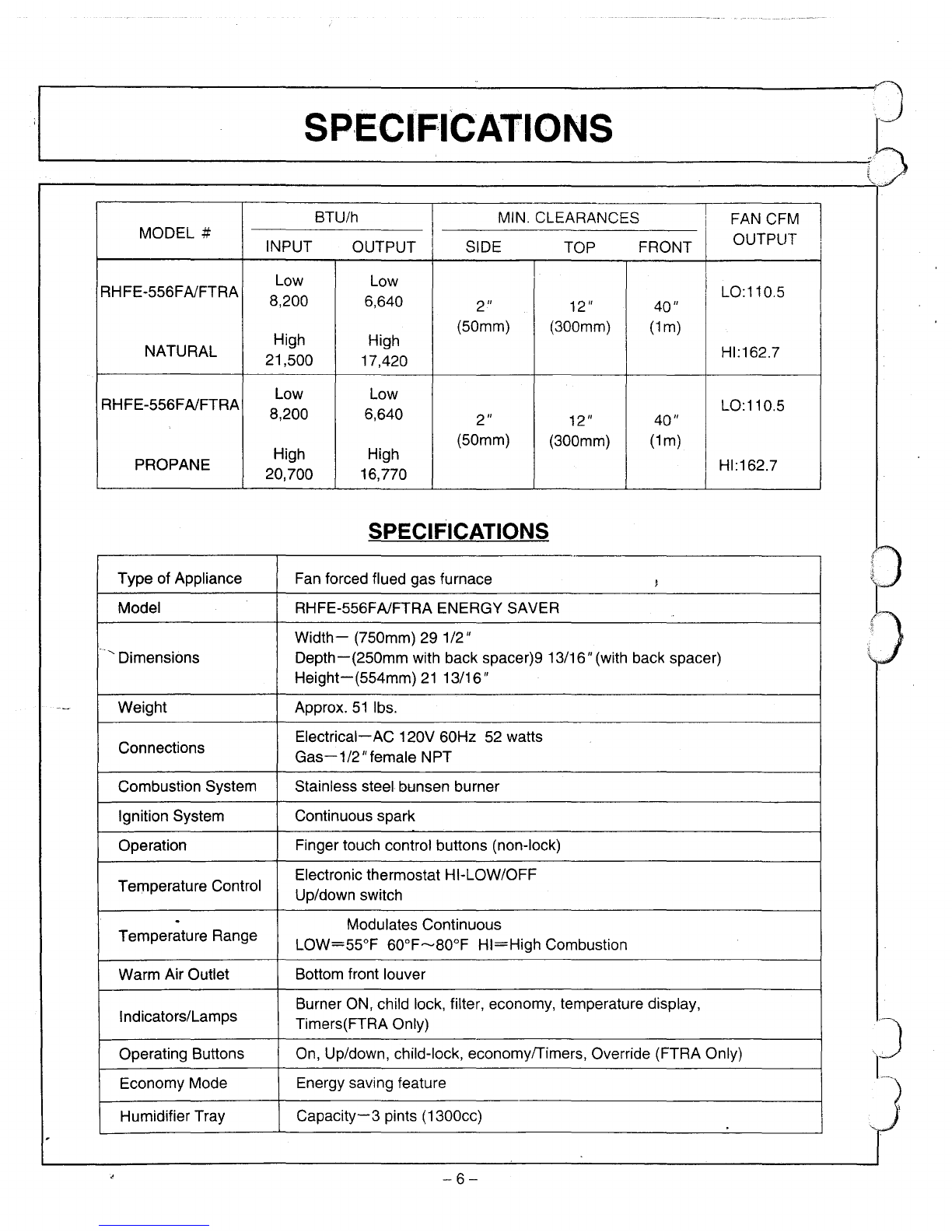

Rinnai RHFE-556FA Quick start guide

Other Rinnai Wall Furnace manuals

Popular Wall Furnace manuals by other brands

Empire Heating Systems

Empire Heating Systems FAN TYPE VENTED WALL FURNACE FAW-55IP Installation instructions and owner's manual

Braemar

Braemar WF2000 user manual

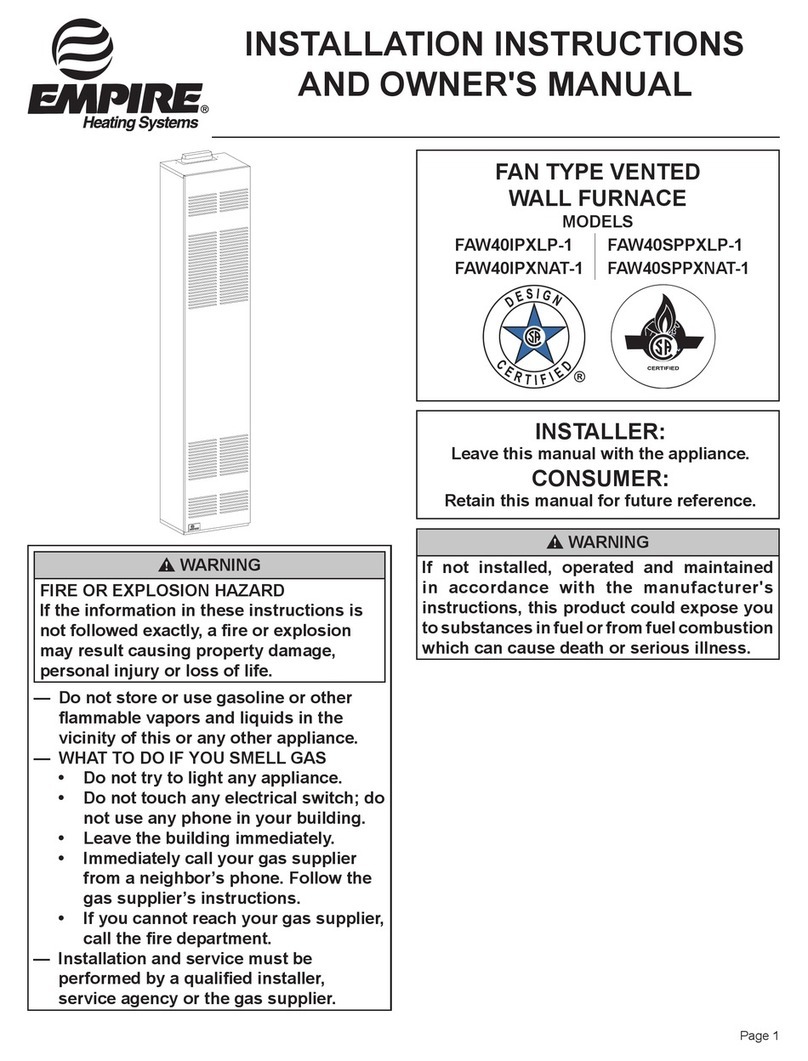

Empire

Empire FAW40IPXLP-1 Installation instructions and owner's manual

Empire

Empire DV-55IP Installation instructions and owner's manual

Empire Heating Systems

Empire Heating Systems DV-35-2SG Installation instructions and owner's manual

Empire Heating Systems

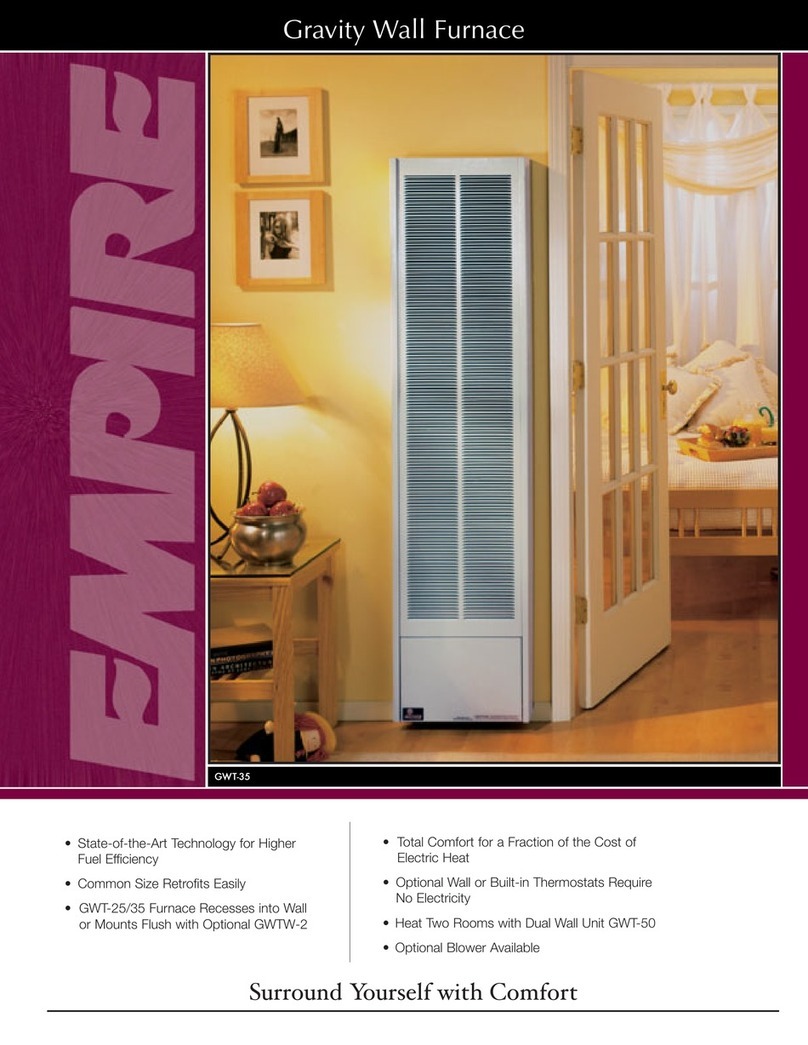

Empire Heating Systems GWT-25-2 SG Installation instructions and owner's manual

Empire Heating Systems

Empire Heating Systems GWT-25-2 SG Installation instructions and owner's manual

Empire Heating Systems

Empire Heating Systems DVC55SPPXLP-1 Installation instructions and owner's manual

Empire Heating Systems

Empire Heating Systems DVC55SPPXLP-2 Installation instructions and owner's manual

Napoleon

Napoleon GDS3700-N Installation and operation instructions

HouseWarmer

HouseWarmer HWDV080DVN-1 owner's manual

Empire Heating Systems

Empire Heating Systems PVS18(N Owner's manual and installation instructions

Empire Heating Systems

Empire Heating Systems DV-25T-1 Installation instructions and owner's manual

Empire Heating Systems

Empire Heating Systems GWT-25 owner's manual

Empire Heating Systems

Empire Heating Systems MV 145 Installation instructions and owner's manual

Longvie

Longvie DV20 owner's manual

Empire

Empire DV-25-2SG Installation instructions and owner's manual

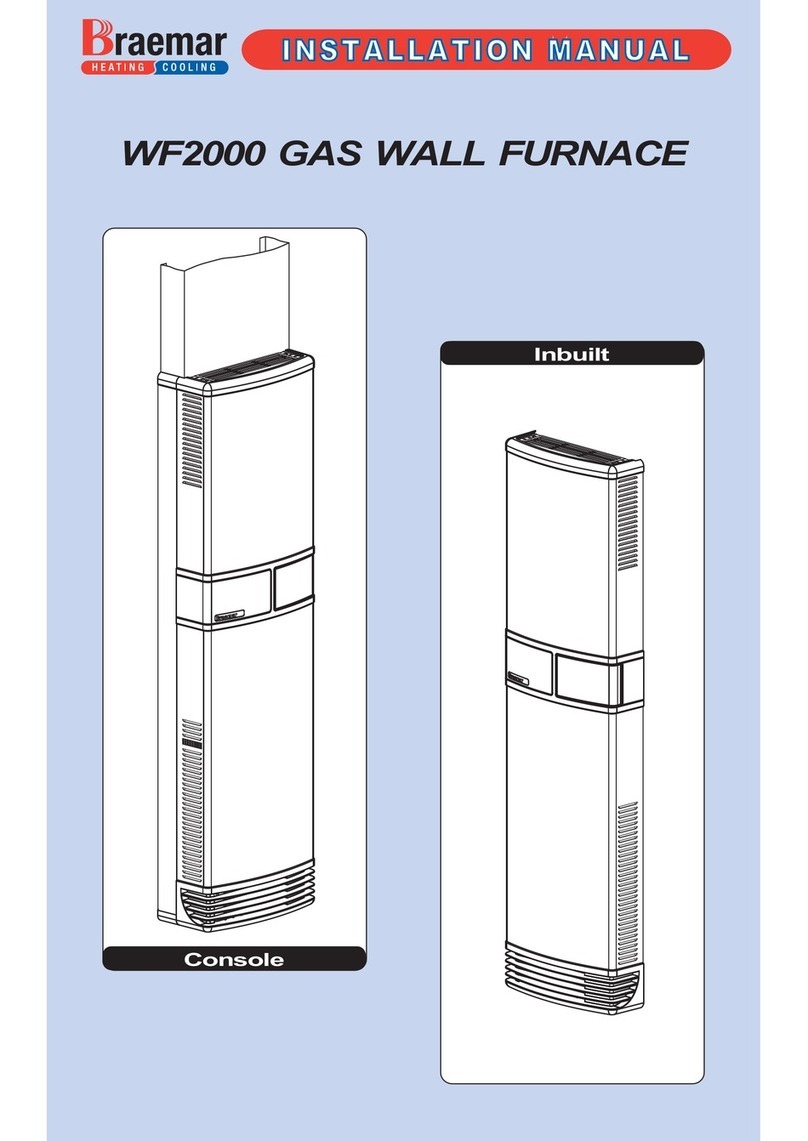

Braemar

Braemar WF2000 installation manual