iv

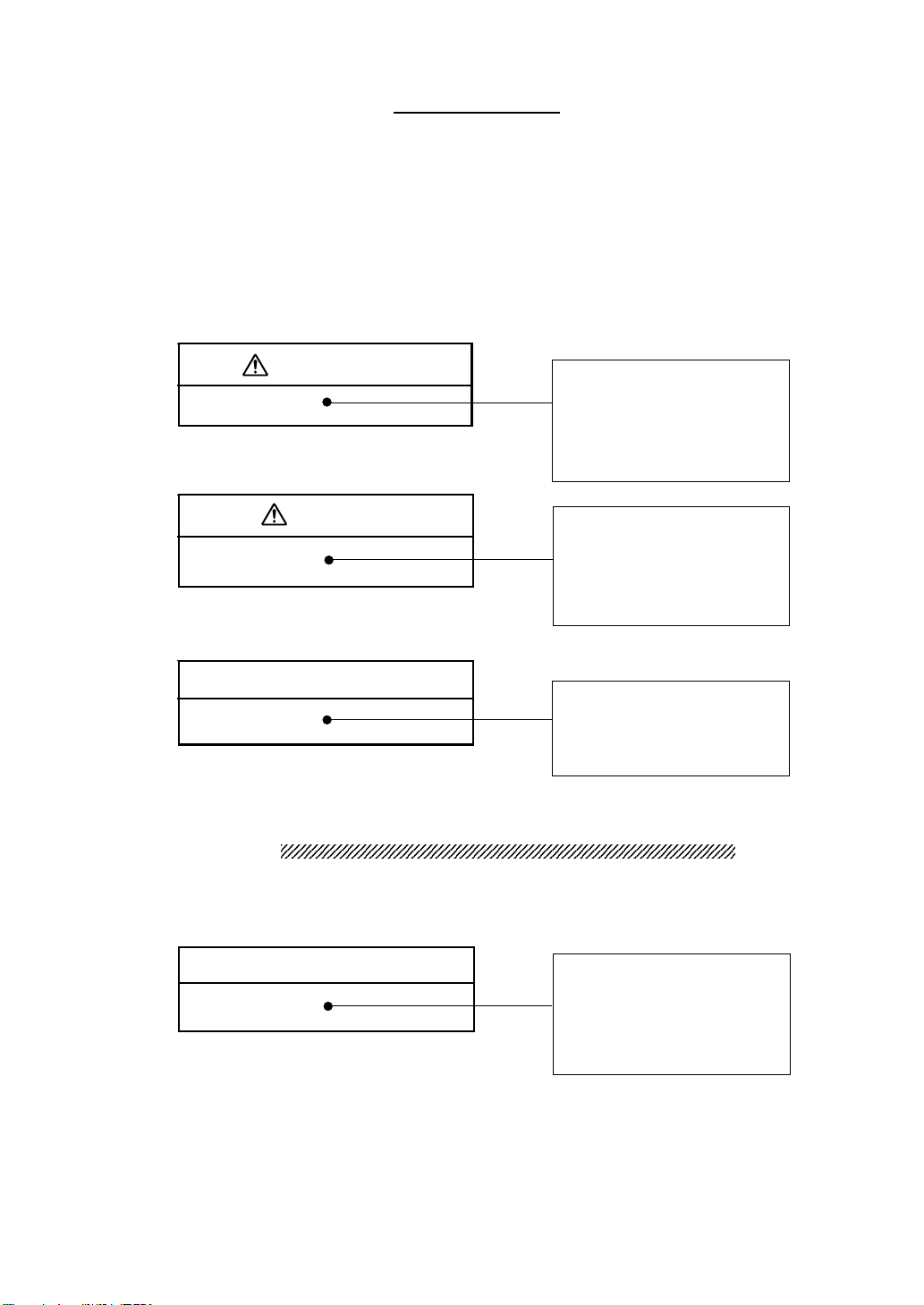

WARNING

Sample fluid danger prevention

When toxic sample fluid comes into contact with any part of the human body

or when toxic gases generated by the sample fluid are breathed, there is a

danger of severe injury or death.

When sample fluid comes into contact with other objects in the vicinity, there

is a risk of fire, explosion, corrosion, deformation or other effects.

Observe the following points closely to prevent the danger of sample fluid

leaks and sample fluid accretion.

zDo not pass sample fluids which can cause corrosion of fluid-contacting

parts (PFA, sapphire) through the system.

zObserve the following points when setting up or dismantling a measurement

system.

- Check the sample fluid for any risks due to toxicity or other harmful

properties.

- Make sure that sample fluid cannot leak from the system and come

into contact with body parts, clothing etc.

- When attaching or detaching tubes, connectors etc., always use

appropriate protective tools and wear dual-layer gloves.

- Double-check all connections before starting the sample fluid flow.

zSince the unit does not incorporate a leak sensor or other safety device,

perform a thorough leak check to verify safety before starting operation.

zThe pressure of sample fluid passed through the unit may not exceed

300 kPa (gauge pressure). Ensure that the supply system (sampler,

sample fluid lines etc.) has sufficient pressure resistance.

zWhen using sample fluid which may produce harmful gases, provide

adequate ventilation as prescribed by applicable laws and regulations.