4

RS/03-GT-016-2019 Date: 2021-02-01

CATALOGUE

1. Manual Introduction...................................................................................................................................................5

2. Applicable Products...................................................................................................................................................5

3. Warning....................................................................................................................................................................... 6

4. Safety Cautions..........................................................................................................................................................6

5. Unloading, Transportation and Storage............................................................................................................... 10

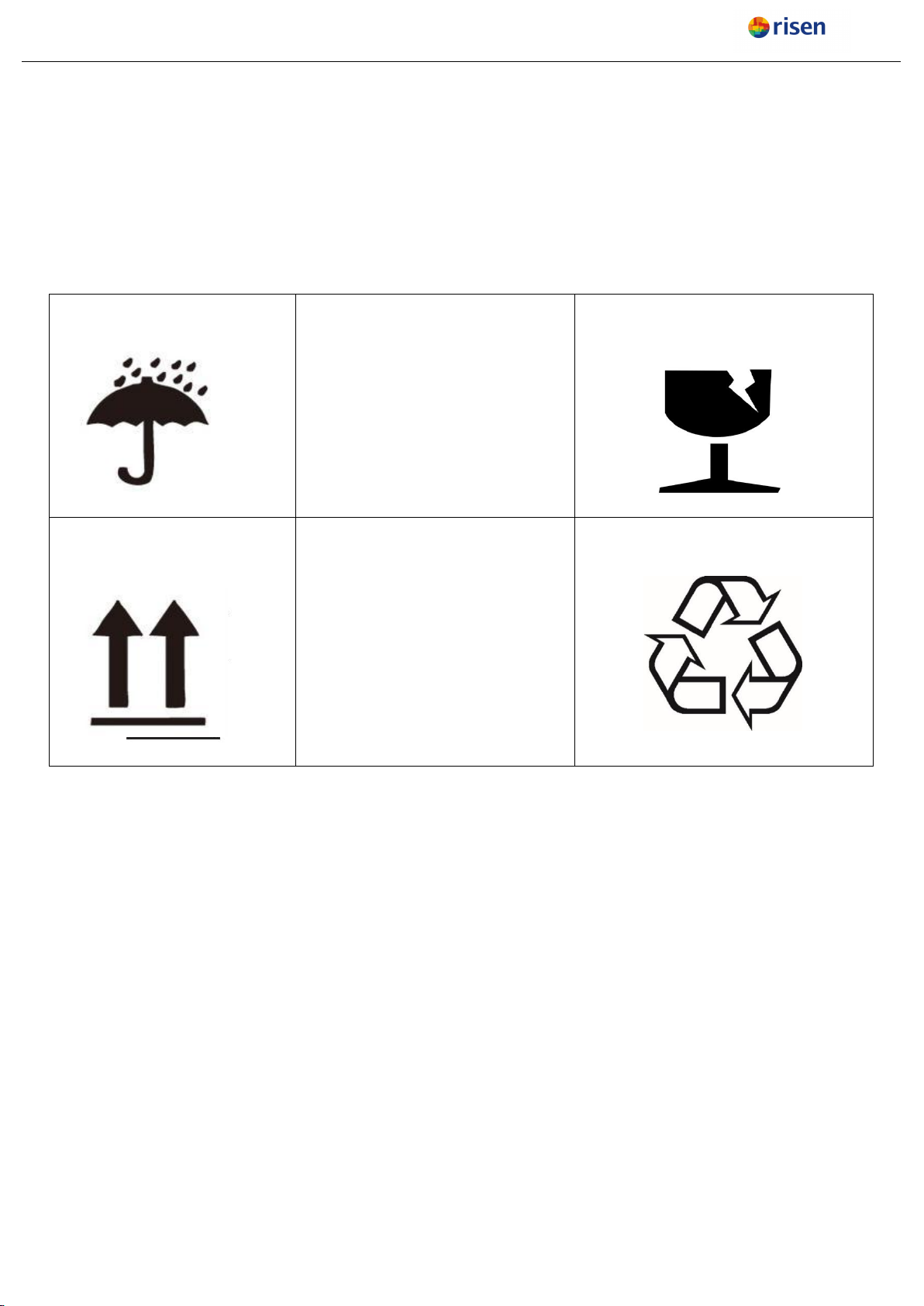

5.1. Markers on outer packaging....................................................................................................................... 10

5.2. Unloading cautions.......................................................................................................................................10

5.3. Secondary transportation and Warning.................................................................................................... 12

5.4. Storage...........................................................................................................................................................13

5.5. Markings on module.....................................................................................................................................13

6. Matters needing attention for unpacking..............................................................................................................14

7. Installation.................................................................................................................................................................14

7.1. Environment conditions and site selection............................................................................................... 14

7.2. Tilt angle of Installation................................................................................................................................ 16

7.3. Installation requirements for bifacial module............................................................................................17

8. Installation Guidelines.............................................................................................................................................18

8.1 Bolting method............................................................................................................................................... 18

8.1.1 Bolts installation:......................................................................................................................................18

8.1.2 Fixture installation:.................................................................................................................................. 19

8.1.3 Offshore PV module connector protection device.................................................................................20

8.2 Installation method of fixed support............................................................................................................21

8.3 Tracking system..............................................................................................................................................24

9. Cable layout..............................................................................................................................................................25

10. Electrical Connection............................................................................................................................................ 27

10.1 Bypass secondary.......................................................................................................................................29

11. Grounding............................................................................................................................................................... 30

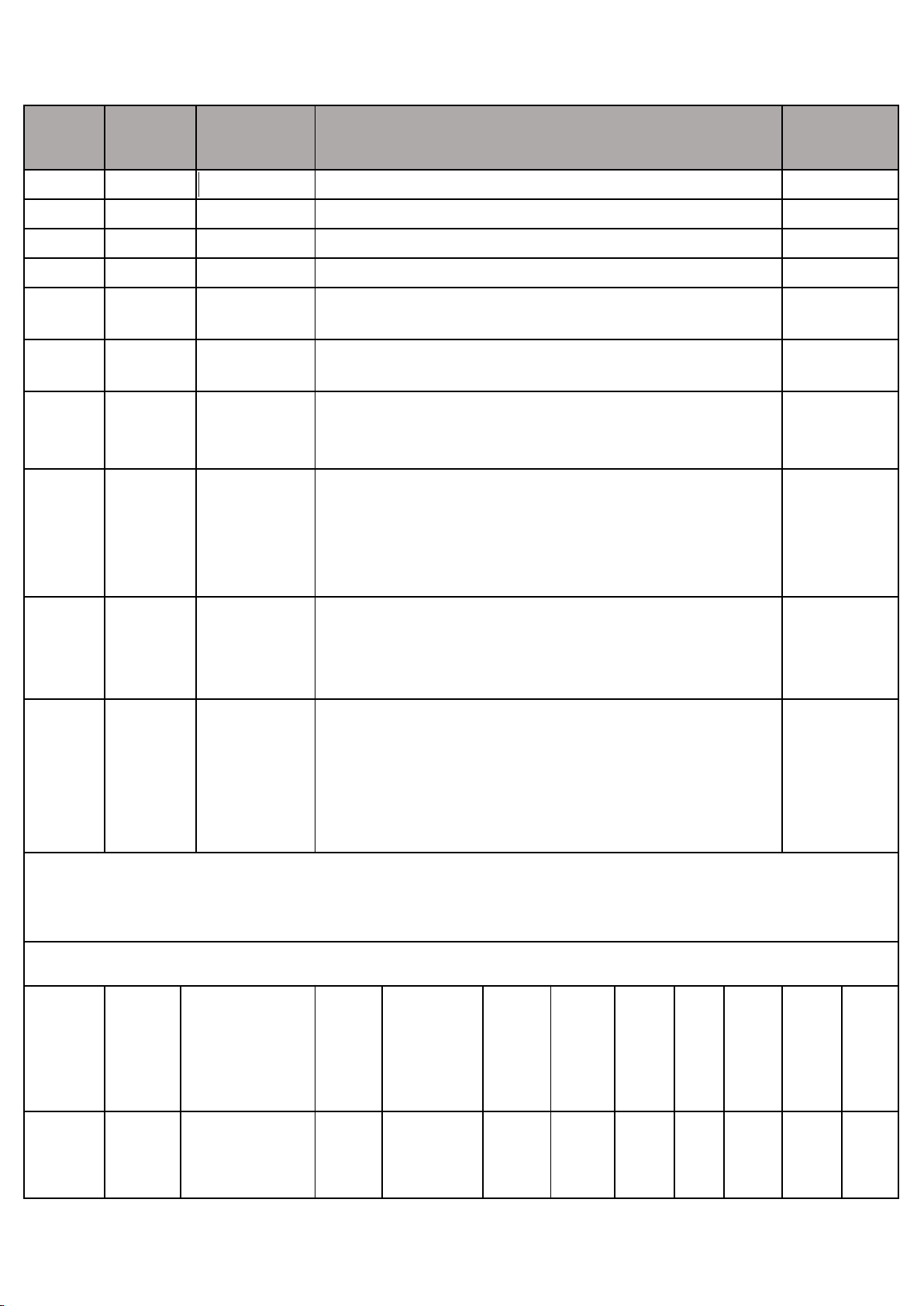

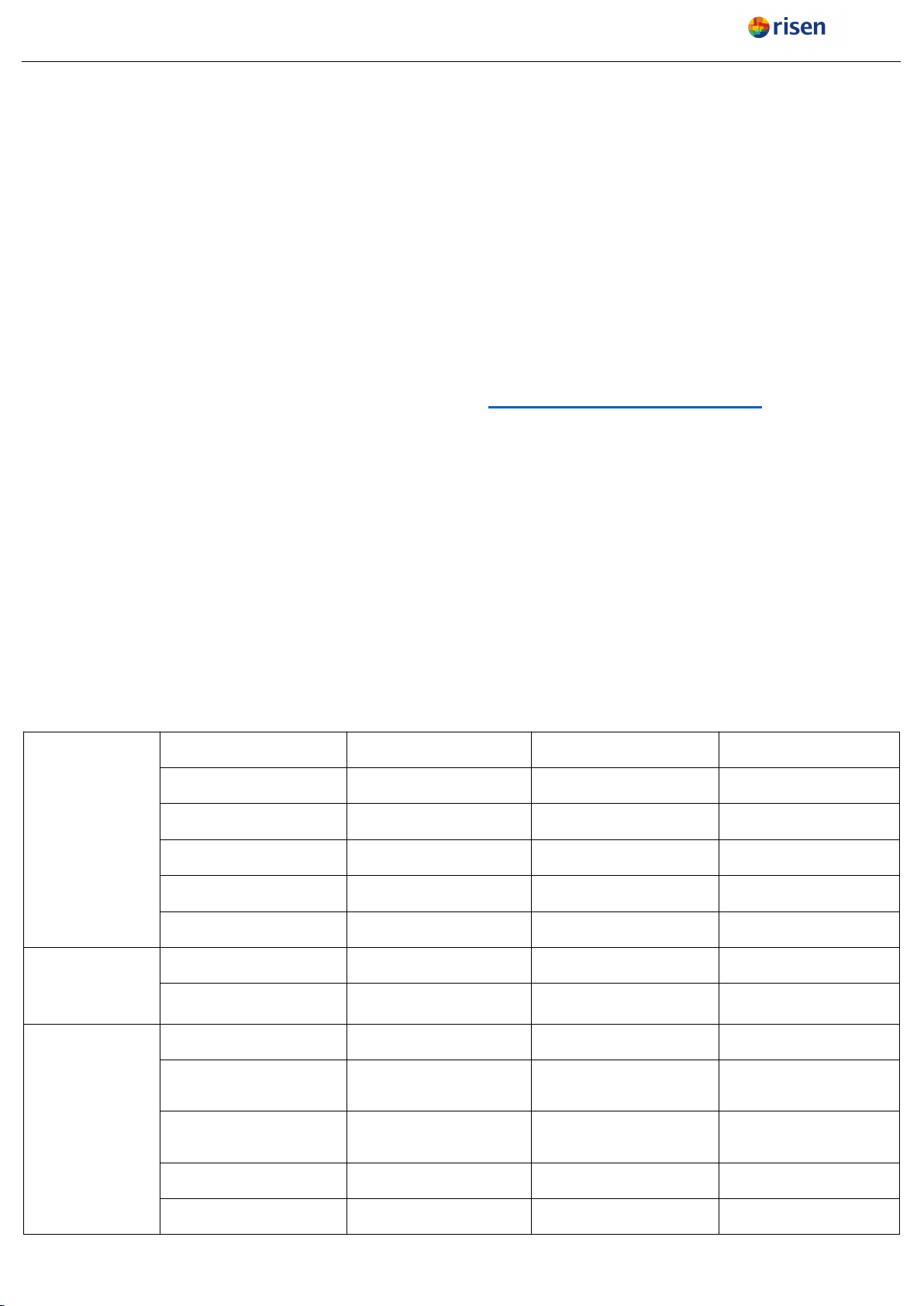

12. Electrical Parameters............................................................................................................................................31

13. Inspection and Maintenance................................................................................................................................32

12.1.PV Module Recycling..................................................................................................................................32

12.2.Module visual inspection and replacement............................................................................................. 33

12.3.Cleaning........................................................................................................................................................34

14. Troubleshooting..................................................................................................................................................... 35

15. DISCLAIMER......................................................................................................................................................... 35