RITAR RA Series User manual

R A

RITAR INTERNATIONNAL GROUP LIMITED

Technical Manual

RA Series VRLA Battery

In order to install and use RA series battery correctly and safely, please read this technical manual and other data together

with battery carefully for a comprehensive understanding.

Prolegomenon

★Pay attention to safety during installation to avoid accident.

★It is required for users to read this manual carefully and keep it well.

★If you have any questions about the Technical Manual or any technical problems, please contact us or our local agent.

Dangerous!

High Voltage……

Don't touch any terminals or connectors

without insulation to avoid electric shock.

Eyes Protection:

Gas from explosion may harm eyes

or even cause blindness.

Prohibition:

Sparks, fire and

smoking.

Vitriol:

May cause blindness

or severe burns.

Wash eyes with clean water immediately

and go to see a doctor.

Do not loosen the safety vales.

Please read carefully the installing and using instructions in this manual.

Keep the battery in a well ventilated environment when in operation.

Battery maintenance and repair should be conducted by experienced technicians.

1

1

2

Check

3

Storage before Installation

This manual is applied to RITAR RA series VRLA batteries (hereafter referred to as battery).

1. After receiving the batteries, please check the packing and make sure the batteries are intact. Avoid bumping during

carrying, and be careful when open the cartons.

2.Please open the cartons near the installation place and check appearance and quantity of the battery accessories after

opening.

3. It's difficult to detect leakage if there are slight damages on the battery shell. Please check carefully and make sure

there is no damage or leakage on the battery shell.

4. If the battery falls to the ground or its shell is bumped abnormally, please report the details to our company for

confirmation and aftermath arrangement.

1.Storage Environment

2.Storage Time

If the battery is not installed immediately after being received, please store it in a clean, ventilated and dark place at

around 5~30℃.

Due to self-discharge, the battery capacity will lose gradually in storage. Do not store the battery

for more than 12 months or it will affect the battery performance eternally. After being stored for 6 months, the battery

should be equalizing charged in voltage of 2.46/cell ± 0.1V for 24 hours and hereafter should be recharged at least

once every 6 months. A relatively high temperature will accelerate the battery self-discharge; from 20℃ when the

temperature increases every 10℃, recharging interval should be reduced half. For example, when the battery is stored

at 35℃, its initial charging and recharging interval should be 3 months. If the battery is not recharged properly, its

performance and life will be affected and the normal guarantee will become invalid.

Battery Features

1.Long Service Life

Heavy duty lead-calcium grids ensure mild corrosion and enable a long designed floating life over 12 years.

4Installation Cautions

2

1. Operating environment: no open flames, sparkles, or heating sources, etc. Please put batteries in a well ventilated

place out of direct sunlight and avoid closed environment. Do not install batteries in any place that is possible to be

immersed by water. Recommended environment temperature is 25±5℃.

2. Before touching the battery, please wear a rubber apron, rubber gloves, safety goggles or other eyes protection

equipments; do not wear metal objects, such as jewelry etc.

3. The battery is very heavy. Be careful and do not pump the battery when moving it.

4. Smoking or lighting fires are strictly forbidden. Keep the battery away from electric arc.

5. Avoid short circuit. The battery has been charged and please prevent battery from short circuit to avoid equipment

damage or personal injury.

6. Fix the bolts and nuts on the connection terminals of the battery to the specified torque; otherwise it may cause

sparks or damages to the terminals.

7. Please clean the battery shell and cover with a damp cloth; to prevent static and spark, do not use a duster or a dry

cloth to clean the battery. It's prohibited to use organic solvent such as rubber solution or naphtha, which will cause

the battery shell cracking.

8. In normal operation, there is no dissociative electrolyte attached on the shell since the battery gets fully sealed.

However, if the battery shell is damaged, dissociative vitriol is possible to leak. In case electrolyte splashes onto

eyes, skin or clothes, flush it with a large quantity of water. If it splashes into eyes, after rinsing with water, please go

to see a doctor promptly.

9. Make sure the positive(+/red) and negative(-/black)terminals are connected properly, otherwise it will cause fire

or damages to the battery or charger.

10. Please use the following protection equipments when you carry, install and maintain batteries.

1)Safety goggles or protective face-shield;

2)Acid-resistant gloves;

3)Acid-resistant apron, safety shoes;

4)Proper carrying instruments;

5)Insulation instruments.

11. Battery poles, terminals and accessories contain lead or lead compounds; lead and some other chemical

substances in battery are harmful to human body.

5Battery Installation

1. Install the battery according to installation drawing.

Please leave at least 700mm passageway as maintenance space.

2. Install Connectors

Before connection, clean battery terminals to metallic shining. Apply the Vaseline onto battery terminals to prevent

large resistance oxide; then install connectors. After installing all battery connectors, make sure all positive(+/red)

2.Excellent and High Efficient Charge/Discharge

3.Sextuple Sealed Construction

4.Low Self Discharge

5. Easy to Install and Use

RITAR batteries are equipped with low resistant plates and conducting parts, which decrease the

internal resistance and ensure the highest discharging efficiency.

Valve regulated sealed construction and sextuple strengthened sealing on terminals and posts prevents electrolyte

leakage, and guarantee the air tight and liquid tight state of batteries in normal operation and prevent external air from

entering battery inner.

Because of the use of lead-calcium grids alloy, RITAR batteries have low self discharge and reliable performance. In

room temperature, self discharge ratio per month of RITAR battery is about 3% of the battery capacity.

It’s easy and convenient to install and the whole battery group has good looking visual. The battery meets the

requirements of level 9 shock resistance.

3

6Working Principle

Notice:

1. RA series batteries are starved electrolyte batteries and shall not be inverted.

Vertical Inverted

2. The battery bank must be of the same brand and model.

3. New and old batteries shall be separated and cannot be mixed or used together.

4. The quantity of parallel connection battery banks shall not be more than 4.

5. When batteries are in parallel connection, the connection resistance should be equal.

6. Do not use gasoline or organic solvent to clean the battery.

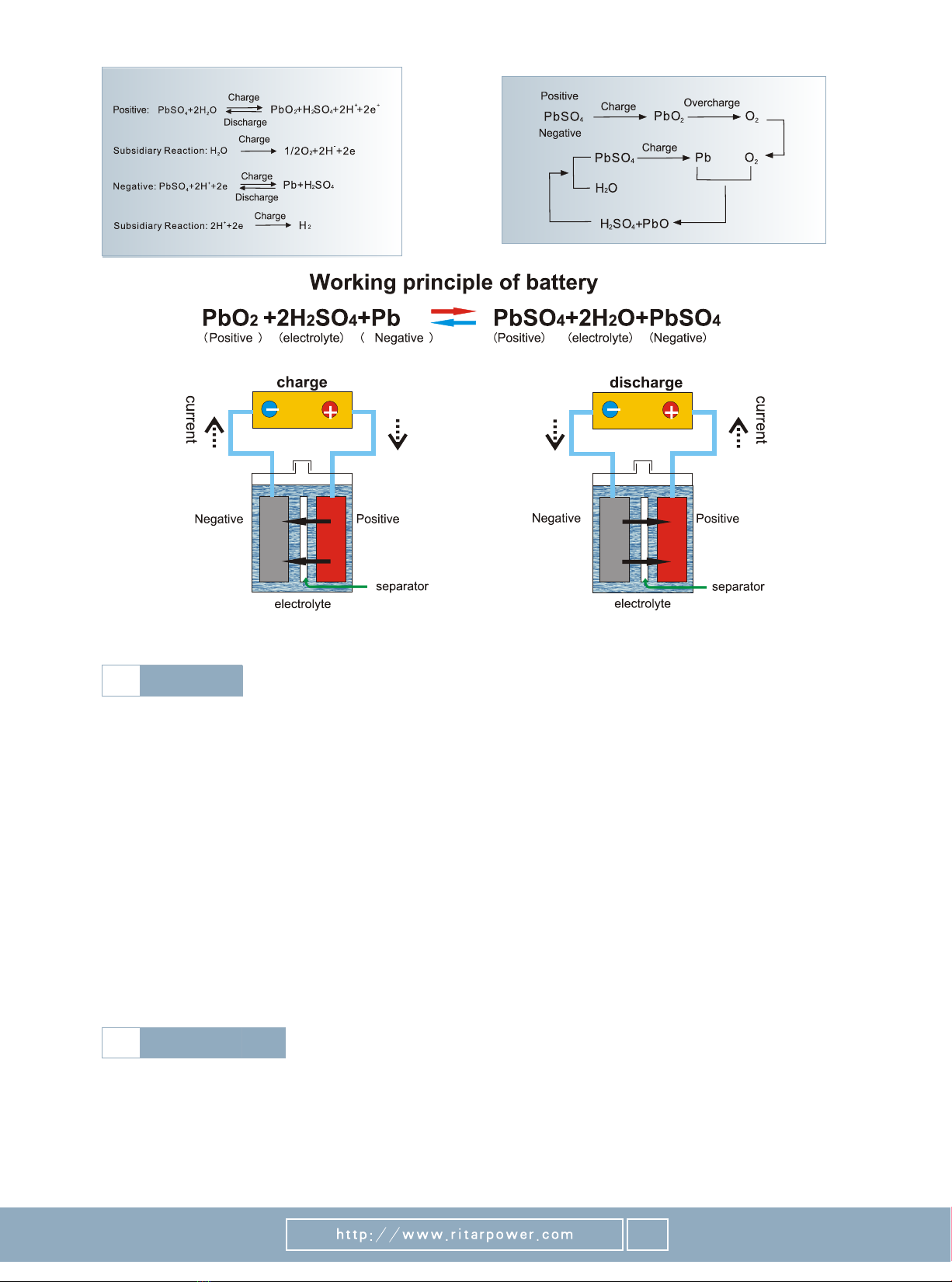

1.Electrochemistry

A lead-acid battery is an electrical storage device that converts electrical energy into potential chemical energy; when

needed the stored chemical energy can be converted back into electrical energy again to be supplied to external

systems. In the discharge state, part of PbO at the positive turns into PbSO , and part of Pb at the negative also turns

2 4

into PbSO4. In this electro-chemical reaction, both positive and negative electrodes generate PbSO . In the charging

4

state, the lead sulfate(PbSO ) at the positive and negative turns into PbO and Pb, respectively. When in discharging,

4 2

the concentration and density of H SO decreases gradually; while in charging, it increases. Battery charging and

2 4

discharging are realized by electrochemical reactions.

2. Oxygen Combination

The positive plate generates oxygen gas in the final stage of charging. Under the condition of excessive additives at

the negative, oxygen spreads to the negative plates through PE compound separator and reacts with spongy lead

and forms lead oxide and then turns into lead sulfate and water. Keep the negative plates in depolarization or under

charge state so that the battery cannot reach the over potential of oxygen gassing. Thus the battery avoids oxygen

gassing and water loss and is made a maintenance free sealed storage battery.

and negative(-/black)terminals are connected properly according to the installation figures; Then tighten the

connecting screws in the specified torque with an insulative moment spanner (M5:6~7 N*m; M6:8~10N*m;

M8:10~12N*m); as for plug type terminals, just plug in and out directly.

3. Measure Voltage

After installing the connectors, measure the terminal voltage of the whole battery bank, which should be about the

total of the cell voltage of series batteries. If they are inconsistent, please check the battery polarity and recheck the

battery connection in a proper torque.

4. Cell Number

Stick the self-adhesive labels of cell number and system polarity sign at prominent position of relevant cells.

The first cell at the positive connecting terminal should be marked as No.1 and the rest is marked by analogy.

5. Install Battery Shield

After checking the voltage and arranging the cell numbers, put the shield at the top of the batteries.

6. Safety Warning

After completion of battery installation, danger warning should be posted at prominent position to prevent safety

accidents.

7Record

4

The operating record of stationary batteries is very important for battery maintenance and protection. This information is

useful for users to confirm battery life and adjust the longevity.

Battery is allowed to operate at a temperature lower than 25℃, however, the charging time will be relatively long. After

installing batteries and a week of float charge, it's required to record the following information:

1)Battery terminal voltage

2)Charger voltage

3) Float charging voltage of each battery

4)Internal resistance of each battery. Within the same battery, put the meter that tests internal resistance at the two

terminals that is in farthest diagonal position.

5)Environment temperature

6) Check if all the connecting points have been fixed to the proper torque (refer to specifications). Use a milliohmmeter to

test internal resistance of each connecting strip. Conduct the test according to the probe potion on the instruction manual.

If the data exceeds 20% of its range of installation, please retighten the screws. If the data still remains high, please wipe

terminals and the interface between terminals and connecting strips.

Put on a mask or a pair of protective glasses when approach batteries, make sure not put batteries next to fire/ smoking

place.

Proper maintenance can prolong battery life and help it meet the design requirements. A good battery maintenance

program can help to judge when battery need to be replaced. If the maintenance way differs from this manual, users can

make the maintenance program according to battery usage and using reliability. All maintenance needs to be executed by

professionals.

8Maintenance

(lead sulfate→sponge lead) (lead sulfate→dioxide alumina)

(water → sulfuric acid, proportion rise)( → , proportion decrease)sulfuric acid water

(sponge lead→lead sulfate) (dioxide alumina→lead sulfate)

5

1.Inspection

Try to make all inspection under float charging conditions. Inspection should be conducted according to instruction

manual from the supplier and record all test data for future collation.

1.1 Monthly inspection

General inspection items and record of every month are as follows:

1.1.1 Float charging voltage of all batteries.

1.1.2 Output current and voltage of charger.

1.1.3 Ambient temperature, ventilation and monitor equipments.

1.1.4 Visual inspection of battery bank appearance:

1)Inspect battery appearance: Check whether there is corrosive phenomenon on terminals, connectors, battery racks.

2)Clean batteries, racks and battery region.

3)Inspect whether there is crack or leakage on battery.

4)Inspect whether there is deformation of battery and rack.

1.2 Quarterly inspection

Quarterly inspection includes the following items; please record all the inspection data. ( Need to collate with previous

records.)

1) Internal resistance of each battery cell;

2) Temperature on negative terminals of each battery cell;

3) Inspect connect resistance at random ( at least check 10% or 6 connectors), if resistance is significantly higher than

the initial value, then need to check all connectors' resistance and dig out reason. (Notice: Please inspect different

connectors every quarter.)

1.3 Yearly inspection and initial inspection

For Yearly inspection and initial inspection, conduct the following checking and record items.

1)Check and record internal resistance of all connectors;

2)Try to check AC current and voltage from rectifier.

1.4 Special inspection

Batteries need inspection to check if they get damaged in special situations (such as over-discharge, abuse

use due to charging machine failure, etc). The inspection includes all yearly checking items and needs to make

records.

2. Ripple Voltage of rectifier

We recommend ripple Voltage of rectifier should not be bigger than 0.5% of charging voltage, and librating

ripple time should be shorter than 8 millisecond.

3. Battery cleaning

Use cloth soaked in water or carbonic acid water to clear battery and cover.

4. Capacity test

If batteries work properly, no need to check capacity. Check capacity only when battery capacity is in doubt.

When battery is in discharge, the cut-off voltage should not be lower than the requirement in the technical

manual.

Before capacity testing, make sure battery get fully charged for more than 48 hours under float charge, if not,

make a equalization charge for 24 hours. Let batteries rest and cool down for 8-24 hours and then conduct

capacity test.

5. Battery replacement

1)In regular battery check discharge, if capacity cannot meet the using requirements, should consider to

replace the battery;

2)Batteries are consumable and have certain life cycle. In comprehensive consideration of the use of

conditions, environmental temperature and other factors, before reaching the battery design service life,

replace it with good battery to fully ensure the safe, reliable and normal operation of the power system. The

replaced old battery should be recycled in accordance with the relevant national laws and regulations.

6

9Common Faults & Solutions

1

2

3

4

5

6

7

No. Common Faults Solutions

Acid leakage Please contact the supplier for solutions.

Crack

Low floating voltage of single cell

High temperature on

battery pole and cell

Abnormal Appearance

Grounding Fault

Abnormal connect & inner resistance

Please contact the supplier for solutions.

After 24-48hrs equalization charger, still low,

p .lease contact the supplier for solutions

Check whether the connection is good,

inspect charger, ventilation and charging current.

Clean dust, and check leakage or ground faulty.

The battery bank shall be insulated from the ground.

Please contact the supplier for solutions.

Check whether the connection is good,

inspect charger, ventilation and charging current.

Table of contents

Other RITAR Camera Accessories manuals

Popular Camera Accessories manuals by other brands

Ikan

Ikan PT4700S-TRIPOD quick start guide

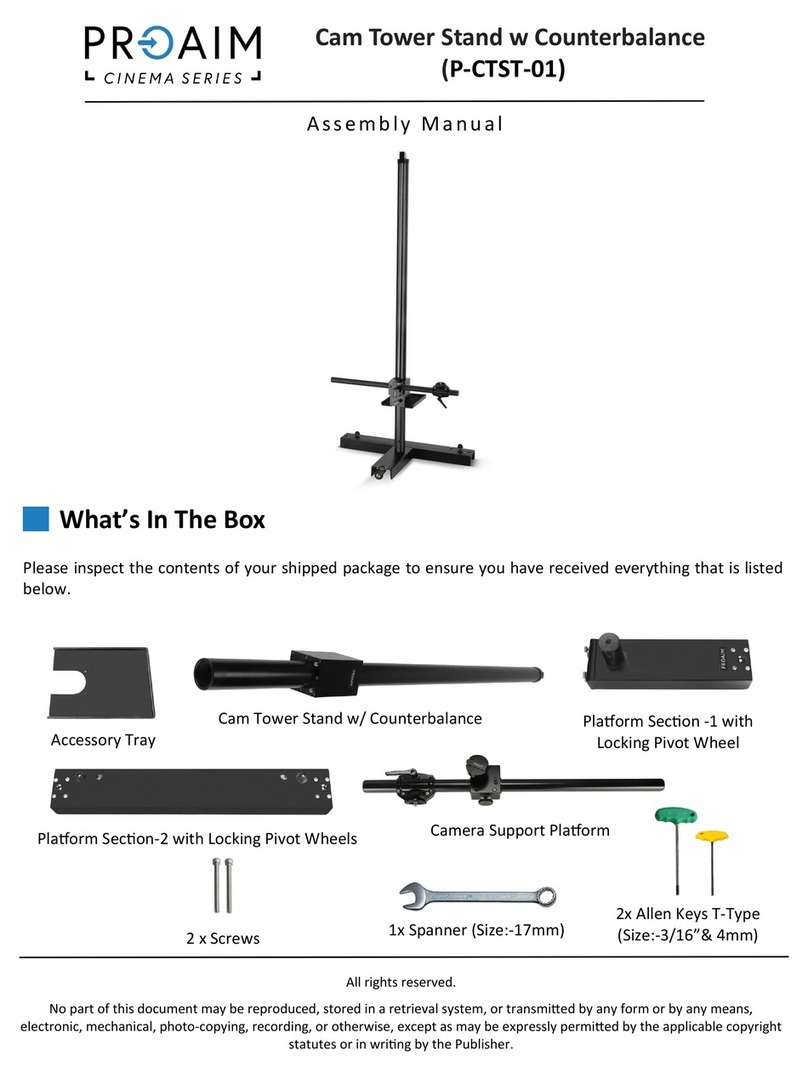

PROAIM

PROAIM CINEMA P-CTST-01 Assembly manual

Nikon

Nikon AFS NIKKOR 80-400mm f/4.5-5.6G ED VR user manual

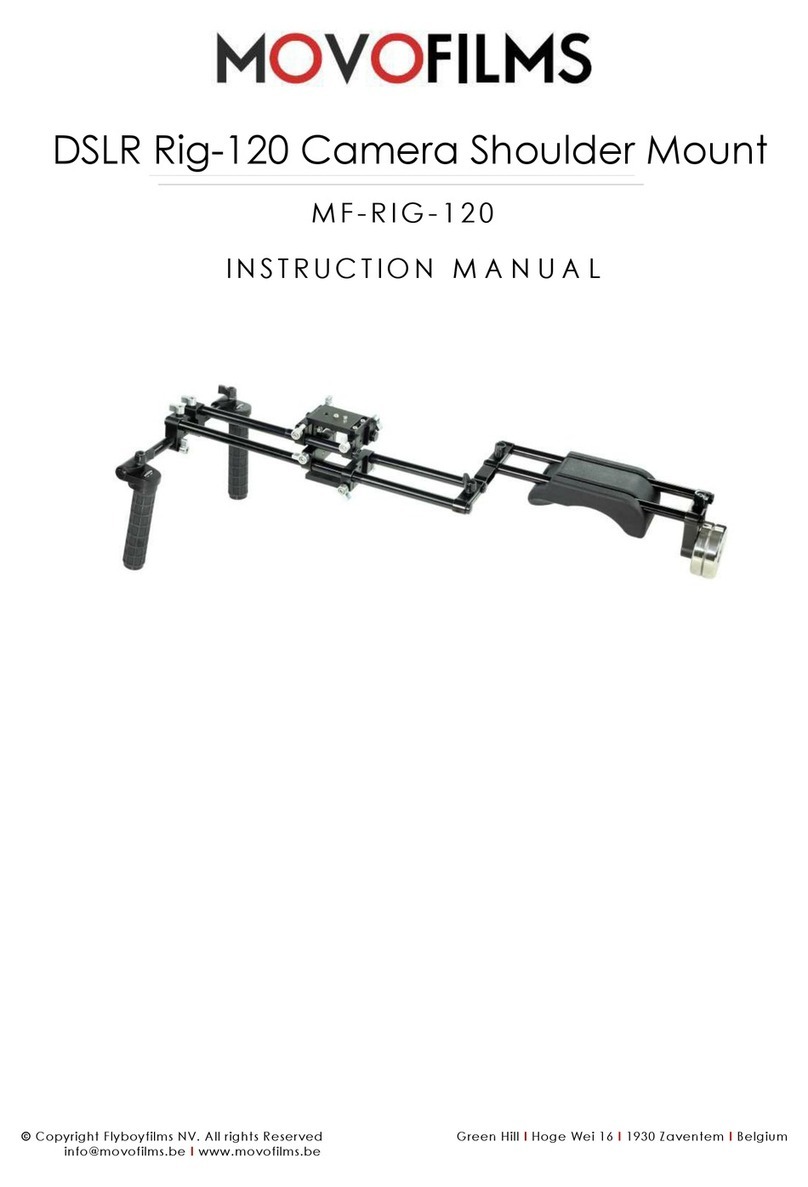

MOVOFILMS

MOVOFILMS MF-RIG-120 instruction manual

Gates Underwater Products

Gates Underwater Products XA25 Setup, use and care guide

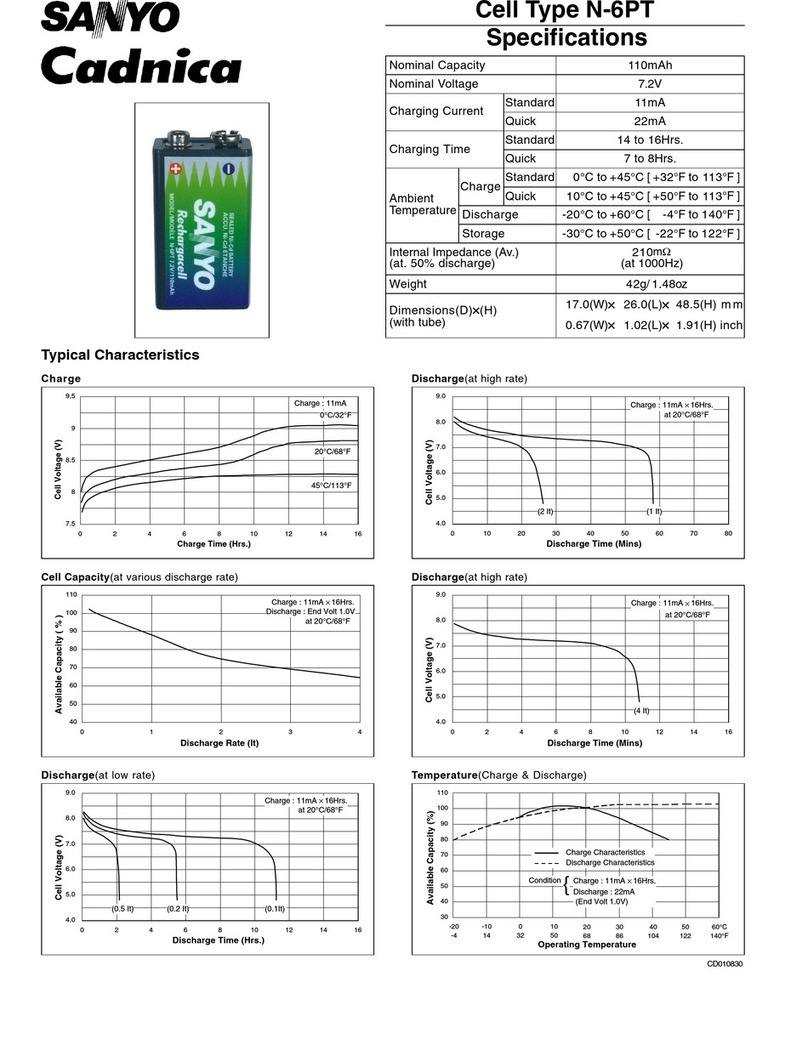

Sanyo

Sanyo Cadnica N-6PT Specifications