© 2014 Rivers Locking Systems (Australia) Pty Ltd

Rivers reserves the right to change specifications without notice Page 1 of 1

MODEL D - OPEN OUT DOOR

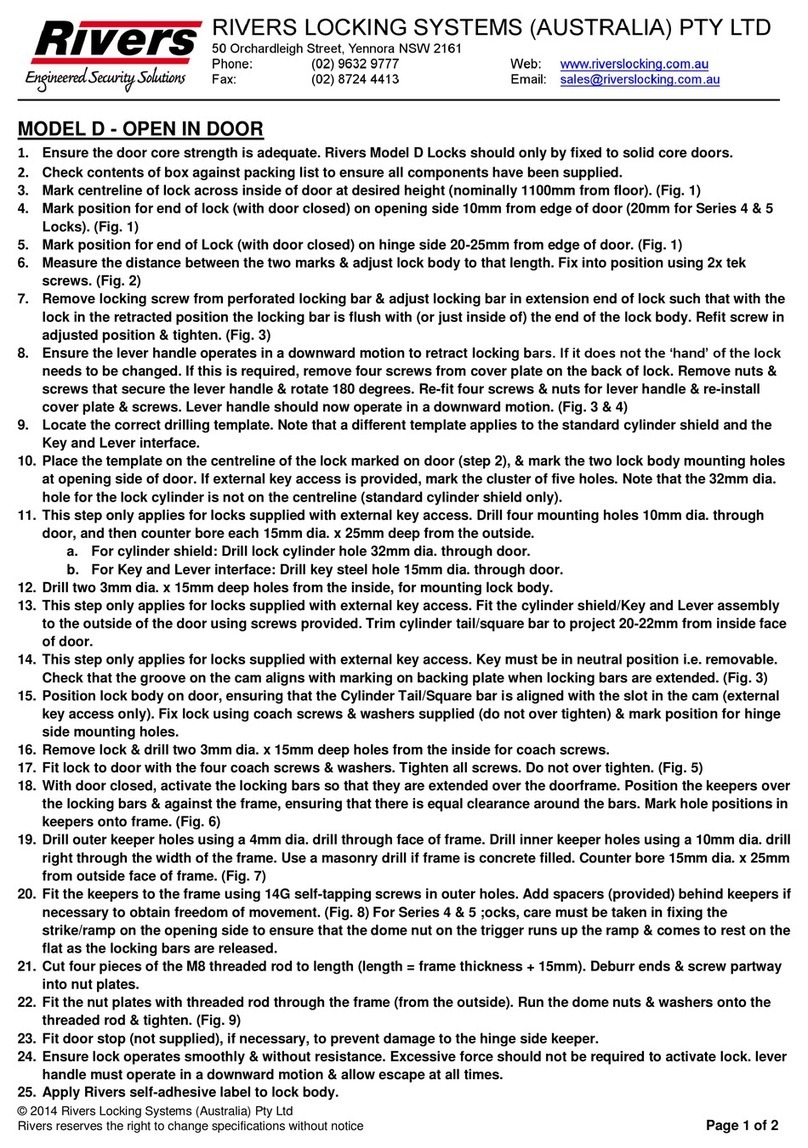

1. Ensure the door core strength is adequate. Rivers Model D Locks should only by fixed to solid core doors.

2. Check contents of box against packing list to ensure all components have been supplied.

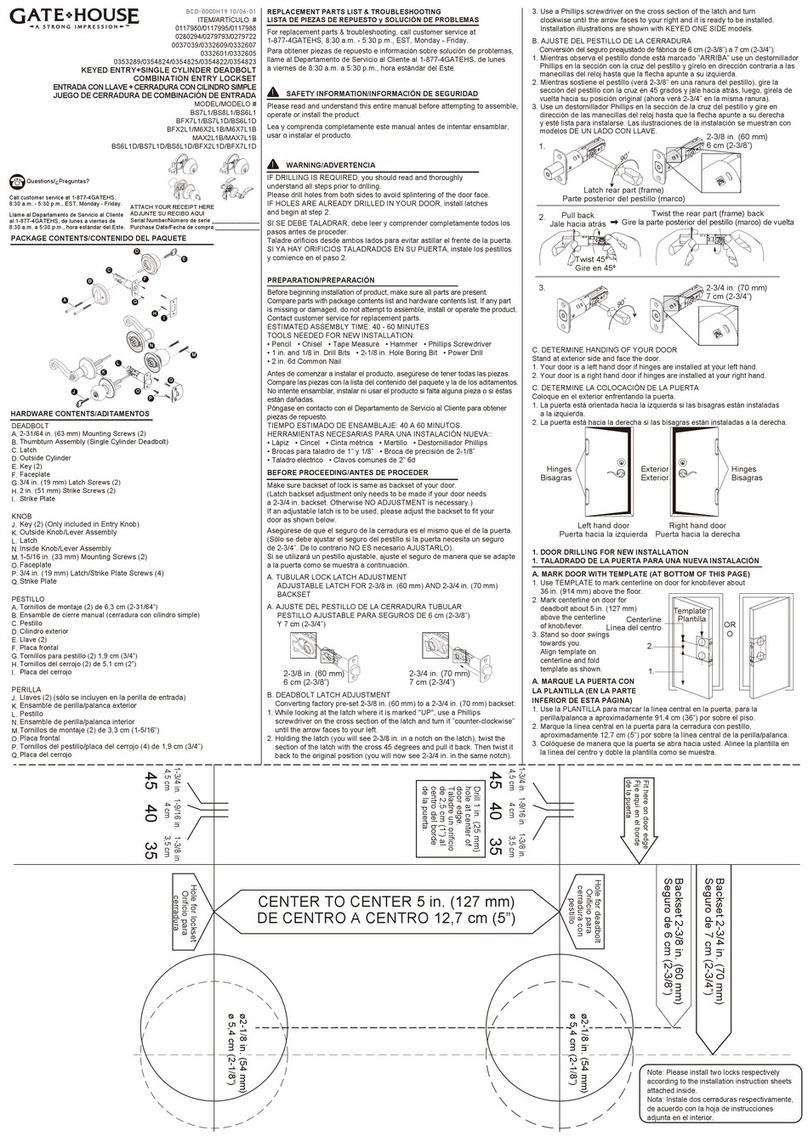

3. Mark centreline of lock across inside of door at desired height (nominally 1100mm from floor). (Fig. 1)

4. Mark position for end of lock (with door closed) on opening side 10mm from frame (20mm for Series 4 & 5 Locks).

(Fig. 1)

5. Mark position for end of lock (with door closed) on hinge side 10-15mm from frame. (Fig. 1)

6. Measure the distance between the two marks & adjust lock body to that length. Fix into position using 2x tek

screws. (Fig. 2)

7. Remove locking screw from perforated locking bar & adjust locking bar in extension end of lock such that with the

lock in the retracted position the locking bar is flush with (or just inside of) the end of the lock body. Refit screw in

adjusted position & tighten. (Fig. 3)

8. Ensure the lever handle operates in a downward motion to retract locking bars. If it does not the ‘hand’ of the lock

needs to be changed. If this is required remove four screws from cover plate on the back of the Lock. Remove nuts

& screws that secure the lever handle & rotate 180 degrees. Re-fit four screws & nuts for lever handle & re-install

cover plate & screws. Lever handle should now operate in a downward motion. (Fig. 3 & 4)

9. Locate the correct drilling template. Note that a different template applies to the standard cylinder shield and the

Key and Lever interface.

10. Place the template on the centreline of lock marked on door (step 2), & mark the two lock body mounting holes at

opening side of door. If external key access is provided, mark the cluster of five holes. Note that the 32mm dia.

hole for the lock cylinder is not on the centreline (standard cylinder shield only).

11. This step only applies for locks supplied with external key access. Drill four mounting holes 10mm dia. through

door and then counter bore each 15mm dia. x 25mm deep from the outside.

a. For standard cylinder shield: Drill lock cylinder hole 32mm dia. through door.

b. For Key and Lever interface: Drill key steel hole 15mm dia. through door.

12. Drill two mounting holes 10mm dia. through door, then counter bore each 15mm dia. x 25mm deep from the

outside.

13. Cut four pieces of the M8 threaded rod to length (length = door thickness + 35mm). Deburr ends & screw partway

into nut plates.

14. This step only applies for locks supplied with external key access. Fit the cylinder shield assembly/key and lever to

the outside of the door using screws provided. Trim cylinder tail/square bar to project 20-22mm from inside face of

door.

15. This step only applies for locks supplied with external key access. Key must be in neutral position i.e. removable.

Check that the groove on the cam aligns with marking on Backing Plate when Locking Bars are extended. (Fig. 3)

16. Fit nut plate assembly to door from outside at opening side of door & position lock body over the threaded rods.

Ensure that the cylinder tail/square bar is aligned with the slot in the cam (external key access only). Fit dome nuts

and washers. Align lock and mark mounting hole positions for hinge side mounting holes. (Fig. 6)

17. Remove lock. Drill two 10mm dia. holes and counter bore 15mm dia. x 25mm deep from front. (Fig. 5 & 6)

18. Fit lock to door with the two nut plate assemblies, dome nuts & washers. Tighten all nuts. Do not over tighten. (Fig.

7)

19. With door closed, activate the locking bars so that they are touching on the doorframe. Mark position of locking

bars on frame. (Fig. 8)

20. Drill a 12mm dia. hole in both sides of frame at top & bottom of locking bar. Use a small cutting wheel to splice

between top & bottom holes, either side. This will create a slot in the frame to accept locking bars.

21. If frame is concrete filled, drill out masonry to a depth so that Locking Bars will not ‘bottom out’ when fully

extended. (Fig. 9 & 10)

22. Clean edges of slots & ensure smooth action of Lock when locking/unlocking.

23. Position the striker plates over the locking bars & against the frame, hold in position & fix in place with self-tapping

screws supplied. For Series 4 & 5 Locks, care must be taken in fixing the strike/ramp on the opening side to ensure

that the dome nut on the trigger runs up the ramp & comes to rest on the flat as the locking bars are released.

24. Ensure lock operates smoothly & without resistance. Excessive force should not be required to activate lock. Lever

handle must operate in a downward motion & allow escape at all times

25. Apply Rivers self-adhesive label to lock body.