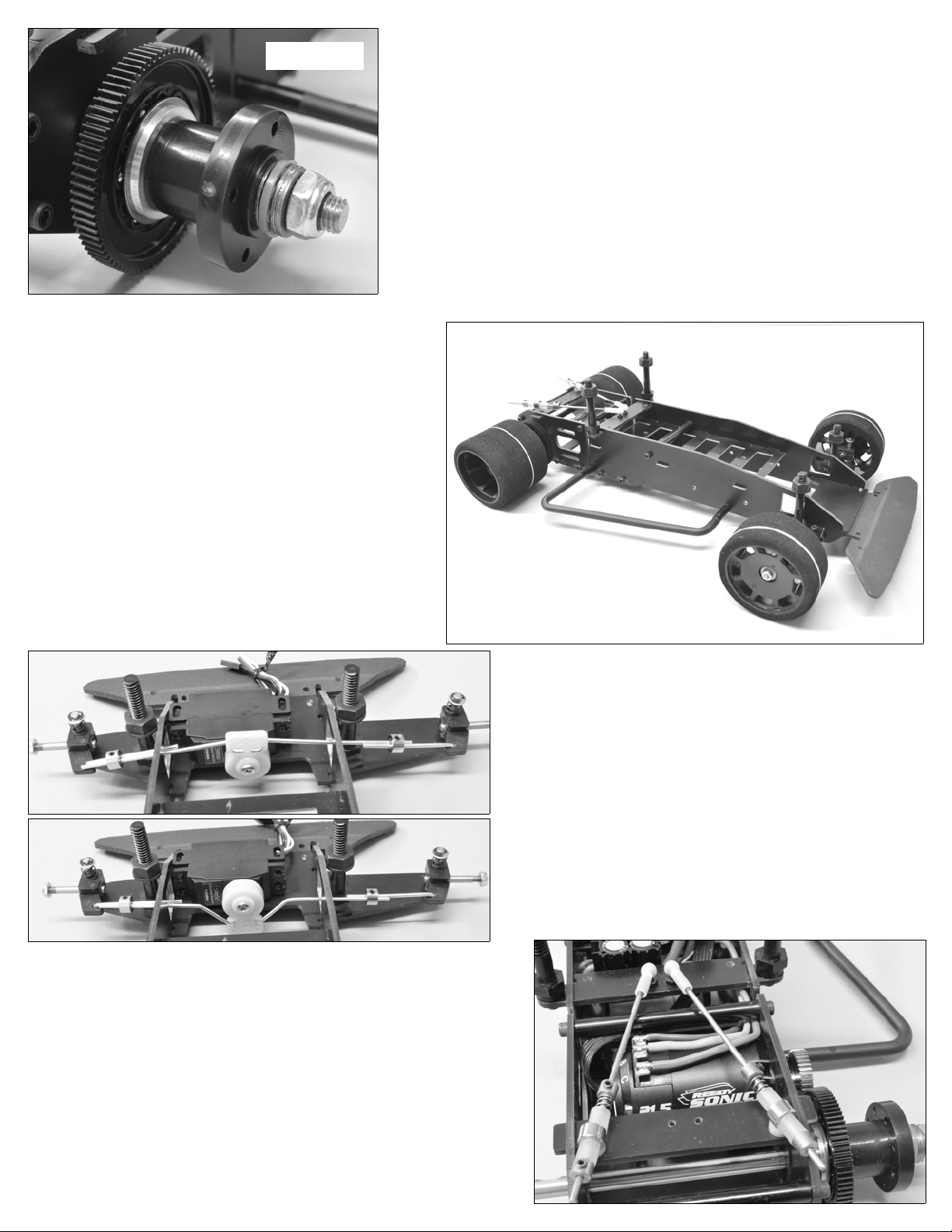

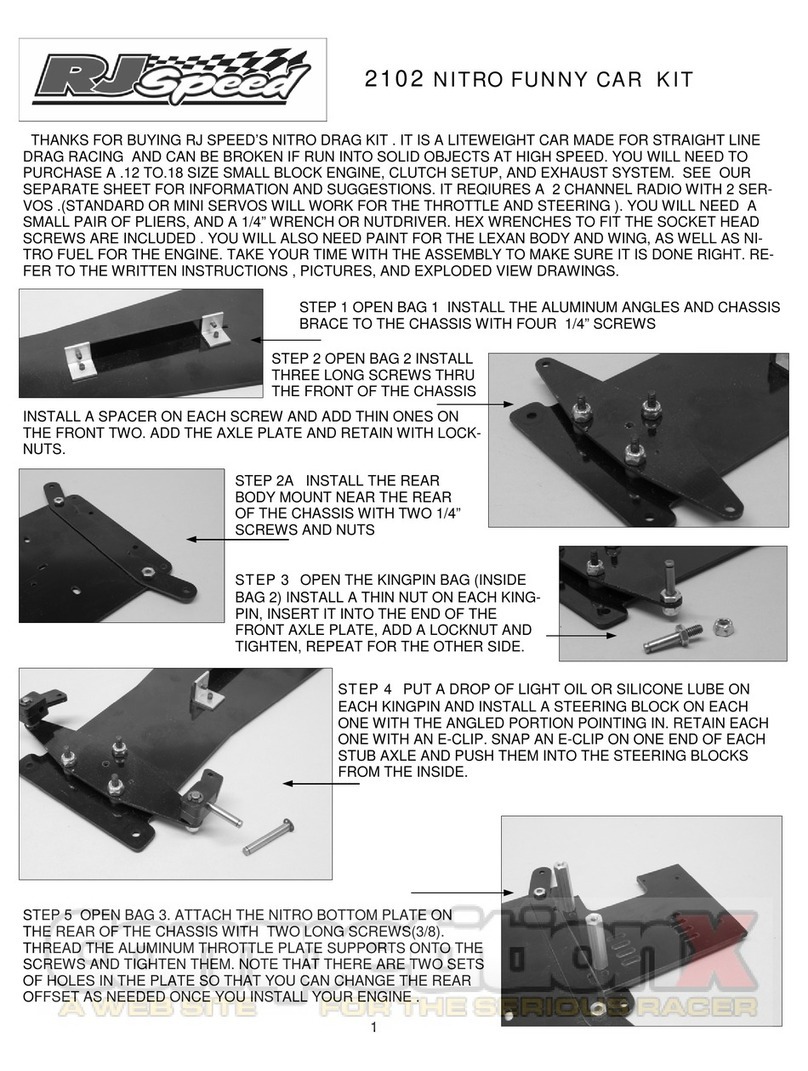

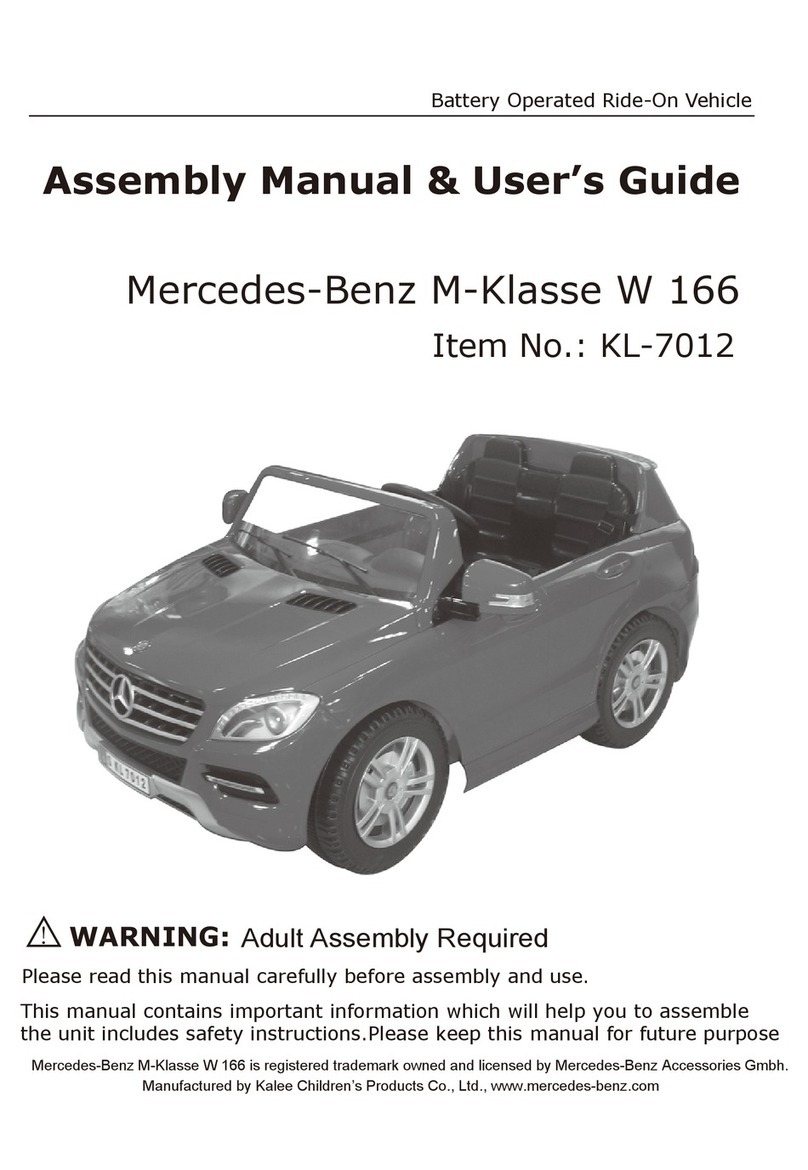

STEP 22 ASSEMBLE YOUR DIFF AS FOLLOWS:

5752 DRIVE RING, GEAR WITH DIFF BALLS , 2ND DRIVE RING, 5740

ALUMINUM ADAPTOR, NYLON HUB, THIN FLAT STEEL WASHER, BLUE

BALL CAGE, 2 THIN FLAT WASHERS, 5736 SPRING WASHER AND 7218

DIFF LOCKNUT. MAKE SURE THAT THE DRIVE RINGS ARE IN PLACE

AND TIGHTEN THE NUT UNTIL IT ‘S HARD TO MAKE THE GEAR SLIP.

YOU CAN ADJUST LATER WITH THE CAR RUNNING.

HINT: YOU CAN SCRATCH THE INSIDE SURFACE OF THE HUB

WHERE IT TOUCHES THE ALUMINUM ADAPTOR A LITTLE WITH

COARSE SANDPAPER AND USE A LITTLE SUPER GLUE TO KEEP THE

HUB FROM SLIPPING ON THE ADAPTOR. ALSO TRIM AROUND THE

EDGE OF THE HOLE IN THE OUTSIDE OF THE HUB TO MAKE SURE

THE BALL THRUST BEARING SITS FLAT.

STEP 22

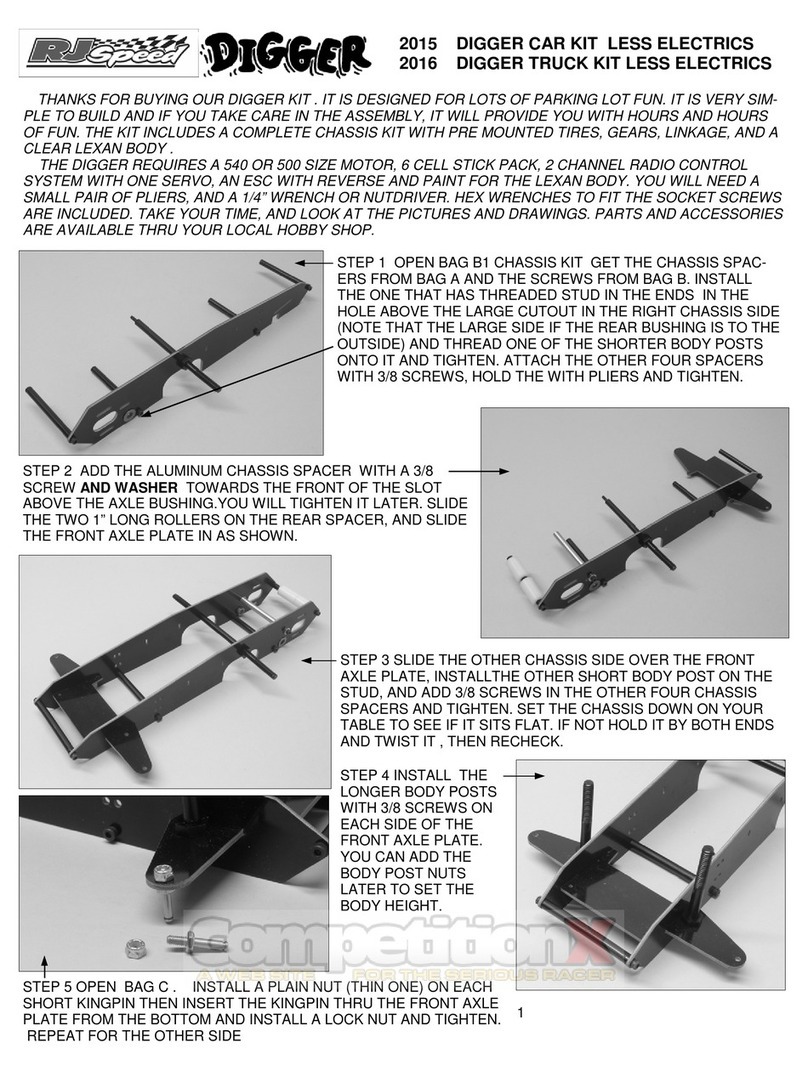

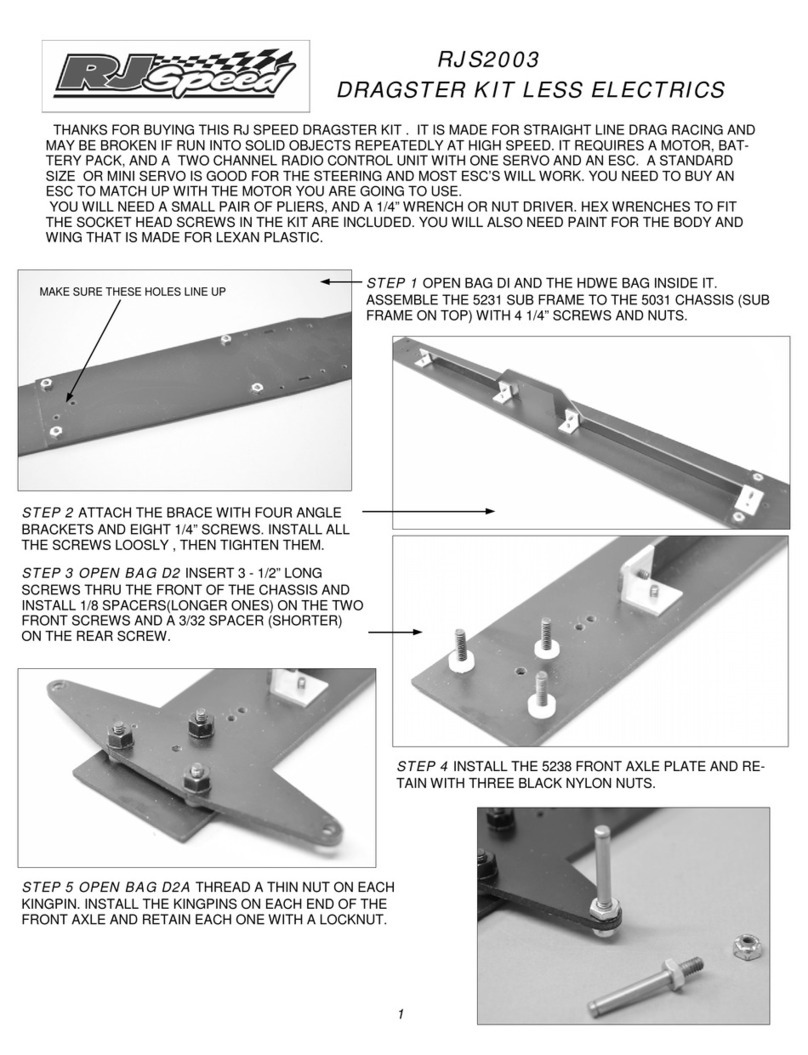

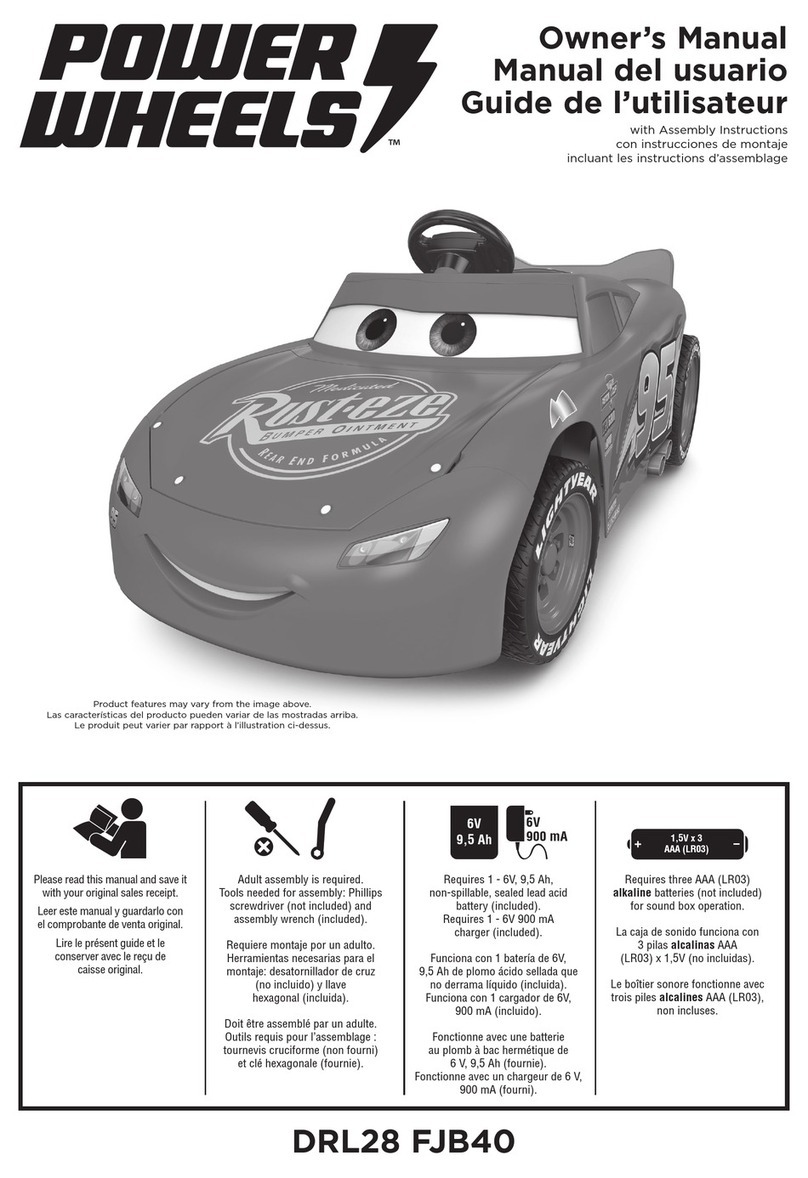

STEP 23 THIS PICTURE SHOWS THE 2424 BODY

POST NUTS INSTALLED, THE 2530 REAR TIRES AT-

TACHED WITH TWO SCREWS EACH AND THE 2520

FRONT TIRES WITH THE 5457 BUSHINGS PRESSED

IN AND INSTALLED ON THE FRONT AXLES AND RE-

TAINED WITH 7207 LOCKNUTS.

IT WILL BE EASIER TO INSTALL THE TIRES AFTER

YOU INSTALL THE MOTOR, BATTERY , AND RADIO

GEAR YOU HAVE PURCHASED.

WE WILL SHOW ONE WAY TO MOUNT THE ELEC-

TRICS AND RADIO GEAR, BUT YOU MAY WANT TO

MAKE CHANGES BASED ON WHAT GEAR YOU HAVE

PURCHASED. YOU MAY ALSO WANT TO SET UP

YOUR STEERING LINKAGE DIFFERENTLY DEPEND-

ING ON THE SIZE OF YOUR SERVO.

YOU SHOULD BE ABLE TO PAINT,TRIM, AND MOUNT

YOUR BODY NOW , ALSO.

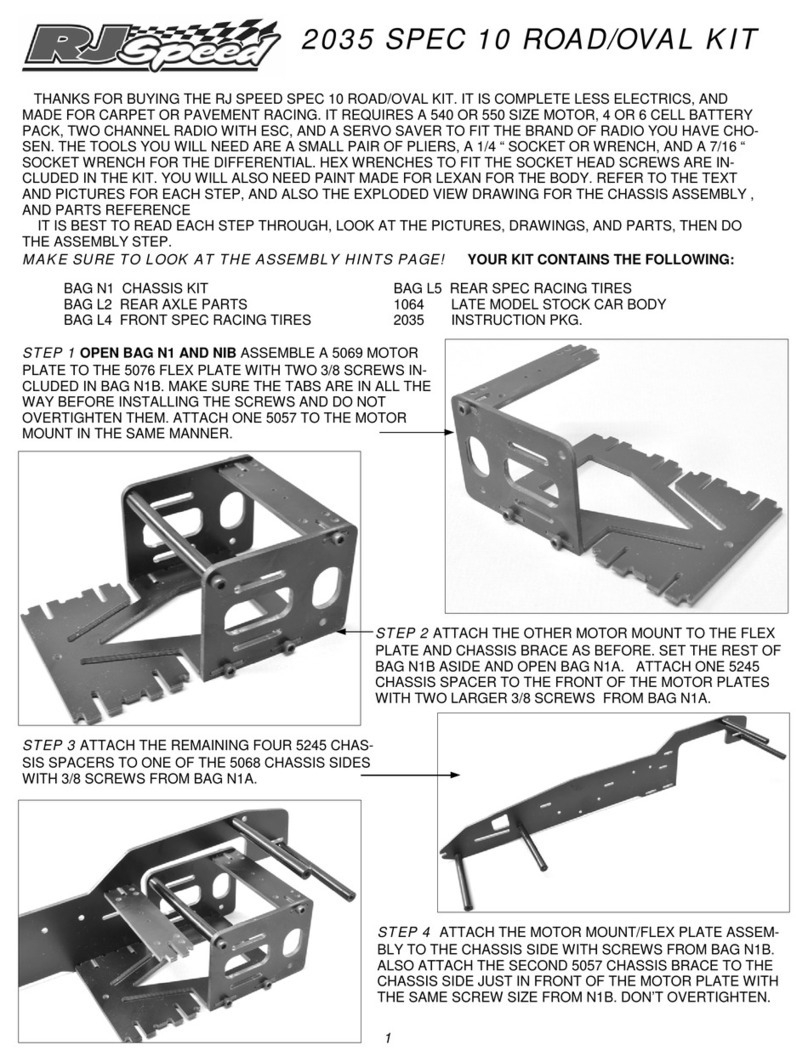

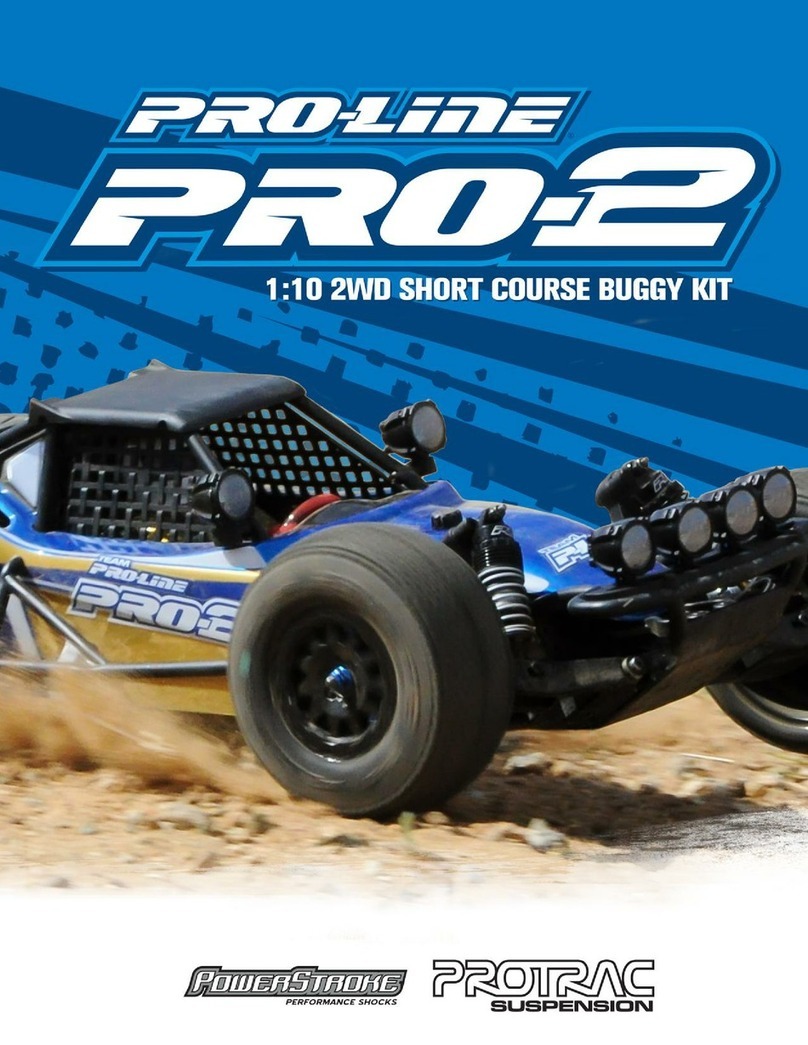

STEP 24 YOU CAN MOUNT YOUR STEERING SERVO

WITH FOAM TAPE INCLUDED IN THE KIT, SCREWS IF

IT HAS THE RIGHT TYPE OF MOUNTS , OR INSTALL

MOUNT POSTS ON THE FRONT AXLE PLATE AND

SCREW THE SERVO TO THEM. YOU SHOULD SET

YOUR SERVO ON THE FRONT AXLE AND HOOK UP

THE LINKAGE TO SEE IF YOU WILL NEED TO BEND

THE LINKAGE WITH THE SIZE OF SERVO YOU HAVE.

THE OUTPUT SHOULD BE NEAR THE CENTER OF THE

CHASSIS. WE SHOW A SMALL SERVO WITH THE ARM

SETUP OR DOWN. ONE WAY REQUIRED BENDING OF

THE LINKS AND THE OTHER DID NOT. MAKE SURE

THAT YOU CHECK THE MOVEMENT OF THE LINKGE

BEFORE YOU ATTACH THE SERVO, ESPECIALLY IF

YOU ARE USING THE TAPE.

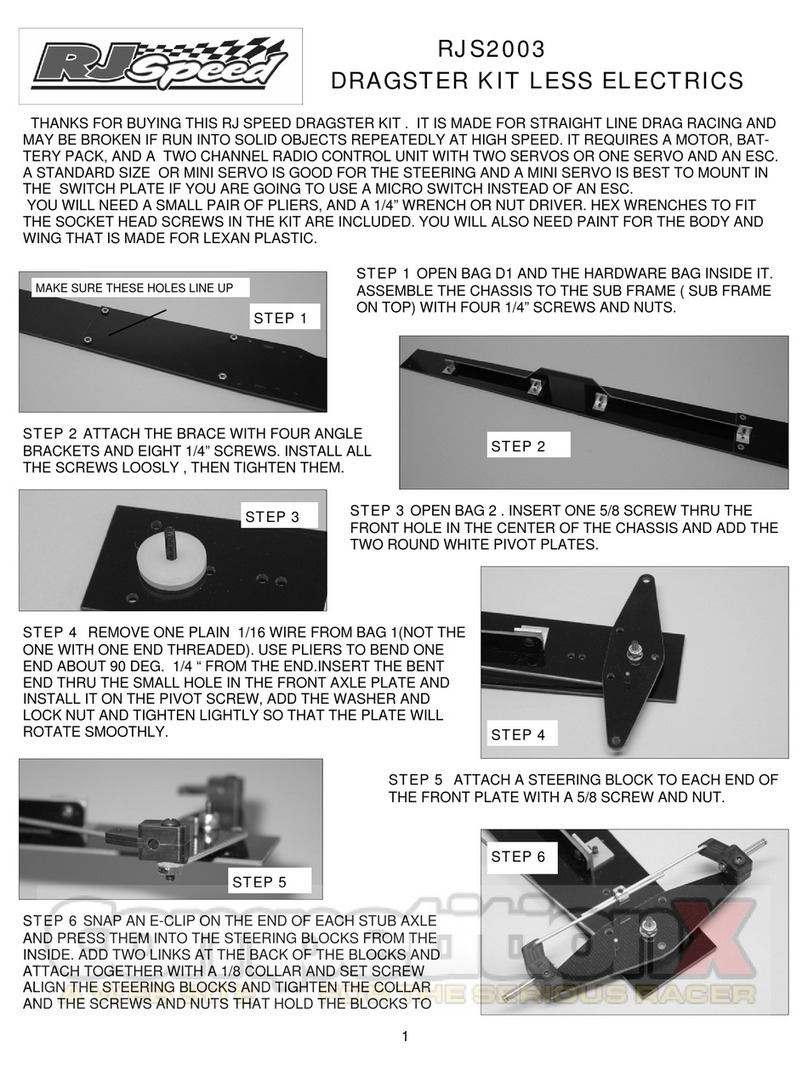

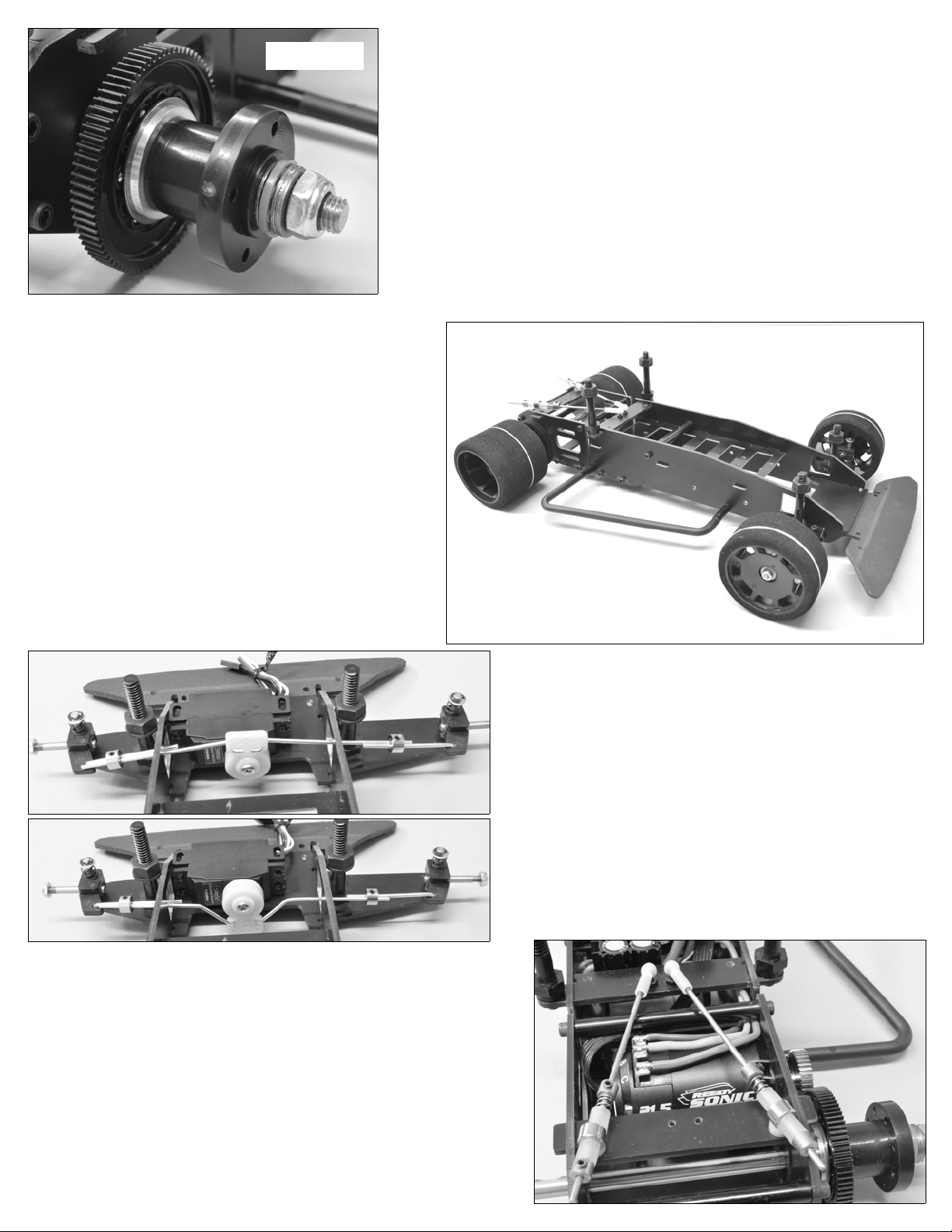

STEP 25 REMOVE THE DAMPERS AS NECESSARY AND IN-

STALL THE 540 SIZE MOTOR YOU HAVE CHOSEN WITH TWO

SCREWS AND WASHERS FROM THE M3 BAG. USE THE IN-

CLUDED PINION GEAR OR YOUR OWN IF YOU NEED A DIFFER-

ENT SIZE. LINE THE PINION UP WITH THE DIFF GEAR AND SE-

CURE WITH THE SET SCREW. MAKE SURE THE SET SCREW

HITS ON THE FLAT OF THE MOTOR SHAFT SO IT WILL NOT SLIP.

ADJUST THE MOTOR UNTIL THERE IS A VERY SMALL AMOUNT

OF PLAY BETWEEN THE GEARS. ROTATE THE AXLE A COUPLE

OF TIMES AND RECHECK THE GEAR MESH BEFORE TIGHTEN-

ING THE SCREWS. THE LARGE PINION GEAR (40T) YOU SEE IN

THE PICTURE WAS USED IN TESTING ON A LARGE CARPET

OVAL. IT IS NOT INCLUDED IN THE KIT. 5